The Ultimate Guide to Fume Exhaust Hoods

Why Fume Exhaust Hoods Are Critical for Laboratory Safety

A fume exhaust hood is a ventilated enclosure designed to protect users from hazardous chemicals, vapors, and particles by continuously drawing contaminated air away from the work area. These essential safety devices serve as the primary method of exposure control in laboratories.

Key Functions of a Fume Exhaust Hood:

- Containment - Captures hazardous fumes at their source

- Ventilation - Removes contaminated air through exhaust systems

- Protection - Shields users from chemical exposure and spills

- Compliance - Meets OSHA and laboratory safety standards

Environmental toxic exposure accounts for 7-19% of human cancers, making proper fume containment a life-saving necessity. A typical fume hood uses 3.5 times as much energy as an entire home, highlighting the importance of selecting efficient models.

Modern fume exhaust hoods come in two main types:

- Ducted hoods - Exhaust contaminated air outside the building

- Ductless hoods - Filter and recirculate cleaned air back into the space

As Mortuary Cooler, I've spent years helping funeral directors and laboratory professionals select ventilation solutions that protect both staff and facilities from harmful chemical exposure.

Related content about fume exhaust hood:

Understanding Fume Exhaust Hood Technology

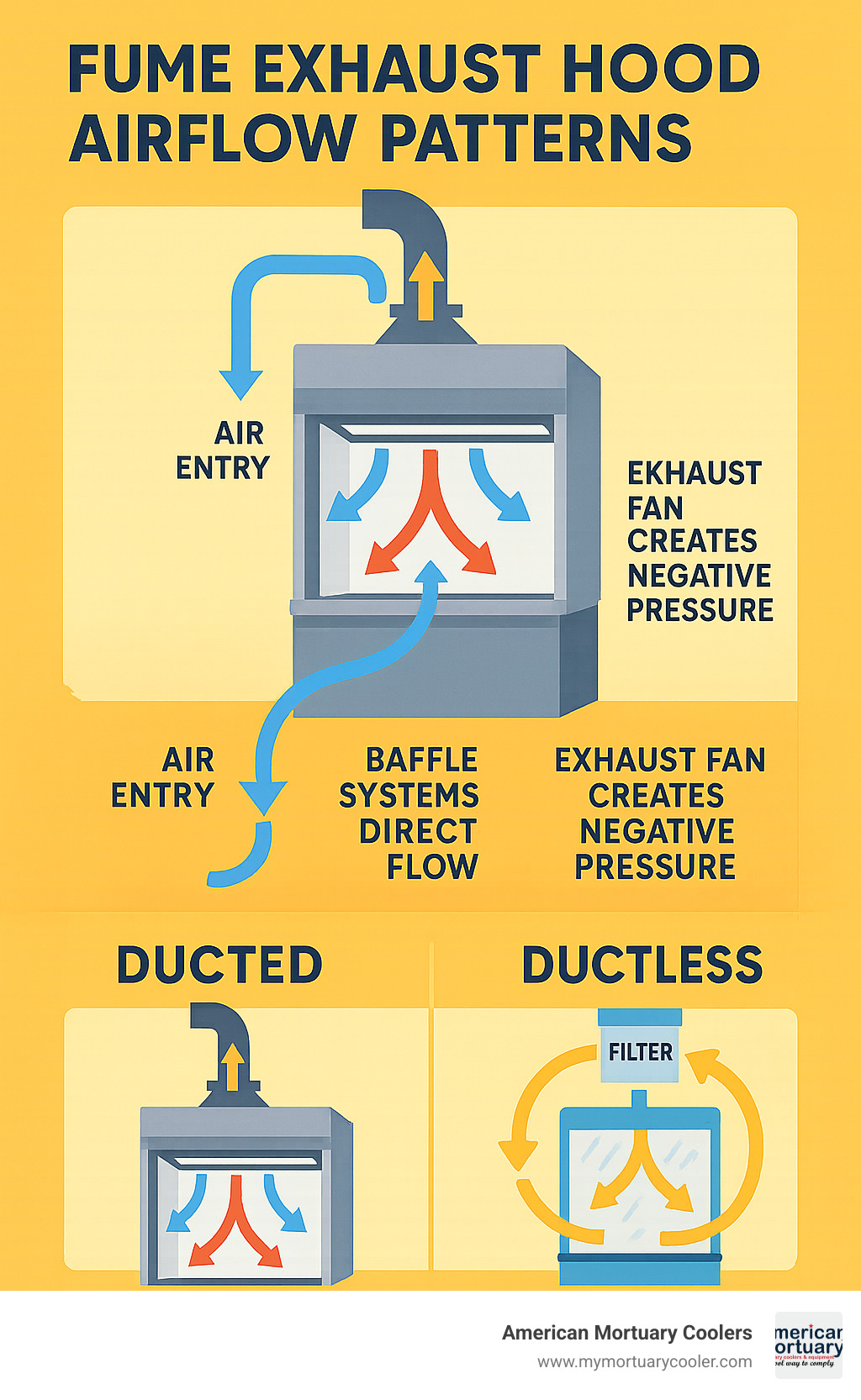

The fume exhaust hood operates through controlled airflow patterns and negative pressure. The hood continuously sucks contaminated air away from you and into its containment area through carefully maintained face velocity - typically between 80 to 120 feet per minute.

