The Ultimate Guide to Cooler Wall Panels: Top Picks & Buying Tips

Why Cooler Wall Panels Are Essential for Modern Cold Storage

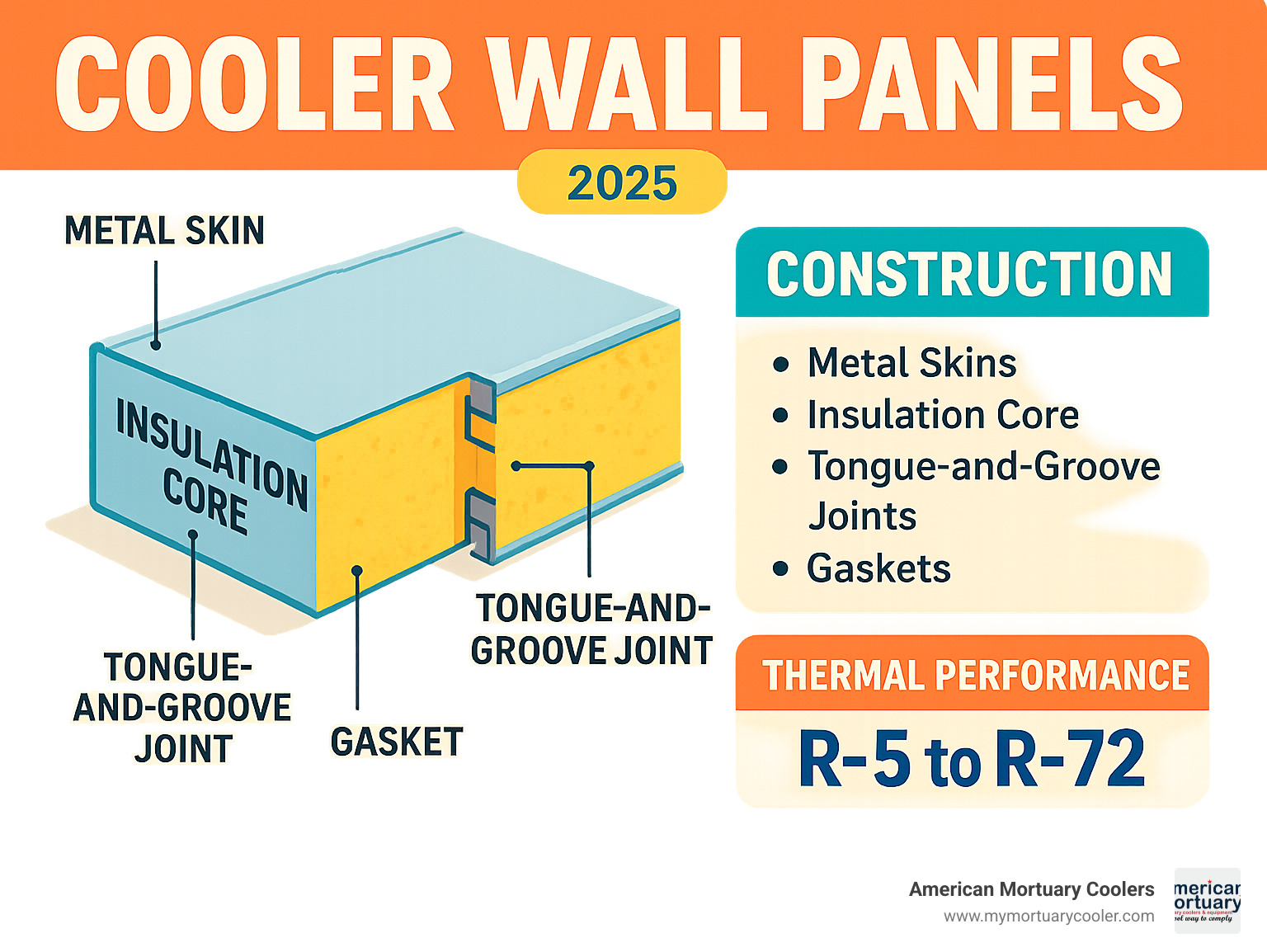

Cooler wall panels are insulated building components that create temperature-controlled environments for cold storage facilities, walk-in coolers, and specialized applications like mortuaries and laboratories. These panels consist of two metal skins with an insulating foam core sandwiched between them, providing superior thermal performance compared to traditional construction methods.

