The Ultimate Guide to Walk-In Cooler Compressors

The Heart of Cold Storage: Understanding Walk-In Cooler Compressors

Walk in cooler compressors are the critical component that keeps your cold storage operating reliably and efficiently. These mechanical workhorses circulate refrigerant through the system, maintaining precise temperatures required for food safety and product preservation.

Quick Reference for Walk-In Cooler Compressors:

- Primary function: Compress refrigerant gas to liquid, enabling heat transfer

- Types: Scroll, reciprocating, semi-hermetic, and screw compressors

- Capacity range: 1 HP to 100 HP for different applications

- Key efficiency metric: Scroll compressors can be up to 35% more energy-efficient than reciprocating models

- Typical lifespan: 10-15 years with proper maintenance

- Critical temperature: Must maintain FDA-required 40°F or below for food safety

The compressor acts as the heart of your refrigeration system, continuously pumping refrigerant through copper lines day and night. As one industry expert puts it: "Compressors are the heart of every ice maker, ice cream machine, refrigerator and freezer in the world."

Understanding how these systems work - and more importantly, how to select, maintain, and troubleshoot them - can save you thousands in emergency repairs and prevent costly product loss. Whether you're dealing with a hot compressor, planning a replacement, or sizing a new system, the right knowledge makes all the difference.

I'm Mortuary Cooler, a national-level supplier specializing in reliable cold storage solutions. With experience in walk in cooler compressors and mortuary cooling systems, I've helped countless facilities select the right equipment for their specific needs and space constraints.

Walk in cooler compressors further reading:

