The Ultimate Guide to Buying the Right Morgue Table

Why the Right Morgue-Table Makes All the Difference

A morgue-table is a specialized stainless steel workspace designed for autopsies, postmortem examinations, and forensic procedures. These tables feature integrated drainage systems, adjustable height mechanisms, and ventilation capabilities to ensure hygiene, staff safety, and workflow efficiency.

Key morgue-table specifications:

- Materials: 14-16 gauge 304 stainless steel construction

- Dimensions: 32-35" wide × 80-85" long, height adjustable 32-38"

- Weight capacity: 600-1,000 lbs (standard), up to 1,000 lbs (bariatric models)

- Drainage: 30° inward slope with ¾" raised edges for fluid containment

- Ventilation: 450-500 CFM backdraft systems for staff protection

- Lifespan: 15-20 years with proper maintenance

Choosing the wrong morgue-table can create serious problems. Staff deal with back strain from poor ergonomics. Inadequate drainage leads to contamination risks. Insufficient weight capacity causes equipment failure at critical moments.

The right table transforms your facility's operations. Adjustable-height mechanisms reduce staff injuries by 40%. Integrated ventilation systems protect against airborne hazards. Quality construction delivers decades of reliable service.

As American Mortuary Coolers, we've helped funeral homes nationwide select morgue-table solutions that meet their specific space and operational needs. Our experience as a national-level mortuary equipment supplier has shown us how the right table choice impacts both staff wellbeing and service quality.

Understanding the Morgue-Table: Function & Fundamentals

The story of the morgue-table is really a story about dignity and progress. Back in the 1800s, medical examiners worked with simple wooden examination boards that offered little protection for either the deceased or the living. Today's sophisticated stainless steel workstations represent more than a century of learning how to honor both safety and respect.

These tables do far more than just hold a body. A quality morgue-table becomes the foundation for precise autopsy procedures, thorough postmortem analysis, and valuable anatomical education in medical schools. Every curve, every drain, every surface angle serves a purpose in keeping things sterile while protecting the people who dedicate their careers to this important work.

The construction standards aren't just impressive numbers on a spec sheet—they're the result of real-world needs. 14-16 gauge 304 stainless steel provides the corrosion resistance that stands up to daily cleaning and disinfection. That 30° inward slope ensures fluids drain properly every single time. Those ¾" raised edges act like gentle guardians, containing liquids during procedures and preventing cross-contamination.

When we talk about weight capacity ranging from 600-1,000 pounds, we're really talking about reliability when it matters most. This robust construction handles decades of daily use without compromising structural integrity.

The importance of proper table design goes beyond our experience—scientific research on autopsy procedure confirms how the right equipment directly impacts both examination quality and staff safety during forensic investigations.

Standard morgue-table dimensions & load limits

Getting the sizing right makes all the difference in your facility's daily operations. Most morgue-table units measure 32-35 inches wide by 80-85 inches long—dimensions that provide adequate workspace without overwhelming smaller prep rooms. The height adjustability from 32-38 inches is crucial for preventing the back strain that can plague staff over years of service.

Those load capacity numbers tell an important story too. Standard models supporting 600-750 pounds handle the vast majority of cases, while bariatric options rated for 1,000 pounds ensure you're prepared for any situation.

Space planning becomes much easier when you know the basics. We always recommend at least 36 inches of clearance on all sides for comfortable staff movement and equipment access.

Morgue-table drainage & ventilation essentials

The difference between a basic table and a professional-grade morgue-table often comes down to how well it handles fluids and air quality. The convex table surface works with built-in drains to manage bodily fluids efficiently, preventing pooling that creates unsanitary conditions. Hair separators and internal sodium-hypochlorite flush systems prevent plumbing nightmares while sanitizing waste.

Backdraft ventilation operating at 450-500 CFM provides the kind of staff protection that lets people focus on their important work instead of worrying about harmful vapors. Negative-pressure airflow systems filter odors and hazardous fumes in real time, creating a safer working environment. Hydro-aspirator systems add extra suction capabilities for complex procedures that demand precise fluid management.

