The Definitive Guide to Freezer Condenser Units

The Essential Role of Freezer Condenser Units in Cold Storage

A freezer condenser unit is the heart of any freezer system, responsible for removing heat from the refrigerant and releasing it outside the freezer cabinet. This crucial component works continuously to maintain the ultra-low temperatures needed for proper freezing.

Quick Facts About Freezer Condenser Units:

| Aspect | Details |

|---|---|

| Function | Converts refrigerant from gas to liquid by removing heat |

| Location | Typically outside or on top of freezer cabinets |

| Common Types | Air-cooled, water-cooled, scroll, semi-hermetic |

| Cost Range | $450-$1,000 for residential; $1,500-$15,000+ for commercial |

| Typical Lifespan | 10-15 years with proper maintenance |

When functioning properly, a freezer condenser unit operates as part of a continuous cycle, working alongside the compressor, expansion valve, and evaporator to maintain consistent freezing temperatures. Understanding this component is critical whether you're maintaining an existing system or selecting a new one for your facility.

The efficiency of your freezer depends heavily on the condenser unit's performance. A poorly functioning or improperly sized unit can lead to temperature fluctuations, increased energy costs, and potentially catastrophic system failures that could compromise your stored contents.

I'm Mortuary Cooler, a national-level supplier of mortuary cooling systems with extensive experience designing and implementing freezer condenser unit solutions for funeral homes across America. My team specializes in creating reliable, energy-efficient refrigeration systems that meet the unique requirements of mortuary operations.

Key freezer condenser unit vocabulary:

Why This Guide Matters

Understanding freezer condenser units isn't just for HVAC technicians. For mortuary professionals, funeral home directors, and facility managers, this knowledge directly impacts your bottom line and operational reliability.

Consider these critical factors:

- Efficiency losses: A dirty or poorly maintained condenser unit can reduce system efficiency by up to 30%, dramatically increasing energy costs.

- Downtime costs: When a freezer system fails, the consequences can be severe—especially in the mortuary industry where temperature control is non-negotiable.

- Selection errors: Choosing an undersized unit won't keep up with cooling demands, while an oversized unit wastes energy and leads to premature component failure.

What Is a Freezer Condenser Unit?

Think of a freezer condenser unit as the unsung hero of your freezer system. It's the component that takes all the heat collected from inside your freezer and releases it to the outside world. Without it, your freezer would quickly become just another cabinet!

When you hear your freezer running, that's often the freezer condenser unit hard at work. It's the "hot side" of your refrigeration system, where an amazing change happens – hot, pressurized refrigerant gas changes into a liquid. This phase change is what makes refrigeration possible.

The freezer condenser unit and compressor work together like dance partners. The compressor squeezes the refrigerant gas, heating it up in the process. Then the condenser's job begins – cooling this hot gas until it condenses into a high-pressure liquid. This liquid refrigerant is now primed to absorb heat when it later expands in the evaporator inside your freezer.

Freezers have special needs compared to regular refrigerators, and their condenser units reflect these differences:

| Feature | Refrigerator Condenser | Freezer Condenser Unit |

|---|---|---|

| Temperature Range | 35-40°F (1-4°C) | -10 to -20°F (-23 to -29°C) |

| BTU Capacity | ~50 BTU per cubic foot | ~70-80 BTU per cubic foot |

| Compressor Size | Typically smaller | Larger for greater cooling capacity |

| Run Time | Cycles on/off more frequently | Longer run cycles |

At American Mortuary Coolers, we build walk-in freezers with condenser units that are significantly more robust than what you'd find in a home freezer. This is essential because walk-ins have more interior space, experience more frequent door openings, and often need to quickly cool items from room temperature to freezing.

