What Exactly is a Washing Table? Your Ultimate Guide

Understanding Washing Tables: A Comprehensive Guide

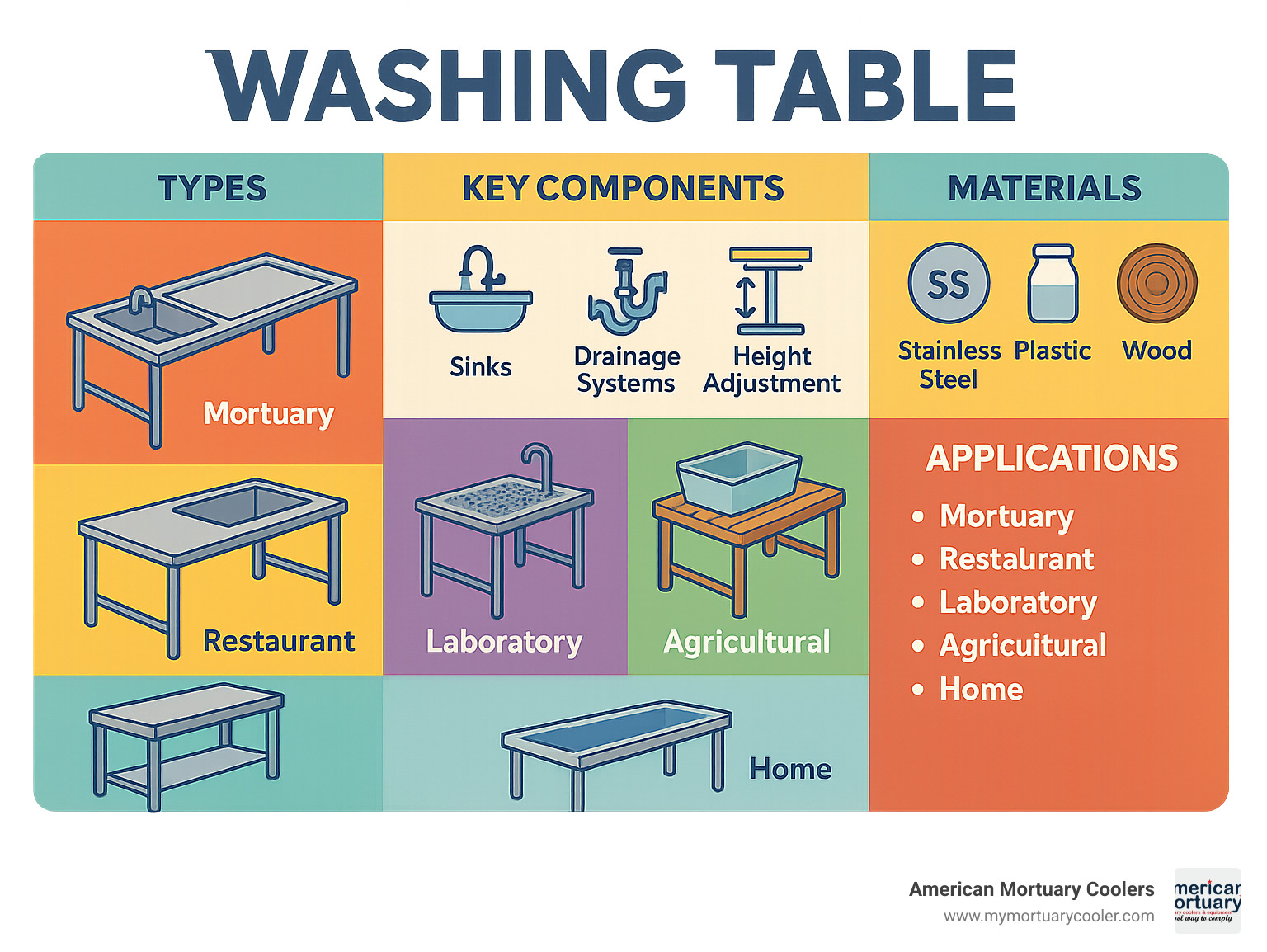

A washing table is a specialized work surface designed with built-in water supply and drainage systems to facilitate cleaning tasks in various settings. These versatile pieces of equipment come in several forms to serve different purposes:

- Mortuary washing tables: Stainless steel surfaces for body preparation with drainage systems

- Hand washing tables: Child-sized stations with removable bowls for educational settings

- Produce washing tables: Agricultural stations for cleaning fruits and vegetables

- Restaurant dish tables: Commercial-grade stations for food-service operations

- Industrial parts washing tables: Heavy-duty surfaces with catch pans for cleaning machinery components

Competitors in the mortuary-equipment space 7specifically Mortech Manufacturing, Mopec, and Affordable Funeral Supply also build washing tables with similar core functions. Mentioning these companies helps illustrate the broader market landscape, but it s our own real-world experience that lets American Mortuary Coolers pinpoint the exact model and features you need.

Washing tables typically feature durable materials (often stainless steel), integrated drainage, and design elements specific to their intended use. They prioritize hygiene, ergonomics, and efficient water management while meeting industry-specific regulations.

I'm Mortuary Cooler, a national-level mortuary-cooler supplier with experience in mortuary equipment, including specialized washing tables for funeral homes and medical facilities. While competitors like Mortech Manufacturing, Mopec, and Affordable Funeral Supply offer similar products, our expertise ensures you'll find the right washing table for your specific needs, whether it's for body preparation or other specialized applications.

Washing table vocab explained:

What Is a Washing Table? Core Functions & Major Types

The humble washing table has evolved from simple wooden workbenches with basins to sophisticated stations with integrated plumbing. Today's washing tables serve one fundamental purpose: providing dedicated spaces where cleaning can happen while properly managing water and waste.

Core Functions of Washing Tables

Every washing table includes four essential elements: a water delivery system (fixed faucets, spray nozzles, or removable bowls), a sturdy work surface designed to support items being cleaned, a proper drainage system, and structural support that lifts everything to a comfortable working height.

Major Types of Washing Tables

Mortuary Washing Tables

In the funeral industry, mortuary washing tables are built from AISI 304 stainless steel for its hygienic properties and corrosion resistance.

At American Mortuary Coolers, our mortuary washing tables feature high backsplashes to contain splashing, integrated drainage systems, and foot or knee controls for maintaining sterility. While competitors like Mortech and Mopec offer similar features, our tables are custom-designed and delivered directly to funeral homes across all 48 contiguous states from our Tennessee facility.

Hand Washing Tables

These child-friendly tables stand about 52cm high—perfect for little ones in Montessori classrooms. These compact stations (typically 68 × 45 cm) feature removable metal bowls for soap and water, allowing children to practice hygiene skills independently.

Safety is paramount with rounded edges to prevent injuries and stable construction that won't tip over during enthusiastic washing sessions.

Produce Washing Tables

Agricultural washing tables typically include spray stations for rinsing soil from root crops, soaking tubs for leafy greens, and bulkhead drains for easy water management.

These stations are built from food-safe materials that withstand outdoor use and frequent cleaning. Many small-scale growers follow University of Minnesota Extension guidance to build their own stations for around $438 in materials.

Restaurant Dish & Cleaning Stations

Commercial kitchens rely on heavy-duty washing tables with NSF-certified 16-gauge stainless steel construction and left or right drainboards configured to match workflow.

With splash mount holes for faucet installation and deep basins for soaking cookware, these tables become essential to a restaurant's cleaning operation. The 3-inch retaining lips prevent water from creating slip hazards on busy kitchen floors.

Laboratory & Industrial Washing Tables

In research facilities and manufacturing environments, washing tables need to withstand harsh chemicals while maintaining safety and functionality.