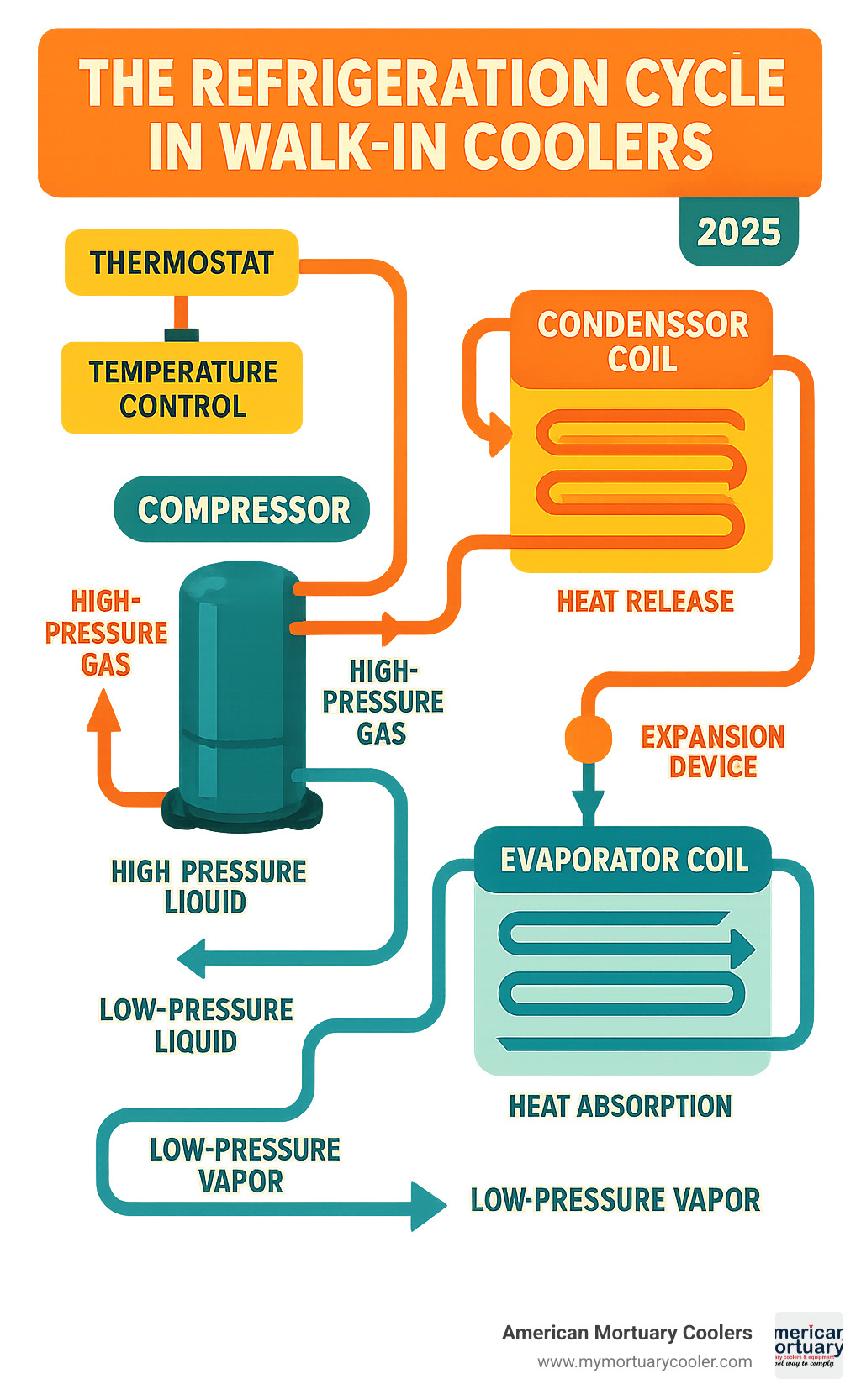

How Walk-In Cooler Compressors Work

Think of walk in cooler compressors as the beating heart of your refrigeration system. They work tirelessly around the clock, using the vapor-compression refrigeration cycle to keep your products at exactly the right temperature.

The system relies on the Ideal Gas Law (PV = nRT). When you squeeze gas into a smaller space (increase pressure), it gets hotter. When you let it expand, it gets colder. That's the magic behind how your walk-in cooler works.

Here's how the compression cycle creates cold temperatures. The refrigerant starts as a cool, low-pressure gas that gets sucked into the compressor. The compressor squeezes this gas hard, turning it into a hot, high-pressure vapor.

This hot gas flows to the condenser coils where it releases heat to the outside air and turns into liquid. The liquid refrigerant then passes through an expansion device where the pressure drops dramatically, making it super cold. Finally, this cold refrigerant flows through the evaporator coils inside your walk-in, absorbing heat from your products and turning back into gas to start the cycle over.

The suction and discharge pressures tell you how well your system is working. Low suction pressure means the evaporator is pulling heat out of your cooler. High discharge pressure means the condenser is working to reject that heat outside.

Modern systems use different refrigerants like R-404A, R-448A, and R-290 (propane). Each has its own characteristics for pressure and temperature relationships. Newer refrigerants like R-448A are becoming popular because they're better for the environment.

Your compressor has controls and safeties built in for protection, including high-pressure switches and motor overload protection.

Key Components of Walk-In Cooler Compressors

Inside every compressor, precisely engineered parts work together. The compressor core houses the actual compression mechanism - reciprocating pistons, scroll sets spiraling together, or screw rotors turning.

The motor windings provide electrical power to drive everything. These copper windings can be fragile when exposed to heat and contamination. Excessive heat or acid in the system can damage these windings quickly.

Every compressor needs an oil pump and lubrication system. The oil lubricates and helps seal gaps between components. Without proper oil levels and clean oil, your compressor won't last long.

The valves and scroll sets control refrigerant flow. Suction valves let low-pressure gas in, discharge valves push high-pressure gas out, and timing must be perfect for maximum efficiency.

The crankcase heater prevents liquid refrigerant from settling in the oil during shutdown. Without it, you could get liquid slugging when the compressor starts up, potentially cracking internal components.

Walk-In Cooler Compressors and System Components

Walk in cooler compressors work as part of a team. Your condenser coils get rid of unwanted heat. When these coils get dirty, your compressor works overtime to maintain temperature.