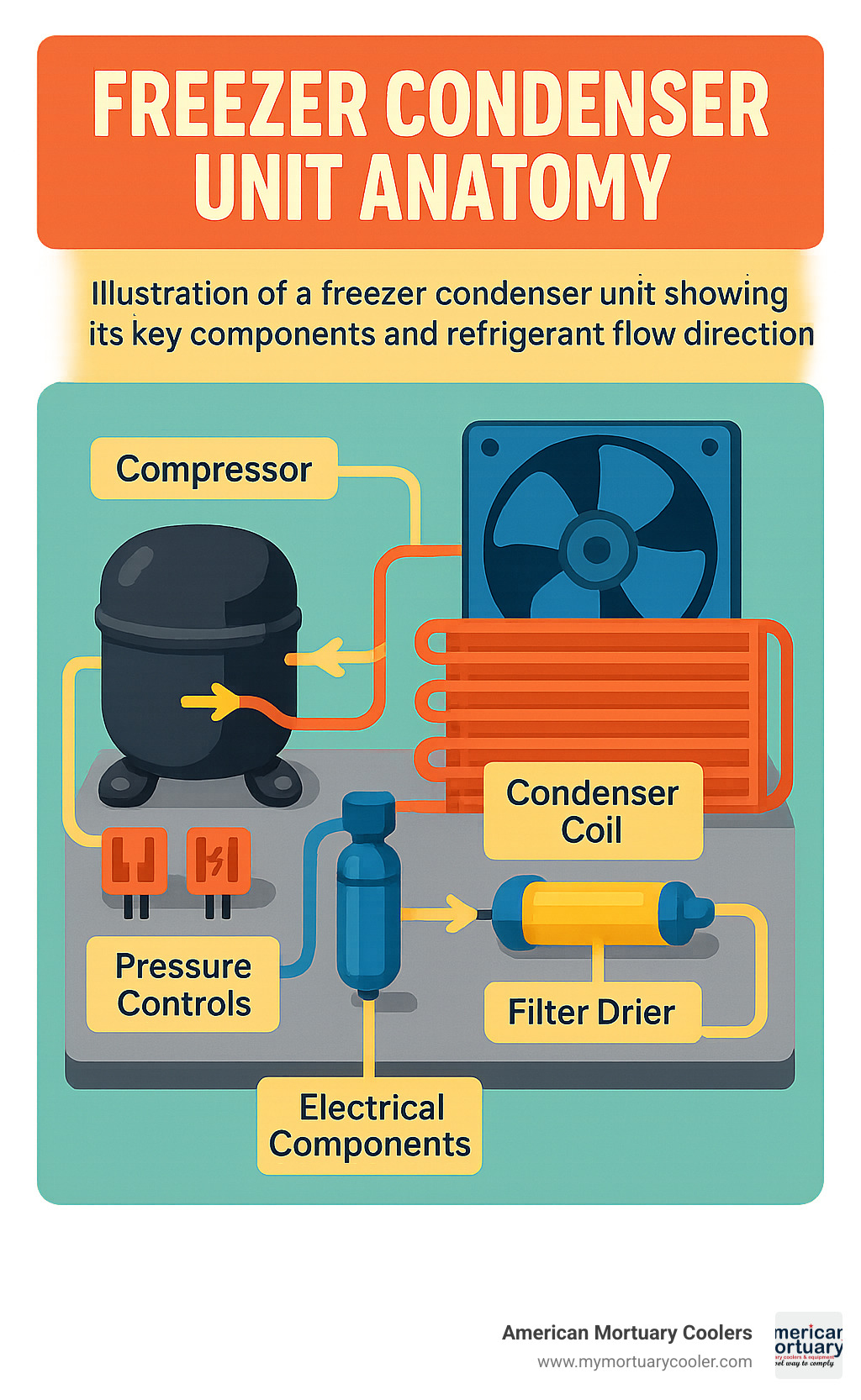

Freezer Condenser Unit Components

Your freezer condenser unit is actually a team of components working in harmony:

The compressor serves as the heart of the system, pumping and pressurizing refrigerant gas. For freezer applications, we use higher-capacity models than those found in standard refrigerators.

