The Definitive Guide to Finding the Best Reach-In Coolers

Why Reach-In Coolers Are Essential for Modern Commercial Operations

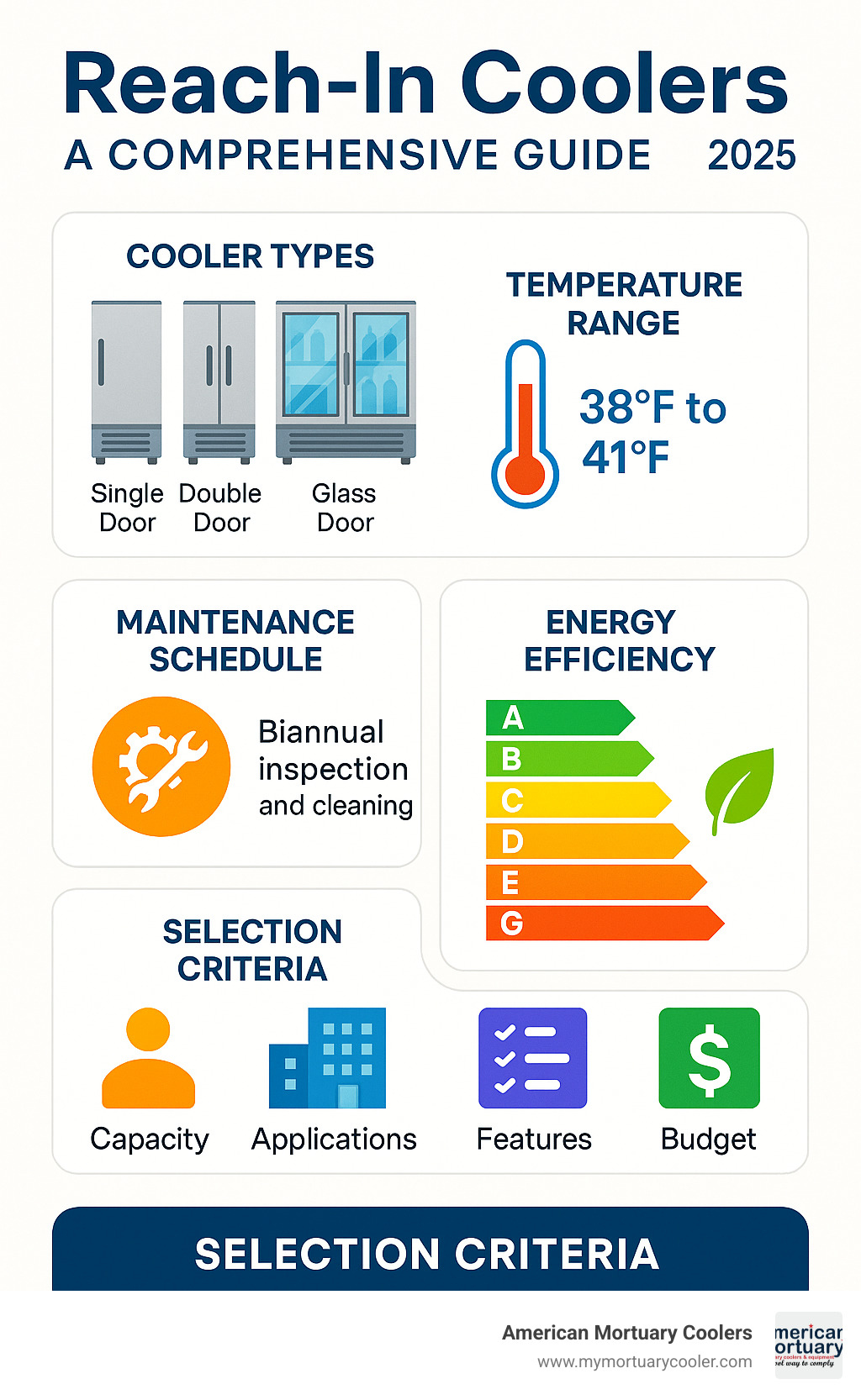

Reach in coolers are upright refrigeration units that provide accessible cold storage for commercial kitchens, medical facilities, and specialty businesses. These versatile units operate at an evaporator temperature of 28°F while maintaining FDA-recommended food storage temperatures between 38°F and 41°F.