The evaporator fans keep air moving across the cold evaporator coils. Without good airflow, you'll get hot spots and constant compressor cycling.

Expansion devices automatically adjust refrigerant flow. A good thermostatic expansion valve (TXV) adjusts based on conditions, while fixed orifices just let whatever wants to flow through.

Modern electronic controllers monitor temperatures, pressures, and adjust defrost cycles automatically based on actual conditions rather than timers.

Defrost heaters prevent ice buildup on evaporator coils in freezer applications. Too much ice prevents heat transfer and makes your compressor work harder.

For hands-on repair guidance, our detailed guide on how to do walk-in cooler repair even if you've never tried it before walks you through the process step by step.

Choosing and Sizing Walk-In Cooler Compressors

Getting the right compressor size isn't guesswork - it's about doing the math correctly from the start. Too small, and your system will run constantly while struggling to maintain temperature. Too large, and you'll waste money on equipment and energy while dealing with short-cycling issues.

The foundation of proper selection is an accurate load calculation. You need to calculate the total BTUH (British Thermal Units per Hour) requirement by looking at your specific situation. Think of it like sizing a heating system for your home - every detail matters.

Room volume is your starting point, but it's not just about cubic feet. A 10x10x8 foot cooler needs different capacity than the same size freezer. The insulation quality makes a huge difference too. Proper R-25 insulation can cut your capacity requirements nearly in half compared to poorly insulated spaces.

Product pull-down requirements vary dramatically. Loading 500 pounds of warm produce at 70°F into your cooler creates a massive heat load compared to just maintaining temperature with existing cold products. Many operators underestimate this factor and end up with undersized systems.

Ambient conditions around your condensing unit directly affect performance. A unit sitting in direct sunlight in Arizona works much harder than one in a shaded, conditioned mechanical room in Minnesota. Higher outdoor temperatures increase condensing pressures and can reduce compressor capacity by 20% or more.

Here's something many people don't consider: door usage patterns. A busy restaurant kitchen with constant door openings needs more capacity than a storage cooler opened twice daily. Installing air curtains can reduce compressor runtime by up to 27%, effectively reducing your sizing requirements.

Walk in cooler compressors range from small 1 HP units for compact applications up to massive 100 HP systems for industrial cold storage. A typical example: a low-temperature condensing unit might provide 7,550 BTUH at -20°F SST with 95°F ambient conditions.

Don't forget about DOE AWEF (Annual Walk-in Energy Factor) regulations. These federal efficiency standards now require high-efficiency motors and components. Always verify DOE compliance for your specific refrigerant and application - non-compliant equipment can't be legally installed.

Primary Factors When Selecting Walk-In Cooler Compressors

Design temperature drives everything else in your selection process. Most walk-in coolers operate at 35°F, which gives you a comfortable safety margin above the FDA's 40°F food safety requirement. Freezers typically run at -10°F to 0°F, while ice cream storage demands even colder temperatures around -18°F.

Your compressor must be specifically rated for these operating conditions. A cooler compressor won't work properly in freezer applications - the operating pressures and oil return characteristics are completely different.

Suction Saturation Temperature (SST) and condensing temperature determine the pressure differential your compressor fights against all day. Think of it like climbing stairs - the bigger the height difference, the more work required. Higher pressure differentials mean more power consumption and reduced efficiency.

Refrigerant compatibility isn't negotiable. Older R-404A systems can't simply switch to newer R-448A refrigerants without checking compressor compatibility, oil types, and sealing materials. The molecular differences between refrigerants affect everything from oil solubility to system pressures.

Electrical requirements must match your facility's power supply exactly. Most commercial units need 208-230V or 460V three-phase power. Single-phase units are available for smaller applications, but three-phase motors run more efficiently and last longer.