Key Benefits of Cooler Wall Panels:

- Energy Efficiency: Up to 30% cooling energy savings compared to standard construction

- Quick Installation: Interlocking tongue-and-groove design reduces installation time by up to 50%

- Superior Insulation: R-values ranging from R-5 to R-72 depending on thickness and core material

- Durability: 15-year warranties with proper maintenance

- Versatility: Available in thicknesses from 35mm to 200mm for various applications

The global insulation market is projected to grow from €58 billion in 2021 to €103 billion by 2030, driven by increasing energy costs and environmental regulations. With buildings accounting for 37% of all global CO2 emissions, choosing the right insulated panels has never been more critical for both cost savings and environmental responsibility.

Modern cooler wall panels use advanced materials like EPS-FR (fire-retardant expanded polystyrene), PIR (polyisocyanurate), and hybrid foams like QuadCore that deliver 11% better thermal performance than traditional options.

I'm Mortuary Cooler, a national-level supplier specializing in mortuary coolers and cold storage solutions across the United States. With experience in cooler wall panels for temperature-critical applications, I've helped funeral homes and commercial facilities select the right panels for their specific needs while ensuring compliance with industry standards.

Important cooler wall panels terms:

Why This Guide Matters

With air conditioners and electric fans accounting for 10% of all global electricity consumption today, the demand for efficient cooling solutions continues to rise. Cooler wall panels represent a convergence of these priorities - they deliver immediate energy savings, reduce construction time, and provide long-term durability that traditional building methods simply can't match.

Understanding Cooler Wall Panels

Cooler wall panels have evolved from basic insulated walls into sophisticated building systems that combine energy efficiency with construction speed. These sandwich panel systems combine two metal skins with a high-performance insulation core, creating a complete building solution in one package.

The metal skins - usually aluminum, stainless steel, or galvanized steel - provide structural strength, while the foam core handles thermal performance. The real innovation happens at the edges, where tongue-and-groove connections fit together like puzzle pieces, secured with cam-lock mechanisms and sealed with heavy-duty gaskets.

What Are Cooler Wall Panels and How Do They Work?

Cooler wall panels create a protective barrier that keeps cold in and heat out, while preventing moisture infiltration. The cam-action locking system creates an airtight seal between panels when properly installed with quality gaskets.

Unlike traditional construction where you're managing separate insulation, vapor barriers, and structural elements, cooler wall panels integrate everything into one streamlined system. The metal skins provide structural strength and hygienic surfaces, while the insulating core prevents heat transfer. The interlocking design eliminates thermal bridges - weak spots where heat can bypass insulation.

Core Materials and R-Values Explained

The insulation core is the heart of any cooler wall panel. R-value measures how well a material resists heat flow - higher numbers mean better insulation performance.