Quick Reference Guide:

- Temperature Range: 38°F to 41°F (FDA recommended)

- Lifespan: Up to 20 years with proper maintenance

- Common Types: Single-door, double-door, glass door, solid door

- Key Industries: Restaurants, medical facilities, florists, convenience stores

- Price Range: $1,000 to $5,000+ depending on size and features

- Energy Efficiency: Look for ENERGY STAR and NSF certifications

Whether you need a single-door unit for a small operation or a triple-door configuration for high-volume storage, these units offer the perfect balance of accessibility and temperature control. The choice between glass doors (for visibility and reduced openings) and solid doors (for better insulation and lower cost) depends on your specific workflow needs.

Commercial reach-in refrigerators can last upwards of 20 years with proper maintenance, making them a smart long-term investment. Many units feature self-cleaning condensers, LED lighting, and adjustable shelving to maximize efficiency and organization.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping businesses select the right reach in coolers for their specific needs. My background includes working with funeral homes, medical facilities, and commercial operations to find durable, customized refrigeration solutions that meet strict temperature and space requirements.

Relevant articles related to reach in coolers:

Reach-In Coolers 101: What They Are & Why They Matter

Think of reach in coolers as the workhorses of commercial refrigeration. These upright cabinets are built tough to handle the daily grind of busy kitchens, medical facilities, and specialty businesses where you need cold storage that's both reliable and easy to access.

Here's where the science gets interesting: these units run their evaporators at 28°F to create the cooling power needed to keep your products fresh. But the actual storage temperature? That's where the FDA's sweet spot of 38°F to 41°F comes in – the perfect range for food safety and freshness.

Reach in coolers aren't just for restaurants, though that's where most people think of them first. Medical facilities rely on them for pharmaceutical storage where temperature precision can mean the difference between effective medications and expensive waste. Floral shops use them to extend the life of delicate arrangements, while convenience stores depend on them for grab-and-go items that customers expect to be perfectly chilled.

The big decision you'll face is choosing between solid doors and glass doors. Glass doors are brilliant for busy operations because staff can see what's inside without opening the door – and every time that door stays closed, you're saving energy and money. Solid doors cost less upfront and offer slightly better insulation, making them perfect for back-of-house storage where visibility isn't as important.

One thing that sets commercial units apart from home refrigerators is NSF certification. When you see that NSF mark, you know the cooler meets strict sanitary standards that health inspectors love to see. It's not just about passing inspections – it's about equipment that's genuinely easier to clean and maintain.

How Reach-In Coolers Differ From Walk-Ins & Merchandisers

Choosing the right refrigeration type can make or break your operation's efficiency. Let's break down what makes reach in coolers unique.

Capacity is where reach-ins shine for most businesses. With storage ranging from 18 to over 35 cubic feet, they give you serious cold storage without eating up your entire floor plan. Walk-in coolers offer massive storage, sure, but they also require construction permits, dedicated space, and sometimes structural modifications that can turn a simple equipment purchase into a major renovation project.

Mobility is another game-changer. Many reach-in models come with heavy-duty casters, which means you can roll them out for those monthly condenser cleanings or rearrange your kitchen layout when business demands change. Try doing that with a walk-in cooler! This flexibility becomes invaluable when you're dealing with tight spaces or evolving operational needs.

The real magic happens in your daily workflow. Reach-ins integrate seamlessly into kitchen operations, letting your staff grab ingredients without abandoning their stations or breaking their rhythm. Merchandisers are designed to look pretty for customers, while walk-ins require staff to leave the main work area entirely – and in a busy kitchen, those extra steps and seconds add up fast.

Types & Configurations of Reach-In Coolers

When you're shopping for reach in coolers, the sheer variety of options can feel overwhelming at first. But here's the good news: this variety exists because different operations have genuinely different needs, and there's likely a perfect match for yours.

Single-door units are the quiet heroes of smaller operations. With 18-25 cubic feet of capacity, they slip into tight spaces where larger units simply won't fit. Think coffee shops, small delis, or as supplemental storage in larger kitchens. They're also budget-friendly, making them perfect for startups.

Double-door configurations earn their reputation as the workhorses of commercial kitchens. Offering 40-50 cubic feet of storage while keeping a reasonable footprint, these units often feature independent temperature controls for each compartment. This means you can store your produce at one temperature while keeping dairy products at another.

