The Definitive Guide to Comparing Cold Room Panels

Why Cold Room Panels Are Critical for Temperature-Controlled Storage

Cold room panels are insulated metal panels that form the walls, floors, and ceilings of temperature-controlled storage facilities. Here's what you need to know:

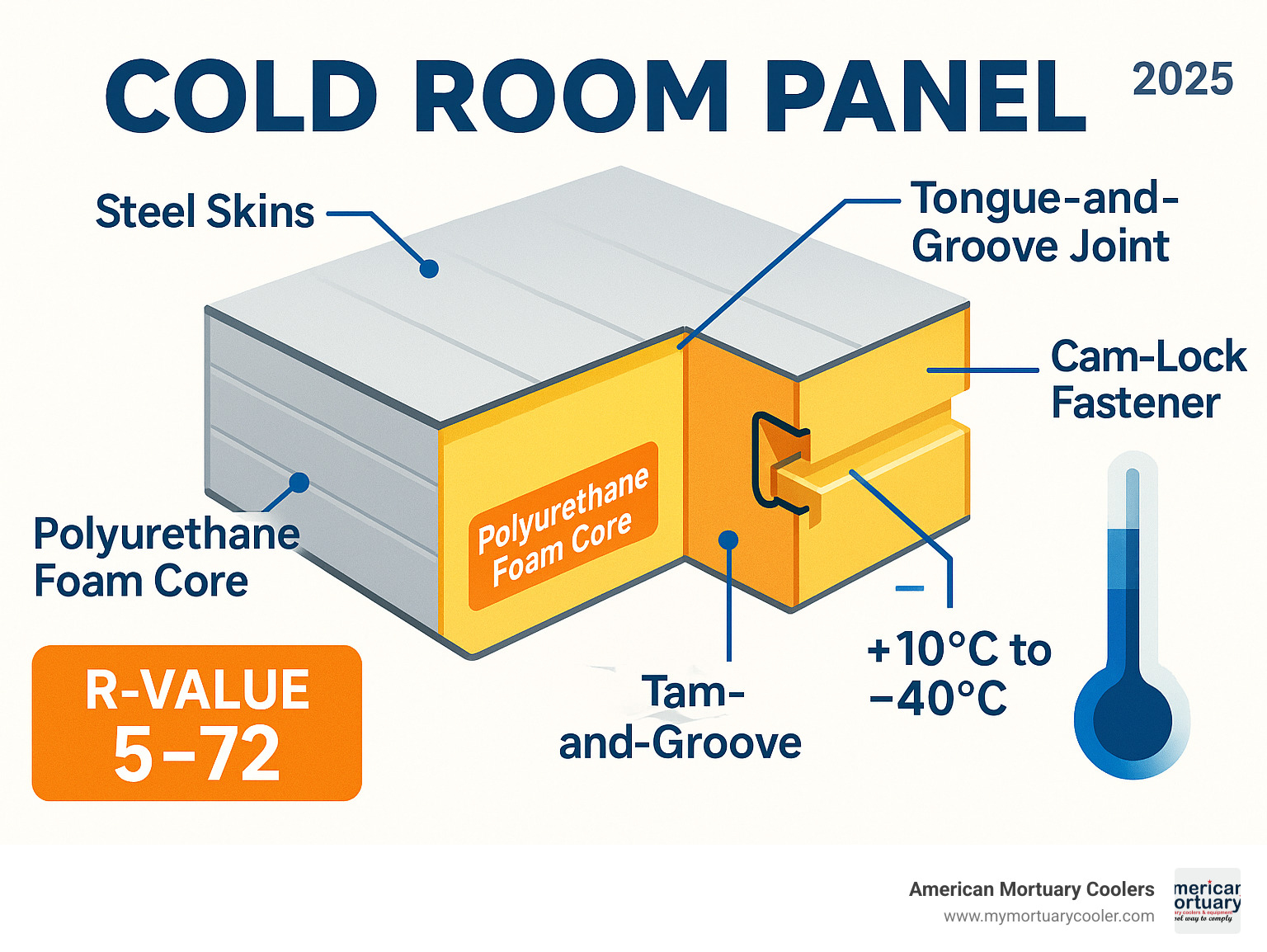

Key Components:

- Steel skins on both sides for durability and hygiene

- Foam insulation core (typically polyurethane or polyisocyanurate)

- Tongue-and-groove joints with cam-lock systems for airtight sealing

- R-values ranging from R-5 to R-72 depending on thickness and core material

Common Applications:

- Food processing and storage facilities

- Pharmaceutical cold chain storage

- Walk-in coolers and freezers

- Mortuary refrigeration systems

- Industrial cold storage warehouses

These panels maintain precise temperatures from +10°C down to -40°C while providing superior energy efficiency compared to traditional construction methods. The modular design allows for easy installation, future expansion, and relocation when needed.

Panel thickness typically ranges from 1 to 8 inches, with thicker panels providing higher R-values for extreme temperature applications. Modern panels achieve R-values up to 9.0 per inch at refrigeration temperatures, significantly reducing energy costs over the facility's lifetime.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes select the right cold room panel solutions for their specific needs. My focus on American craftsmanship and direct shipping has helped countless funeral directors streamline their operations while ensuring reliable temperature control for their facilities.

Know your cold room panel terms:

Cold Room Panel Basics: What You Need to Know

When you're dealing with temperature-controlled storage, cold room panels aren't just walls—they're the heart of your entire system. Think of them as the guardians standing between your valuable inventory and the unpredictable outside world.

These panels work around the clock to maintain precise temperatures, whether you're storing fresh produce at your local grocery store or maintaining dignity in funeral home facilities. Understanding how they work can save you thousands in energy costs and prevent costly temperature failures.

What is a cold room panel?

A cold room panel is essentially a high-tech sandwich that would make any engineer proud. The construction is beautifully simple yet incredibly effective: two tough steel skins wrapped around a foam core that's designed to stop heat transfer in its tracks.

Here's what makes up this thermal sandwich: Outer steel skins form the protective shell, usually made from pre-painted galvanized steel, stainless steel, or aluminum depending on your needs. The foam core does the heavy lifting when it comes to insulation—typically high-density polyurethane (PUR) or polyisocyanurate (PIR) foam that creates millions of tiny air pockets to block heat transfer.

The magic happens at the edges, where tongue-and-groove profiles with integrated gasket channels create airtight seals between panels. Modern fastening systems use cam-lock mechanisms or barrier strip connectors that snap together like precision-engineered puzzle pieces.

Most panels measure 42 inches wide and can stretch up to 20 feet long, though custom lengths up to 9,500mm are available from specialty manufacturers. This modular design means you can build anything from a compact mortuary cooler to a warehouse-sized cold storage facility using the same basic building blocks.

Primary Functions & Key Applications

Cold room panels do much more than just keep things cold. They create airtight barriers that prevent contamination, support heavy loads from shelving and refrigeration equipment, and provide surfaces that are easy to clean and sanitize—crucial for maintaining health standards.

At American Mortuary Coolers, we've watched these panels perform flawlessly across incredibly diverse applications. In food processing and storage, they handle everything from walk-in coolers maintaining fresh produce at +2°C to blast freezers preserving seafood at -40°C. The food industry demands panels that meet strict USDA standards while resisting bacterial growth.

Pharmaceutical applications require even more precision. Temperature-sensitive medications and vaccines need consistent storage conditions, often with monitoring systems built right into the panel structure. These installations can't afford temperature fluctuations that might compromise life-saving medications.

In mortuary storage—our area of expertise—panels maintain consistent temperatures while providing easy access for funeral directors. Families trust us to preserve their loved ones with dignity, and that trust depends on reliable temperature control that never fails.

Industrial logistics operations use panels engineered to support massive loads while maintaining thermal efficiency across warehouse-sized spaces. These installations often feature specialized floor panels designed to handle constant forklift traffic without compromising the thermal envelope.

The beauty of modern cold room panels lies in their incredible versatility. The same technology that keeps a restaurant's ingredients fresh can preserve pharmaceutical products or provide respectful storage in funeral homes—all while delivering the energy efficiency that keeps operating costs manageable.

