The Ultimate Guide to Buying an Embalming Sink

Why Every Funeral Home Needs the Right Embalming-Sink

An embalming-sink is a specialized stainless steel workstation designed for the safe preparation, cleaning, and chemical processing of human remains in mortuary settings. These sinks serve as the central hub for fluid drainage, instrument cleaning, and waste disposal during the embalming process.

Key Components of an Embalming-Sink:

- Primary Function: Drainage and waste collection during arterial and cavity embalming

- Materials: 304-grade stainless steel construction for durability and hygiene compliance

- Configurations: Single, double, or triple bowl designs with wall-mount or floor-stand options

- Essential Features: Hydro-aspirators, high-pressure spray hoses, GFCI outlets, and instrument storage

- Safety Standards: Must meet OSHA guidelines and local plumbing codes for mortuary facilities

The right embalming-sink dramatically improves workflow efficiency in your prep room. It provides proper drainage for embalming fluids, secure mounting for hydro-aspirators, and easy-to-clean surfaces that meet strict sanitation requirements. Poor sink selection leads to workflow bottlenecks, safety hazards, and potential regulatory violations.

Modern embalming-sink stations integrate seamlessly with hydraulic tables, roller-top trolleys, and other mortuary equipment. They feature trigger-spray taps, perforated drain grids, and optional ventilation systems that protect staff while streamlining the embalming process.

As American Mortuary Coolers, we've helped funeral homes across the country select durable, budget-friendly embalming-sink solutions that fit their specific space constraints and workflow needs. Our experience as a national mortuary cooler supplier has shown us how the right embalming-sink choice directly impacts both operational efficiency and long-term cost savings.

What Is an Embalming Sink and Why It Matters

Think of an embalming-sink as the heart of your prep room - it's where everything flows together, literally. This specialized stainless steel workstation handles drainage, waste disposal, and the critical hydro-aspiration that makes modern embalming possible.

The primary function of an embalming sink goes beyond what you'd expect from a regular sink. During the embalming process, it manages the complex flow of embalming fluids going in while blood and other bodily fluids come out. This maintains the right pressure, prevents backflow, and keeps your workflow efficiency smooth and safe.

During arterial embalming, your sink becomes the endpoint for blood displacement. As preservative chemicals enter through the vascular system, blood exits through drainage tubes that lead straight into your embalming-sink. The drainage system needs to handle this continuous flow without any hiccups or contamination issues.

Sanitation isn't just important here - it's absolutely critical. Your sink handles formaldehyde-based chemicals, blood, and other materials that require careful disposal. The seamless construction and smooth surfaces of a quality embalming-sink prevent biofilm buildup and make thorough disinfection between cases much easier. This keeps you in line with OSHA compliance standards and protects your staff.

The hydro-aspiration system built into modern sinks creates the vacuum power you need for cavity work. Without this, you'd struggle with trocar aspiration and fluid removal from body cavities.

The Embalming-Sink in the Modern Embalming Process

During the arterial phase, your sink works as the drainage hub while blood flows out through venous tubes and preservative fluids enter the arterial system. The cavity phase puts your sink's hydro-aspirator to work, creating the vacuum needed to remove gases and fluids from body cavities through trocar aspiration.

Surface cleaning and final prep work rely heavily on your sink's spray systems. High-pressure spray hoses let you thoroughly clean both the body and your work surfaces, while the sink's drainage handles all the runoff.

Staff safety is built into every aspect of modern sink design. GFCI outlets protect against electrical hazards in wet environments, while proper ventilation prevents chemical vapor buildup.

Key Features, Components & Accessories to Look For

Choosing the right embalming-sink starts with understanding your bowl configuration needs. A single bowl design works perfectly for smaller funeral homes - it's straightforward, cost-effective, and gets the job done. Double bowl configurations are invaluable for busy funeral homes because you can separate clean and contaminated materials. Triple bowl setups are for high-volume facilities or teaching labs requiring maximum separation of different waste streams.

Your gooseneck faucet gives you clearance for large instruments and containers. The real game-changer is getting wrist blade handles that you can bump with your arm instead of grabbing with contaminated gloves. Foot-pedal controls represent a major step up in both functionality and hygiene, letting you control water flow and drainage without breaking sterile technique.