The sash serves as both your safety barrier and the hood's air inlet. Inside the hood, baffles guide air evenly throughout the space, eliminating dead spots where fumes might accumulate. Every component is designed to keep contaminated air moving smoothly toward the exhaust system.

For technical details and safety protocols, check out this Scientific research on laboratory chemical hoods from Princeton's environmental health team.

What is a Fume Exhaust Hood?

A fume exhaust hood is your first line of defense against hazardous chemicals, vapors, and particles. It's essentially a ventilated workspace that creates local exhaust ventilation - capturing dangerous substances right at the source before they can spread.

These hoods protect your entire facility by preventing toxic substances from building up in your lab's air, protecting equipment from corrosive vapors, and keeping you compliant with OSHA regulations.

How Does a Fume Exhaust Hood Work?

The operation revolves around maintaining negative pressure inside the hood. An exhaust fan continuously pulls air through the hood and sends it either outside or through filtration systems.

Room air enters through the sash opening at the critical face velocity. The hood's internal design guides airflow to capture every wisp of vapor, while the exhaust fan pulls contaminated air through ductwork and away from your building. This negative pressure creates an invisible force field that always moves air away from you.

Types & Core Components of a Fume Exhaust Hood

The fundamental decision comes down to ducted versus ductless systems. Ducted hoods exhaust contaminated air directly outside, while ductless units filter and recirculate air back into your space.

Polypropylene blowers have revolutionized the industry, weighing 50% less and costing 50% less than fiberglass or stainless steel alternatives while offering superior chemical resistance.