Insulation Materials & Performance Metrics

Think of cold room panel insulation like choosing the right jacket for different weather. You wouldn't wear a light windbreaker in a blizzard, and you shouldn't use basic foam when you need serious temperature control. The insulation core is what does the heavy lifting in keeping your cold room actually cold.

After years of helping funeral homes choose the right equipment, I've learned that understanding insulation materials can save you thousands in energy costs over the life of your facility. Let's walk through what really matters.

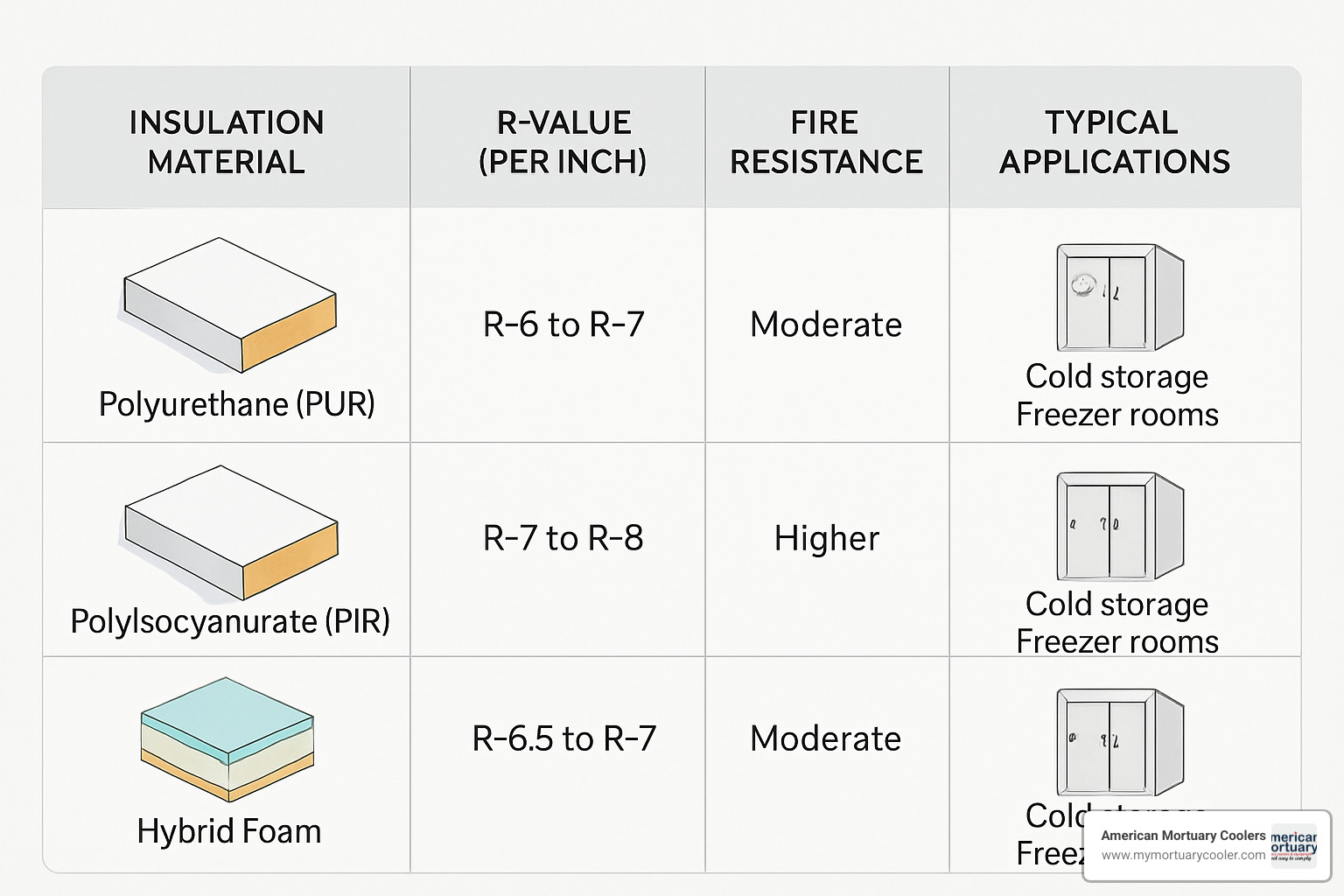

Comparing Core Materials

Polyurethane (PUR) foam is the reliable workhorse you'll find in most standard applications. With R-values between 5.0 and 7.1 per inch, it gets the job done at a reasonable price. Think of it as the dependable pickup truck of insulation materials. The downside? Fire performance isn't its strong suit, which can be a concern depending on your local codes.