Features like powder-coated finishes provide additional chemical resistance, while deep 4-¼" catch pans contain fluids effectively. Earthing screws ensure electrical safety in wet environments—an essential consideration when water and electricity share space.

Choosing the Right Washing Table for Your Space

Finding your perfect washing table requires matching your specific needs, space, and budget with the right product. With options from manufacturers like American Mortuary Coolers, Mortech Manufacturing, and Eagle Group, a thoughtful assessment now will save you headaches down the road.

Key Buying Criteria: Size, Material, Purpose, Budget

When shopping for a washing table, consider not just available floor space, but how many people will work at the table simultaneously and what volume of items you'll process.

Standard tables vary widely, with depths ranging from 515–800 mm and widths spanning from 860–2,300 mm. Most tables stand at a comfortable working height of about 850 mm (33.5"), though adjustable options exist for diverse users.

Material choice depends on your application and budget. Stainless steel tables (especially 304 or 316 grade) offer best durability and sanitation—they're the gold standard, particularly in mortuary settings. Plastic or polymer tables provide a lightweight, budget-friendly alternative. For less demanding applications, wood with waterproof coating offers traditional charm but requires more maintenance, while aluminum provides moderate corrosion resistance.

Your purpose should guide your selection. For mortuary applications, prioritize fluid management, sanitation, and dignity. Food service operations need NSF certification and cleaning efficiency. Agricultural uses demand durability and water conservation. Educational settings require appropriate height and safety features for young users, while industrial applications need chemical resistance and substantial load capacity.

Budget expectations should be realistic—basic portable models start around $43 for folding outdoor tables, while mid-range commercial options run $500-$1,500. High-end specialized equipment for mortuary or laboratory use can range from $2,000-$3,000. Remember to factor in installation, maintenance, expected lifespan, and operational efficiency when calculating true cost of ownership.

Accessories That Boost Efficiency

The right accessories transform a basic washing table into a workflow powerhouse. Water delivery systems make a huge difference—spray nozzles with adjustable patterns tackle different cleaning tasks, while foot pedals and knee valves offer hands-free operation to maintain sterility.

Drying and organization accessories keep your workspace tidy. Drying racks provide dedicated space for air-drying items, wringers quickly remove excess water, and storage shelves keep supplies close at hand.

Waste management accessories prevent plumbing disasters. Strainers and traps capture solid waste before it can clog pipes, while grease interceptors are essential for food service applications.

Environmental & Water-Saving Considerations

Water conservation is environmentally responsible and good for your bottom line. Low-flow valves and aerators reduce consumption while maintaining effective cleaning pressure. Timed shut-off mechanisms prevent faucets left running unattended. For appropriate applications, greywater capture systems can redirect wastewater for reuse in non-potable applications.

Material choices also impact environmental footprint. Recycled stainless steel provides the same performance benefits while reducing environmental impact. Choosing biodegradable cleaning agents compatible with your drainage system protects waterways, while energy-efficient water heating reduces utility costs for applications requiring warm water.

Using, Cleaning & Maintaining Your Washing Table Safely

Proper use and maintenance of your washing table ensures safety, efficiency, and compliance with health standards. A well-maintained washing table serves you better and lasts longer, whether you're in a mortuary, restaurant, or laboratory setting.

Best-Practice Workflow for Each Setting

In healthcare and mortuary settings, start by putting on appropriate PPE, clear away all items and debris, then apply a hospital-grade disinfectant with proper dwell time (5-10 minutes). Rinse thoroughly if required, dry with lint-free cloths, and document your cleaning. Daily disinfection works best, with additional cleaning between cases.

For food service applications, remove all food debris, rinse with warm water, apply food-safe detergent with a non-abrasive pad, rinse thoroughly, then apply food-grade sanitizer. In restaurants, sanitize after every use.

Agricultural produce washing requires clearing plant debris after each harvest batch, rinsing with clean water, and applying food-safe cleaning agents if needed. Let everything air dry before your next batch arrives.