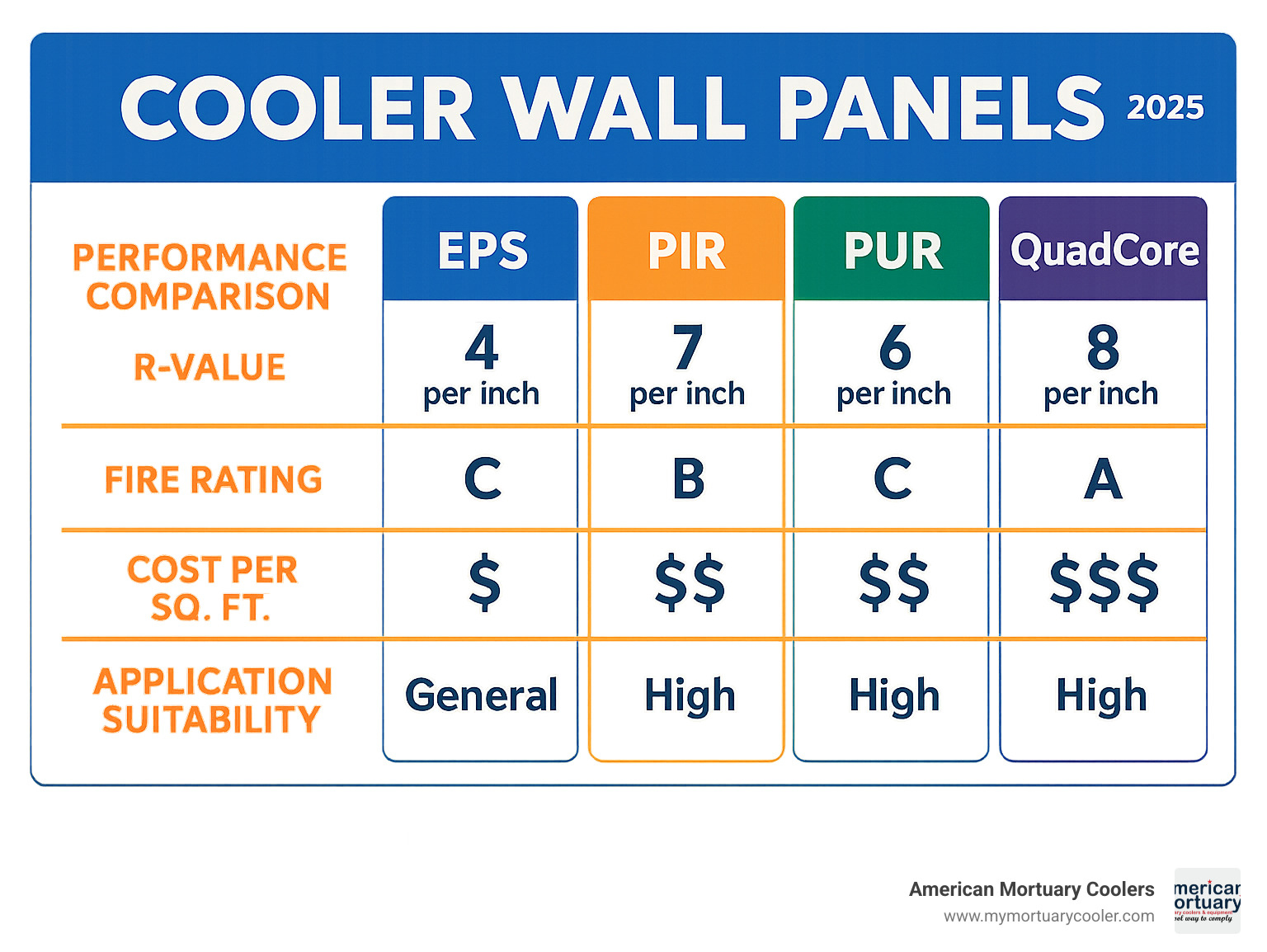

EPS (Expanded Polystyrene) cores are reliable workhorses offering consistent R-values that don't fade over time. A 150mm EPS panel typically delivers R-values up to 3.94, providing solid performance at the most cost-effective price per R-value.

PIR (Polyisocyanurate) and PUR (Polyurethane) cores deliver higher performance. PIR excels when fire resistance is required, while both materials use closed-cell foam technology that maintains insulating properties under challenging conditions.

QuadCore represents cutting-edge panel technology, delivering 11% better thermal performance than PIR and up to 60% improvement over PUR. Cold storage panels using these advanced cores can achieve R-values up to R-9.0 per inch at 35°F, with the most robust 8-inch panels reaching maximum R-values of R-72.

For facilities requiring the highest hygiene standards, PVC liners provide antimicrobial surfaces meeting FDA, USDA, and cGMP requirements - perfect for food processing and pharmaceutical applications.

Types of Insulation Cores & Performance Comparison

When choosing cooler wall panels, the insulation core determines performance. All quality cooler wall panels use closed-cell foams that won't absorb moisture or lose insulating power over time. The panels must meet strict standards like ASTM E84 for fire performance and NSF 7 for food-safe applications.

EPS: Lightweight & Budget Friendly

EPS (Expanded Polystyrene) cores are the workhorse of cooler wall panels. What makes EPS special is its consistent performance - EPS-FR (fire-retardant) cores maintain their R-values year after year while offering excellent moisture resistance.

The biggest advantage is cost. EPS gives you the most insulation value per dollar, making it perfect for budget-conscious projects where performance can't be compromised. Plus, these panels are 100% recyclable.

PUR/PIR: Mid-Range High Performance

Polyurethane (PUR) and Polyisocyanurate (PIR) cores hit the sweet spot between affordability and performance. These thermoset foams pack more insulating power into each inch, allowing thinner panels while maintaining excellent thermal performance.

PIR offers superior fire performance, making it ideal when fire codes are strict or safety is paramount. The closed-cell structure of both materials resists moisture and maintains strength even when temperatures fluctuate.