These ventilation systems integrate smoothly with your facility's existing HVAC or operate as self-contained units, depending on your setup.

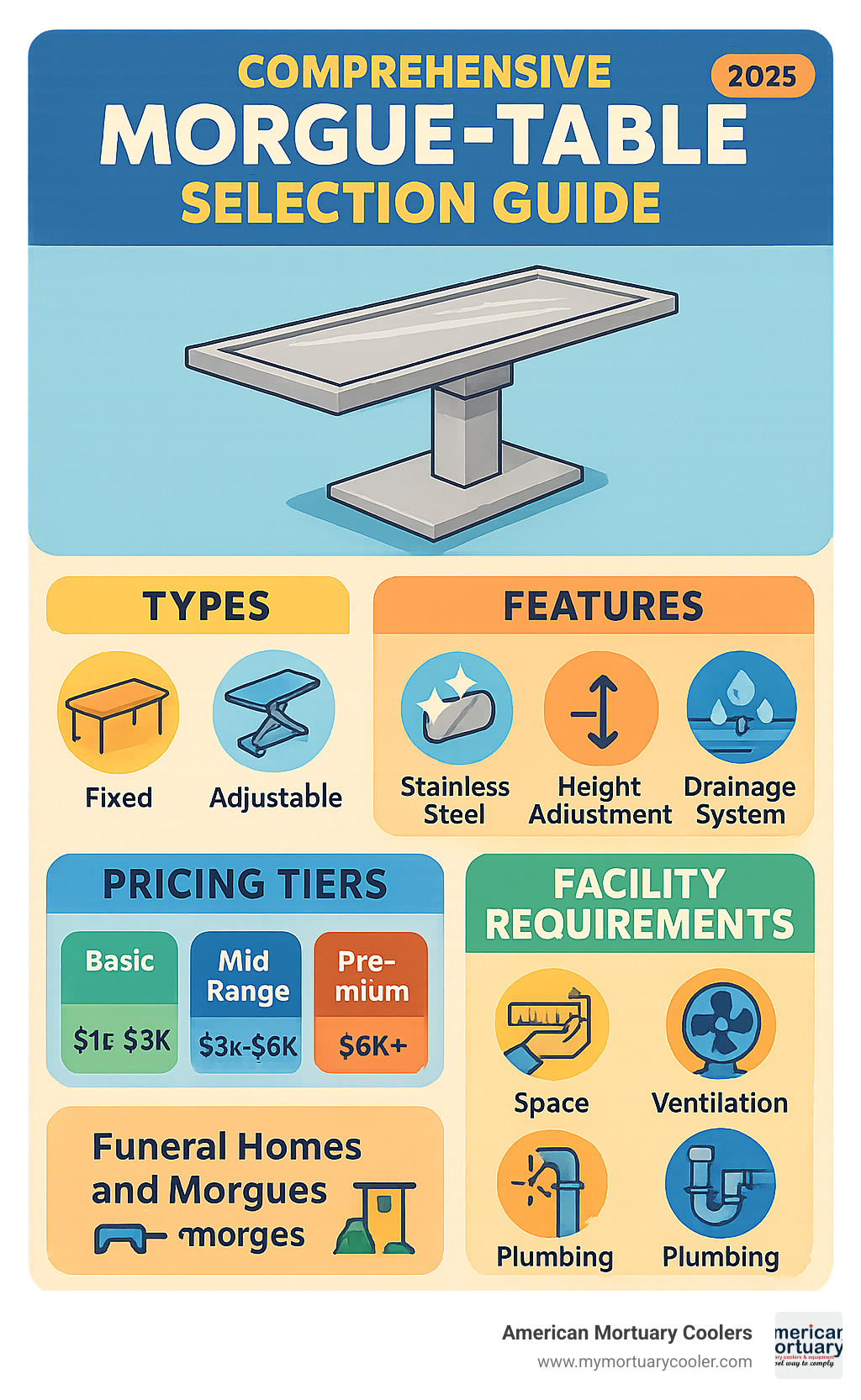

Comparing Morgue-Table Types & Configurations

Choosing the right morgue-table type can feel overwhelming at first. The good news? Each configuration exists for specific reasons, and understanding your facility's needs makes the decision much clearer.

