The Ultimate Guide to Mortuary Dead Body Storage Freezer Door Manufacturers

What Is Mortuary Dead Body Storage Freezer Doors Manufacture?

Mortuary dead body storage freezer doors manufacture is the process of designing, building, and customizing insulated doors for morgue refrigeration units that safely preserve human remains. These doors are engineered for:

| Feature | Purpose |

|---|---|

| Tight Sealing | Prevents heat loss and maintains low temps |

| Stainless Steel | Ensures durability and easy cleaning |

| Thick Insulation | Increases energy efficiency and reduces costs |

| Locks & Alarms | Provides security and safety alerts |

| Custom Sizes & Styles | Fits any facility, capacity, or use case |

Quick facts:

- Most doors are made from 304-grade stainless steel and 8–10 cm polyurethane insulation.

- Each chamber in a multi-body cabinet has its own secure, gasket-sealed door.

- Temperature is typically set between -10°C and +5°C, with options as low as –20°C for forensic or long-term storage.

If you're searching for reliable, durable, and customizable freezer doors for mortuary cabinets—whether for a hospital, funeral home, or research lab—manufacturers now offer modular solutions that meet strict hygiene, energy, and safety standards.

As American Mortuary Coolers, a national supplier of mortuary coolers in the US, we bring decades of expertise in mortuary dead body storage freezer doors manufacture—helping funeral directors and facility managers get durable, American-made solutions shipped direct and supported locally.

Key mortuary dead body storage freezer doors manufacture vocabulary:

Why This Guide Matters

When procuring mortuary equipment, facility managers face complex decisions about door specifications, safety compliance, and long-term durability. Poor door quality can lead to temperature fluctuations, energy waste, and most critically, compromised preservation of human remains. With mortuary cabinets available in configurations ranging from 1 to 15 bodies, understanding door manufacturing becomes essential for making informed purchasing decisions.

Safety and compliance requirements vary by jurisdiction, but all facilities must meet basic hygiene standards. The wrong door choice can result in failed inspections, increased maintenance costs, and operational disruptions during critical times when families depend on your services.

Fundamentals of Mortuary Freezer Doors

Think of mortuary freezer doors as the gatekeepers of preservation. They're the critical barrier standing between the carefully controlled environment inside your storage chambers and the unpredictable world outside. Without proper doors, even the most sophisticated cooling system becomes useless.

The primary function of these doors goes far beyond just opening and closing. They must maintain precise temperatures while providing secure, hygienic access to storage chambers. Most mortuary cabinets feature individual doors for each chamber—and there's a good reason for this design choice.

Each door comes with its own lock and key, giving you improved security and operational flexibility. This means you can access one chamber without disturbing the others, which is especially important during busy periods or when handling multiple cases simultaneously.

Front-loading systems are the most common setup, where doors open toward you for easy gurney access. Side-loading configurations work well when space is tight, allowing you to maximize your facility's footprint. For larger operations, modular systems can combine multiple door types to create the perfect workflow for your specific needs.

Whether you're dealing with single-door units for smaller facilities or multi-door systems for high-volume operations, the fundamentals remain the same: reliable sealing, easy access, and consistent temperature control.

What Is a Mortuary Freezer Door?

A mortuary freezer door is a heavily insulated, airtight barrier designed to maintain temperatures between -20°C and +10°C for preserving human remains. But that simple definition doesn't capture the engineering that goes into each door.

These doors prevent decomposition by creating a sealed environment that slows bacterial growth and tissue breakdown. Most mortuary dead body storage freezer doors manufacture focuses on the typical factory setting range of -10°C to +5°C, though customization allows for ultra-low temperatures down to -30°C for specialized forensic applications.

Here's what makes mortuary doors different from your kitchen refrigerator: they must withstand frequent opening cycles while maintaining rock-solid temperature stability. We're talking about doors that might be opened dozens of times per day, yet still maintain their seal integrity year after year.

