The Ultimate Guide to Hydraulic Table Options

Why Hydraulic Tables Are Essential for Modern Workplaces

Hydraulic-table- systems provide smooth, controlled lifting and positioning for heavy loads across multiple industries. These versatile work surfaces use fluid power to raise, lower, and sometimes tilt or rotate materials with minimal physical effort from operators.

Key Benefits of Hydraulic Tables:

- Load Capacity: Handle 300 lbs to 2,400 lbs depending on model

- Height Range: Typically adjust from 21" to 49" for ergonomic positioning

- Applications: Industrial material handling, mortuary prep, pet grooming, massage therapy

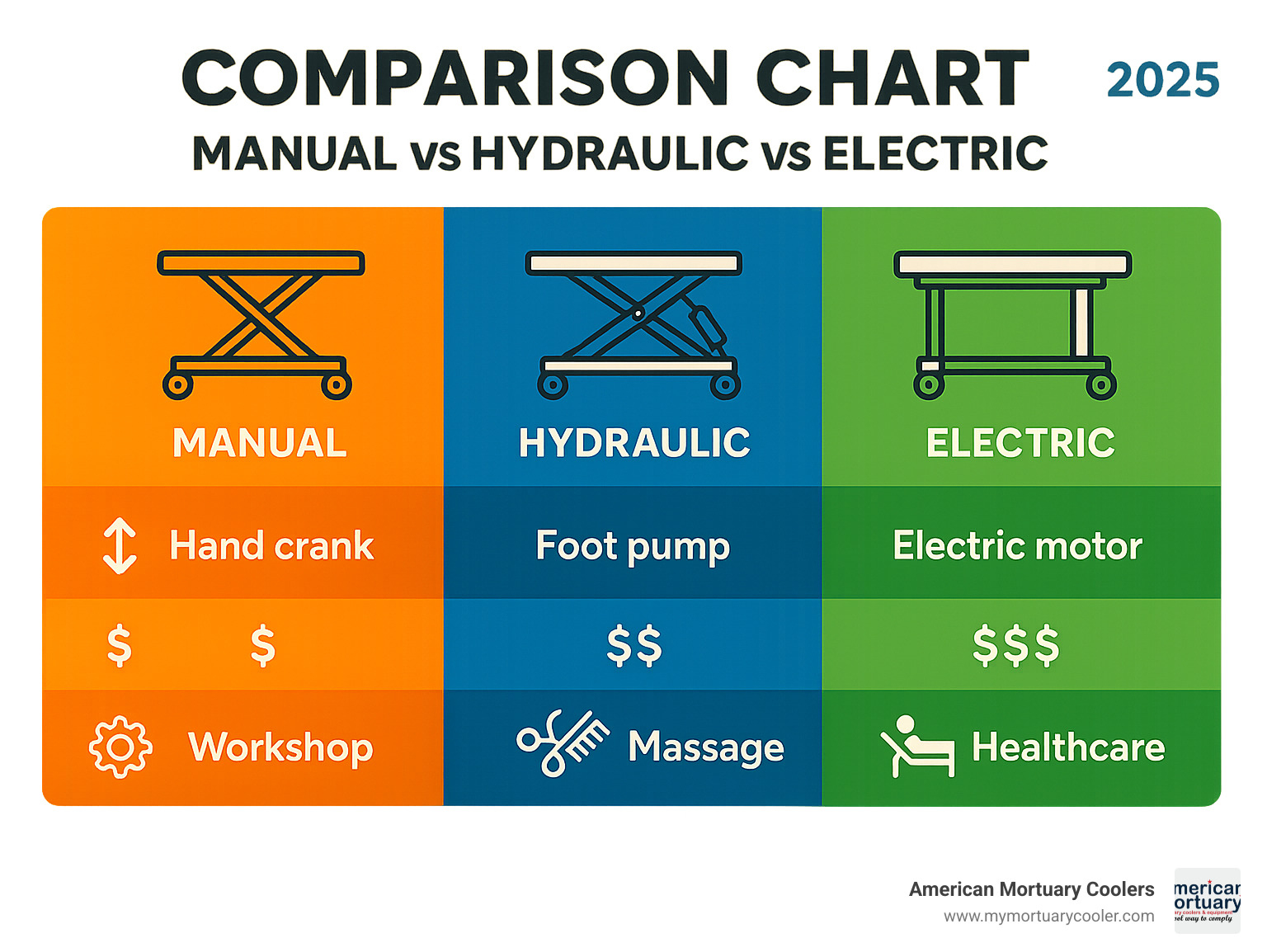

- Power Options: Manual foot pump, electric actuator, or combination systems

- Mobility: Available with locking casters for easy repositioning

From Vestil's 300-lb manual post tables priced under $1,000 to heavy-duty industrial systems capable of lifting 2,400 lbs with full rotation, hydraulic tables offer solutions for every budget and application. The key advantage over manual alternatives is the dramatic reduction in operator strain while maintaining precise control over load positioning.