The condenser coil is where the magic happens – hot pressurized refrigerant releases its heat through these tubes and fins. Modern units often feature microchannel technology for better efficiency.

In air-cooled units, fan motors pull air across the condenser coils. Commercial freezer units typically employ multiple fans to ensure proper airflow and heat removal.

The receiver tank acts like a refrigerant reservoir, storing excess liquid refrigerant to handle varying cooling demands and ensuring a steady supply to the expansion valve.

To protect the system, a filter-drier removes moisture and contaminants from the refrigerant, preventing corrosion and blockages that could damage your system.

Freezer Condenser Unit in the Refrigeration Cycle

Your freezer condenser unit plays a crucial role in the refrigeration cycle – a continuous process with four main stages:

During compression, the compressor pulls in cool, low-pressure refrigerant gas from the evaporator and squeezes it, creating hot, high-pressure gas – like when you pump up a bicycle tire and the pump gets warm.

Next comes condensation, where the freezer condenser unit does its primary work. The hot gas enters the condenser, releases heat to the surrounding air or water, and transforms into a high-pressure liquid – similar to how water vapor condenses on a cold glass on a humid day.

The expansion stage begins when this high-pressure liquid passes through an expansion device (typically a thermostatic expansion valve in commercial freezers). This creates a sudden pressure drop, causing some refrigerant to flash into vapor and dramatically cooling the mixture.

Finally, during evaporation, this cold refrigerant mixture flows through the evaporator inside your freezer, absorbing heat from the air. This heat absorption causes the remaining liquid refrigerant to boil and completely evaporate into a low-pressure gas again.

Then the whole beautiful dance begins again!

Two important concepts that directly impact how well your condenser performs are subcooling (additional cooling of the liquid refrigerant below its condensing temperature) and superheat (heating of the refrigerant vapor above its evaporation temperature). Both increase system efficiency and protect your compressor.

Types of Freezer Condenser Units & How to Choose the Right One

Picking the perfect freezer condenser unit for your needs doesn't have to feel overwhelming. Think of it like choosing the right vehicle—different types serve different purposes, and finding your ideal match makes all the difference in performance and efficiency.

By Cooling Method:

The first big decision is how your unit will shed heat. Air-cooled condenser units are the workhorses of the industry—they're straightforward, more affordable upfront, and don't require water connections. The downside? When summer temperatures soar, they have to work harder.

Water-cooled condenser units shine in consistency. No matter how hot it gets outside, these units maintain steady performance by using water instead of air to remove heat. They're perfect for facilities in hot climates, though they do require water supply and drainage systems.

For the best of both worlds, evaporative condenser units combine air and water cooling by misting water over the coils while air passes through. They're efficiency champions but need more regular maintenance to prevent mineral buildup.

By Location:

Where your unit lives matters too. Indoor condenser units stay protected from the elements inside mechanical rooms, but they need proper ventilation—otherwise, they're just heating your building!

Outdoor condenser units free up valuable indoor space and naturally vent heat to the atmosphere. We often recommend these for mortuary facilities where indoor space is at a premium. Just remember they'll need weather protection and possibly low-ambient controls for cold climates.

When selecting your freezer condenser unit, consider these practical factors:

Your horsepower needs will typically range from 1/2 HP for small units up to 100 HP for industrial applications. The refrigerant type matters too—options include R-404A, R-507, and R-448A, with environmentally-friendly CO₂ systems gaining popularity.

Don't forget to check electrical compatibility—most commercial units run on 208-230V or 460V, in either single or three-phase configurations. Your local climate conditions play a huge role too; a unit that works perfectly in Minnesota might struggle in Miami.

Air-Cooled vs. Water-Cooled Freezer Condenser Units

Air-cooled units win on simplicity. They're less expensive to install, don't consume water, and have fewer components that could potentially fail. Maintenance is generally straightforward—keep the coils clean and ensure good airflow. For most small to medium mortuary operations, we find air-cooled units provide the best balance of cost and reliability.

