The Definitive Guide to R404A Refrigerant

Why R404A Refrigerant Still Matters in 2024

R404A is a hydrofluorocarbon (HFC) blend that has been the backbone of commercial refrigeration for nearly three decades, but fast-moving regulations now force operators to plan its exit strategy.

Quick R404A Reference:

- Composition: 44% R-125, 52% R-143a, 4% R-134a

- GWP: 3,922 (extremely high)

- Safety: ASHRAE A1 (non-flammable, low toxicity)

- Boiling Point: ‑46.5 °C (-51.7 °F)

- Status: Banned for new equipment in EU (2020); recycled stock allowed until 2029

- Main Uses: Walk-in freezers, transport reefers, ice machines, mortuary coolers

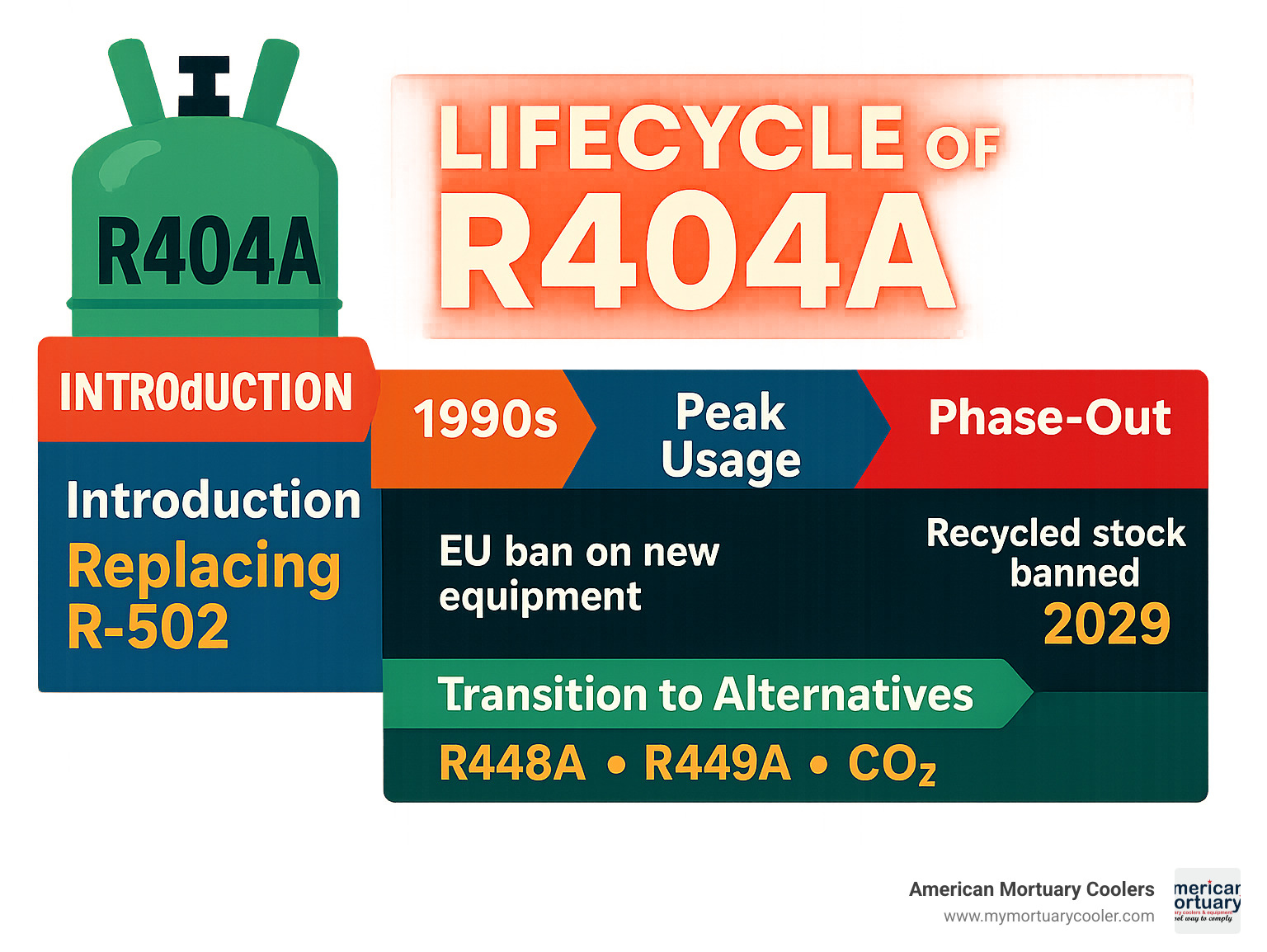

After replacing ozone-depleting R-502 in the 1990s, R404A dominated medium- and low-temperature systems across Europe and North America. The downside emerged later: with a Global Warming Potential of 3,922, just 1 kg of leaked R404A warms the planet as much as almost 4 t of CO₂.