I'm Mortuary Cooler, a national-level mortuary equipment supplier specializing in American-made cooling and prep room solutions. Through years of working with funeral homes across the country, I've seen how the right hydraulic-table- can transform daily operations by improving ergonomics and workflow efficiency.

Hydraulic-table- vocab to learn:

Understanding hydraulic-table- Mechanics

When you first see a hydraulic-table- in action, it almost seems like magic. You press a foot pedal or flip a switch, and hundreds of pounds rise smoothly and effortlessly. But there's solid engineering behind this seemingly effortless operation.

The secret lies in the scissor-lift mechanism that most hydraulic tables use. Picture an accordion that expands upward - that's essentially how these systems work. The scissor design spreads weight evenly across the entire platform, preventing wobbling or dangerous tipping.

At the heart of every system is the hydraulic-pump. In manual systems, you operate this pump with a foot-pedal - a few gentle pumps can raise several hundred pounds without breaking a sweat. For those who want even more convenience, electric-actuator systems do the pumping for you at the touch of a button.

The real genius happens inside the pistons. When you pump hydraulic fluid into these cylinders, they extend and push the scissor mechanism upward. When you release the fluid, the platform lowers in a controlled manner. It's simple, reliable, and incredibly effective.

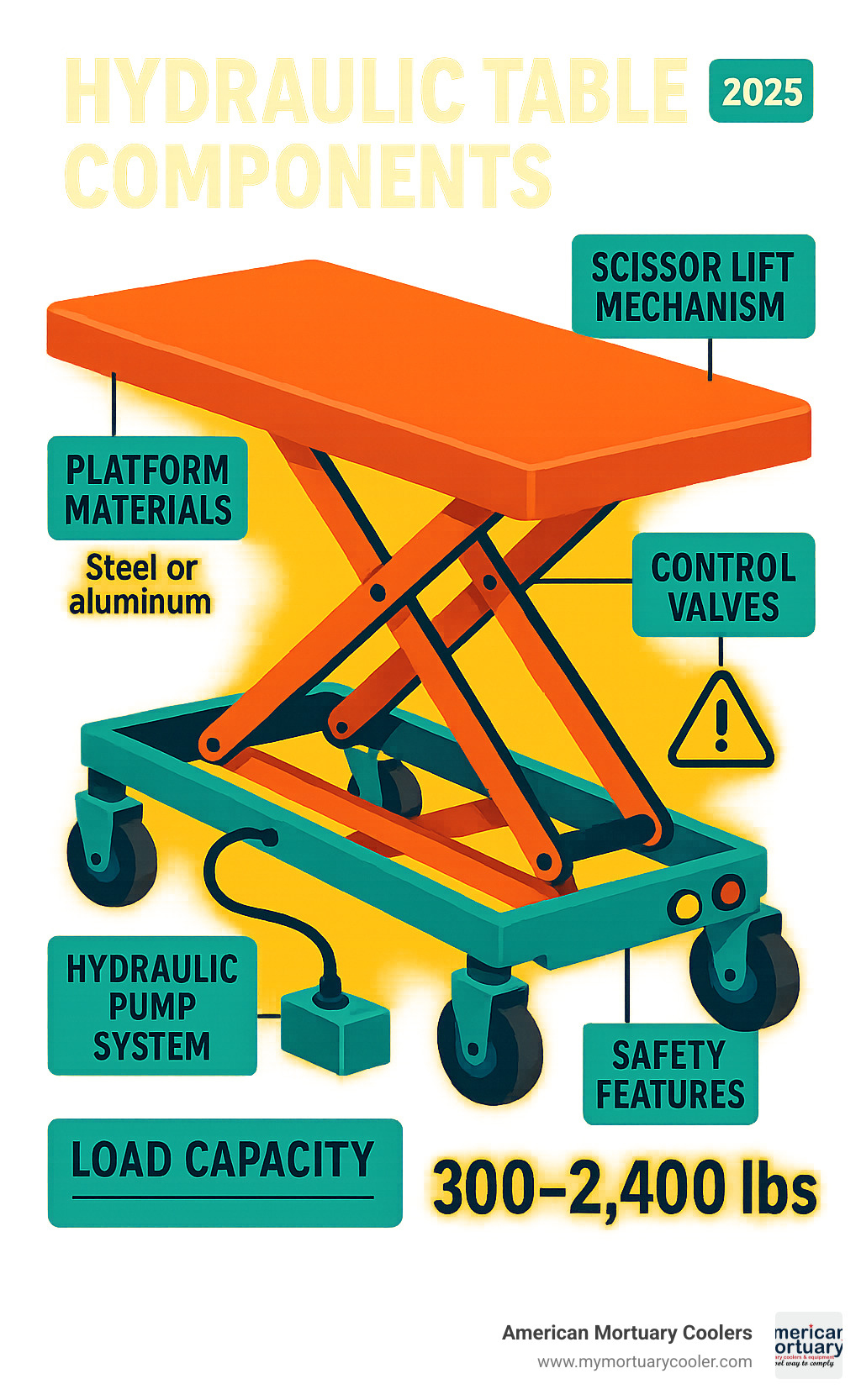

Key Components of a hydraulic-table-

The platform-material tells you a lot about how a table is meant to be used. Industrial tables often feature steel platforms with rubber coating for grip and durability. In mortuary equipment, we always recommend 304 stainless steel platforms for corrosion resistance and easy cleaning.

The frame-steel construction determines whether your table will last years or decades. Quality manufacturers use welded steel frames with extra reinforcement at stress points.

When it comes to pump-types, you have three main choices. Manual foot pumps are simple and reliable - they work anywhere without needing electricity. Electric pumps offer push-button convenience but require power access. Some premium systems give you both options.

The control-valve system manages how your table goes up and down. The best tables include a down-speed control that prevents sudden drops. This valve lets you lower loads gradually and safely, even when fully loaded.