GFCI outlets aren't optional - they're life-savers. Most modern embalming sinks include two GFCI electrical receptacles positioned safely away from water sources. The high-pressure spray hose handles body cleaning, instrument rinsing, and sink sanitization with multiple spray patterns for different jobs.

The hydro-aspirator is the heart of your embalming process. This device uses water pressure to create the vacuum needed for cavity aspiration and fluid removal. A quality hydro-aspirator provides consistent suction while preventing clogs.

Anti-clog strainers catch hair, tissue fragments, and other debris before they cause expensive backups. Built-in instrument drawers keep frequently used tools within arm's reach with drip rails to prevent contamination. Back-splash protection saves your walls and simplifies cleanup.

Eyewash stations integrated into or mounted near your embalming-sink aren't just good practice - they're required by ANSI Z358.1 standards.

For more comprehensive guidance on mortuary equipment selection, our Essential Embalming Equipment guide covers everything you need to know.

Must-Have Add-Ons for Your Embalming-Sink

Spray rinsers turn your basic hose into a precision cleaning tool with multi-pattern spray heads and shut-off valves. Break tanks create an air gap between your sink drainage and the building's sewer system, preventing contamination through backflow. Cart latches secure your embalming trolleys during procedures, preventing unexpected movement. Perforated grids create a stable work surface within your sink bowl while allowing drainage underneath.

Optional High-Tech Upgrades

Vacuum breakers prevent backflow contamination in water supply lines. Integrated ventilation systems capture vapors and aerosols before they spread. Touchless sensors control water flow and drainage without physical contact, maintaining perfect sterile technique. LED task lighting provides focused illumination with adjustable positioning and dimming controls.

Materials, Hygiene & Regulatory Standards

When investing in an embalming-sink, material choice makes all the difference. Most quality embalming sinks use 304-grade stainless steel construction, which balances durability and affordability while handling daily chemical assault from formaldehyde-based embalming fluids and industrial-strength cleaning agents.

For challenging environments or high case volumes, 316-grade stainless steel represents the premium choice. The addition of molybdenum gives superior resistance to chlorides and aggressive chemicals. While the upfront cost is higher, facilities near coastal areas or those using harsh chemicals often find the extended service life justifies the investment.

Chemical resistance isn't just about the sink bowl - every component that touches embalming fluids must maintain integrity over years of exposure. Seamless welds eliminate tiny crevices where bacteria hide and multiply, ensuring surfaces actually get clean during disinfection.

The CDC guidelines for mortuary facilities emphasize proper drainage systems that prevent cross-contamination and surfaces that can be thoroughly disinfected. EPA discharge regulations vary by location but focus on protecting municipal water systems from contamination.

Class A air gaps provide that critical barrier between your drainage system and the building's clean water supply, often required by local health codes. NSF finish standards provide an excellent benchmark for surface quality and cleanability.

For deeper insights into industry standards, the Sink Or Swim article offers valuable perspectives from experienced professionals.

How the Right Materials Protect Staff and the Environment

Corrosion resistance directly impacts your bottom line and staff safety. When sink surfaces deteriorate from chemical exposure, they develop rough spots where bacteria can hide from disinfectants. Quality stainless steel maintains its smooth finish year after year.

Biofilm prevention requires both smart material choices and thoughtful design. Seamless construction and mirror-smooth surfaces give bacteria nowhere to establish protective colonies. Easy sterilization depends on surface quality - non-porous stainless steel allows disinfectants to reach and destroy microorganisms effectively.

Meeting Local & Federal Codes with Your Embalming-Sink

OSHA requirements cover electrical safety, chemical exposure protection, proper GFCI protection, adequate lighting, and sufficient space for safe operation. ANSI Z358.1 standards govern emergency eyewash equipment with specific performance and placement requirements - eyewash facilities must be within 10 seconds travel time from chemical exposure areas.

State funeral board regulations vary dramatically but most include specific requirements for prep room equipment and sanitation procedures. Plumbing code compliance ensures your installation meets professional standards, typically addressing drainage sizing, proper venting, backflow prevention, and waste handling procedures.