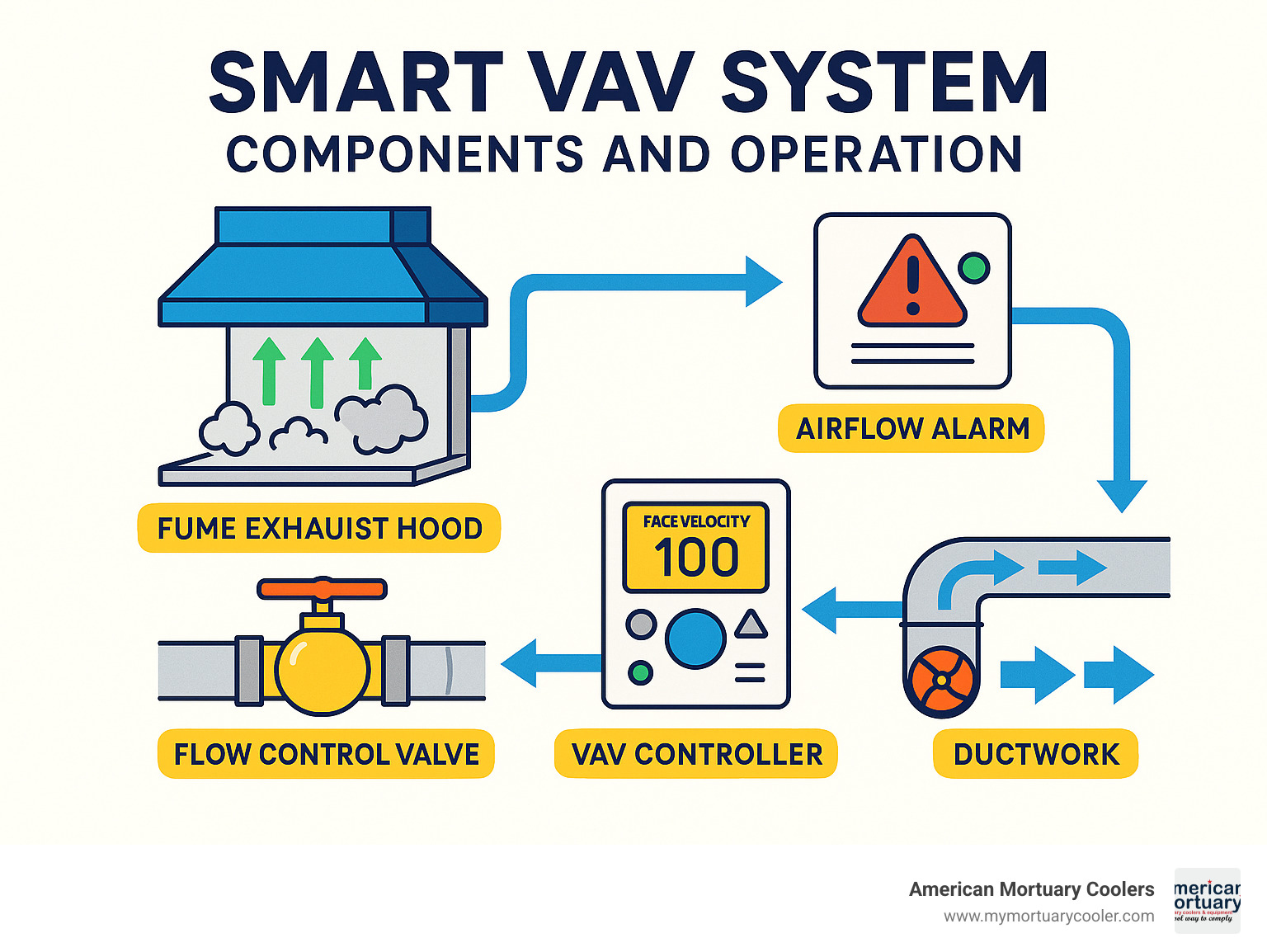

The choice between constant air volume (CAV) and variable air volume (VAV) systems affects both performance and operating costs. VAV systems can cut energy consumption dramatically.

| Feature | Ducted Systems | Ductless Systems |

|---|---|---|

| Installation | Requires ductwork to exterior | Minimal installation requirements |

| Operating Cost | Higher energy consumption | Lower energy consumption |

| Maintenance | Minimal filter maintenance | Regular filter replacement |

| Chemical Compatibility | Handles all chemicals | Limited by filter capacity |

For detailed comparisons, refer to Scientific research on ducted vs ductless systems.

Ducted Fume Exhaust Hood Variants

Bypass hoods feature a bypass opening above the sash that maintains airflow even when the sash is closed, preventing excessive negative pressure.

Low-flow or high-performance hoods use advanced designs to maintain excellent containment while using 30-50% less energy than traditional models.

Canopy hoods mount above equipment to capture rising thermal plumes without fully enclosing the work area.

Ductless & Specialty Hoods

Carbon filter systems use activated carbon to absorb organic vapors and gases, requiring replacement every 6-12 months.

HEPA filtration captures 99.999% of particles 0.3 microns and larger, often combined with carbon filters for comprehensive protection.

Perchloric acid hoods feature wash-down systems and non-combustible construction to prevent explosive crystal formation.

Radioisotope hoods include lead shielding and specialized filtration for radioactive materials.

Selecting, Installing & Maintaining Your Fume Exhaust Hood

Choosing the right fume exhaust hood starts with understanding your specific chemicals and applications. Chemical compatibility extends beyond the hood interior to include ductwork, fans, and exhaust systems.

Location matters significantly. A hood in a high-traffic area faces constant airflow disruption that can compromise containment. Supply air diffuser placement is equally critical to avoid disrupting airflow patterns.

Our experience with ventilated cabinet options shows that comprehensive ventilation design requires thinking beyond just the primary equipment.

Sizing & Specification Checklist

Standard widths include 1000mm, 1200mm, 1500mm, 1800mm, and 2000mm. Face velocity should maintain 80-120 feet per minute with maximum deviation of ±20% from average.

Material selection depends on your applications: mild steel with epoxy coating for general chemistry, stainless steel for acidic environments, polypropylene for chemical resistance, and phenolic resin for high-temperature work up to 350°F.