Every professional table needs a reliable safety-lock mechanism. Some systems automatically lock at preset heights, while others use manual pins or hydraulic locks.

How Hydraulic Power Works

The science behind hydraulic power comes down to Pascal's-law - pressure applied to trapped fluid spreads equally in all directions. In practical terms, this means a small amount of force on your foot pedal can generate tremendous lifting power at the platform.

Here's how the fluid-force multiplication works: imagine your foot pump has a 1-inch diameter piston, and the lift cylinder has a 4-inch diameter. That gives you a 16-to-1 force advantage. Press down with 20 pounds of force, and you get 320 pounds of lifting power.

The lift-ratio determines both your lifting strength and operating speed. Higher ratios mean more power but slower movement. One of the best features of hydraulic systems is their energy-efficiency. Once you raise the platform, it stays there without using any additional power. For more technical details on fluid power principles, Scientific research on fluid power provides additional engineering insights.

Major Types & Industry Applications

When you start exploring hydraulic-table- options, you'll quickly find just how many different industries rely on these versatile workhorses. From busy warehouse floors to quiet funeral homes, from pet grooming salons to home workshops, hydraulic tables adapt to meet wildly different needs.

The beauty lies in how each application shapes the design. A lift-table hauling heavy parts in a factory needs rugged durability and smooth mobility. Grooming-tables require non-slip surfaces that clean easily. Mortuary-tables must handle substantial weight while resisting chemicals used in embalming. Industrial-carts prioritize strength and maneuverability, while massage-tables focus on whisper-quiet operation.

Industrial & Warehouse Uses

Walk through any modern warehouse or manufacturing facility, and you'll see hydraulic tables earning their keep with material-handling tasks. These sturdy platforms lift, position, and transport everything from delicate electronics to massive engine blocks.

Pallet-positioning represents one of the most common uses. Instead of workers constantly bending and stretching to reach items at awkward heights, hydraulic tables bring the work to the perfect level. This prevents back injuries that cost companies thousands in workers' compensation claims.