QuadCore & Hybrid Foams: Next-Gen Efficiency

QuadCore technology delivers 11% better thermal performance than PIR and 60% improvement over PUR. This hybrid foam maintains superior insulating properties across a wider temperature range, making it ideal for mortuary applications where consistent temperature control is essential.

For facilities requiring decades of flawless performance or where energy efficiency is a top priority, QuadCore represents the best available technology. For complex projects requiring custom engineering, Technical Services for advanced panels can provide detailed specifications and support.

Applications & Benefits Across Industries

Cooler wall panels serve diverse industries with specific requirements for temperature control, hygiene, and durability. Their versatility extends beyond simple cold storage to HVAC retrofits, where superior insulation properties dramatically improve energy efficiency in existing buildings.

Walk-In Coolers & Freezers

The most common application for cooler wall panels is in walk-in coolers and freezers across restaurants, grocery stores, and warehouses. These panels enable businesses to create custom-sized cold storage spaces rather than settling for pre-built units.

Restaurant applications benefit from quick installation and easy expansion capabilities. When business grows or requirements change, additional panels can be added without major construction disruption. Grocery stores appreciate the ability to create different temperature zones within the same facility.

For comprehensive guidance, our The Complete Guide to Walk-In Cooler Features and Prices covers everything from sizing to energy efficiency considerations.

Specialty Uses: Laboratories, Mortuaries & Grow Rooms

Temperature-critical applications like laboratories, mortuaries, and controlled-environment agriculture rely on cooler wall panels for precise environmental control. These applications often require specialized features like antimicrobial PVC surfaces or improved structural capabilities.

At American Mortuary Coolers, we've seen how cooler wall panels provide the reliability and cleanliness essential for mortuary applications. The panels' ability to maintain consistent temperatures while providing easy-to-clean surfaces makes them ideal for sensitive environments where contamination control is paramount.

Key Benefits Over Traditional Construction

Cooler wall panels offer significant advantages over traditional construction. Installation time reduces by up to 50%, translating to lower labor costs and faster project completion. Energy savings of up to 30% are achievable thanks to eliminated thermal bridging and superior insulation performance.

The panels' relocatable nature means they can be disassembled and moved if facility requirements change. Long-term durability is backed by 15-year warranties when properly maintained, providing excellent return on investment.

Buying & Installation Guide for Cooler Wall Panels

When investing in cooler wall panels, understanding your options makes the difference between success and costly mistakes. Modern panels come in sizes to fit almost any application, from compact restaurant walk-ins to massive warehouse cold storage.

Cooler wall panels typically come in widths ranging from 24 to 42 inches for commercial applications, with panels up to 45⅝ inches wide for larger facilities. Thickness options run from 35mm for moderate temperature applications up to 200mm for deep-freeze requirements.

Cost involves several factors. Material selection drives base price - EPS cores offer budget-friendly options while QuadCore technology commands premium pricing. Panel thickness impacts both material cost and shipping expenses. Quality manufacturers back their cooler wall panels with comprehensive warranties and ensure compliance with essential standards like NSF/ANSI for food safety, UL 471 for fire performance, and FM4882 for property protection.

Selecting the Right Cooler Wall Panels for Your Project

Choosing the right cooler wall panels starts with key questions: What temperatures will you maintain? Will panels support heavy equipment? Do local fire codes require specific ratings?

Load requirements matter significantly. Standard panels work for simple enclosures, but heavy equipment or dense storage systems need panels engineered for those loads. Target temperature determines insulation thickness - a 35°F produce cooler needs far less insulation than a -10°F freezer.

Fire code compliance varies by location and building type. Hygiene class requirements become critical in food processing and pharmaceutical applications where FDA, USDA, or cGMP compliance isn't negotiable.

Our A Practical Guide to Choosing the Right Freezer Panels walks through the decision process step-by-step.

Installation Best Practices & Common Mistakes to Avoid with Cooler Wall Panels

Installing cooler wall panels correctly separates successful projects from expensive do-overs. The foundation is proper substrate preparation - supporting structure must be level, plumb, and engineered for panel loads.

Gasket integrity makes or breaks thermal performance. Those rubber seals between panels create the airtight seal essential for efficiency. Damaged gaskets during installation or using wrong sealant can create air leaks that destroy performance.

Using the wrong sealant is surprisingly common. Not all sealants work with foam cores, and some become brittle at low temperatures. Food-grade sealant rated for your operating temperature range is essential.