The downside? When temperatures climb above 95°F, efficiency drops. They also generate more noise, which might be a consideration depending on your facility's layout.

Water-cooled units are the performance champions. They maintain consistent efficiency regardless of outside temperatures and operate more quietly. Many larger facilities appreciate their stable operating conditions, which can extend equipment life significantly.

Compressor Technologies Inside a Freezer Condenser Unit

Scroll compressors have revolutionized commercial refrigeration with their orbital motion and reduced moving parts. We've found they strike an excellent balance for mortuary applications—quiet enough not to disturb the solemn atmosphere while offering superior reliability with 10-20% better efficiency than traditional compressors.

Semi-hermetic reciprocating compressors are the field-serviceable workhorses of the industry. If something goes wrong, a technician can open them up for repairs rather than replacing the entire unit. They handle tough conditions well and are cost-effective for certain applications, particularly larger ones.

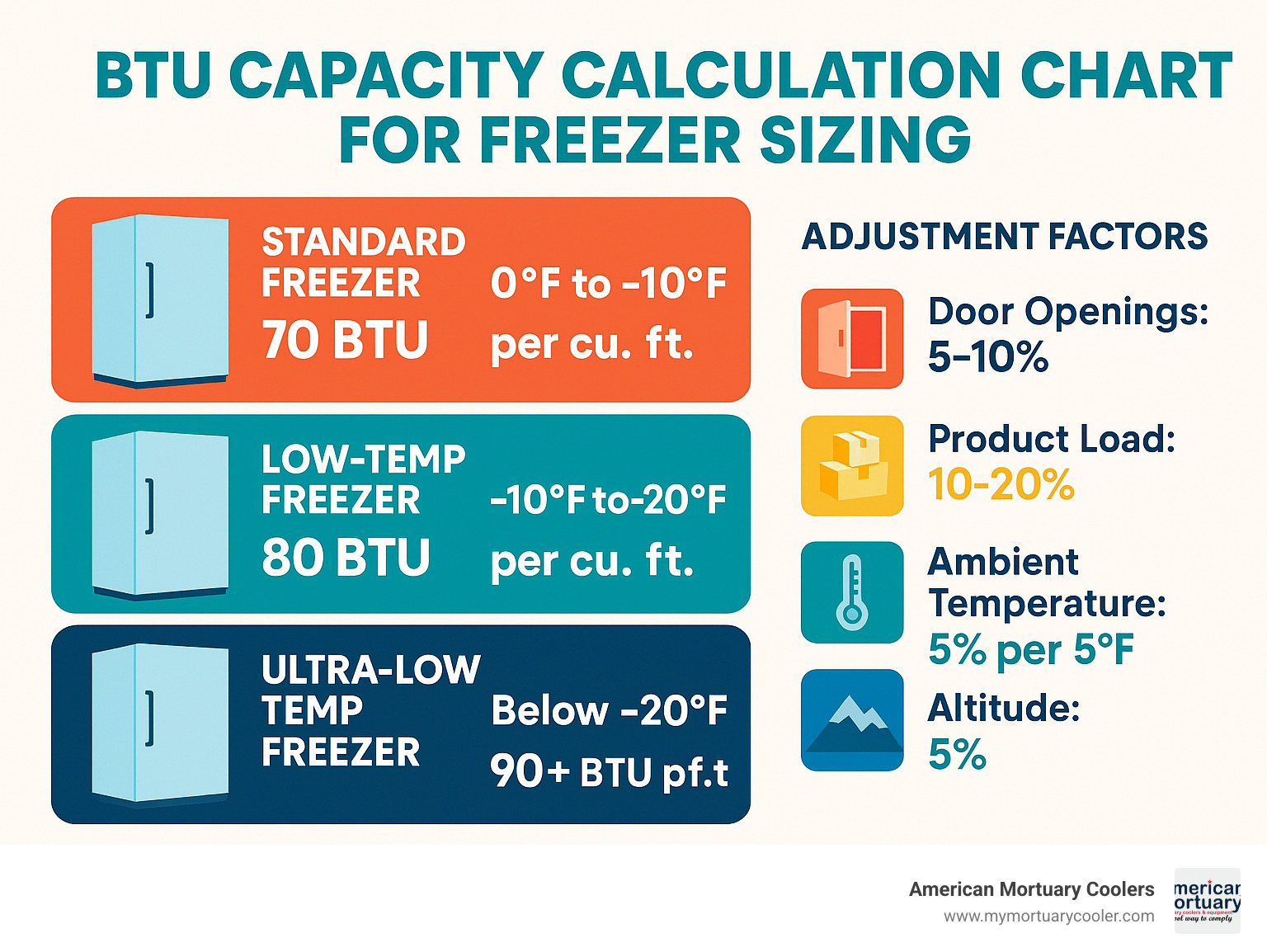

Sizing & Capacity Calculator for Your Application

Getting the size right is crucial when selecting a freezer condenser unit. Too small, and your unit will run constantly without reaching target temperatures; too large, and you'll waste energy while causing excessive wear from short-cycling.

For freezer applications, the rule of thumb is 70-80 BTUs per cubic foot of interior space. This is higher than refrigerators because freezers must maintain much lower temperatures—creating a bigger temperature differential requires more cooling power.

Let's walk through a real-world example for that 10' × 8' × 8' mortuary freezer operating at -10°F:

- Base requirement: 640 ft³ × 80 BTU/ft³ = 51,200 BTUs

- Adding 5% for moderate door openings: +2,560 BTUs

- Adding our 10% safety margin: +5,120 BTUs

- Total requirement: 58,880 BTUs

- Converting to tons: 58,880 ÷ 12,000 = 4.9 tons

- Appropriate compressor size: 5 HP

Installation, Maintenance & Troubleshooting

Installing and maintaining your freezer condenser unit isn't just about technical compliance—it's about protecting your investment and ensuring reliability when you need it most. At American Mortuary Coolers, we've seen how proper setup and regular care can add years to your equipment's life while preventing those middle-of-the-night emergencies no funeral director wants to face.