Temperature control isn't just about the cooling system—it's about preventing those precious degrees from escaping every time someone opens a door. That's why these doors feature reinforced hinges, multiple gasket seals, and safety mechanisms that ensure both security and emergency access when needed.

Key Door Variations

Modern mortuary facilities have moved far beyond the "one-size-fits-all" approach. Today's door variations are designed around real-world workflow challenges and space constraints.

Hinged doors remain the most popular choice for individual body chambers, opening up to 120° using gas jacks for smooth, ergonomic access. There's something reassuringly familiar about a hinged door—it's intuitive for staff and requires minimal training.

Sliding doors shine in facilities with narrow corridors where a swinging door would create traffic jams. They're particularly popular in older buildings where space efficiency matters more than tradition.

Lift-up doors offer vertical opening for top-loading configurations, though they're less common due to ergonomic considerations. Roll-up doors work beautifully for large openings in walk-in coolers and bariatric units, where you need maximum access without space constraints.

For facilities handling larger cases, bariatric options and compartmental doors provide individual access to specific storage levels in multi-tier systems. This flexibility means you can customize your setup based on your actual caseload rather than hoping a standard configuration will work.

The choice between these variations often comes down to your facility's layout, staff preferences, and the types of cases you handle most frequently. Each has its place in modern mortuary dead body storage freezer doors manufacture.

Materials & Processes in mortuary dead body storage freezer doors manufacture

Building a quality mortuary door isn't just about slapping some metal together. It's about creating a reliable barrier that protects what matters most—the dignity of those in your care and the peace of mind of grieving families. That's why mortuary dead body storage freezer doors manufacture starts with choosing the right materials.

Most manufacturers rely on 304-grade stainless steel for both the inner and outer surfaces. This isn't just for looks—it provides excellent corrosion resistance and makes cleaning a breeze. For facilities that use harsh chemicals or operate in challenging environments, 316-grade stainless steel offers even better chemical resistance, though it comes at a higher cost.

Scientific research on stainless corrosion

The real magic happens with the insulation. Polyurethane foam (PUF) fills the space between those steel panels, typically 8-10 cm thick. This isn't your average foam—it's injected using foamed-in-place techniques that eliminate those pesky thermal bridges that can cause temperature inconsistencies.

Magnetic gaskets create that crucial airtight seal while still allowing doors to open smoothly. Nobody wants to wrestle with a stubborn door during a difficult time. Anti-condensation heater wires embedded in the door frames prevent moisture buildup that could compromise seals or create hygiene headaches down the road.

Modern manufacturers also use eco-friendly refrigerants and CFC-free insulation materials, keeping environmental impact in check while maintaining superior performance.