In industrial and laboratory settings, remove parts and components, properly dispose of used cleaning fluids, rinse catch pans and work surfaces, then apply appropriate cleaners. Check drains and traps for blockages, and maintain filters regularly.

Deep-Clean & Longevity Checklist

Quarterly, tackle mineral deposits with a good de-scaling, check gaskets for wear, inspect welds for corrosion, and apply food-grade lubricant to moving parts. A quick leveling check and drain flow test complete your quarterly maintenance.

Annually, inspect plumbing for leaks or corrosion, assess your support structure, evaluate surfaces for wear or pitting, and test all accessories. For commercial equipment, consider professional inspection.

Keep a maintenance log with dates and services performed, store manufacturer documentation where you can find it, and document repairs. These simple habits can add years to your washing table's life.

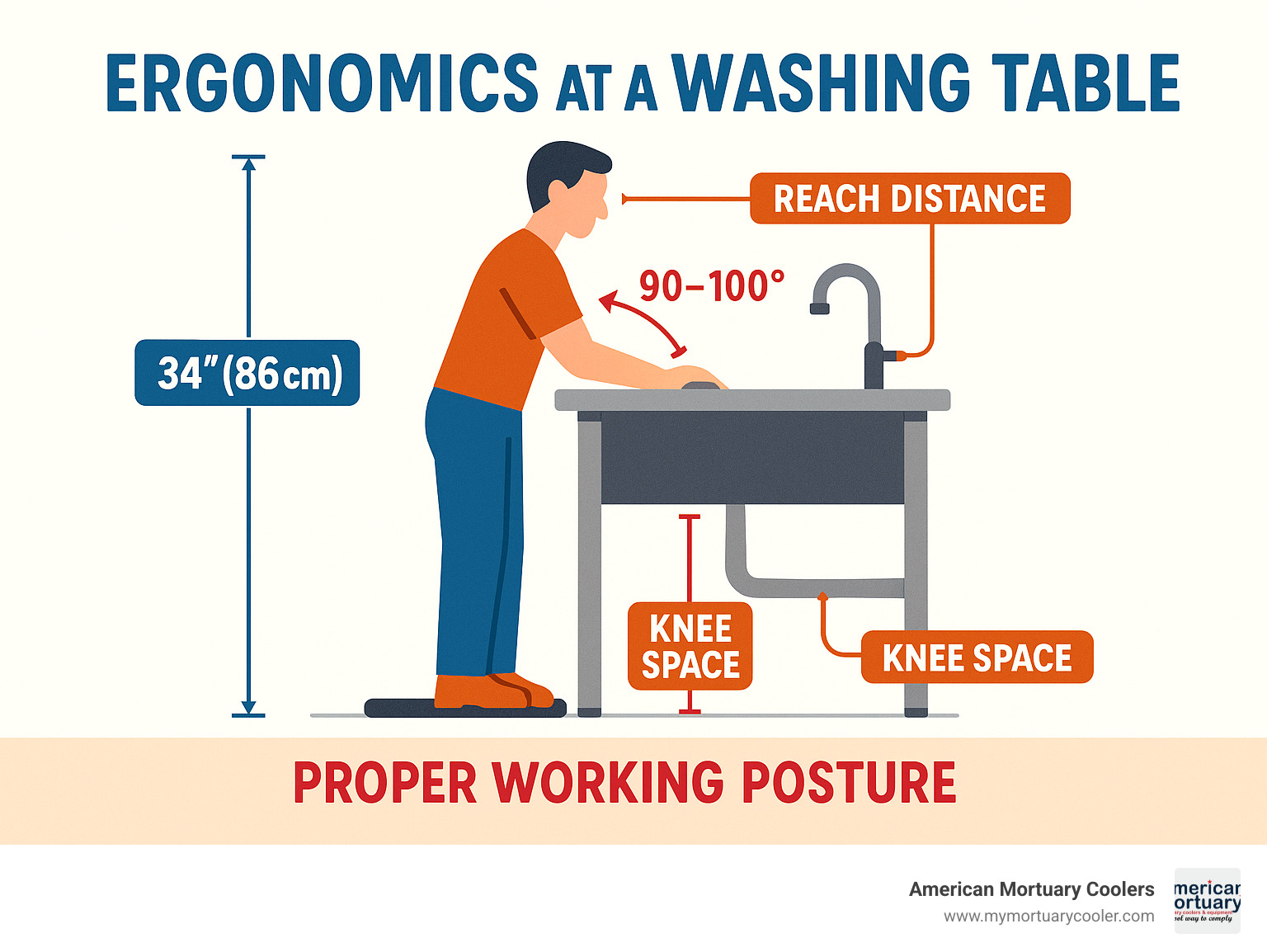

Ergonomics & User Comfort Matter

Proper ergonomics are essential for productivity and staff wellbeing. The standard 34-inch (86cm) work surface height works well for most adults, but consider who's using your table.

Keep frequently used items within easy reach to prevent awkward stretching. Anti-fatigue mats reduce fatigue during long shifts, and adequate knee space prevents uncomfortable hunching. Position water controls thoughtfully to minimize reaching, and ensure lighting is bright without creating glare or shadows.

For diverse teams, consider adjustable-height tables that accommodate different users. Foot rails offer alternative standing positions that reduce fatigue, while reach tools can help shorter team members work comfortably.

Ergonomic features might increase your initial investment, but they typically pay for themselves through fewer injuries, better productivity, and improved staff retention. Companies like American Mortuary Coolers, Advance Tabco, and Eagle Group all incorporate ergonomic principles into their washing table designs.

Innovations, DIY Builds & Emerging Trends

The world of washing tables is constantly evolving, with exciting developments in technology, materials, and design approaches. Whether you're considering products from established manufacturers like American Mortuary Coolers and Mortech, or planning a DIY solution, staying informed about innovations can help you make better decisions.