Noise levels matter more than you might think. Scroll compressors typically run much quieter than reciprocating models - important if your condensing unit sits near customer areas or noise-sensitive spaces. Proper vibration isolation mounting helps too.

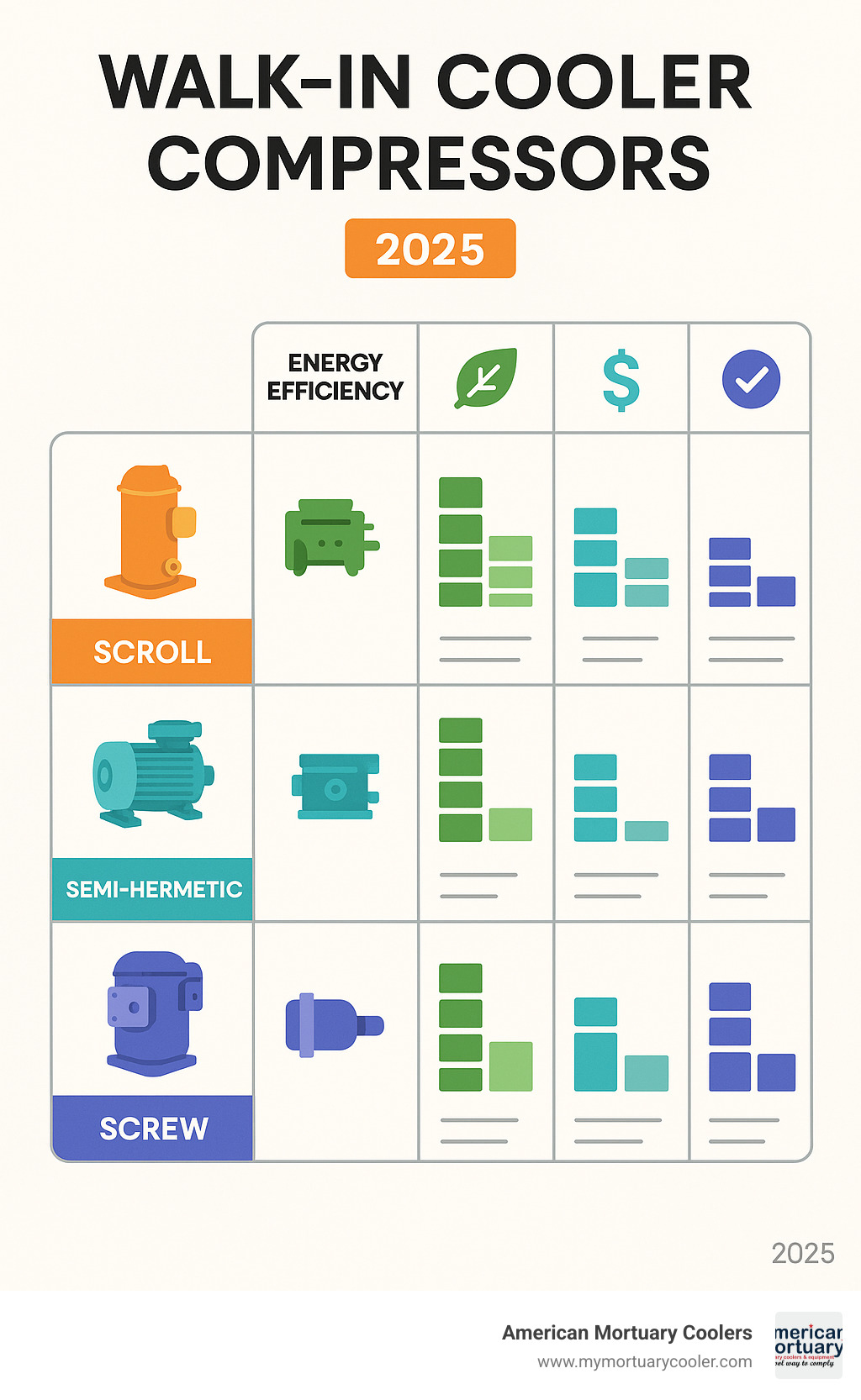

Scroll vs. Reciprocating vs. Semi-Hermetic vs. Screw

Scroll compressors are the efficiency champions for most walk-in applications. Laboratory testing consistently shows up to 35% better energy efficiency compared to reciprocating models. They achieve this through fewer moving parts - just two spiral-shaped scrolls that compress refrigerant smoothly without the hammering action of pistons.