That climate punch has triggered strict limits. The EU banned service with virgin refrigerants above GWP 2,500 in 2021, and the U.S. AIM Act is phasing down HFC production to 15 % of baseline by 2036. New equipment can no longer use R404A, and prices for remaining supplies are climbing fast.

For funeral-home directors, these rules directly affect mortuary cooler budgets and long-term reliability. Understanding timelines and retrofit options now prevents costly emergency changes later.

At American Mortuary Coolers, we’ve helped facilities nationwide transition existing R404A units or design new systems around low-GWP refrigerants. Early planning always saves money and downtime.

What Is R404A and Why It Matters

When the world decided to phase out ozone-depleting refrigerants in the 1990s, the commercial refrigeration industry faced a massive challenge. They needed a replacement that wouldn't harm the ozone layer but could still keep food frozen and funeral homes operating smoothly.

R404A stepped up to fill that gap. This hydrofluorocarbon blend became the hero of commercial refrigeration, offering zero ozone depletion potential while delivering the same reliable cooling power that businesses depended on. For nearly three decades, it's been the workhorse keeping everything from grocery store freezers to mortuary coolers running perfectly.

But the very refrigerant that saved the ozone layer has now become an environmental concern due to its incredibly high global warming potential. That's why understanding R404A matters more than ever in 2024.

Chemical Composition of R404A

R404A is a carefully crafted recipe with three main ingredients, each playing a specific role in creating the perfect refrigeration blend.

R-125 makes up 44% of the mix and brings the heavy lifting power for cooling capacity. This component gives R404A its excellent low-temperature performance that mortuary applications require.

R-143a takes the biggest share at 52% and handles the efficiency side of things. It's the component that keeps your compressor running smoothly and your energy bills reasonable.

R-134a rounds out the blend with just 4%, fine-tuning the entire mixture's thermodynamic properties, making everything work together harmoniously.

This precise 44/52/4 ratio creates what we call a near-azeotropic mixture. The three components stick together and behave almost like a single refrigerant. The temperature glide is minimal at just 0.8 K, which is why R404A systems are so predictable and easy to work with.

Here's something critical for technicians: R404A must always be charged as a liquid. If you try to charge from the vapor phase, those three components can separate, leaving you with poor performance and potential system damage.

Main Applications of R404A

R404A didn't just replace R-502 - it conquered the entire commercial refrigeration world. Walk into any supermarket, and you're likely surrounded by R404A systems keeping your food fresh and frozen.

Supermarket refrigeration became R404A's biggest success story. Those glass-door freezers displaying ice cream, the walk-in coolers where staff grab produce, and the ice machines at the deli counter - they've all relied on R404A for decades.

Transport refrigeration is another area where this refrigerant shines. From the small refrigerated van delivering flowers to the massive 53-foot trailer hauling frozen foods cross-country, R404A has kept goods at the right temperature mile after mile.

Cold storage facilities and food processing plants adopted R404A for its consistent performance in large-scale applications.

At American Mortuary Coolers, we've seen R404A excel in specialized applications like mortuary coolers. The refrigerant's reliability and precise temperature control make it ideal for funeral homes that can't afford cooling system failures.

R404A vs Historical R502

The transition from R-502 to R404A was like upgrading from a reliable old truck to a newer model that's better in almost every way. The industry didn't just get environmental compliance - they got genuine performance improvements.

Cooling capacity stayed strong with R404A delivering equivalent or slightly better performance than R-502 under most conditions. Compressor discharge temperatures dropped significantly - we're talking about 9°C (14°F) lower than R-502 in many applications. For equipment longevity, this was huge.

Zero ozone depletion potential was obviously the main driver for the switch, but R404A delivered this environmental benefit while actually improving system efficiency in many low-temperature applications.

The transition was so successful that R404A became the undisputed champion of commercial refrigeration for nearly three decades. Unfortunately, its high Global Warming Potential of 3,922 has now put it in the regulatory crosshairs.

Physical, Thermodynamic & Safety Properties

When you're working with R404A refrigeration systems, understanding how this refrigerant behaves is crucial for proper operation. These aren't just numbers on a chart - they're the characteristics that determine whether your mortuary cooler runs smoothly or gives you headaches.