Types, Configurations & Design Considerations for Choosing the Right Embalming-Sink

Choosing the right embalming-sink configuration starts with understanding your space and workflow needs. Wall-mount configurations are perfect for limited floor space, attaching directly to structural walls without taking up floor real estate. Floor-stand models offer rock-solid stability and can accommodate larger, more complex sink configurations with integral support legs.

Elevating systems bring ergonomics into the equation. Some models adjust from 32" to 38", letting different staff members customize height for comfort during lengthy procedures.

Center approach designs position the sink bowl in the middle of your work station, giving access from multiple directions and working beautifully with hydraulic tables. Left/right approach configurations put the sink bowl to one side, leaving more continuous workspace on the opposite side.

Ventilated station designs integrate air handling directly into the sink station, capturing vapors and aerosols right at the source. Compact models are engineered for smaller funeral homes, combining sink, aspirator, and storage functions in a single efficient unit.

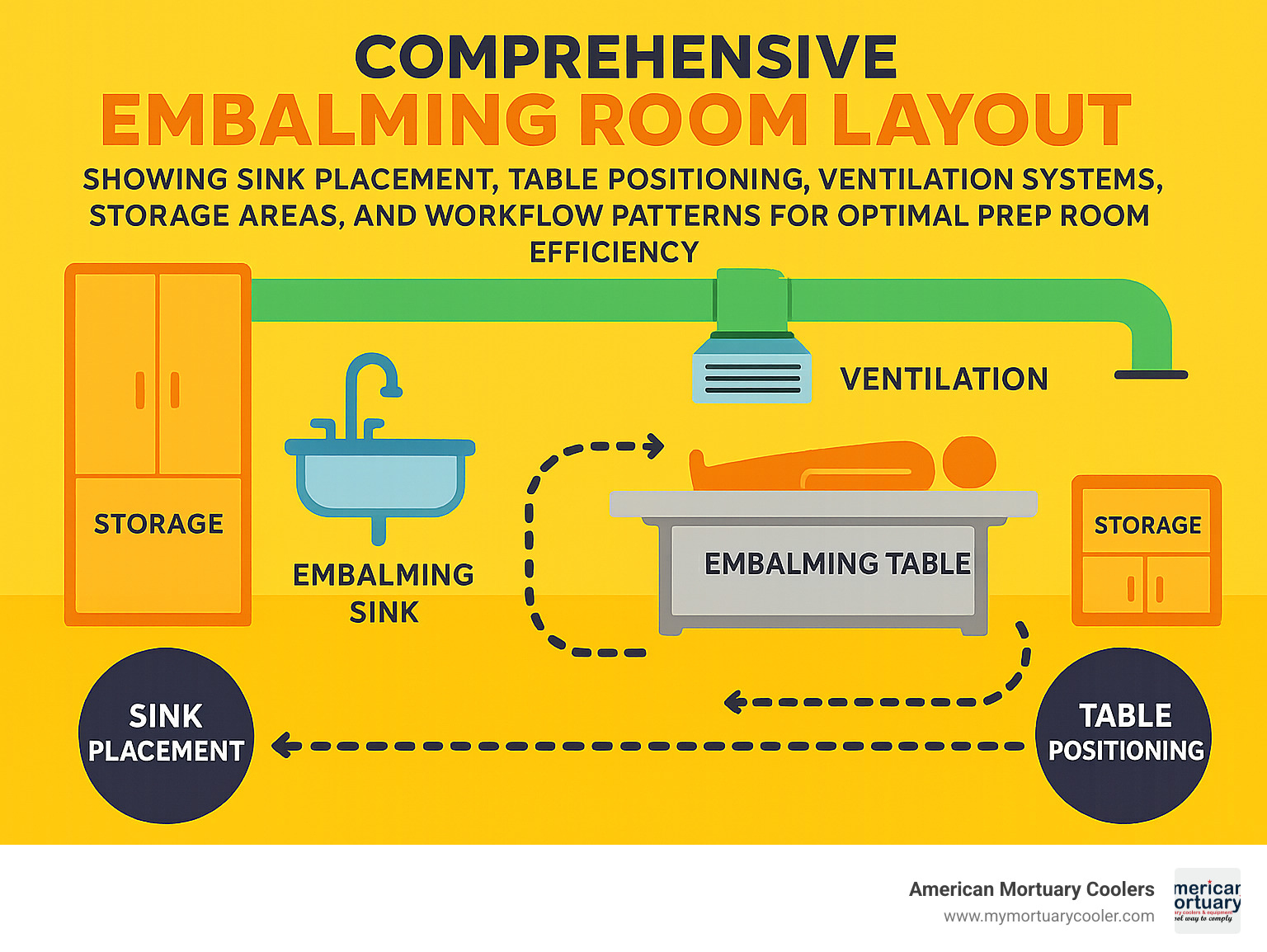

Workflow mapping should drive every decision about sink selection and placement. Think about how your staff moves through the prep room during different procedures.

For comprehensive equipment selection guidance, review our The Complete Guide to Buying Embalming Equipment.

| Configuration | Best For | Key Benefits | Considerations |

|---|---|---|---|

| Single Bowl | Small facilities, limited budgets | Simple operation, easy cleaning, cost-effective | Limited separation of waste streams |

| Double Bowl | Medium facilities, moderate case volume | Clean/dirty separation, improved workflow | Requires more space, higher cost |

| Ventilated Station | High-volume facilities, chemical-sensitive staff | Superior vapor control, improved safety | Higher initial cost, requires ventilation connection |

Matching Embalming-Sink Size to Case Volume and Room Layout

Small funeral homes handling 50-150 cases annually typically benefit from single-bowl configurations with compact, wall-mounted designs that maximize floor space. High-volume morgues processing hundreds of cases need more robust configurations - double or triple bowl designs that separate waste streams and enable multiple staff members to work simultaneously. Teaching labs require larger sinks with multiple approach angles and improved visibility for demonstration purposes.

Integrating the Embalming-Sink with Tables, Trolleys & Coolers