The reliability advantage is significant too. Fewer moving parts mean fewer things can break. Scroll compressors run quieter and smoother, making them ideal for small to medium walk-in applications starting around 1 HP capacity.

Reciprocating compressors still have their place in smaller applications up to 1 HP. They're the most cost-effective option upfront and parts are widely available. However, all those pistons, connecting rods, and valves mean higher maintenance requirements and more potential failure points.

Semi-hermetic compressors offer the best of both worlds for repairability. Unlike sealed units, you can actually open them up for service. The motor and compressor components are accessible, which means major repairs are possible instead of complete replacement. They're available from 0.5 HP to 30 HP and carry virtually no refrigerant leakage risk.

Screw compressors dominate large industrial applications from 1 to 100 HP. Yes, they're noisier than other types, but they deliver superior energy savings and reduced oil consumption in big systems. Rotary modifications can save more than 10% in energy compared to standard designs.

For detailed performance data and real-world case studies, check out this Copeland Scroll Compressor study on food preservation applications.

Maintenance, Troubleshooting & Common Failure Modes

Taking care of your walk in cooler compressors is like maintaining a reliable truck - regular attention keeps them running for decades. With proper maintenance, these workhorses can last 10-15 years, with some units running reliably for over 30 years.

The most critical maintenance task is condenser coil cleaning every 60-90 days. Dirty coils trap heat and force the unit to work overtime. In dusty environments, you might need to clean them more frequently.

Refrigerant charge verification is equally important. Low refrigerant makes your compressor work harder while delivering less cooling. Look for oil stains around connections or ice formation in unusual places - these often signal refrigerant leaks.

Don't overlook oil analysis and level checks. Compressor oil lubricates moving parts and provides sealing. Contaminated oil turns acidic and can damage internal components, while low oil levels cause bearing wear.

Electrical connections deserve regular attention. Loose connections create heat and voltage drops that can damage motor windings. Check for proper voltage and compare amp draw to nameplate ratings.

Installing air curtains can reduce compressor runtime by up to 27% by keeping warm air from rushing in when doors open.

Regular diagnostic monitoring of amp draw, suction and discharge pressures, and superheat readings helps catch problems early. Abnormal numbers often appear weeks before actual failures occur.

Common failure causes include overheating from dirty coils, liquid flood-back from defrost problems, and acid formation from moisture contamination. Many warranty claims get denied because these preventable issues weren't addressed.

Signs Your Walk-In Cooler Compressors Need Replacement

When your walk in cooler compressor starts showing its age, several warning signs become obvious. A hot compressor housing that's too hot to touch indicates serious problems. While compressors normally run warm, they shouldn't feel like a stovetop burner.

Short cycling behavior - where the compressor starts and stops frequently - suggests internal damage or system problems. This constant starting puts enormous stress on motor windings.

High amp draw beyond nameplate ratings means your compressor is working harder than designed. This indicates worn internal components that can't compress efficiently anymore.

Loud knocking or grinding noises typically indicate bearing wear, broken valves, or damaged scroll sets. When you hear these sounds, replacement is usually more cost-effective than repairs.

Poor pull-down performance becomes evident when your system runs constantly but can't reach or maintain set temperatures. This loss of capacity develops gradually as internal wear reduces compression ability.

Step-by-Step Troubleshooting Guide for Walk-In Cooler Compressors

Start troubleshooting with a power supply check. Verify proper voltage at the unit and check for loose connections or corrosion. Many compressor problems that look mechanical are actually electrical issues.