R404A has a normal boiling point of -46.5°C (-51.7°F), which makes it perfect for those low-temperature applications where you need reliable performance. The critical temperature sits at 72.0°C (161.7°F), giving you a good operating window for commercial refrigeration work.

Key Thermodynamic Numbers

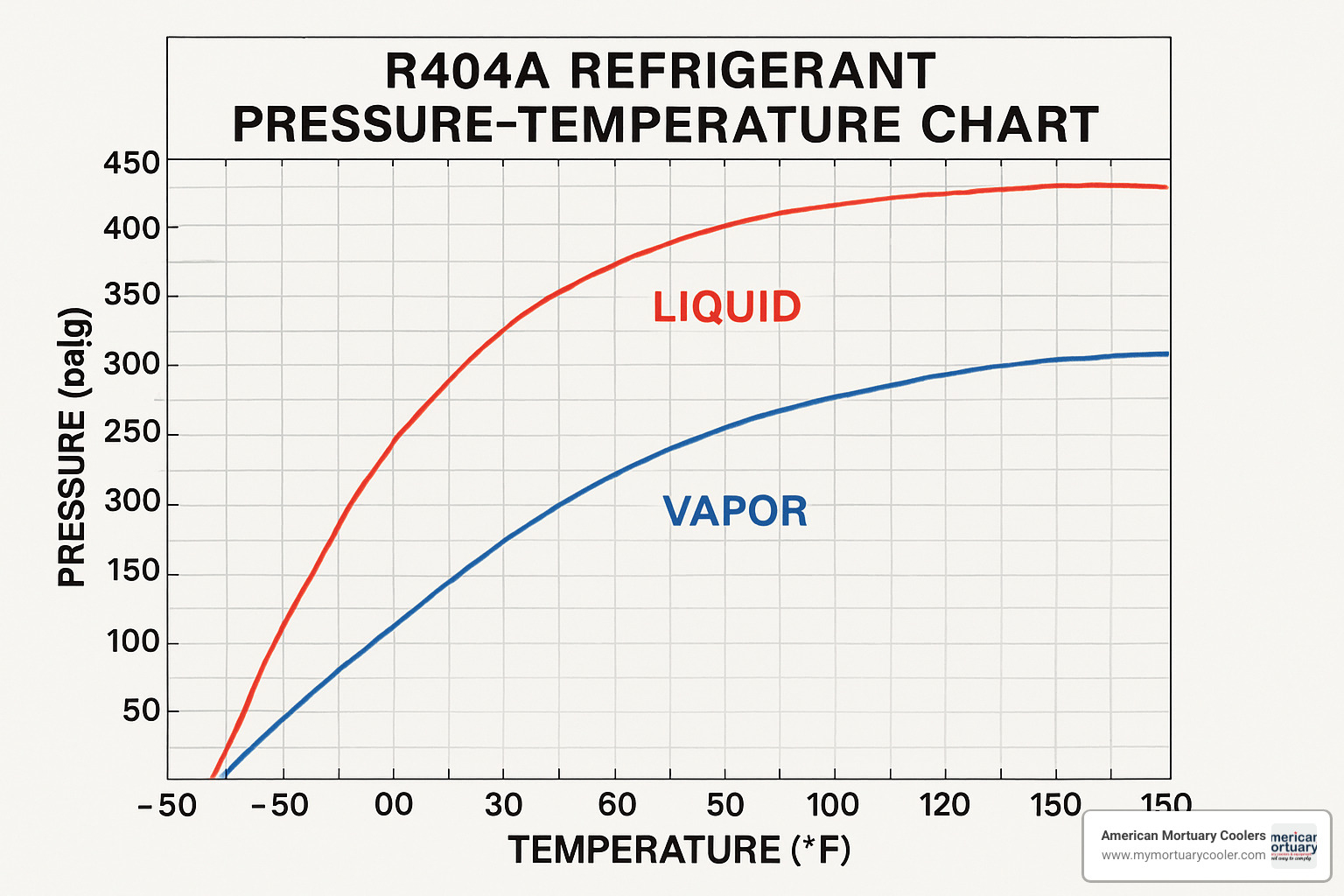

The pressure-temperature relationship of R404A tells the story of how your system will perform. At 0°F, you're looking at about 32.6 psig vapor pressure - perfect for freezer applications where you need that deep cold. Bump the temperature up to 32°F, and you'll see liquid pressure at 51.1 psig with vapor pressure at 50.0 psig.

When things heat up to 100°F (which happens more often than we'd like in equipment rooms), pressures jump to around 236.8 psig for liquid and 234.6 psig for vapor. That nonlinear pressure increase is something to keep in mind when designing systems or troubleshooting on hot summer days.