Fixed-pedestal models anchor directly to your floor, providing rock-solid stability during procedures. Hydraulic-lift tables add electric height adjustment, letting staff position the table perfectly without breaking their backs. Mobile trolley units roll where you need them, perfect for facilities that wear multiple hats.

Vented workstations bring their own air filtration systems, while L-shaped configurations create natural teaching environments where students can observe without crowding. Bariatric models handle heavier loads safely, and teaching-ready stations include camera mounts for educational recording.

The key is matching your table type to your actual workflow. A busy medical examiner's office handling 2,000 cases yearly needs different features than a small regional lab doing occasional work.

Fixed vs Hydraulic vs Mobile

Fixed-pedestal tables are the dependable workhorses of the morgue world. Once installed, they're not going anywhere – which is exactly what high-volume facilities want. These tables bolt directly to your floor and connect permanently to utilities. The result? Zero wobble during procedures and decades of trouble-free service.

Hydraulic-lift systems change everything for staff comfort. Electric foot pedals adjust table height hands-free, so your team can find the perfect working position for each procedure. Staff consistently report less back pain and fatigue when facilities upgrade from fixed-height tables.

Mobile trolleys with lockable casters solve the flexibility puzzle. Small labs love being able to convert a general room into an autopsy suite when needed, then roll the table away for other uses. You'll sacrifice some stability compared to fixed models, but modern designs minimize vibration remarkably well.

Vented & L-Shaped morgue-table solutions

Vented workstations solve a common problem neatly. Instead of relying on overhead ventilation systems, these tables include backdraft ventilation built right into the structure. This works particularly well in older buildings where modifying ductwork would be expensive or complicated.

L-shaped configurations transform teaching environments completely. The main surface handles procedures while the secondary surface provides dedicated space for instruments and specimens. Students get clear sightlines from multiple angles without getting in anyone's way.

Specialized Bariatric & Teaching-Ready models

Bariatric models address a reality many facilities face today. With 1,000-pound weight capacities and reinforced construction, these tables handle larger individuals safely. The wider surfaces and improved structural support prevent equipment failure and protect staff during transfers.

Teaching-ready configurations include modular camera mounts, improved lighting systems, and observation platforms. Medical schools consistently report better student engagement when procedures are clearly visible from multiple angles.

Key Features, Materials & Specs That Matter

When selecting a morgue-table, certain features separate basic models from professional-grade workstations that truly serve your staff and facility needs. Understanding these specifications helps you make an informed investment that pays dividends for years to come.