Triple-door models are where things get serious. With 60+ cubic feet of storage, these units serve large restaurants, institutional kitchens, and operations that need to store diverse products. Some models cleverly offer different temperature zones within the same unit, giving you incredible flexibility.

The half-door models represent some innovative thinking in refrigeration design. These units combine full-height storage with half-height compartments, creating organization options that make inventory management much easier. With 611 products available in this category, they've clearly struck a chord with operators who value smart storage solutions.

Undercounter and chef base units solve the eternal kitchen problem of needing storage exactly where you're working. These space-saving designs fit beneath prep tables or serve as work surfaces themselves, integrating cold storage directly into your prep workflow.

For operations that need mobility, slide-in mobile units offer a clever approach to refrigeration. These units insert into medium to large vans without the expense of full cargo-van refrigeration systems. They're perfect for catering services, food trucks, or any operation that needs to take their cold storage on the road.

The choice between glass and solid doors impacts both your daily operations and your energy bills. Glass doors let your staff see what's inside without opening the unit, reducing energy loss and helping with inventory management. Solid doors cost less upfront and provide slightly better insulation, but require more door openings.

Top-mount and bottom-mount compressors each have their place depending on your environment. Cassette modules represent the latest innovation, allowing technicians to quickly swap out refrigeration components when service is needed.

Core Reach-In Coolers Layouts You'll See on the Market

Understanding the basic layouts helps you match your reach in coolers to your actual storage needs rather than just going with what looks impressive.

Single-zone units maintain one consistent temperature throughout the entire cabinet. They're straightforward, reliable, and work perfectly when you're storing similar products with the same temperature requirements. Most restaurants start with single-zone units because they're simpler to operate and maintain.

Dual-temperature models represent a step up in sophistication. These units feature separate compartments with independent temperature controls, letting you store fresh produce at 38°F in one section while keeping beverages at 35°F in another. The flexibility comes at a higher price point, but it can eliminate the need for multiple single-zone units.

Specialty pharmacy units take precision to another level entirely. Designed for medical and pharmaceutical applications, these units feature precise digital temperature controls, comprehensive alarm systems, and data logging capabilities to meet strict regulatory requirements. If you're in healthcare, these specialized units aren't optional – they're essential for compliance.

Compressor Placement Showdown – Top vs Bottom

The location of your compressor might seem like a minor detail, but it significantly impacts performance, maintenance, and your energy bills. After years of working with operations in every kind of environment, we've learned that placement matters more than most people realize.

Bottom-mounted compressors excel in hot environments because they work with physics instead of against it. Heat naturally rises, so placing the compressor lower reduces the workload on your refrigeration system. This typically translates to lower energy consumption and better performance in those sweltering commercial kitchens where temperatures regularly hit 85°F or higher.

Top-mounted compressors shine in dusty environments. Bakeries, pizzerias, and operations where flour and other particulates fill the air benefit from having the compressor liftd away from floor-level debris and spills. The higher position keeps critical components cleaner and reduces maintenance headaches.

| Feature | Top-Mount | Bottom-Mount |

|---|---|---|

| Heat Resistance | Good | Excellent |

| Dust Protection | Excellent | Good |

| Energy Efficiency | Good | Better in hot environments |

| Maintenance Access | Harder to reach | Easier access |

| Floor Space | More clearance needed | Less clearance needed |

| Best Environment | Dusty (bakeries, pizza) | Hot kitchens |

Modern units increasingly feature removable cassette refrigeration systems, which make maintenance easier regardless of compressor placement. This innovation allows technicians to quickly swap out refrigeration components, minimizing the downtime that used to plague older units when major service was needed.

Key Features, Materials & Energy Performance Checklist

When you're shopping for reach in coolers, it's easy to get overwhelmed by all the technical specifications. But don't worry – I'll walk you through the features that actually matter for your operation's success and your bottom line.

Let's start with what these units are made of. Stainless steel construction isn't just about looking professional (though it certainly does). It's your best friend when health inspectors come calling, and it'll still look great after years of daily use. Some manufacturers offer aluminum options that are lighter on your budget and easier to move around, while glass-reinforced plastic (GRP) provides excellent insulation for specialized applications where temperature control is absolutely critical.

The real magic happens in the insulation. Look for units with 4-inch thick foamed-in-place urethane insulation rated R-29 for coolers and R-32 for freezers. I know those numbers might sound like engineering jargon, but here's what they mean for you: better insulation keeps your food fresher longer and your energy bills lower. These ratings actually exceed EISA energy standards, so you're getting more than the government requires.