The temperature glide of just 0.8 K is what makes R404A so user-friendly. You don't have to worry about the complex calculations that come with other refrigerant blends that have higher glides. It behaves almost like a pure refrigerant, which simplifies everything from system design to field service.

If you need detailed pressure-temperature data for field work, check out our Cheat Sheet to R404a P-T Chart: Quick Reference Guide.

Safety Classification and Health Risks

R404A earned its ASHRAE A1 safety classification by being non-flammable and having low toxicity. This is why it became the go-to choice for commercial applications - you don't have to worry about fire hazards or extreme toxicity concerns.

Frostbite is the biggest immediate danger. With a boiling point of -46.5°C, liquid R404A will freeze your skin instantly on contact. Always wear insulated gloves - PVA, neoprene, or butyl rubber work well - along with proper eye protection.

Asphyxiation is the sneaky risk that catches people off guard. R404A vapors are heavier than air, so they settle in low areas and can push out oxygen. If you're working in a basement equipment room or confined space, make sure you have adequate ventilation.

At high concentrations, R404A can cause cardiac sensitization, which affects your heart rhythm. You'd need pretty extreme exposure to reach these levels, but it's another reason to ensure good ventilation.

If temperatures get above 250°C (which can happen in compressor failures), R404A breaks down into hydrofluoric acid and carbonyl halides - both compounds you definitely don't want to breathe. This is why proper system design and maintenance matter so much.

Environmental Footprint: GWP & ODP

This is where R404A goes from hero to villain in the environmental story. When it replaced R-502 in the 1990s, everyone celebrated because it had zero ozone depletion potential (ODP).

Well, not exactly. R404A has a Global Warming Potential of 3,922, which means 1 kg of this refrigerant escaping into the atmosphere equals 3,922 kg of CO2 in terms of climate impact over 100 years. To put that in perspective, a small leak from a mortuary cooler can have the same climate impact as driving a car for months.

The EU's F-Gas Regulation (EU) 2024/573, which took effect on March 11, 2024, specifically targets high-GWP refrigerants like R404A. The regulation aims to phase out HFCs by 2025 and has already banned using virgin R404A for service and maintenance in many applications.

This is why the industry is scrambling to find alternatives. Companies like Chemours have developed their Opteon™ refrigerants low-GWP portfolio specifically to address this challenge. These newer refrigerants can deliver similar performance with dramatically lower environmental impact.

At American Mortuary Coolers, we're helping funeral homes steer this transition. The good news is that newer low-GWP alternatives can often provide better energy efficiency along with environmental benefits.

Replacing R404A: Alternatives & Retrofit Best Practices

The clock is ticking on R404A. Europe banned virgin refrigerants with GWP above 2,500 in January 2021, and the U.S. is following suit with the AIM Act. By 2036, HFC production will drop to just 15% of baseline levels.

If you're running mortuary cooling equipment with R404A, this isn't a problem for "someday" - it's happening now. The good news? There are proven alternatives that can actually improve your system's performance while meeting environmental regulations.

Low-GWP Alternatives (R448A, R449A, CO2)

The replacement refrigerant market has matured significantly since the early days of R404A phase-out panic. Today's alternatives aren't just environmentally better - many actually outperform the original.