Polyisocyanurate (PIR) foam steps things up a notch. Delivering 7.0 to 7.2 per inch R-value, PIR handles extreme temperatures better than PUR and offers superior fire resistance. This makes it our go-to recommendation for most mortuary applications where reliability matters most.

QuadCore technology represents the current gold standard in cold room panel insulation. This proprietary hybrid foam from Kingspan achieves an impressive 8.0 per inch at 75°F and up to 9.0 per inch at 35°F. That's 11% better thermal performance than PIR and up to 60% improvement over standard PUR. The fire resistance is also best-in-class, which helps with insurance requirements.

Expanded Polystyrene (EPS) serves as the budget option when performance requirements are more moderate. It's adequate for less demanding temperature control situations, but you get what you pay for in terms of long-term efficiency.

Rock wool excels where fire codes demand non-combustible insulation. With thermal conductivity of 0.044 W/m²·K and density of 100-110 kg/m³, it's incredibly fire-resistant but requires thicker panels to match the R-values of foam cores.

Need technical guidance on which core material suits your specific application? The experts at Technical Services can help you steer the options.

Standard Sizes, Thicknesses & R-Values

Cold room panels come in standardized dimensions that make installation straightforward while giving you flexibility for different applications. Most commercial panels measure 42 inches wide, though you'll find variations from 24 to 45⅜ inches depending on the manufacturer and intended use.

Thickness ranges from 1 to 8 inches, and this is where the magic happens for temperature control. Light commercial applications typically use 1 to 3 inches, providing R-values from R-5 to R-21. Standard cold storage bumps up to 4 to 6 inches for R-28 to R-54 performance. Extreme applications like blast freezers require 7 to 8 inches, delivering R-63 to R-72.

The relationship between thickness and performance isn't perfectly linear due to thermal bridging effects, but here's what you can expect in real-world applications:

| Thickness | PUR R-Value | PIR R-Value | QuadCore R-Value |

|---|---|---|---|

| 2 inches | R-10-14 | R-14-15 | R-16-18 |

| 4 inches | R-20-28 | R-28-31 | R-32-36 |

| 6 inches | R-30-42 | R-42-45 | R-48-54 |

| 8 inches | R-40-56 | R-56-60 | R-64-72 |

For most mortuary applications, 4-inch panels with PIR cores hit the sweet spot. They provide R-31 performance that easily maintains required temperatures while meeting fire safety requirements that funeral homes need for insurance compliance. The upfront investment in better insulation typically pays for itself within the first few years through reduced energy costs.

Length options are generous too, with standard panels available from 8 to 20 feet, extended lengths up to 30+ feet for warehouse applications, and custom lengths available with proper engineering support.

Selecting & Installing the Right Solution

After years of helping funeral homes across the country, I've learned that selecting the right cold room panel system isn't about finding the most expensive option—it's about matching the solution to your specific needs. Think of it like buying a car: you wouldn't purchase a heavy-duty truck just to drive to the grocery store, but you also wouldn't haul a trailer with a compact car.

The key is understanding what you're actually trying to accomplish. Are you maintaining a gentle refrigeration temperature for short-term storage, or do you need serious freezing power for extended preservation? The answer drives everything from panel thickness to installation complexity.

Choosing Panel Thickness for Specific Cold Room Panel Applications

Temperature requirements tell the whole story when it comes to cold room panel thickness. It's not complicated once you understand the basic principle: the bigger the temperature difference between inside and outside, the thicker your panels need to be.