Hydraulic tables work best when the sink is positioned for easy access during body positioning and fluid management. Roller-top trolleys require adequate clearance for easy positioning and removal. Body lift systems often integrate directly with sink drainage systems, while refrigerated storage systems should be positioned to minimize transport distances.

At American Mortuary Coolers, we understand how critical proper integration is between all mortuary equipment. Our custom solutions ensure your embalming-sink works seamlessly with your cooler systems and other equipment for maximum efficiency and safety.

Installation, Maintenance & Troubleshooting

Getting your embalming-sink installed correctly is crucial. Most quality manufacturers provide factory plumbing completion - meaning complex internal connections are already done. When your sink arrives, only basic trade hook-ups remain.

Electrical hook-ups require special attention in mortuary environments. The combination of water and electricity demands strict adherence to safety codes, particularly GFCI protection. Hire licensed electricians who understand mortuary facility requirements.

Vent lines prevent sewer gases from backing up into your prep room while maintaining adequate drainage flow. Floor drains around your sink area provide essential backup protection when spills happen. Backflow prevention protects everyone's water supply from contamination through vacuum breakers, air gaps, and check valves.

Once installed, proper maintenance becomes your daily reality. Routine disinfection should follow manufacturer guidelines and facility protocols. Most embalming-sinks need daily cleaning with approved disinfectants, plus deeper sanitization between cases.

Descaling removes mineral buildup that can clog spray systems. Gasket checks prevent small problems from becoming big headaches - inspect all seals regularly for wear, cracking, or chemical damage. Leak detection should be part of your regular routine.

For older sinks, resurfacing can restore smooth surfaces and extend service life significantly. Keep a spare parts inventory of common wear items like gaskets, spray heads, and drain strainers.

Step-by-Step Maintenance Schedule for an Embalming-Sink

Daily rinse procedures remove chemical residues and biological materials from all surfaces using hot water and approved detergents. Weekly deep clean addresses hidden areas - clean aspirator systems, descale spray heads, and sanitize every surface. Monthly hardware audit verifies everything works as intended - test drain flow rates, check electrical components, and confirm safety systems function properly. Annual gasket replacement prevents unexpected failures even for gaskets that look fine.