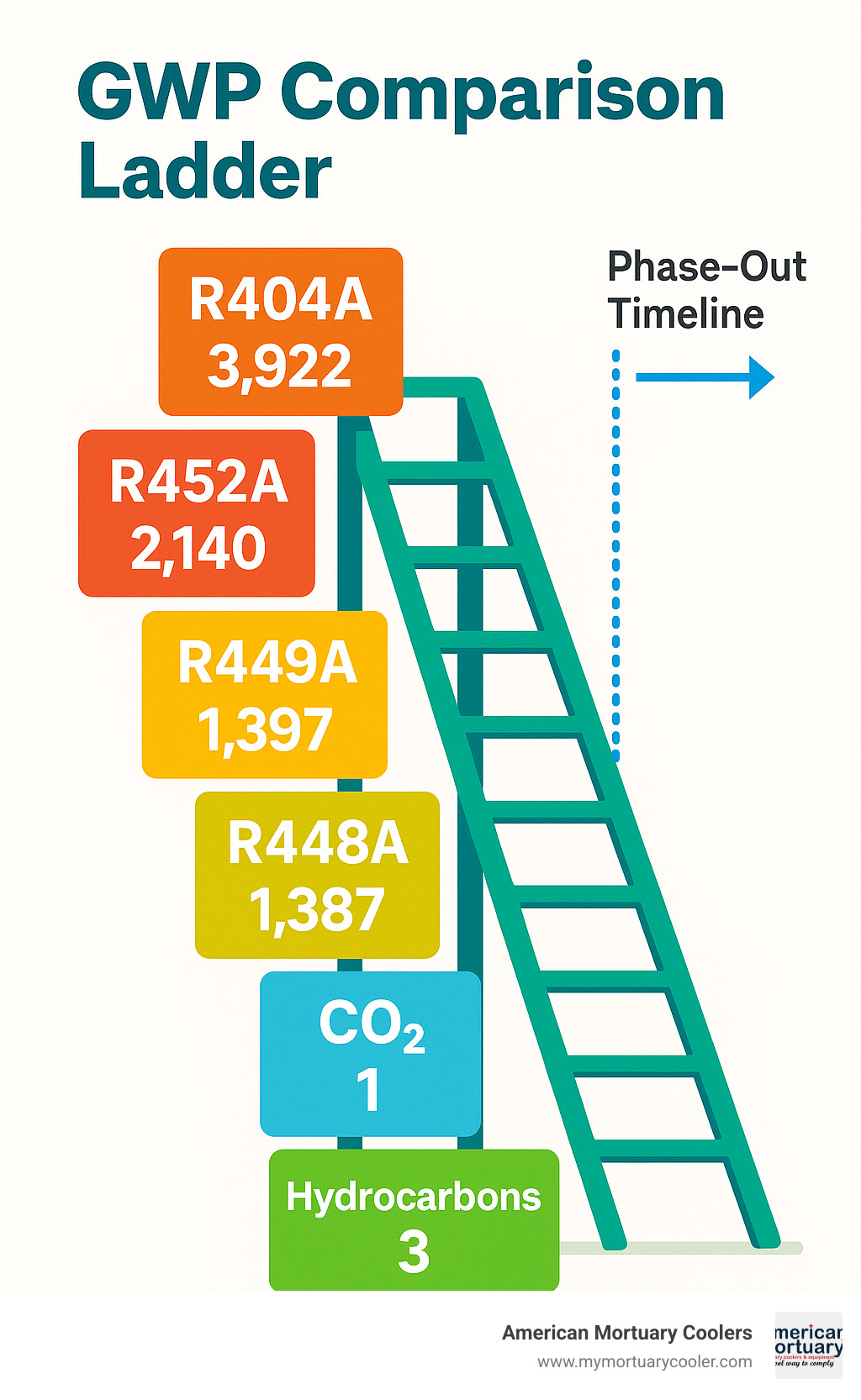

R448A has become the most popular R404A replacement. With a GWP of 1,387, it cuts environmental impact by nearly two-thirds while delivering up to 11% better efficiency. The HFO blend works with existing POE lubricants and requires minimal system modifications. Most of our mortuary cooler retrofits at American Mortuary Coolers use R448A because it's proven reliable in critical applications.

R449A offers similar environmental benefits with a GWP of 1,397. This HFO blend excels in medium-temperature applications and has shown excellent long-term stability in commercial systems.

R452A serves as a stepping-stone solution with a GWP of 2,140. While still above some regulatory thresholds, it works exceptionally well in reciprocating compressor applications and buys time for facilities planning longer-term upgrades.

CO2 (R744) represents the ultimate environmental solution with a GWP of just 1. Modern CO2 systems work even in hot climates thanks to improved designs, though they're more complex and typically better suited for new installations rather than retrofits.

Hydrocarbon refrigerants like R290 (propane) offer GWP values of 3 or less with excellent thermodynamic properties. However, their flammability requires special handling procedures and may not be suitable for all applications.