Installation Best Practices

Think of your freezer condenser unit installation as building a foundation—get it right, and everything else falls into place. For air-cooled units, proper breathing room is essential—at least 18-24 inches of clearance from walls or obstructions. It's like giving your unit its own personal space to function efficiently.

When installing indoors, ventilation becomes critical. That hot air needs somewhere to go, and without proper exhaust, you're essentially asking your unit to work in a sauna. Outdoor units need protection from debris while still maintaining airflow—position them away from areas where leaves and dirt naturally collect, and consider the direction of prevailing winds.

Preventative Maintenance to Extend Freezer Condenser Unit Life

Think of your freezer condenser unit like your car—regular oil changes and tune-ups prevent breakdowns on the highway. The single most important maintenance task? Keeping those condenser coils clean. Aim for quarterly cleaning at minimum, more often in dusty environments. Dirty coils force your system to work harder, driving up operating pressures and energy costs while shortening compressor life.

Listen to your equipment. Unusual fan noises often signal bearing wear before catastrophic failure occurs. While you're there, check those fan blades for damage or buildup that could throw them out of balance.

For systems operating in varying climates, head-pressure controls need regular verification. These components ensure your freezer condenser unit performs consistently regardless of whether it's a scorching summer day or a frigid winter night.

Want to learn more about preventing common freezer problems? Check out our guide on How to Fix an Iced Evaporator with These 5 Easy Changes.

Common Signs of a Failing Freezer Condenser Unit

Your freezer condenser unit will usually tell you when it's struggling—if you know the language. High head pressure often signals dirty condenser coils or fan problems. It's like your system running a fever, indicating something's not right.

Short cycling—when the compressor frequently starts and stops—suggests control problems or improper sizing. This puts tremendous strain on components, much like constantly starting and stopping your car in traffic.