Common Issues & Quick Fixes

Slow drainage usually means debris has accumulated in drain lines or strainers. Remove and clean all strainers first, looking for obstructions. Spray-hose leaks typically develop at connection points - check all fittings and replace damaged O-rings or gaskets. Aspirator vacuum loss can stem from water pressure issues or connection leaks - check water pressure first, then inspect all connections. Odor backflow suggests problems with drainage venting or trap seals - verify that all drain traps contain adequate water and vent systems are clear.

Frequently Asked Questions about Embalming-Sinks

How often should an embalming-sink be sanitized during a typical workday?

Your embalming-sink needs thorough sanitization after each case and a deep clean at day's end. High-volume facilities often need intermediate cleaning during complex cases, especially when switching between different chemical systems or handling cases with infectious concerns.

The sanitization process covers all surfaces that contact fluids or instruments - sink bowl, faucets, spray systems, drain areas, and surrounding work surfaces. Use EPA-approved disinfectants and give them proper contact time to work effectively.

Can a wall-mounted embalming-sink support heavy autopsy work?

Absolutely, but installation quality makes all the difference. A properly mounted embalming-sink can handle demanding autopsy requirements, including heavy organs, large instruments, and significant forces during cavity procedures.

Wall-mounted systems need adequate structural support - mounting to structural walls or reinforced areas that handle both static weight and dynamic loads during use. Professional-grade wall-mounted sinks are engineered for these demands, but installation must be performed by qualified professionals who understand structural requirements and mortuary work stresses.

What plumbing specifications are required for the hydro-aspirator?

Hydro-aspirators need 40-60 PSI minimum water pressure to create effective suction, plus 3-5 gallons per minute of consistent flow. On the drainage side, you'll typically need 2-inch minimum drain lines, though larger facilities often require 3-inch or bigger pipes.

Proper venting is crucial for drainage problems and consistent suction performance. Don't forget backflow prevention devices - vacuum breakers or air gaps prevent aspirated materials from entering the clean water supply and are usually required by local health codes.

Conclusion

Choosing the right embalming-sink isn't just about buying equipment - it's about investing in the heart of your prep room operations. After helping funeral homes across the country upgrade their facilities, we've seen how the right sink choice transforms daily workflows and protects the people who matter most: your staff and the families you serve.

The workflow efficiency improvements speak for themselves. When your embalming-sink works seamlessly with your hydraulic tables and trolleys, your staff can focus on what they do best instead of fighting with poorly designed equipment. We've watched funeral directors cut procedure times by 20-30% simply by upgrading to properly sized, well-positioned sink systems. Over hundreds of cases each year, those minutes add up to hours of saved time and reduced physical strain.

Staff safety remains our top priority in every recommendation we make. The GFCI protection, chemical-resistant construction, and integrated eyewash systems we specify aren't just regulatory requirements - they're essential protections for your most valuable asset. Your experienced embalmers represent years of training and expertise that can't be easily replaced. Protecting them with quality equipment makes both human and financial sense.