Next, take pressure readings at both suction and discharge ports. Compare these to manufacturer specifications for your specific refrigerant and operating conditions. Abnormal pressures point toward refrigerant problems, system restrictions, or compressor wear.

Perform thorough leak detection using electronic detectors or soap bubble solutions. Check all connections, valves, and coil joints. Even small leaks can cause major performance problems.

Defrost verification is crucial for freezer applications. Ice buildup on evaporator coils acts like insulation and can cause liquid refrigerant to flood back to the compressor, potentially causing damage.

Complete your inspection with airflow checks on both condenser and evaporator fans. Ensure coils are clean and fans are moving adequate air. Poor airflow is a leading cause of compressor overheating and premature failure.

For specific guidance on addressing freeze-up issues that can damage compressors, see our detailed guide on how to fix evaporator freeze-up even if you've failed in the past.

Latest Technologies & Environmental Compliance

The world of walk in cooler compressors is changing faster than ice melts in July. New technologies are making these systems smarter, more efficient, and friendlier to our environment - while saving you serious money on energy bills.

Variable-speed drives are revolutionizing how compressors operate. Instead of running full-blast all the time like your old truck, these smart systems adjust their speed based on actual cooling needs. When your walk-in isn't working as hard, neither is your compressor. This translates to substantial energy savings during those quieter periods.

Digital scroll modulation takes precision to the next level. These systems can vary compressor capacity in real-time, maintaining tighter temperature control than ever before. Think of it as cruise control for your refrigeration system - it automatically adjusts to maintain exactly the right temperature while using the least energy possible.

The refrigerant landscape is shifting dramatically due to environmental regulations. The AIM Act phase-down is pushing the industry away from high-GWP (Global Warming Potential) refrigerants toward more environmentally friendly options. R-448A and R-449A are becoming popular replacements that offer excellent performance with lower environmental impact. These newer refrigerants work well in existing systems with minimal modifications.

R-290 (propane) is gaining serious traction as a hydrocarbon option. While it requires special safety considerations due to its flammability, R-290 offers near-zero GWP and excellent energy efficiency. Many manufacturers are now offering R-290-compatible systems, especially for smaller walk-in applications.

Smart IoT controllers are bringing walk-in refrigeration into the digital age. These systems provide real-time monitoring and remote control capabilities, sending alerts to your phone when something needs attention. Imagine getting a text message before your compressor fails instead of finding it when you walk into a warm cooler Monday morning.

Adaptive defrost systems represent a major leap in efficiency. Instead of running defrost cycles on a fixed schedule regardless of need, these intelligent systems monitor actual ice buildup and only defrost when necessary. This can save significant energy - especially important since defrost cycles temporarily shut down cooling and consume extra power.

DOE AWEF standards are driving these efficiency improvements across the industry. The new Annual Walk-in Energy Factor requirements mean that all new systems must meet minimum efficiency ratings. This regulation is pushing manufacturers to develop better compressors and system designs.

When considering indoor versus outdoor condensing units, each option has distinct advantages. Outdoor units don't add heat to your building, reducing the load on your HVAC system, but they face weather exposure and potential vandalism. Indoor units stay protected from the elements but require adequate ventilation and will add some heat to your space.

For the latest developments in compressor technology and innovation, Copeland's refrigeration compressor page offers detailed technical information on cutting-edge solutions that are shaping the future of commercial refrigeration.

Frequently Asked Questions About Walk-In Cooler Compressors

When it comes to walk in cooler compressors, I get the same questions repeatedly. Let me share the answers that really matter for keeping your cold storage running smoothly.

How long do walk-in cooler compressors last?

A well-maintained walk in cooler compressor typically runs strong for 10-15 years. I've seen some workhorses keep running for over 30 years when treated right.

The secret is proper care. Maintenance quality makes the biggest difference. Units that get regular coil cleaning and proper refrigerant level checks can easily hit that 15-year mark or beyond.