Cost Breakdown & ROI

Understanding true cost means looking beyond initial purchase price to total ownership cost. Material prices vary - EPS cores offer lowest cost per square foot while QuadCore commands premium pricing but delivers superior performance.

Labor costs typically favor cooler wall panels because installation moves faster than traditional construction. Energy savings begin immediately and continue for the system's life. Well-designed panel systems can reduce cooling costs by 30%, often paying for premium panel cost within the first few years.

Environmental Impact & Sustainability

When considering cooler wall panels, you're making a choice that extends far beyond temperature control. These panels deliver environmental benefits that compound over time.

Cooler wall panels typically have lower embodied carbon than traditional construction methods due to efficient manufacturing processes and reduced material waste. The real environmental story emerges at end-of-life: closed-loop EPS recycling programs mean panels don't become landfill material but get processed into new products.

Modern foam blowing agents have eliminated ozone-depleting substances, and evolving refrigerant regulations keep pushing system efficiency higher. Quality cooler wall panels can help earn LEED credits for building projects through exceptional energy performance and sustainable material content.

The most compelling environmental argument comes from life-cycle performance analysis. Energy savings from cooler wall panels typically offset manufacturing impact within just a few years. Research from Scientific research on modular wall heating/cooling savings shows high-performance building envelope systems deliver significant long-term environmental benefits.

Designing for Future Retrofits

Smart facility planning means thinking beyond today's needs. Cooler wall panels shine because they're designed with the future in mind.

Demountable systems allow panels to be carefully disassembled and moved to new locations or reconfigured for different uses. Panel reuse works because of modular design and standardized connections - tongue-and-groove joints and cam-lock mechanisms maintain integrity through multiple installations.

Circular construction principles create systems that can be easily taken apart and reconfigured, squeezing maximum value from every dollar while keeping waste out of landfills. At American Mortuary Coolers, we've seen how this flexibility serves clients - funeral homes can expand coolers as business grows, then potentially repurpose panels for different uses later.

Frequently Asked Questions about Cooler Wall Panels

How long do cooler wall panels last?

Quality cooler wall panels last 15-25 years with proper care, backed by solid 15-year warranties. The actual lifespan depends on core material quality - EPS cores maintain their R-value throughout their entire service life. Environmental conditions play a role, but panels typically outlast traditional construction methods. Regular maintenance extends life even further.

Can panels be retrofitted into existing buildings?

Absolutely. Their modular design makes them perfect for retrofit work without major demolition. Panels can often be installed directly over existing walls, saving time and money while avoiding construction mess. Installation is usually much faster than traditional methods. The main consideration is ensuring existing structure can handle the load and maintaining vapor barrier continuity.

What certifications should I look for?

For food applications, NSF/ANSI 7 certification is essential. Fire safety requires UL 471 certification for fire resistance and ASTM E84 ratings for flame spread. Building codes vary by location - you might need specific certifications like BAL-40 for bushfire-prone areas. Pharmaceutical or food processing may require FDA, USDA, and cGMP compliance. Match certifications to your specific application requirements.

Conclusion

Cooler wall panels represent the future of cold storage construction, delivering energy savings of up to 30% while cutting installation time in half compared to traditional methods. These panels offer reliability and performance that traditional construction simply can't match.

At American Mortuary Coolers, we've built our reputation on understanding that when temperatures matter most, there's no room for compromise. Our experience in the funeral industry has taught us the critical importance of reliable temperature control in sensitive applications.

Our nationwide delivery across the contiguous 48 states means you're never too far from the right solution. We understand every project is unique, which is why we take time to understand your specific requirements before recommending optimal cooler wall panels for your application.

Building or upgrading cold storage doesn't have to be overwhelming. Our team helps you steer the options - from selecting the right core material to ensuring proper certifications. For comprehensive guidance on custom cooling solutions, explore our A Comprehensive Guide to Custom Cooling Solutions to understand how custom approaches maximize both efficiency and performance.

The choice of cooler wall panels ultimately means choosing sustainability, efficiency, and long-term value. As energy costs continue climbing and environmental regulations tighten, investing in high-performance insulated panels positions your facility for success while benefiting the environment.

We're here to help you make that choice with confidence. Whether planning a new facility or upgrading existing cold storage, the right cooler wall panels can transform your operation's efficiency and reliability for decades to come.