Retrofitting Existing Systems from R404A

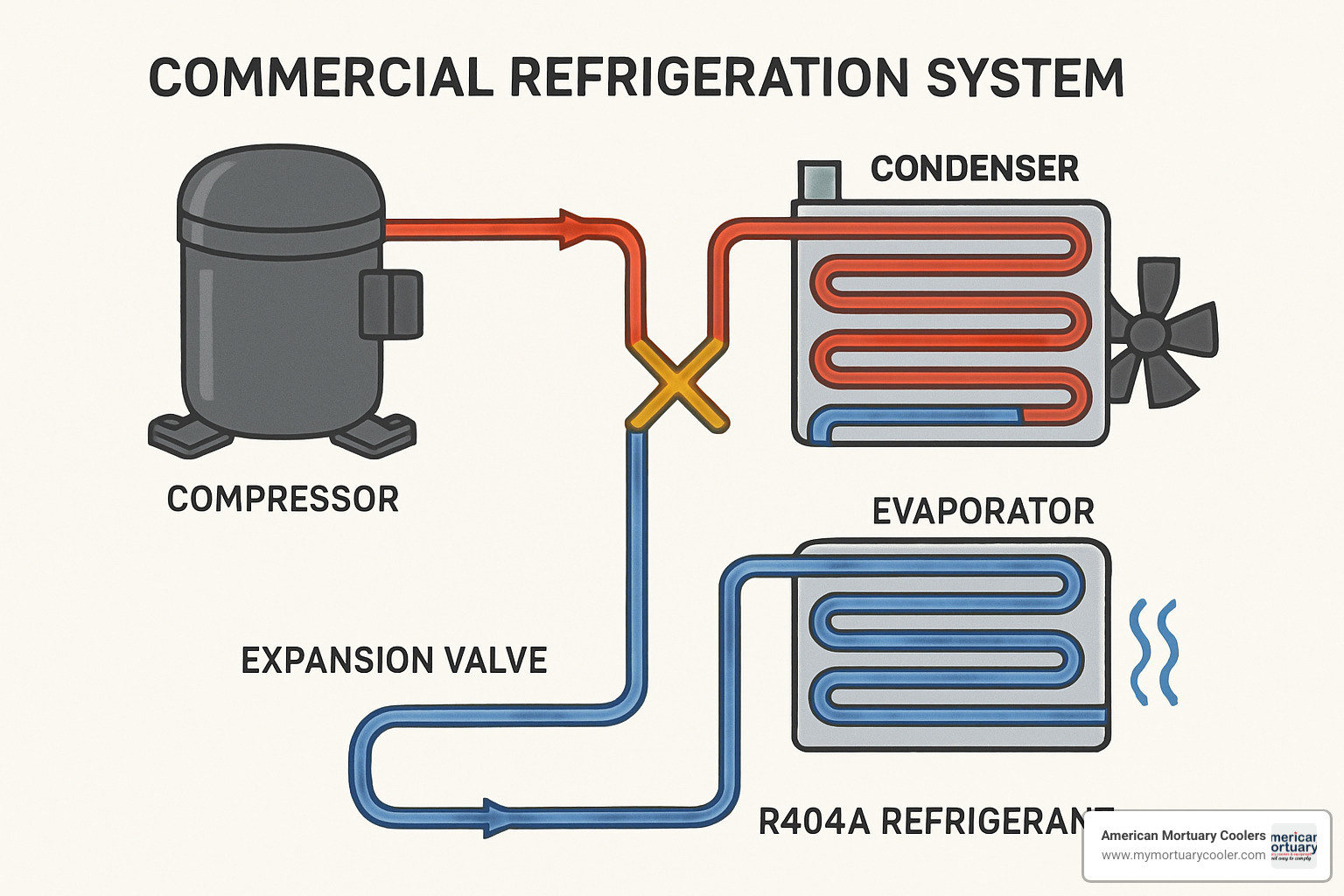

Converting an R404A system isn't as daunting as it might seem, but it does require careful planning. The key is taking it step by step.

Start with baseline data collection. Document your current system's temperatures, pressures, and energy consumption. This information becomes crucial for evaluating whether your retrofit was successful.

System assessment comes next. Look at your expansion valves, gaskets, and seals. Most modern components are compatible with replacement refrigerants, but older systems may need updates.

Refrigerant recovery must be done properly with certified equipment. Record the exact amount of R404A removed - you'll need this for calculating the new refrigerant charge. Most replacements require 95-105% of the original charge.

Oil changes are often necessary, though many R404A systems already use POE oil that's compatible with replacement refrigerants. The key is ensuring the oil is clean and dry.

System modifications typically involve adjusting expansion valve settings and replacing filter-driers. With R448A, you'll usually need to close the expansion valve 1-2 turns to prevent flood-back.

For a deeper understanding of how these systems work, our Refrigeration System 101: Understanding the Basics guide covers the fundamentals every facility manager should know.

Component & Lubricant Compatibility

One of the biggest advantages of modern R404A replacements is their compatibility with existing system components. The refrigerant manufacturers learned from earlier transition problems and designed these alternatives to work with installed equipment.

Elastomers and seals in most modern refrigeration systems handle HFO blends without issues. However, if your mortuary cooler is more than 15 years old, consider replacing seals proactively.

Expansion valves from R404A systems typically work well with replacement refrigerants, though superheat settings need adjustment. The larger temperature glide of some replacements affects heat transfer characteristics.

Compressor compatibility is rarely an issue with modern equipment. Most compressor manufacturers have approved their units for multiple refrigerants.