Installation Best Practices

Keep duct runs short and straight - every elbow increases static pressure. Size ducts for 3000-4000 fpm transport velocity and use chemically compatible materials.

Provide tempered replacement air and locate supply diffusers at least 10 feet from hood openings. Professional commissioning includes ASHRAE 110 tracer gas testing and face velocity measurements.

Maintenance & Troubleshooting

Daily maintenance includes visual inspection and airflow indicator checks. Monthly tasks cover face velocity measurements and filter inspection. Annual professional service provides comprehensive system evaluation.

Common issues: low airflow alarms suggest blocked baffles or fan problems, excessive noise indicates bearing issues, and poor containment points to face velocity problems.

Safety, Energy Efficiency & Regulatory Standards

Safety requires keeping your head out of the hood - only hands and arms should enter the work area. Personal protective equipment remains essential even with a properly functioning hood.

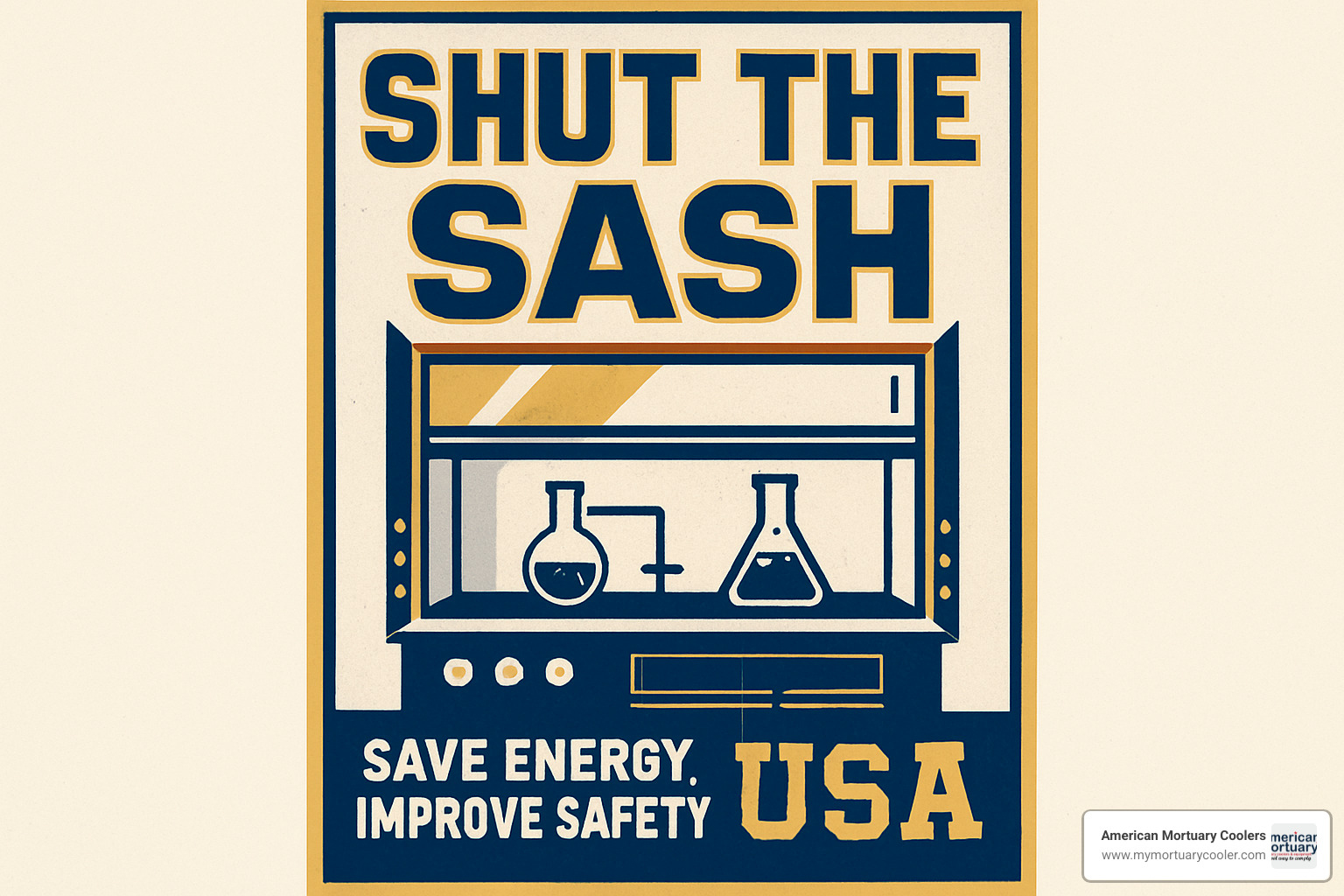

Proper sash management saves money and energy. One institution saved $180,000 annually by maintaining a 30% sash-closure campaign. When not actively working, lowering the sash significantly reduces energy costs.