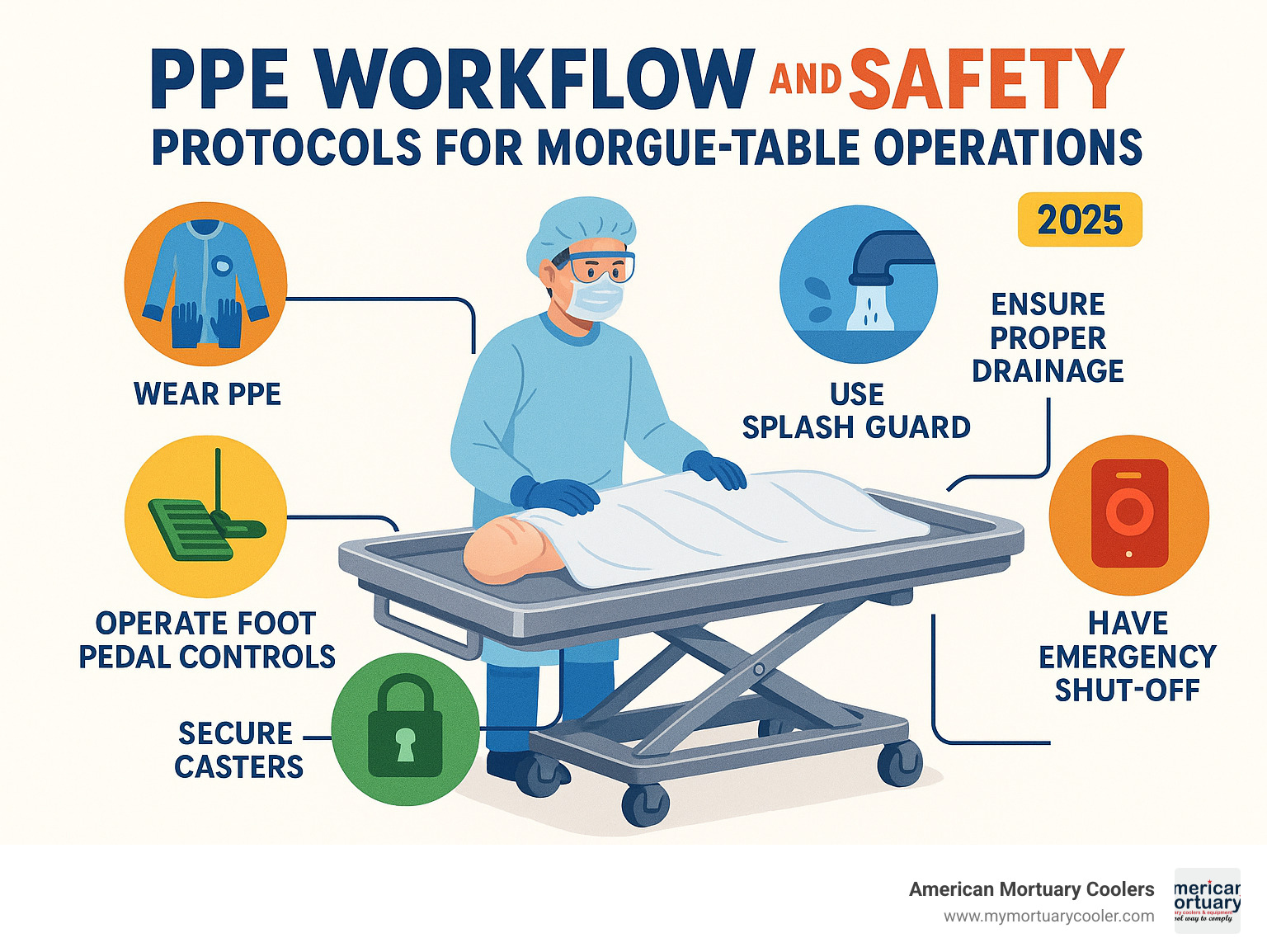

Height adjustability stands out as perhaps the most impactful feature for daily operations. Premium tables offer height ranges from 32 to 38 inches, accommodating staff members of different heights while reducing the back strain that plagues many professionals in this field. Electric foot-pedal controls let technicians adjust height without stopping their work or contaminating their hands – a seemingly small detail that makes a huge difference during lengthy procedures.

Perforated work surfaces provide superior drainage capabilities while maintaining the structural strength needed for heavy-duty use. These precisely engineered holes allow fluids to flow efficiently without compromising the table's ability to support substantial weight. Combined with integrated sinks measuring 12-14 inches long by 8-12 inches deep, these features streamline instrument cleaning and specimen handling throughout procedures.

Safety considerations drive many design choices. GFCI-protected electrical outlets power equipment safely in wet environments where standard outlets would create serious hazards. PPE hooks and storage compartments keep protective equipment organized and within easy reach, reducing the time staff spend searching for essential items during critical moments.

The engineering details matter more than you might expect. Convex table tops with anti-drip troughs contain fluids effectively while preventing spillage onto floors – protecting both staff safety and facility cleanliness. These thoughtful design elements combine to create work environments that feel safer and more efficient.