Lubricant systems present fewer challenges than expected. The POE oils used with R404A work well with most HFO replacement blends. The critical factor is oil cleanliness - moisture can cause acid formation with some new refrigerants.

For detailed information about specific alternatives, Opteon™ XP40 (R-449A) provides comprehensive compatibility data and application guidelines.

| Property | R404A | R448A | R452A |

|---|---|---|---|

| GWP | 3,922 | 1,387 | 2,140 |

| Safety Class | A1 | A1 | A1 |

| Boiling Point | -46.5°C | -50.7°C | -48.1°C |

| Glide | 0.8K | 7.0K | 2.1K |

| Oil Compatibility | POE | POE | POE |

| Charge Adjustment | Baseline | -5% | -10% |

Handling, Storage & Disposal of R404A

Working with R404A safely requires understanding its unique characteristics and following proper procedures. The refrigerant's high GWP of 3,922 means that even small releases can have massive environmental consequences, making careful handling more important than ever.

You'll typically find R404A available in cylinder sizes ranging from 9 kg up to massive 720 kg drums for large commercial installations. Most suppliers now use dual-port valve cylinders, which makes liquid-phase charging much easier. R404A must always be charged as a liquid to prevent the blend components from separating.

Safe Storage & Transport

Storing R404A properly isn't just about following regulations - it's about keeping your team safe and your refrigerant usable. The Department of Transportation classifies R404A as a compressed gas, which comes with specific requirements.

Temperature control is your first priority. Never let cylinders exceed 52°C (125°F), which means keeping them away from direct sunlight, heating equipment, and hot storage areas.

Keep cylinders upright at all times during storage and transport. When liquid R404A gets into the valve mechanism, it can cause sudden, dangerous pressure releases. A 24-pound cylinder actually weighs about 45 pounds when full, so use proper lifting techniques.

Ventilation in storage areas is critical because R404A vapors are heavier than air. If vapors accumulate in low areas, they can displace oxygen and create serious asphyxiation risks.

For facilities managing multiple cylinders, tracking systems like Cylinder Tracking help monitor inventory and ensure proper rotation of refrigerant stock.

Leak Detection, Recovery, Disposal

With R404A's enormous climate impact, finding and fixing leaks quickly isn't just good practice - it's an environmental responsibility. Every pound that escapes is equivalent to nearly two tons of CO2 in climate impact.

Electronic halogen detectors calibrated for HFC refrigerants are essential tools for any facility using R404A. Don't wait for obvious signs like frost or hissing sounds. Regular leak checks can catch small problems before they become expensive environmental disasters.

Recovery requirements under EPA Section 608 are strict. Systems containing more than 200 pounds of refrigerant must be evacuated to 10 inches of mercury vacuum before disposal or major repairs.

The recycling window for R404A is closing fast. Under current EU regulations, recovered refrigerant can only be recycled for reuse until December 31, 2029. After that date, all R404A must be destroyed rather than reused.

Documentation has become increasingly important as regulations tighten. Keep detailed records of every refrigerant purchase, system charge, recovery operation, and disposal.

Regulatory Landscape & Compliance

The regulatory environment around R404A is changing rapidly, and staying compliant requires understanding multiple overlapping rules.

EPA's SNAP program has been systematically listing R404A applications as "unacceptable" with specific phase-out dates. Different equipment categories have different deadlines, so check the current status for mortuary cooling applications specifically.

The AIM Act brings European-style HFC phase-downs to the United States. Production and consumption allowances drop to just 15% of baseline levels by 2036, which means R404A will become increasingly scarce and expensive.

European regulations are already more restrictive. The updated F-Gas Regulation (EU) 2024/573, which took effect in March 2024, bans virgin R404A for service and maintenance in most applications. The goal is complete HFC phase-out by 2025.

State-level regulations can be even stricter than federal rules. California, for example, has implemented faster timelines than EPA requirements. Check your local regulations because compliance failures can result in significant penalties.

At American Mortuary Coolers, we help funeral homes steer these regulatory changes while planning equipment upgrades and refrigerant transitions.

Frequently Asked Questions about R404A

What makes R404A's GWP so high?

The sky-high Global Warming Potential of R404A comes down to some unfortunate chemistry. When scientists created this blend back in the 1990s, they were focused on solving the ozone hole problem - and they succeeded brilliantly at that. But they didn't fully grasp how potent these replacement chemicals would be as greenhouse gases.

R404A's blend of R-125 and R-143a is the real culprit here. R-125 makes up 44% of the blend and has a GWP around 3,500. R-143a, which makes up 52%, is even worse at about 4,470 GWP. When you mix these together in R404A's specific recipe, you get a refrigerant that traps nearly 4,000 times more heat than the same amount of CO2.