Door systems might seem simple, but they're where many cheaper units fall short. Quality reach in coolers feature self-closing doors with 120° stay-open features – perfect for those busy moments when you need both hands free to load ingredients. The heavy-duty gaskets and cam-action locking devices create air-tight seals that prevent your cold air (and money) from escaping.

Gone are the days of squinting into dimly lit coolers. LED lighting has become the standard, and for good reason. These lights give you better visibility while using less electricity than old-fashioned bulbs. Many units include vapor-proof fixtures because nobody wants electrical issues in a humid commercial kitchen.

Modern digital temperature displays take the guesswork out of food safety. You can set precise temperatures and actually see what's happening inside your unit. Some models even include door alarms that'll let you know if someone forgot to close the door properly – a feature that pays for itself the first time it prevents a costly loss of inventory.

Adjustable shelving might not sound exciting, but it's incredibly practical. Your storage needs will change, and being able to reconfigure your shelves means you can adapt without buying new equipment. Look for heavy-duty shelving that can handle significant weight while remaining easy to clean.

Here's where the real savings come in: ENERGY STAR qualified units can dramatically reduce your electric bills over their 20-year lifespan. NSF certification ensures your unit meets strict sanitary design standards, making cleaning easier and keeping health inspectors happy.

The Ultimate Guide to Energy-Efficient Coolers

Innovative Add-Ons for Modern Reach-In Coolers

The refrigeration world has changed dramatically in recent years, and today's reach in coolers come with features that would have seemed like science fiction just a decade ago.

Lithium battery integration is revolutionizing mobile refrigeration. These new systems provide up to 95% of battery power before needing a recharge, compared to only about 50% for older lead-acid batteries. If you're running a catering business or need mobile refrigeration, this technology is a game-changer.

IoT monitoring systems might sound fancy, but they're incredibly practical. Smart sensors track everything from temperature and humidity to how often doors are opened and how much energy you're using. The best part? They send alerts directly to your smartphone when something needs attention. This technology helps prevent costly product losses and keeps you compliant with food safety regulations without constant manual checking.

For specialized applications, glycol prep zones offer ultra-precise temperature control. While most food service operations won't need this level of precision, pharmaceutical storage and scientific research applications benefit from glycol-cooled prep tables integrated with reach-in storage systems.

Sizing, Budgeting & Customization Roadmap

Choosing the perfect reach in coolers for your operation doesn't have to be overwhelming. Think of it like buying a car – you need to know where you're going, how much you can spend, and what features matter most to your daily workflow.

Start with your space. Grab a tape measure and check your available footprint carefully. Don't forget those sneaky clearance requirements – your unit needs breathing room on all sides for proper airflow. Nothing's worse than ordering the perfect cooler only to find it won't fit through your doorway or leaves your staff playing refrigerator Tetris every time they need ingredients.

Calculate your actual capacity needs using real numbers from your operation. The industry rule of thumb suggests 1 cubic foot per 28 meals served, but this varies wildly depending on whether you're serving simple sandwiches or elaborate multi-course dinners. Consider your delivery schedules, prep volume, and those crazy busy periods when you need every inch of cold storage.

Budget planning becomes much easier when you understand the price tiers. Single-door units with basic features typically start around $1,000 to $2,000. Double-door workhorses with standard commercial features run $2,000 to $3,000. Triple-door units or specialty configurations push into the $3,000 to $4,000 range. Custom configurations and specialized applications can exceed $5,000, but they're often worth every penny for the right operation.

Financing options can make higher-quality equipment accessible without straining your cash flow. Many suppliers offer lease programs that spread costs over time while giving you access to better features and warranties. Remember to calculate the total cost of ownership – an energy-efficient unit might cost more upfront but save hundreds annually on electricity bills.

Customization possibilities are nearly endless. Need custom finishes to match your kitchen aesthetic? No problem. Want specialized door configurations or mobile units with heavy-duty wheels? We can make that happen. Medical facilities often require precise temperature monitoring and alarm systems that go beyond standard commercial features.

At American Mortuary Coolers, we understand that every operation has unique needs. While we specialize in mortuary equipment, our expertise in custom refrigeration solutions applies to any business requiring precise temperature control and durable construction.