Material selection directly impacts both performance and longevity. Grade 304 stainless steel provides excellent corrosion resistance for most applications, handling daily exposure to cleaning chemicals and bodily fluids without degrading. 316 stainless steel offers superior protection in facilities with particularly harsh chemical environments, though it commands a premium price. The gauge thickness (14-16) determines durability and resistance to denting from heavy instruments or equipment impacts.

| Feature | Morgue-Table | Embalming Table |

|---|---|---|

| Primary Use | Autopsy/Forensic | Body Preparation |

| Weight Capacity | 600-1,000 lbs | 400-600 lbs |

| Ventilation | 450-500 CFM required | Optional |

| Drainage | Deep trough system | Basic slope |

| Construction | 14-16 gauge steel | 16-18 gauge steel |

| Height Range | 32-38" adjustable | Fixed 32-34" |

Essential accessories & add-ons

Body-bridge sets provide additional support during procedures, distributing weight evenly across the table surface to prevent stress concentration that could damage equipment or compromise examination quality. Integrated scales eliminate the need for separate weighing equipment, streamlining workflow while improving measurement accuracy – particularly valuable in forensic settings where precise documentation matters.

Specialized drains with hair separators prevent the blockages that can shut down operations at the worst possible moments. These engineered systems maintain sanitary conditions while protecting your facility's plumbing infrastructure from costly damage.

Splash-guards protect surrounding areas from fluid contamination during procedures, reducing cleanup time and maintaining professional appearance standards. Foot-pedal controls enable hands-free operation of height adjustment, water flow, and ventilation systems – keeping procedures moving smoothly without contamination concerns.

For mobile units, heavy-duty casters with individual locks provide the stability needed during use while maintaining the flexibility to reconfigure spaces as needed. These aren't standard furniture wheels – they're engineered to handle substantial weight while rolling smoothly across various floor surfaces.

Storage solutions include underbelly cupboards for supplies and instrument trays for organized tool access. Strategically positioned power outlets accommodate various equipment needs without creating the cord hazards that plague poorly planned installations.

More info about embalming instruments provides additional context on complementary equipment that works alongside morgue tables in mortuary settings, helping you plan a complete workspace solution.

Ergonomics, Safety & Compliance Checklist

When it comes to morgue-table safety, there's no room for shortcuts. Your staff deserve protection, and your facility needs to meet strict regulatory requirements that keep everyone safe during difficult procedures.

OSHA regulations set the foundation for workplace safety in morgue environments. CDC guidelines tackle the contamination control side, establishing protocols that prevent dangerous exposures to biological hazards. Meanwhile, NFPA-99 electrical standards ensure your power systems won't create hazards in wet environments.

Staff comfort directly impacts safety outcomes. A forensic pathologist hunched over a table that's too low will make mistakes after hours of strain. Tables need to accommodate the staff height range in your facility - typically everyone from 5'2" to 6'4". Quality adjustable-height mechanisms prevent the repetitive strain injuries that plague facilities using fixed-height equipment.

Anti-fatigue features make a real difference during long procedures. GFCI outlets provide essential electrical protection in environments where water and electricity mix regularly. Lockable casters on mobile units prevent dangerous movement during critical moments.

Regulatory standards every morgue-table must meet

ANSI standards address the structural backbone of your equipment. UL certification focuses on electrical safety, particularly important given the wet conditions typical in morgue environments. ISO-9001 quality management verification means the manufacturer follows consistent processes that deliver reliable results.

The tricky part comes with local health codes, which often add requirements beyond federal standards. Some jurisdictions mandate specific ventilation rates or particular drainage configurations. We always recommend checking with local authorities early in your planning process.

Installation & room-planning tips

Utility hookups require more planning than many facilities expect. Your hot and cold water lines need sufficient flow rates to support cleaning systems. Two-inch drain pipes handle the substantial fluid volumes generated without backing up.