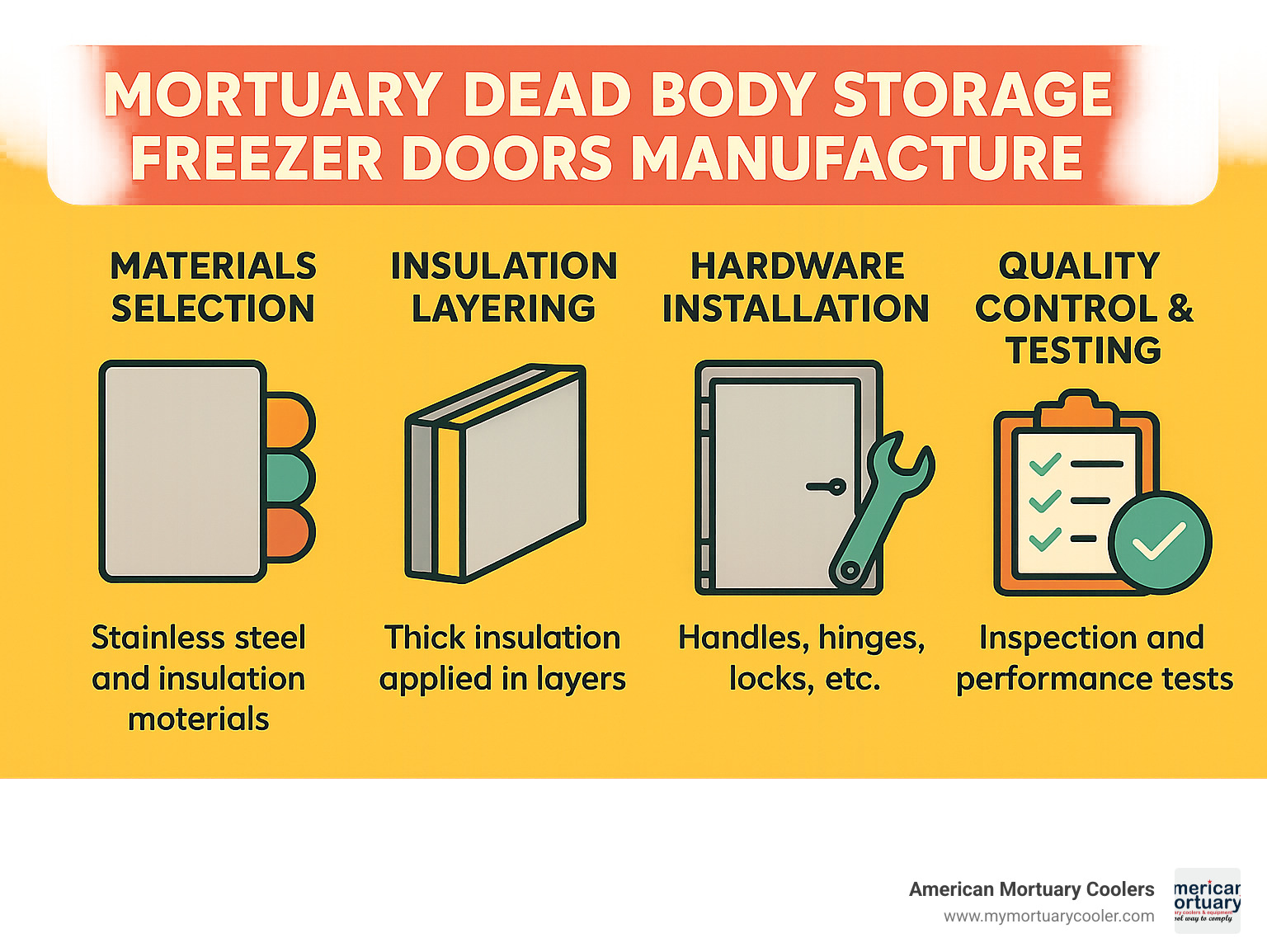

Key Steps in mortuary dead body storage freezer doors manufacture

The manufacturing process follows strict quality protocols that would make a Swiss watchmaker proud. It all starts with CNC fabrication for precise sheet metal cutting—computer-controlled machines ensure every panel meets exact specifications.

Panel lamination comes next, where inner and outer steel sheets get bonded with that insulation core we talked about. This isn't a simple sandwich—it requires careful temperature and pressure control to create a uniform bond.

Gasket insertion involves fitting those magnetic sealing strips into precision-machined channels. Get this wrong, and you'll have temperature fluctuations that can compromise preservation quality. Leak testing follows, where each door undergoes rigorous pressure testing to verify those airtight seals actually work.

The final steps include weld finishing to create smooth, hygienic surfaces and comprehensive pressure balancing to ensure doors operate smoothly under varying temperature conditions. Every door gets a thorough inspection before it leaves the factory.

Insulation & Energy Efficiency

That 8-10 cm of PUF insulation isn't just thick for show—it delivers impressive R-values that keep your energy costs manageable. High-density foam injection eliminates air pockets that could create cold spots or thermal bridges.