Used Equipment Inventory › Returns & Refunds Policy› Health & Safety Policy

Calculating the Right Capacity for Your Operation

Getting the capacity right for your reach in coolers requires looking beyond simple cubic footage. You're not just buying storage space – you're investing in operational efficiency.

Analyze your menu volume during peak periods, not average days. Track how much cold storage you actually use during your busiest service periods and highest delivery days. Seasonal variations can dramatically impact your needs – a restaurant serving holiday catering might need 50% more capacity in December than July.

Factor in shelving clearances when calculating usable space. That 40-cubic-foot unit won't actually hold 40 cubic feet of product. Air needs to circulate around items for proper cooling, and you'll need flexibility to adjust shelving for different container sizes. Plan on about 70-80% of total capacity being practically usable.

Think about growth over the next 3-5 years. It's almost always more cost-effective to buy slightly larger capacity upfront than to squeeze in additional units later. Consider your business expansion plans, menu development, and changing customer demands. A growing operation that starts with undersized refrigeration often ends up with a patchwork of units that creates workflow headaches.

The sweet spot is buying about 20% more capacity than your current peak needs. This gives you room to grow while ensuring your current operation runs smoothly even during unexpected busy periods.

Maintenance, Troubleshooting & Longevity Best Practices

Think of your reach in coolers like a reliable workhorse—treat them well, and they'll serve you faithfully for decades. We've seen units that are still running strong after 20 years, and the secret isn't complicated. It's all about consistent care and catching small problems before they become expensive headaches.

The beauty of modern reach-in units is that most maintenance tasks are straightforward. If you've got a unit with casters, you're already ahead of the game. Those wheels make monthly coil cleaning a breeze instead of a back-breaking chore. Just roll the unit out, grab your coil brush, and give those condenser coils the attention they deserve.

Temperature logs might seem like busy work, but they're your early warning system. When temperatures start creeping up gradually, it's usually a sign that something needs attention—often before you'd notice any other symptoms. Keep a simple log, and review it monthly for patterns.

Door gaskets are the unsung heroes of refrigeration. They work 24/7 to keep the cold in and the warm air out. A quick visual check each month can save you hundreds in energy costs. If you can slide a dollar bill through a closed door without resistance, it's time for new gaskets.

The defrost cycles in modern units are pretty smart, but they still need occasional oversight. If you're seeing unusual ice buildup or hearing the unit working harder than usual, the defrost system might need professional attention.

Many operators find that service contracts make financial sense, especially for multi-unit operations. A good technician can spot potential issues during routine visits and often prevent costly emergency repairs. Plus, regular professional maintenance helps protect your warranty coverage.

Common Reach-In Coolers Problems & Fixes

Even the best-maintained reach in coolers can develop quirks over time. The good news? Most problems have straightforward solutions, and many you can handle yourself.

Icing issues are probably the most common complaint we hear about. Before you panic, check the obvious stuff first. Are staff members propping doors open during busy periods? Is someone storing hot items before they've cooled down? Sometimes the simplest explanation is the right one. If the door seals look good and usage patterns are normal, the defrost timer might need adjustment.

Warm spots inside the unit usually mean air isn't circulating properly. We've seen this happen when someone overpacks a shelf or blocks the internal vents with tall containers. The fix is usually as simple as rearranging items to allow better airflow. Think of it like organizing your closet—everything needs a little breathing room.

When doors won't seal properly, start with the gaskets. They take a beating in busy commercial environments and often need replacement before anything else shows wear. If the gaskets look fine, check the hinges. Sometimes a simple adjustment gets everything lined up again.

A compressor that never stops running is trying to tell you something important. Dirty coils are often the culprit—they make the system work much harder to maintain temperature. If cleaning doesn't solve the problem, you're probably looking at a refrigerant issue that needs professional attention.

High energy bills from your refrigeration equipment usually trace back to maintenance issues. Clean coils, good door seals, and proper temperature settings solve most efficiency problems. It's amazing how much money you can save with basic upkeep.

The key to troubleshooting is staying calm and checking the simple stuff first. Most problems have logical explanations, and many can be fixed without calling a technician. When in doubt, though, don't hesitate to call for professional help—it's usually cheaper than trying to fix something you're not sure about.