Clearance zones around the table enable safe movement when staff are focused on their work. We recommend 36 inches minimum on all sides, though 48 inches works better for high-traffic areas or teaching environments.

Electrical requirements include dedicated circuits for table motors, ventilation systems, and equipment outlets. GFCI protection isn't optional in these wet environments - it's literally a lifesaver.

Budgeting, Pricing & ROI Guide

Let's talk numbers. Morgue-table pricing ranges from around $1,095 for entry-level mobile units to $19,995 for sophisticated electric-lift systems with all the bells and whistles.

Think of it in tiers. Basic mobile trolleys that work well for smaller facilities run $4,000 to $7,000. The sweet spot for most operations falls in the $15,000 to $20,000 range for solid pedestal models that deliver reliable performance year after year.

Premium systems with bariatric capabilities and teaching features push into $18,000 to $30,000 territory. That might sound steep, but consider this: a quality table lasts 15-20 years with proper care. Break that down monthly, and you're looking at reasonable operational costs for equipment that protects your staff and serves families with dignity.

The stainless steel gauge makes a real difference in both price and longevity. Thicker 14-gauge construction costs more upfront than 16-gauge, but it resists dents and wear much better over time. Ventilation systems add $2,000 to $4,000 to the base price, but they're not optional if you care about staff safety.

Don't forget the extras. Freight costs typically run 5-10% of the table price, depending on your location and the size of the unit.

Learn more about operating-table options to understand how medical equipment pricing works across different categories.

Smart purchasing checklist for your facility

Here's where many facilities go wrong: they buy based on what they think they need instead of what they actually use. Case-mix analysis reveals the truth about your requirements. If 90% of your cases are standard, paying extra for bariatric capabilities might not make sense. But if you serve a diverse community, that higher weight capacity becomes essential.

Staff feedback matters more than you might think. The people using the table daily understand workflow challenges that don't show up in product brochures.

Demo trials are worth requesting, especially for major purchases. Seeing how the table fits your space and workflow prevents expensive mistakes.

Consider your future growth too. A facility expecting to expand case volume in the next five years might benefit from a more robust system now rather than upgrading later. Financing options include outright purchase, leasing arrangements, and rent-to-own programs.

Maintenance & cleaning protocols

A morgue-table is only as good as the care it receives. Daily disinfection isn't negotiable - use EPA-registered chemicals and follow the full contact time. This isn't the place to rush through cleaning procedures.

Clean stainless steel with the grain using non-abrasive cleaners. Going against the grain creates scratches that trap bacteria and look unprofessional. Hot water and mild detergent handle most daily cleaning needs.

Enzymatic drain flushes once a week prevent the biological material buildup that creates expensive plumbing problems. Daily hot water flushing keeps things flowing smoothly.

Quarterly polishing keeps the stainless steel looking professional and maintains its corrosion resistance. Annual professional service should be non-negotiable for hydraulic systems, electrical components, and ventilation performance. A well-maintained table that lasts 20 years costs far less than replacing one prematurely due to neglect.

Frequently Asked Questions about Morgue Tables

We get these questions all the time from funeral directors and facility managers looking to upgrade their prep rooms. Let's clear up the most common confusion points about morgue-table selection and operation.

How does a morgue-table differ from an embalming or dissection table?

Think of it this way - while embalming tables focus on preparation and presentation, morgue-tables are built for the heavy-duty work of forensic examination and autopsy procedures. The differences go way beyond just appearance.

Weight capacity tells the biggest story. Morgue tables handle 600-1,000 pounds safely, while embalming tables typically max out around 400-600 pounds. That extra strength comes from 14-16 gauge stainless steel construction versus the lighter 16-18 gauge material in standard embalming tables.

Ventilation systems separate the two completely. Morgue tables require negative-pressure backdraft systems operating at 450-500 CFM to protect staff from airborne hazards during forensic procedures. Most embalming tables don't include ventilation at all - it's just not needed for their intended use.