Unusual compressor noises deserve immediate attention. That rattling or knocking sound isn't just annoying—it's your equipment crying for help. Similarly, any burnt electrical smell around your unit requires urgent investigation, as it often indicates motor winding problems.

Replacing or Upgrading a Freezer Condenser Unit

When the time comes to replace your freezer condenser unit, view it as an opportunity rather than just an expense. First, consider whether a retrofit might work—sometimes replacing just the condensing unit while keeping the existing evaporator makes sense, but compatibility must be carefully evaluated.

With ongoing refrigerant regulations, ensure your new system uses a refrigerant with long-term availability. The refrigeration industry continues to move toward more environmentally friendly options, and you don't want to invest in yesterday's technology.

New installations must meet Department of Energy efficiency standards for walk-in coolers and freezers. These regulations aren't just bureaucratic problems—they ultimately save you money through reduced operating costs.

Energy Efficiency, Regulations & Next-Gen Features

Let's face it—energy costs aren't getting any cheaper, and that's why the efficiency of your freezer condenser unit matters more than ever. As someone who's helped countless mortuary professionals steer these waters, I've seen how understanding today's regulations and new technologies can save you thousands in operating costs.

The regulatory landscape has gotten pretty complex in recent years. The Department of Energy's Walk-In Cooler and Freezer (WICF) standards now set minimum efficiency requirements for condensing units. Meanwhile, the EPA's Significant New Alternatives Policy (SNAP) program keeps tightening the rules on which refrigerants we can use based on their global warming potential.

But here's the good news—these regulations have pushed manufacturers to develop some impressive innovations that actually work in your favor.

Today's high-efficiency freezer condenser units often feature low-GWP refrigerants like R-448A and R-449A. These newer options perform similarly to the old standby R-404A but with a much smaller environmental footprint. Many units now use microchannel coils made of aluminum that transfer heat more efficiently while requiring less refrigerant charge than traditional copper/aluminum designs.

Many of our mortuary clients are particularly excited about cloud monitoring systems. These platforms track your system's performance in real-time and can alert you to potential issues before they cause a failure—critical peace of mind when you're storing deceased loved ones.

The best part? While these technologies might cost more upfront, they typically pay for themselves within 1-3 years through energy savings. For mortuary freezers that run 24/7, the return on investment is often even quicker.

Meeting Energy Codes with Modern Freezer Condenser Units

Meeting today's energy codes isn't just about the condensing unit itself—it requires thinking about your freezer as a complete system.

Your freezer condenser unit works hand-in-hand with your insulation. High-R-value panels reduce the overall cooling load, which means your condenser doesn't have to work as hard (or use as much energy). We've seen cases where upgrading insulation allowed clients to install a smaller, less expensive condensing unit while still maintaining perfect temperatures.

For more information on energy-efficient cooling options, check out our Ultimate Guide to Energy Efficient Coolers.

Emerging Technologies Shaping Freezer Condenser Units

The refrigeration world never stands still, and several exciting technologies are ready to transform freezer condenser units in the coming years.

CO₂ transcritical booster systems represent one of the most promising developments. These systems use carbon dioxide (R-744) as the refrigerant, offering excellent environmental credentials with zero ozone depletion and minimal global warming impact. While they operate differently than traditional systems and require specialized knowledge to maintain, they're gaining traction in commercial applications.

For smaller applications, propane micro-packaged systems using R-290 (propane) offer impressive efficiency with minimal refrigerant charge. Their self-contained design reduces leak potential, an important environmental consideration.

At American Mortuary Coolers, we're constantly evaluating these emerging technologies to determine which ones make sense for our mortuary clients. While we accept innovation, we never lose sight of what matters most in your business: absolute reliability when families are counting on you.

Frequently Asked Questions About Freezer Condenser Units

How much does a freezer condenser unit cost?

When it comes to pricing a freezer condenser unit, I've found that costs can vary dramatically depending on what you need. Think of it like buying a car - there's a big difference between a compact sedan and a heavy-duty truck!