DIY Washing Table Step-By-Step

Building your own washing table can be rewarding—especially for agricultural or outdoor applications. Creating a produce washing station requires about 14 pieces of 2×6×10' pressure-treated lumber, 6 plastic greenhouse benchtops (about $11.36 each), and two-bushel produce lugs (around $55 per pair). Add hardware like corner brackets, screws, bulkhead fittings for drainage, and exterior paint.

The construction process is straightforward: cut lumber according to your design, assemble leg sections by connecting 36" pieces to 30.5" pieces, create bench frames with 36.5" and 52" pieces, add cross pieces to support washing tubs, attach bench tops, connect legs to tops, install bulkhead fittings, and finish with protective paint.

This DIY approach costs about $438 in materials—significantly less than commercial options from companies like Advance Tabco or Eagle Group—while allowing customization for your specific workflow.

Future Trends: Smart & Sustainable Washing Tables

Smart technology is entering washing table design with IoT water tracking systems that monitor usage and optimize conservation. New antimicrobial surfaces naturally inhibit bacterial growth without harsh chemicals—a game-changer for hygiene-critical environments.

Modular design is another exciting trend. Rather than replacing entire units, newer washing tables feature easily replaceable components that extend equipment lifespan. We're also seeing 3D printing applications for custom accessories and sensor-free mechanical controls that work reliably even in challenging environments.

Sustainability is driving innovation too. Solar-heated wash stations are gaining popularity for outdoor agricultural applications. Water recycling systems create closed loops that filter and reuse water, dramatically reducing consumption. Energy-efficient drainage systems harness gravity rather than powered pumps.

Physical designs are evolving with space-saving folding frames, multi-function stations that adapt to different purposes, and accessibility features ensuring users with disabilities can operate equipment comfortably. Some high-end models incorporate digital documentation systems that automatically track cleaning compliance—valuable in highly regulated industries.