Anti-condensation heaters might sound like overkill, but they're essential for preventing moisture buildup on door surfaces. This is especially important in humid climates where condensation can become a real problem.

Energy efficiency isn't just about saving money—it's about reliability. Even tiny gaps in door seals can dramatically increase compressor runtime, leading to premature equipment failure and unexpected downtime. Quality manufacturers test seal effectiveness using pressure decay methods that simulate years of real-world use.

The best part? Modern mortuary dead body storage freezer doors manufacture has become so refined that properly installed doors can maintain their sealing integrity for decades with minimal maintenance.

Design Features, Safety Mechanisms & Compliance

Safety isn't just a feature in mortuary dead body storage freezer doors manufacture—it's absolutely essential. Modern doors come packed with multiple layers of protection that keep both your staff and facility secure.

Every chamber gets its own individual lock and key system, giving you complete control over access. Spring door latches provide that satisfying "click" when doors close properly, while internal release handles ensure anyone accidentally trapped inside can get out safely. These OSHA-compliant safety releases are literally lifesavers.

Digital alarm systems have revolutionized mortuary safety. These smart systems constantly monitor door position, temperature changes, and power status. When a door stays open too long, door-ajar sensors immediately alert your staff before temperature problems develop. Some advanced systems even connect to the internet, sending alerts straight to your phone when issues arise.

Antimicrobial finishes on door surfaces provide an extra layer of protection against harmful bacteria. These special coatings work around the clock to keep surfaces cleaner between your regular cleaning cycles.

| Door Type | Security Features | Hygiene Features | Safety Mechanisms |

|---|---|---|---|

| Individual Chamber | Lock & Key, Spring Latch | Magnetic Gaskets, Seamless Corners | Internal Release, Emergency Alarm |

| Walk-in Cooler | Electronic Lock, Access Control | Antimicrobial Coating, Floor Drains | Safety Release Handle, Backup Power |

| Bariatric Unit | Heavy-duty Lock, Reinforced Frame | Easy-clean Surfaces, Condensate Management | Load-rated Hinges, Fail-safe Mechanisms |

Compliance requirements can feel overwhelming, but they're there for good reasons. ISO 9001 certification ensures consistent quality management throughout manufacturing. CE marking opens doors to European markets, while NSF certification proves your equipment meets strict sanitary standards. UL approval on electrical components gives you peace of mind about safety and reliability.

Quality Assurance in mortuary dead body storage freezer doors manufacture

Before any door leaves the factory, it goes through rigorous Factory Acceptance Testing (FAT). This isn't just a quick once-over—it's a comprehensive evaluation that simulates real-world conditions.

Temperature mapping uses precise sensors to verify uniform cooling throughout every storage chamber. Cycle testing puts doors through thousands of open-close cycles, simulating years of daily use to catch potential problems before they reach your facility.

At American Mortuary Coolers, we maintain ISO 9001:2015 certification across all our manufacturing facilities. This commitment to quality extends from our Tennessee headquarters to our regional service centers in Atlanta, Chicago, Columbia, Dallas, Los Angeles, New York, and Pittsburgh.

Certifications require ongoing audits and detailed documentation. We don't just meet these standards once—we maintain them year after year because your reputation depends on our reliability.

Hygiene & Decontamination

Cleanliness isn't optional in mortuary work—it's absolutely critical. That's why modern door design focuses heavily on seamless construction that eliminates every possible hiding spot for bacteria.

Coved base corners might seem like a small detail, but they make thorough cleaning much easier. These rounded corners prevent debris buildup and allow cleaning solutions to reach every surface. Smooth stainless steel surfaces resist staining and won't absorb odors, no matter how thoroughly you need to clean them.

Condensate management systems prevent water accumulation that could become a breeding ground for harmful microorganisms. Sloped surfaces naturally guide moisture away from storage areas, while removable gaskets allow for deep cleaning and replacement when needed.