For smaller units in the ½ to 2 horsepower range (what you might see in a small funeral home), expect to invest between $450 and $2,500. Medium-sized commercial units that most standard mortuaries need (3-7.5 HP) typically run from $2,000 to $7,000. If you're operating a larger facility with substantial freezer space, those industrial-grade 10+ HP units start around $8,000 and can exceed $25,000 for specialized applications.

Don't forget about installation! This usually adds another 50-100% to your equipment costs, depending on the complexity of your setup. Most of our mortuary clients find their sweet spot with commercial-grade units in the 3-7.5 HP range, with total installed costs between $4,000 and $12,000.

What is the typical lifespan and warranty?

A freezer condenser unit is a lot like a car in terms of longevity - how long it lasts depends largely on how well you take care of it!

With proper maintenance, commercial units typically serve faithfully for 10-15 years. I've seen well-maintained systems still running strong after 20+ years in some funeral homes. On the flip side, neglected units often struggle to make it past the 8-year mark.

Regarding warranties, most manufacturers offer standard coverage of 1 year on parts with 5 years on the compressor (the heart of the system). Extended warranties up to 10 years are available if you want extra peace of mind, though they'll add to your initial investment. Labor is typically covered for the first year if an authorized contractor handles the installation.

Can I oversize my freezer condenser unit for future expansion?

It's perfectly natural to think about the future when investing in a freezer condenser unit - but bigger isn't always better. In fact, an oversized unit can create more problems than it solves.

When a unit is too large for the space it's cooling, it tends to short cycle - turning on, cooling the space too quickly, and shutting off again. This constant on-off cycling is hard on components and actually reduces efficiency. You'll also see poorer humidity control since the unit doesn't run long enough to properly dehumidify the air.

Instead of significant oversizing, consider these smarter approaches to future-proofing:

Look into modular designs that allow you to add capacity later as your needs grow. Multiple smaller units can be a great solution - you can activate additional units only when needed. Variable capacity systems with digital scroll or inverter compressors operate efficiently even at partial loads, giving you flexibility.

If you do want some buffer, a modest oversizing of 10-15% additional capacity is generally acceptable without causing performance issues. This gives you a little room to grow without the drawbacks of a significantly oversized system.

Conclusion

Choosing the right freezer condenser unit isn't just about technical specifications—it's about ensuring peace of mind for your mortuary operation. After all, temperature reliability isn't optional in your line of work.

At American Mortuary Coolers, we understand the unique challenges funeral homes face. That's why we've built our reputation on creating custom refrigeration solutions that truly work for mortuary professionals. Based in Tennessee, we're proud to deliver our systems directly to mortuary professionals across all 48 contiguous states, ensuring your equipment arrives in perfect condition and ready for installation.

What makes our approach to freezer condenser units different? We focus on what matters most to you:

We take the time to properly size your system, making sure it perfectly matches your facility's specific needs—not too small that it struggles, and not so large that it wastes energy cycling on and off.

Our energy-efficient designs significantly reduce your monthly operating costs, with most clients seeing 15-30% savings compared to their older systems.

We select components known for their durability and reliability, because we understand that downtime simply isn't an option in your business.

Every system we build meets or exceeds all relevant regulations, giving you one less thing to worry about.

The right freezer condenser unit, properly maintained, becomes an investment that pays dividends through reduced energy bills, minimal downtime, and equipment that can last 15+ years or more. But beyond the financial benefits, there's something even more valuable—the confidence that comes from knowing your temperature-sensitive operations are protected by equipment you can trust.

Whether you're planning a new facility, replacing aging equipment that's becoming unreliable, or troubleshooting issues with your current system, understanding your freezer condenser unit options helps you make choices that will serve your business well for years to come.

For more information about our mortuary coolers and freezers, including custom options for unique spaces, visit our website or reach out directly. At American Mortuary Coolers, we're not just building refrigeration systems—we're building relationships with the professionals who depend on them every day.