What makes it worse is how long these chemicals stick around in the atmosphere. While CO2 might cycle out in decades, the HFC components in R404A can persist for 15-50 years, continuing to trap heat the entire time.

It's a classic case of solving one environmental problem while accidentally creating another. The good news is that we now have replacement refrigerants that perform just as well without the massive climate impact.

Can I still buy virgin R404A after 2024?

This is probably the question I get asked most often, and the answer is getting more complicated every year. The short version? It depends on where you are and what you're using it for, but virgin R404A is becoming harder to find and much more expensive everywhere.

In Europe, the door is already closing fast. They banned virgin R404A for most service work back in January 2021. The only exception is recycled refrigerant, and that lifeline ends on December 31, 2029. After that, it's game over for R404A in the EU.

Here in the United States, we're following a similar path but with a more gradual timeline. The EPA's SNAP program has been systematically banning R404A in different applications. The AIM Act is squeezing production allowances tighter each year, dropping to just 15% of baseline levels by 2036.

What this means practically is that virgin R404A is still available for some applications, but prices are climbing steadily. We've seen costs triple in some markets as supply gets constrained. Many of our funeral home clients are choosing to retrofit their systems now rather than face even higher refrigerant costs down the road.

My advice? Don't wait until you're forced to make a decision. Planning your transition now gives you more options and better pricing.

Which lubricant should I use when I retrofit from R404A?

Here's some good news in all this transition complexity - the oil situation is usually pretty straightforward. Most R404A systems already use POE (polyolester) oil, which plays nicely with the popular replacement refrigerants like R448A and R449A.

The key is making sure your existing oil is still in good shape. If you've been running the same oil for years, or if the system has had contamination issues, this retrofit is the perfect time for a fresh start. Clean, dry POE oil is essential for the new HFO blends to perform properly.

During our retrofit projects at American Mortuary Coolers, we typically replace the filter-driers and check oil moisture content. If the oil looks good and tests dry, we often leave it in place. If there's any doubt, we do a complete oil change - it's cheap insurance for a smooth transition.

One important note: if you're working with an older system that somehow still has mineral oil from pre-R404A days, you'll need to completely flush and change to POE oil. Mineral oil and modern refrigerants don't mix well.

The bottom line? Stick with POE oil, make sure it's clean and dry, and follow your new refrigerant manufacturer's recommendations for oil quantities. Most systems need little to no adjustment in oil volume when switching from R404A to its modern replacements.

Conclusion

The story of R404A reads like a classic tale of unintended consequences. This refrigerant blend stepped up as the hero in the 1990s, saving commercial refrigeration from ozone-depleting CFCs. For nearly three decades, it powered everything from supermarket freezers to mortuary coolers with reliable, efficient performance.

But while R404A protected the ozone layer, its Global Warming Potential of 3,922 made it a climate change villain. Every kilogram that leaked into the atmosphere packed the warming punch of nearly four tons of CO2. That's why regulators worldwide are pulling the plug on this once-celebrated refrigerant.

The transition timeline is moving fast. Europe already banned virgin R404A for most applications back in 2021. The U.S. is following suit with aggressive phase-downs under the AIM Act. By 2029, even recycled R404A will be off-limits in the EU. The R404A era is ending.

But here's the good news: the alternatives are actually better. Modern low-GWP refrigerants like R448A and R449A don't just reduce environmental impact by 60-70% - they often improve system efficiency too. Some facilities see energy savings of 5-15% after retrofitting from R404A. It's one of those rare situations where doing the right thing for the planet also helps your bottom line.

At American Mortuary Coolers, we've been helping funeral homes across Tennessee, Georgia, Illinois, and beyond prepare for this transition. Our custom mortuary cooling systems are engineered to handle whatever refrigerant the future brings. Whether you need a retrofit of your existing R404A system or want a new installation designed for ultra-low-GWP refrigerants like CO2, we've got you covered.

The secret to success? Don't wait until you're forced to act. Start planning now while you have options and can make informed decisions. Emergency retrofits are expensive and stressful. Smart planning lets you choose the best alternative for your specific needs and budget.

For the technical data to support your planning, our Ultimate Guide to 404a P-T Charts: Pressure Temperature Reference has everything you need for system design and troubleshooting.

The R404A chapter is closing, but the next one looks promising. Lower environmental impact, better efficiency, and continued reliable performance - that's a future worth embracing. Contact us to discuss how we can help your mortuary cooling systems make the transition smoothly and successfully.