The drainage design reflects different purposes too. Morgue tables feature deeper troughs with integrated hair separators and specialized waste disposal systems. Embalming tables use basic sloped surfaces since fluid management needs are much simpler.

Basic dissection benches used in educational settings are even more stripped down - they're essentially sturdy tables without the sophisticated systems that make morgue tables suitable for professional forensic work.

What ventilation rate is recommended to protect staff?

450-500 CFM (cubic feet per minute) is the industry standard for backdraft ventilation on autopsy tables. This isn't just a suggestion - it's what actually protects your staff from harmful vapors and airborne particles during procedures.

We've seen facilities try to get by with less ventilation, and it never works out well. Staff complain about odors, and more importantly, they face real health risks from inadequate air filtration. The investment in proper ventilation pays for itself in staff retention and safety compliance.

Self-contained ventilation units work great if your building's HVAC system can't handle the additional load. These units filter and exhaust air directly without requiring major ductwork modifications. They're especially popular in older funeral homes where retrofitting central systems would be expensive.

The airflow needs to create negative pressure around the work surface to pull contaminants away from staff breathing zones. Too little airflow and you don't get protection. Too much creates uncomfortable drafts that make detailed work difficult.

How long will a high-quality morgue-table last with proper care?

15-20 years is what you can expect from a quality morgue-table with proper maintenance. We've seen well-maintained tables from the 1990s still going strong in busy facilities.

The key is that "proper care" part. Daily disinfection, weekly drain maintenance, and annual professional inspections make all the difference. Tables that get neglected start showing problems within 5-7 years, even with premium construction.

14-16 gauge 304 stainless steel construction gives you that longevity, but only if you follow cleaning protocols. Use the right chemicals, clean with the grain direction, and never use abrasive materials that scratch the surface. Those scratches become contamination harbors that compromise both hygiene and durability.

Weight limit compliance matters more than most people realize. Constantly overloading a 750-pound table with 900-pound cases puts stress on welds and mechanisms that shortens lifespan significantly. Respect the ratings and your table will serve you for decades.

The hydraulic systems and electrical components typically need attention around the 10-year mark, but that's normal maintenance rather than replacement. Factor those service costs into your long-term budgeting and you'll get excellent value from your investment.

Conclusion

Choosing the right morgue-table transforms how your facility operates every single day. Your staff will feel the difference in their backs and shoulders when they have proper height adjustment. They'll breathe easier knowing ventilation systems are protecting them from harmful vapors. Most importantly, they can focus on treating each person with the dignity they deserve.

The math on quality construction is straightforward. A premium morgue-table that costs $18,000 and lasts 20 years costs less per year than a $8,000 table that needs replacement every 8 years. When you factor in reduced maintenance, fewer repairs, and better staff retention from improved working conditions, the value becomes even clearer.

We've seen this story play out hundreds of times across funeral homes nationwide. The director who initially balks at spending extra for adjustable height ends up thanking us years later when their longtime embalmer doesn't have chronic back pain.

At American Mortuary Coolers, we know your facility isn't just another sale to us. Every funeral home serves their community differently. Some handle primarily traditional services, while others focus on cremation preparation. Teaching facilities need visibility features that private mortuaries don't require.

That's why we take time to understand your specific situation before recommending equipment. Our Tennessee-based team has designed custom solutions for prep rooms in century-old buildings and state-of-the-art facilities alike. Whether you need a compact mobile unit that fits through narrow doorways or a full teaching station with integrated cameras, we'll work within your budget and timeline.

The investment you make today in the right morgue-table will serve your staff and families for decades to come. Quality equipment doesn't just perform better - it gives everyone confidence that procedures will go smoothly, safely, and with appropriate respect.

Ready to explore your options? Our Mortuary Table resource page has additional technical details and sizing guides. When you're ready to discuss your specific needs, our team provides personalized consultation and direct delivery throughout the contiguous 48 states.

Your staff deserves equipment that supports them. Your families deserve the dignity that comes from proper facilities. Let us help you choose the morgue-table solution that serves both.