Regulatory compliance covers ANSI Z9.5, OSHA workplace safety requirements, and EN 14175 standards. These specify minimum face velocity requirements and testing procedures.

For comprehensive information about energy-efficient operations, review Scientific research on energy savings.

Energy-Saving Features & Programs

VAV controls can reduce energy consumption by 30-60% compared to constant volume systems while maintaining consistent face velocity.

Occupancy sensors and hibernation programs detect when hoods are unoccupied and automatically reduce airflow to minimum safe levels.

Sash management programs combine technology with education through "Shut the Sash" campaigns and visual reminders.

Compliance Checklist

Face velocity requirements: maintain 80-120 fpm average with maximum ±20% deviation. Airflow alarm systems provide early warning with visual and audible indicators.

Annual inspection requirements include professional testing, ASHRAE 110 tracer gas testing, and comprehensive documentation. Maintain detailed logs of all testing, maintenance, and modifications.

Innovations, Accessories & Customization Options

Modern fume exhaust hood innovations focus on safety and efficiency. Polypropylene fans weigh half as much as traditional alternatives while costing 50% less and offering superior chemical resistance.

Integrated scrubber systems neutralize exhaust streams before discharge, valuable for facilities with strict environmental regulations. Smart sensor technology monitors face velocity, chemical concentrations, and filter saturation in real-time.

Popular Add-Ons & Upgrades

Worktop selection includes epoxy resin for general chemistry, stainless steel for durability, phenolic resin for chemical resistance, and custom cutouts for specific equipment.

Service fixtures bring utilities directly to your workspace: water, gas, electrical connections, emergency shower stations, and specialty gas connections.

Lighting upgrades improve visibility with LED systems that slash energy consumption. Remote monitoring systems provide digital displays, building automation integration, and data logging capabilities.

Our experience with embalming room upgrades shows how proper accessories transform challenging work environments into efficient, safe spaces.

Frequently Asked Questions about Fume Exhaust Hoods

What capture velocity should my fume exhaust hood maintain?

Your fume exhaust hood needs to maintain face velocity between 80 and 120 feet per minute for safe operation. Measure this with the sash at 18 inches using calibrated instruments.

Face velocity varies across the opening, but no measurement should deviate more than 20% from the average. Take readings at multiple points to ensure uniform airflow.

How often do filters need to be replaced on ductless hoods?

Ductless fume exhaust hood filters typically need replacement every 6 to 12 months, depending on usage and chemical types. Monitor filter saturation rather than calendar dates using pressure drop measurements.

Pre-filters deserve monthly attention to protect expensive downstream filters. Keep detailed replacement records to optimize schedules and budget accurately.

Can one blower serve multiple fume exhaust hoods safely?

I strongly recommend against shared blower systems. Each hood should have dedicated equipment for maximum safety. Shared systems create backflow between hoods, make airflow adjustment impossible, and create catastrophic single points of failure.

Individual blower systems provide improved safety, easier maintenance, and operational flexibility that justify the additional investment.

Conclusion

Choosing the right fume exhaust hood system creates a safe workspace where your team can focus on important work without worrying about harmful chemical exposure. Environmental toxic exposure accounts for 7-19% of human cancers, making your hood a potentially life-saving investment.

The energy efficiency opportunity is significant. When a typical fume hood consumes 3.5 times as much energy as an entire home, implementing VAV controls and proper sash management can slash operating costs by 30-60% while maintaining protection.

At American Mortuary Coolers, our experience with specialized applications has taught us that American-made quality and direct support make all the difference when safety is on line. Our direct delivery across the contiguous 48 states means you get the equipment and expertise you need.

For facilities looking at comprehensive safety upgrades, our Comprehensive Guide to Funeral Director Equipment shows how proper ventilation integrates with other safety systems.

When it comes to chemical safety, cutting corners isn't an option. Quality fume exhaust hood systems, regular maintenance, and proper training are essential for protecting your most valuable asset: your people.