Some facilities choose antimicrobial coatings for additional protection against pathogen growth. These specialized finishes provide continuous protection between cleaning cycles, giving you extra confidence in your facility's hygiene standards.

Technology, Customization & Cost

Today's mortuary dead body storage freezer doors manufacture has acceptd smart technology that would have seemed like science fiction just a decade ago. Modern doors now feature digital PID temperature controllers that maintain precise temperatures within fractions of a degree. These aren't your grandfather's simple thermostats—they're sophisticated systems that learn your facility's patterns and adjust accordingly.

IoT monitoring systems have revolutionized how funeral directors manage their facilities. You can now receive alerts on your smartphone if a door is left ajar or if temperatures drift outside safe ranges. Some systems even predict maintenance needs before problems occur, saving both money and stress during critical times.

The push toward sustainability has brought us eco-friendly foam insulation and solar-ready electrical systems. These innovations don't just help the environment—they significantly reduce your monthly utility bills. Many facilities report energy savings of 20-30% after upgrading to modern door systems.

An Essential Guide to Mortuary Cold Room Doors

Capacity-Driven Door Configurations

Every funeral home has different needs, and door configurations reflect this reality beautifully. Single-body units feature compact hinged doors perfect for smaller facilities or overflow capacity. These units maximize space efficiency without sacrificing functionality.

Two to four-body cabinets represent the sweet spot for many funeral homes. Each chamber gets its own door with individual locks, giving you complete control over access and security. The shared refrigeration system keeps costs reasonable while maintaining professional standards.

Six to ten-body systems step into modular territory with sophisticated door arrays. These larger units often feature independent temperature control for different chambers—handy when you need varying temperatures for different preservation needs.

Walk-in coolers and roll-in freezers require heavy-duty doors with oversized openings. These systems prioritize workflow efficiency, allowing easy gurney access and movement. The doors themselves become architectural features, built to handle frequent use while maintaining perfect seals.

Bariatric configurations deserve special mention. These reinforced systems handle oversized remains with dignity and respect, featuring wider openings and stronger hardware without compromising the gentle operation families expect.

Budgeting & Total Cost of Ownership

Let's talk numbers honestly. Door costs typically represent 15-25% of your total mortuary cooler investment—a significant portion that deserves careful consideration. Understanding what drives these costs helps you make smarter decisions.

Material choices make the biggest impact on pricing. 304-grade stainless steel handles most applications beautifully, while 316-grade offers superior chemical resistance for facilities using aggressive cleaning agents. Thicker insulation costs more upfront but pays dividends through energy savings.

Labor costs reflect the precision required in mortuary dead body storage freezer doors manufacture. Custom sizing, specialized features, and quality control testing all require skilled craftspeople. This isn't mass production—it's careful fabrication of equipment that must perform flawlessly when families need you most.

Shipping considerations often surprise first-time buyers. These doors are heavy, oversized items that require special handling. Distance matters, but our Tennessee location helps us serve the contiguous 48 states efficiently.

Here's where smart buying pays off: energy efficiency and maintenance costs dramatically affect your long-term expenses. Premium doors with superior seals and insulation typically recover their extra cost through energy savings within 3-5 years. Cheap doors that leak air will punish you monthly through higher utility bills.

Standard 2-body cabinets start around $230,000 including doors, with larger systems scaling proportionally. Custom configurations and specialized features add 10-30% to base pricing—but they're often worth every penny for the right application.

Extended warranties and local service support minimize those dreaded middle-of-the-night emergencies. When you're dealing with grieving families, equipment downtime isn't just inconvenient—it's heartbreaking. Quality construction and reliable support protect both your business and your reputation.

Frequently Asked Questions about Mortuary Freezer Door Manufacturing

When it comes to mortuary dead body storage freezer doors manufacture, facility managers and funeral directors often have practical questions about maintenance, compliance, and upgrades. Here are the most common concerns we hear from customers across our service network.