The Vestil manual table shows how industrial design meets practical needs. With its 300-pound capacity and compact 16" x 16" platform, it handles serious shop tasks without overwhelming smaller workspaces. The height adjusts from 31" to 49", while telescoping posts provide stability for heavy components.

Medical, Mortuary & Lab Settings

In mortuary and medical environments, hydraulic-table- systems become absolutely essential tools. Autopsy-tables and embalming-tables must handle tremendous loads - often 650 to 1,000+ pounds - while maintaining precision needed for detailed work.

Stainless-steel construction becomes non-negotiable in these settings. The MOBI Bariatric Autopsy Trolley exemplifies this approach with its heavy-gauge 304 stainless steel build and impressive 1,000-pound capacity. This provides the chemical resistance essential when working with embalming fluids and disinfectants.

Height adjustment proves crucial for professional effectiveness and worker health. Most systems range from 30" to 38", accommodating different staff heights and procedural requirements.

For comprehensive guidance on selecting the right equipment for your prep room, our Hydraulic Embalming Tables: Prep Room Supplies resource covers everything you need to know.

Pet Grooming & Wellness

Professional groomers face a unique challenge - their "clients" range from tiny Chihuahuas to massive Great Danes. Grooming-stands with hydraulic adjustment solve this problem neatly, allowing table height to match both the animal and the groomer's comfort zone.

The spa-massage world has acceptd hydraulic tables for their smooth, quiet operation. The Master Massage TheraMaster demonstrates this perfectly with its 21" to 34" height range and substantial 550-pound capacity. The electric actuator provides whisper-quiet adjustment that won't disturb relaxed clients.

DIY & Maker Projects

The availability of scissor-kits and individual components has opened hydraulic table construction to skilled DIY builders. Welded-frames form the backbone of most DIY hydraulic tables, requiring solid welding skills and proper tools for safe fabrication.

Cost-saving motivates many DIY projects. While commercial hydraulic tables can cost thousands of dollars, a DIY approach can achieve similar functionality for a fraction of the price. However, this path requires careful attention to safety considerations that commercial manufacturers handle through professional engineering.

The DIY build forum offers valuable community support for builders tackling these projects. DIY builders must carefully consider load ratings, safety factors, and proper hydraulic component selection.

Choosing the Right Model: Specs, Features & Budget

Finding the perfect hydraulic-table- doesn't have to be overwhelming. Think of it like buying a car - you need to match the features to your actual needs, not just go for the biggest engine. The sweet spot is where your requirements meet your budget without paying for bells and whistles you'll never use.

Load-capacity sits at the heart of every decision. The trusty Vestil manual table handles 300 pounds perfectly for most shop work, while the Master Massage table steps up to 550 pounds for professional therapy settings. Industrial systems can hoist 2,400 pounds while rotating a full circle - though that capability comes with a matching price tag.

Platform-size varies as much as the applications themselves. That compact 16" x 16" Vestil surface works great for tools and smaller projects. Mortuary tables stretch to 35" x 85" for their specialized work. Industrial giants can reach 125" x 76" when dealing with massive workpieces.

The height-range determines whether your back will thank you at the end of each day. Most quality tables give you 15-20 inches of adjustment. The Master Massage unit travels from 21" to 34", while the Vestil reaches 31" to 49" for standing work applications.

Buying Checklist

Smart shoppers start with weight-rating that exceeds their heaviest load by at least 25%. Don't forget to count tooling, fixtures, or accessories that'll ride along.

Duty-cycle matters more than most people realize. Manual foot pumps work beautifully for occasional adjustments, but they'll wear you out with constant use. Electric systems handle high-frequency operation effortlessly.

Power-source requirements affect both installation and daily operation. Manual systems need zero electrical connections but demand physical effort. Electric systems require proper voltage and may need professional electrical installation.

Caster-type impacts both mobility and floor protection. Heavy-duty polyurethane casters roll smoothly without marking floors. Total-lock brakes that secure both rolling and swiveling aren't optional - they're essential for safety.

Price Bands & ROI

Budget-DIY projects under $500 appeal to skilled builders with welding equipment and hydraulic knowledge. This route demands significant time investment and places safety responsibility squarely on your shoulders.

Mid-range systems between $1,000-$4,000 hit the sweet spot for many professionals. Quality manual tables like the Vestil unit and electric options like the Master Massage TheraMaster deliver professional capability without breaking the budget.