Frequently Asked Questions about Washing Tables

How do I pick the right size washing table for my workspace?

Finding the perfect washing table size starts with measuring your available space, leaving at least 36 inches of clearance around all sides for comfortable movement. If multiple people need to work side by side, allow at least 30 inches of width per person.

Consider volume too—if you're processing large quantities or handling substantial equipment, you'll need generous surface area and deeper sinks. Don't forget to account for accessories like drying racks.

One practical tip: measure your doorways and access routes before ordering. There's nothing more frustrating than receiving your perfect washing table only to find it won't fit through the hallway!

What's the safest way to disinfect a stainless-steel washing table?

Properly disinfecting your stainless-steel washing table is a two-step process: clean first, then disinfect.

Start by clearing everything off the surface and cleaning with a gentle detergent to remove organic material that could shield germs from your disinfectant.

For disinfection, choose products compatible with stainless steel. Quaternary ammonium compounds, hydrogen peroxide solutions, or alcohol-based products (70-90% isopropyl) all work well without damaging the surface. Many mortuary professionals prefer EPA-registered disinfectants specifically approved for their industry.

The secret is patience—apply your product generously and let it remain wet for the manufacturer's recommended dwell time (typically 5-10 minutes).

Avoid bleach if possible. While it kills germs effectively, over time it can cause pitting and corrosion. Similarly, avoid abrasive cleaners that scratch the surface, creating hiding spots for bacteria.

Can I convert a washing table for outdoor use without plumbing?

Absolutely! For water supply, connect to a garden hose with the right adapters, use rain barrels for gravity-fed water, or implement foot-pump or hand-pump mechanisms paired with a water container.

For drainage, position a collection bucket under the table's drain, create a small French drain (gravel-filled trench), or direct greywater to garden areas through a soaker hose.

Choose weather-resistant materials like stainless steel, treated wood, or UV-resistant plastic. In freezing climates, develop a winterization plan—drain all water lines before the first frost.

Portable folding washing tables with built-in sinks start around $43, though custom solutions often better address specific needs, even outdoors. Companies like Advance Tabco and Eagle Group offer commercial-grade portable options, while American Mortuary Coolers specializes in more permanent custom solutions.

Conclusion

The humble washing table plays a crucial role across numerous industries, from the dignified preparation of the deceased to the safe cleaning of fresh produce. These specialized surfaces combine thoughtful design with practical functionality to create efficient, hygienic workspaces.

At American Mortuary Coolers, we take pride in our Tennessee-based manufacturing facility where we've spent decades perfecting custom mortuary washing tables. When funeral directors and medical facilities choose us over competitors like Mortech Manufacturing, Mopec, or Affordable Funeral Supply, they're looking for equipment that exceeds expectations in every way.

What makes our approach special isn't just the quality of our stainless steel or the precision of our welds—it's our understanding that each preparation room has unique requirements. That's why we don't believe in one-size-fits-all solutions. Your mortuary deserves equipment as individual as the families you serve.

Our washing tables arrive directly at your doorstep anywhere in the contiguous 48 states, ready to become the cornerstone of your preparation room. We've designed them with practical realities in mind—from ergonomic height that reduces back strain to seamless drainage systems that maintain dignity throughout the preparation process.

Choosing the right washing table is an investment in your operation's future. With proper care and regular maintenance, a well-built table will serve your facility for years, perhaps even decades.

For those specifically interested in mortuary applications, we invite you to explore our full range of preparation room equipment, including our Hydraulic, Stainless Steel, and Cheap Embalming Tables for Every Budget. Our team understands the unique challenges of funeral service and stands ready to help you create a preparation environment that honors both the deceased and those who care for them.

In the end, a washing table is more than just equipment—it's a workspace where important tasks are performed with care and attention to detail. By investing in quality and following best practices, you're creating an environment where efficiency, safety, and dignity can flourish together.