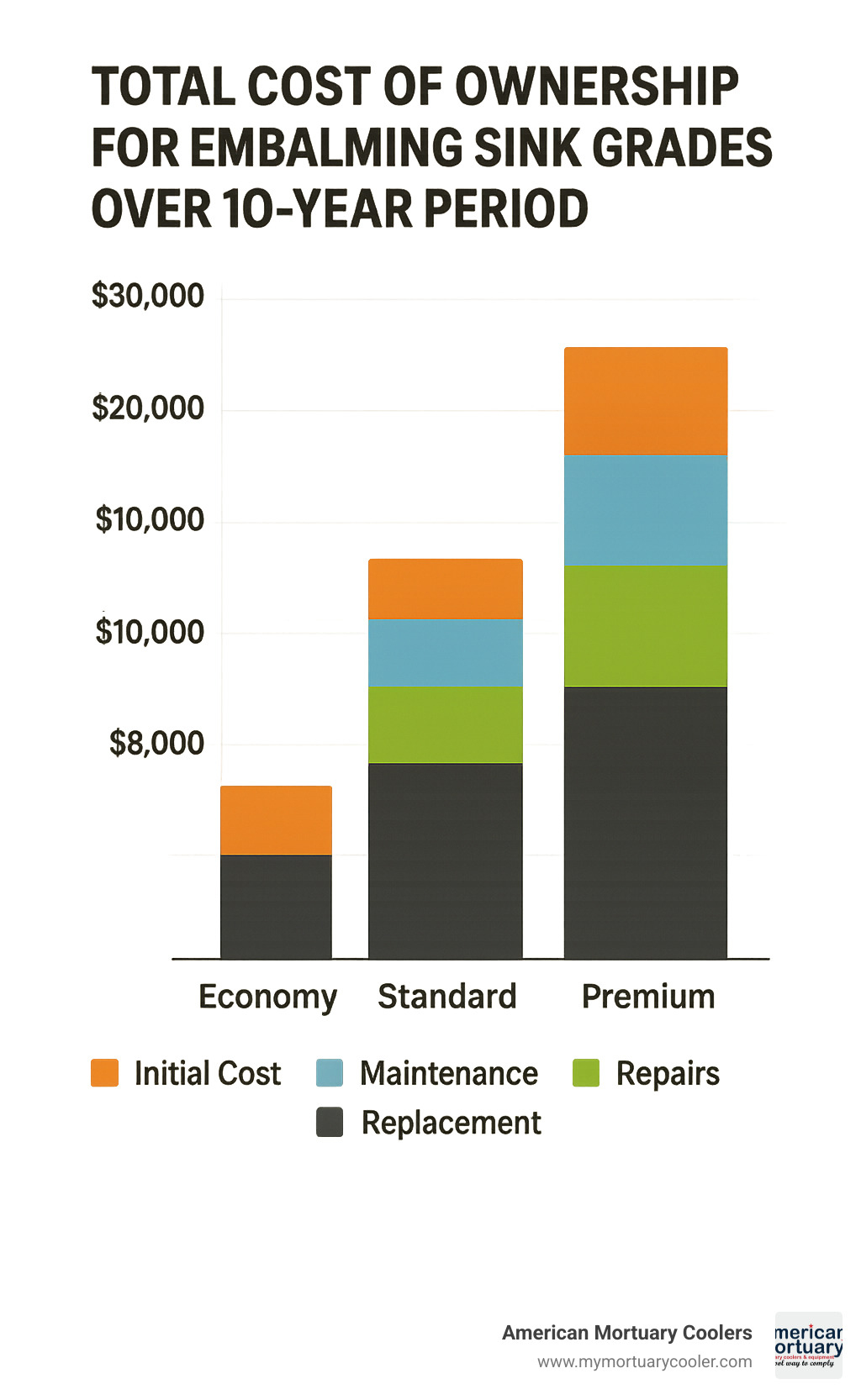

The long-term ROI from quality embalming-sink systems becomes clear when you compare total ownership costs over 10-15 years. Yes, premium systems cost more upfront. But when you factor in reduced maintenance, fewer repairs, and avoided regulatory violations, the math strongly favors quality construction. We've seen cheap sinks fail within 3-5 years, while properly specified stainless steel systems serve facilities for decades.

At American Mortuary Coolers, we understand that no two funeral homes are exactly alike. Your space constraints, case volume, and workflow preferences all influence the best sink choice for your facility. That's why we take a custom solutions approach, working with you to find equipment that fits your specific needs rather than trying to force a one-size-fits-all solution.

Our experience serving funeral homes across the contiguous 48 states has taught us that the best equipment decisions consider both current needs and future growth. Whether you're planning a new facility, upgrading existing equipment, or dealing with an unexpected failure, we're here to help you make choices that will serve your facility well for years to come.

The right embalming-sink will quietly do its job for decades, supporting your staff through thousands of procedures while maintaining the safety and efficiency standards your families deserve. Take the time to evaluate your options carefully, and don't hesitate to reach out for guidance when you need it.

Ready to explore your next equipment upgrade? Check out our The Ultimate Guide to Finding the Best Embalming Tables to ensure all your prep room equipment works together as a cohesive system.