Heavy-duty systems from $5,000-$20,000 provide industrial-grade performance with high load capacity, tilt/rotation, and sophisticated controls.

The ergonomic benefits often provide the real return on investment. Reduced worker fatigue and injury risk deliver value that's hard to quantify but easy to feel.

Latest Innovations & Trends

Wireless-remotes boost both safety and convenience by letting operators control functions from optimal positions. Programmable-heights let operators store frequently-used positions for instant recall.

Smart-sensors can monitor load weight, detect overload conditions, and provide diagnostic information for predictive maintenance. These features are emerging on premium systems and will likely become standard as sensor costs continue dropping.

For insights into where this technology might head, Careers at Amazon Robotics showcases ongoing innovations in robotics and automation across industrial applications.

Safe Operation, Maintenance & Compliance

Working safely with a hydraulic-table- isn't just about following rules - it's about understanding that these powerful machines deserve your respect. Whether you're handling a 300-pound grooming table or a 2,400-pound industrial system, the hydraulic power that makes your job easier can also cause serious harm if you're not careful.

The foundation of safe operation starts with proper training. Don't just hand someone the manual and expect them to figure it out. Take time to walk through every control, demonstrate proper loading techniques, and practice emergency procedures.

Load-balancing prevents those heart-stopping moments when a table starts to tip. Even if your hydraulic-table- is rated for 300 kg, that capacity assumes the weight is distributed properly across the platform. Always center your load and think about how the weight is positioned before you start lifting.

Regular inspection schedules catch problems before they become dangerous failures. A weekly walk-around checking for hydraulic leaks, damaged components, and proper caster operation takes just a few minutes but can prevent costly downtime and injuries.

Hydraulic-fluid care might seem like a minor detail, but it's the lifeblood of your system. Clean hydraulic fluid should look clear and flow smoothly. Check fluid levels regularly and don't wait until you see problems to address fluid quality.

How to Safely Operate a hydraulic-table-

Training tips should cover both the routine stuff and what to do when things go wrong. Start new operators with light loads so they can get a feel for the controls without pressure. Show them proper loading techniques, demonstrate each control function, and walk through emergency procedures step by step.

Brake engagement is non-negotiable before loading or unloading anything. Never try to load an unsecured table. It can roll away or tip during loading, and that's how people get hurt.

Down-speed control prevents those terrifying moments when a heavy load drops too fast. Quality hydraulic-table- systems include control valves that let you lower loads gradually and safely, even when they're at maximum capacity.

Emergency stop procedures should be second nature to every operator. Know exactly how to stop all table functions immediately if something goes wrong. Never exceed the rated capacity or use your table for something it wasn't designed to do.

Maintenance Routine & Troubleshooting

Leak checks should be part of your regular routine because hydraulic fluid leaks always get worse, never better. What starts as a small drip can quickly become a system failure and a serious slip hazard.

Seal replacement requires understanding your hydraulic system and having the right tools for the job. Some seals are straightforward to replace, while others need professional service. Keep spare seals for common wear items, but be honest about your skill level.

Lubrication of moving parts keeps everything running smoothly and extends component life. The scissor mechanism, pivot points, and caster bearings all need regular attention according to the manufacturer's schedule.

Periodic testing verifies that all your safety systems actually work when you need them. Test emergency stops, speed controls, and safety locks on a regular schedule. Document your test results so you can track system performance over time.

For additional guidance on lift system maintenance and troubleshooting, our More info about lift systems resource provides detailed technical information to keep your equipment running safely and efficiently.

Frequently Asked Questions about Hydraulic Tables

What advantages do hydraulic tables offer over manual lifts?

The difference between hydraulic-table- systems and manual lifts is like comparing a sports car to a bicycle - both get you there, but one makes the journey much easier! The biggest game-changer is force multiplication. When you press that foot pedal with just 20 pounds of pressure, hydraulic magic can lift 300+ pounds without breaking a sweat.

Precision control sets hydraulic systems apart from their manual cousins. Try making tiny height adjustments with a manual crank when you're positioning a 500-pound load - it's like trying to thread a needle while wearing boxing gloves. Hydraulic systems give you that smooth, controlled movement that lets you dial in exactly the right position.

Your back will thank you for choosing hydraulic over manual. We've heard from countless funeral directors who switched from manual embalming tables to hydraulic ones - the difference in operator fatigue is night and day.