How often should gaskets be replaced?

The magnetic door gaskets on your mortuary freezer are working hard every day to maintain that critical seal. Under normal operating conditions, you can expect them to last 3 to 5 years before showing signs of wear.

But here's the thing—high-traffic facilities that open doors frequently may need replacements every 2 to 3 years. It's not just about time; it's about usage patterns and environmental conditions.

Watch for these warning signs: visible cracking or tearing in the gasket material, doors that feel harder to close than usual, or temperature alarms going off more frequently. Even small gaps can cause your compressor to work overtime, driving up energy costs significantly.

The good news? We stock replacement gaskets for all our door models and can walk you through the installation process. Many facilities handle basic gasket replacement in-house, though we're always available for technical support when needed.

What certifications are mandatory for export?

Export requirements can feel overwhelming, but the specific certifications depend entirely on where you're shipping your equipment. CE marking is essential for European markets, while Health Canada approval opens doors to our northern neighbors.

For medical device classifications, FDA registration may be required depending on the intended use. Some countries have additional requirements for electrical components, refrigeration systems, or stainless steel food-contact surfaces.

Here's what makes this easier: we maintain current certifications for major export markets as part of our standard manufacturing process. When special certifications are needed for unique destinations, we can expedite the process—though it's always best to discuss export requirements early in your planning process.

Our Tennessee facility has handled exports to over 20 countries, so we've steerd most certification challenges before. Just let us know your destination, and we'll provide a clear roadmap for compliance requirements.

Can doors be retro-fitted to existing cabinets?

This is one of our most frequent questions, especially from facilities looking to upgrade older equipment. The short answer is yes, most doors can be retrofitted—but there are important considerations to keep in mind.

Frame dimensions are the biggest factor. If your existing cabinet frames match our standard door sizes, retrofitting is usually straightforward. However, upgrading to modern insulation standards might require some frame modifications to accommodate thicker door construction.

Older cabinets sometimes have different hinge configurations or electrical connections that need updating. Safety features like internal release handles and door-ajar sensors may require additional wiring work.

Here's how we handle retrofits: We offer field surveys to assess your specific situation and provide detailed proposals that include any structural changes needed. Our technicians can evaluate your existing equipment and give you honest feedback about whether retrofitting makes financial sense compared to replacement.

Sometimes the most cost-effective approach is a complete upgrade, especially when factoring in energy savings from modern insulation and sealing technology. We'll help you crunch the numbers so you can make the best decision for your facility's long-term needs.

Conclusion & Next Steps

When it comes to mortuary dead body storage freezer doors manufacture, the difference between good and great lies in the details. You need doors that won't fail when families are counting on you most. That means precision engineering, top-grade materials, and manufacturers who understand the funeral industry's unique challenges.

At American Mortuary Coolers, we've spent decades perfecting our craft right here in Tennessee. We know that every facility has different needs—whether you're running a small family funeral home or managing a large hospital morgue. That's why we don't believe in one-size-fits-all solutions.

Our approach is simple: We listen to what you need, design it right the first time, and deliver it anywhere in the contiguous 48 states. No middlemen, no surprises, just reliable equipment backed by people who care about your success.

Designing Your Ideal Mortuary Cooler: The Power of Customization

What sets us apart? We're not just manufacturers—we're partners in your operation. When you call with questions about door specifications or need emergency support, you'll talk to real people who know your equipment inside and out. Our regional service network means help is never far away.

Whether you're replacing a single door that's seen better days or planning a complete facility upgrade, we're here to make the process as smooth as possible. We'll walk you through every option, explain the technical details in plain English, and make sure you get exactly what your facility needs.

Ready to get started? Contact our team today for immediate assistance with door specifications, pricing, or any technical questions. We'll help you select the perfect door solution that keeps your facility running smoothly and meets all compliance standards—because that's what your families deserve.