Operating conditions play a huge role. A compressor in a dusty warehouse or dealing with constant temperature swings will wear out faster than one in a clean, stable environment.

Installation quality matters more than most realize. When a system is properly sized and installed, it doesn't have to work overtime. Oversized units short-cycle, undersized ones never rest - both scenarios cut lifespan significantly.

What affects compressor energy consumption most?

If your electric bill is concerning, here are the biggest energy drains:

Condenser coil cleanliness is the number one culprit. Dirty coils trap heat and force your compressor to work overtime. We're talking about a 20% increase in energy use or more when coils get really dirty.

Refrigerant charge issues are sneaky energy wasters. Both overcharging and undercharging kill efficiency, but undercharging is more common. Low refrigerant makes your compressor run longer trying to reach temperature.

Temperature differential is basic physics working against you. The bigger the gap between your walk-in temperature and outside temperature, the harder your compressor works.

System leaks create a double problem - you lose refrigerant AND let warm air sneak in. Air infiltration around doors and seals forces longer run times.

Compressor type makes a substantial difference. Modern scroll compressors use up to 35% less energy than older reciprocating models. Upgrading could pay for itself in energy savings.

Can I retrofit to a low-GWP refrigerant?

With new environmental regulations pushing out high-GWP refrigerants, this question comes up constantly. The short answer is: sometimes, but it's complicated.

System compatibility is the first hurdle. Some newer refrigerants require different oils and sealing materials than what's in your system. It's not always a simple drain-and-fill operation.

Pressure ratings can be tricky. New refrigerants might operate at different pressures than your current setup was designed for. Your existing components need to handle these pressure changes safely.

Cost considerations often surprise people. Between labor, new refrigerant, potential component changes, and system modifications, retrofitting can sometimes cost more than replacing an older system entirely.

My advice? Always consult with a qualified technician before attempting any refrigerant conversions. They can evaluate your specific system and help you weigh the costs and benefits.

Conclusion

Walk in cooler compressors are the beating heart of any successful cold storage operation, and getting them right makes all the difference between smooth sailing and costly headaches. Think of it this way - you wouldn't buy a car without understanding the engine, so why would you invest in refrigeration without knowing your compressor options?

The journey from scroll to reciprocating to semi-hermetic compressors isn't just about technical specs. It's about finding the perfect match for your specific needs. That scroll compressor might cost more upfront, but those 35% energy savings add up faster than you'd expect. Meanwhile, a trusty reciprocating unit might be exactly what your smaller operation needs.

Here's what really matters: proper selection saves money, regular maintenance prevents disasters, and staying current with technology keeps you competitive. Those 60-90 day coil cleanings aren't just busywork - they're insurance against expensive failures. And when you spot those warning signs like hot housings or short cycling, addressing them quickly can save thousands in emergency repairs.

The refrigeration world is changing rapidly with low-GWP refrigerants and smart IoT controllers becoming the new standard. These aren't just environmental feel-good measures - they're practical improvements that reduce operating costs and improve reliability. The AIM Act phase-down means these changes are coming whether we're ready or not.

When problems do arise, systematic troubleshooting beats panic every time. Start with the basics - power supply, pressure readings, and airflow checks - and you'll solve most issues before they become emergencies. Prevention is always cheaper than replacement.

At American Mortuary Coolers, we've seen how the right cold storage solution can transform operations. Our custom mortuary coolers are built with the same attention to detail and quality components discussed throughout this guide. We understand that when you're preserving what matters most, reliability isn't negotiable. That's why we deliver directly across the contiguous 48 states, ensuring you get exactly what you need, when you need it.

Whether you're planning a new installation or upgrading existing equipment, the principles remain the same: choose quality components, size them properly, maintain them religiously, and stay informed about new technologies. Your compressor investment will reward you with years of trouble-free operation.

For comprehensive installation guidance that complements your compressor selection, review our guide on how to install a walk-in cooler the right way.