Here's something really neat: once you raise a hydraulic-table-, it stays put without any effort from you. Manual systems often fight back, requiring constant tension or finicky locks to maintain position. Hydraulic systems just hold their ground, rock-solid and ready for whatever you throw at them.

How often should hydraulic fluid be replaced?

Think of hydraulic fluid like the oil in your car - it doesn't last forever, but how long it lasts depends on how hard you work it. A massage table that gets gentle daily use might go 2-3 years between fluid changes. But if you're running an industrial hydraulic-table- in a busy warehouse, you might need fresh fluid every year or even more often.

Contamination is the silent killer of hydraulic systems. Water sneaking in through humidity or tiny leaks causes rust and damages seals. Dirt and metal particles from normal wear can turn your smooth hydraulic fluid into liquid sandpaper that destroys pumps and valves.

Your eyes are your best diagnostic tool here. Fresh hydraulic fluid looks clear and clean, like good cooking oil. If it's cloudy, dark, or has floating particles, it's crying out for replacement. Don't wait for your scheduled maintenance if the fluid looks rough - address it right away.

Can I convert a manual table to powered operation later?

Converting a manual hydraulic-table- to electric operation is technically possible, but it's a bit like putting a turbo engine in an old pickup truck - doable, but not always the smartest move. The existing hydraulic pump, cylinders, and valves might work with electric power, but you'll need to add a motor, controls, and electrical connections.

Compatibility is the big question mark. Some manual pumps just weren't designed for the continuous operation that electric motors demand. We always recommend having a qualified technician evaluate your existing system before you start shopping for conversion parts.

Here's the reality check: by the time you buy a quality electric actuator, control system, and pay for professional installation, you might spend almost as much as a brand-new electric table. Plus, you'll still have an older hydraulic system underneath all those shiny new electric parts.

At American Mortuary Coolers, we usually suggest that customers consider a new electric hydraulic-table- instead of conversion. You'll get modern safety features, full warranty coverage, and the peace of mind that comes with a system designed from the ground up for electric operation.

Conclusion

After exploring everything from basic manual systems to sophisticated industrial hydraulic-table- units, one thing becomes crystal clear: these aren't just pieces of equipment - they're game-changers for any business that handles heavy materials or prioritizes worker comfort.

The reliability of hydraulic systems speaks for itself. We've seen funeral homes running the same hydraulic embalming tables for decades with nothing more than basic maintenance. That's the kind of dependability you get when you invest in quality hydraulic technology.

The efficiency gains go way beyond just lifting heavy things. When your staff isn't fighting with manual cranks or struggling to position equipment, they can focus on what really matters - doing their job well. A massage therapist who can adjust table height at the touch of a button provides better care. A mortuary professional working at the perfect height maintains dignity and precision throughout lengthy procedures.

But here's what really gets our attention - the ergonomic-benefits that protect your most valuable asset: your people. Back injuries from lifting and awkward positioning don't just hurt employees; they hurt your bottom line through lost productivity, medical costs, and the hassle of finding temporary coverage. A good hydraulic table eliminates most of these risks before they happen.

At American Mortuary Coolers, we've watched countless funeral homes transform their operations with the right equipment choices. There's something satisfying about seeing a prep room that flows smoothly, where staff members aren't grimacing as they adjust heavy tables or strain to reach the right working height.

We're not just selling equipment - we're your one-stop-shop for solutions that actually work in the real world. Our Tennessee-based team understands that every funeral home has unique needs, which is why we offer custom manufacturing alongside our standard products. When you need a hydraulic-table- that fits your specific space or handles particular requirements, we can make it happen.

Our direct delivery service across all 48 contiguous states means you're not dealing with multiple vendors or wondering when your equipment will arrive. We handle everything from manufacturing to your doorstep, so you can focus on serving families during their most difficult times.

For funeral professionals specifically, our comprehensive The Definitive Guide to Buying Hydraulic Embalming Tables walks through every consideration from load capacity to chemical resistance.

Whether you're upgrading worn-out equipment or planning a brand-new facility, we're here to help you make choices that will serve you well for years to come. The right hydraulic-table- isn't just about lifting - it's about creating a workspace where your team can do their best work safely and comfortably.

American Mortuary Coolers has built our reputation on providing durable, custom solutions that funeral professionals can count on. When you're ready to see how the right hydraulic equipment can improve your daily operations, we're just a phone call away.