Frequently Asked Questions About Reach-In Coolers

We get a lot of questions about reach in coolers from business owners trying to make the right choice for their operations. Here are the answers to the most common questions we hear, based on our years of experience helping businesses across the country find the perfect refrigeration solutions.

How long do reach-in coolers last with proper care?

Here's some great news for your budget planning: commercial reach in coolers can last upwards of 20 years when you take good care of them. That's a pretty impressive return on investment when you think about it.

The secret to reaching that 20-year mark lies in three key design elements. First, quality units feature thick insulation that maintains its effectiveness over decades. Second, strong structural end frames provide the backbone that keeps everything aligned and working smoothly. Third, energy-efficient coil designs resist wear and reduce the strain on the entire system.

But here's the thing – that 20-year lifespan isn't automatic. You'll need to stay on top of regular maintenance, including those monthly coil cleanings we mentioned earlier and annual professional inspections. Think of it like taking your car in for regular oil changes. Skip the maintenance, and you'll be shopping for a replacement much sooner than you'd like.

What temperature should my reach-in hold for food safety?

Food safety isn't something you want to guess about, so let's get specific. The FDA recommends programming commercial reach in coolers within the temperature range of 38°F to 41°F to ensure optimal freshness and preservation of your stored items.

Now, you might wonder why the units operate at an evaporator temperature of 28°F if the recommended storage temperature is higher. That's because the evaporator needs to run colder than the storage area to effectively remove heat from the cabinet. It's like how your home air conditioner blows much colder air than your target room temperature.

Keep a separate thermometer in your unit to verify temperatures, and maintain temperature logs for health department inspections. Many modern units include digital displays and alarm systems that make this monitoring much easier than the old days of manual temperature checks.

Which door type—glass or solid—saves more energy?

This question always sparks interesting discussions because the answer isn't as straightforward as you might expect. Glass doors can actually save energy by minimizing door openings, since your staff can see what's inside without opening the unit. Every time someone opens a door to look around, cold air escapes and warm air rushes in.

However, solid doors provide slightly better insulation and come with a more affordable price tag. They're the better choice when maximum thermal efficiency is your top priority, or when budget constraints are a major factor in your decision.

The best choice depends on your specific operation. If you have staff frequently searching for items, glass doors will likely save energy and improve workflow efficiency. But if you're storing items that don't require frequent access, or if you're in an extremely hot environment, solid doors might be the smarter choice.

At American Mortuary Coolers, we help businesses nationwide evaluate these decisions based on their specific needs and operating environments. Whether you need a standard configuration or a custom solution, we're here to ensure you get the right reach in coolers for your operation.

Conclusion

Choosing the perfect reach in coolers for your business comes down to understanding your unique needs and matching them with the right features. From compact single-door units that fit snugly in small cafes to impressive triple-door configurations that handle the demands of busy restaurant kitchens, there's a solution for every operation.

The journey we've taken together through this guide shows just how much these hardworking units can do for your business. Whether you're keeping fresh ingredients at the perfect temperature for tomorrow's lunch rush or maintaining precise conditions for sensitive medical supplies, the right refrigeration becomes your silent business partner.

At American Mortuary Coolers, we've seen how the right equipment transforms operations. Based here in Tennessee with delivery reaching across all 48 contiguous states, we've built our reputation on understanding that one size definitely doesn't fit all. Our work with funeral homes, medical facilities, and commercial kitchens has taught us that reach in coolers need to work as hard as the people who depend on them.

Your path forward starts with these key decisions: First, measure your space carefully and calculate what capacity will serve both your current needs and future growth. Then choose between glass doors (great for reducing energy waste from unnecessary openings) and solid doors (better insulation and friendlier to your budget). Consider whether your hot kitchen environment calls for bottom-mount compressors or if your dusty workspace needs the protection of top-mount systems.

Don't forget the certifications that matter. NSF certification keeps health inspectors happy, while ENERGY STAR ratings keep your utility bills manageable. These aren't just nice-to-have features—they're investments in your operation's long-term success.

The math is simple: quality reach in coolers pay for themselves through lower energy costs, fewer emergency repairs, and the confidence that comes with reliable temperature control. When you're storing ingredients worth hundreds of dollars or materials that can't be replaced, cheap equipment becomes expensive fast.

Ready to find your perfect match? Our team knows these units inside and out, and we're here to help you steer the options without the sales pressure. We'll help you find equipment that delivers reliable performance for the next two decades.