Cooler applications running between +2°C to +10°C work beautifully with 4-inch panels offering R-28 to R-31 performance. This is your standard refrigeration zone—perfect for storing flowers, cosmetics, or short-term preservation needs. We typically recommend PIR cores because they handle moisture better than basic foam, and funeral homes deal with enough humidity challenges already.

Freezer applications operating from -15°C to -25°C need to step up to 4-6 inch panels with R-31 to R-45 performance. The extra thickness pays for itself through energy savings, especially if you're running the system 24/7. PIR or QuadCore materials really shine here because they maintain their insulating properties even when things get seriously cold.

Blast freezer applications hitting -30°C to -40°C require the heavy hitters: 6-8 inch panels with R-45 to R-72 performance. These installations aren't common in most funeral homes, but if you need this level of cooling, don't try to cut corners. QuadCore technology is worth the investment because the energy savings add up fast.

For mortuary storage applications, we typically work in the -2°C to +4°C range, which means 4-inch panels with R-31 performance handle the job perfectly. This balances energy efficiency with cost-effectiveness while maintaining the professional standards families expect and deserve.

Here's something most people don't consider: ambient heat load makes a huge difference. A cooler in Arizona needs thicker insulation than one in Minnesota. Similarly, if your panels face direct sunlight or sit next to heat-generating equipment, you'll need to upgrade your specifications accordingly.

Joint Systems & Airtight Installation

The best insulation in the world won't help if your cold room panels leak air like a screen door. I've seen too many installations fail because someone skimped on the sealing system or rushed through the installation process.

Cam-lock systems use mechanical fasteners with eccentric cams that pull panels tightly together while compressing gaskets for airtight seals. Installation only requires a standard wrench, and the system allows for future disassembly if you need to relocate. These work best for permanent installations where you want maximum structural integrity.

Tongue-and-groove joints create natural alignment and sealing surfaces through interlocking profiles. When you combine them with quality EPDM gaskets, these systems provide excellent air sealing with faster installation times. This approach works particularly well for modular installations that might need future expansion.

EPDM gaskets are the unsung heroes of proper panel installation. These rubber seals compress between panel edges to prevent air infiltration. Quality gaskets feature double ridges that create backup sealing surfaces—because redundancy matters when you're protecting someone's loved one.

Getting gasket compression right is critical. Too little compression allows air leaks that waste energy and compromise temperature control. Too much compression damages the gasket or prevents proper panel alignment. It's a Goldilocks situation—you need it just right.

For detailed installation guidance, check out our comprehensive guide on How to Install a Walk-In Cooler the Right Way. We've refined this process through thousands of installations across our service regions, and the guide covers everything we've learned along the way.

Accessories & Structural Considerations

Cold room panels don't work alone—they're part of a complete system that includes doors, structural supports, and various accessories that ensure everything functions properly for years to come.

Door integration requires careful planning because doors create stress points in your panel system. Proper door framing needs reinforced panels or structural framing to handle the repeated stress of opening and closing. Door size affects panel layout, so planning the door location during initial design prevents costly modifications later.

Health profiles become essential in applications requiring easy cleaning. These special PVC trim pieces eliminate hard-to-clean crevices at panel junctions. While not always necessary for basic mortuary storage, they're crucial if you're dealing with embalming areas or other spaces requiring frequent sanitization.

Shelving and equipment loads add complexity because panels must support more than just their own weight. Standard panels handle typical shelving systems just fine, but heavy refrigeration equipment may require additional structural support or reinforced panel specifications. It's better to over-engineer this aspect than find load limits the hard way.

Trim and finishing protect panel cores from moisture infiltration while providing a professional appearance. Interior and exterior corners require special attention to maintain thermal continuity and prevent thermal bridging—those spots where heat sneaks through and undermines your insulation performance.

For more insights into proper design considerations, our guide on Everything You Need to Know About Walk-In Cooler Panels covers the technical details that make the difference between a good installation and a great one.

Innovations, Certifications & Future Trends

The cold room panel industry isn't standing still—and that's good news for anyone who needs reliable temperature control. From our vantage point serving funeral homes across the country, we've watched this technology evolve from basic insulated boxes to sophisticated systems that practically think for themselves.

Latest Technology in Cold Room Panels

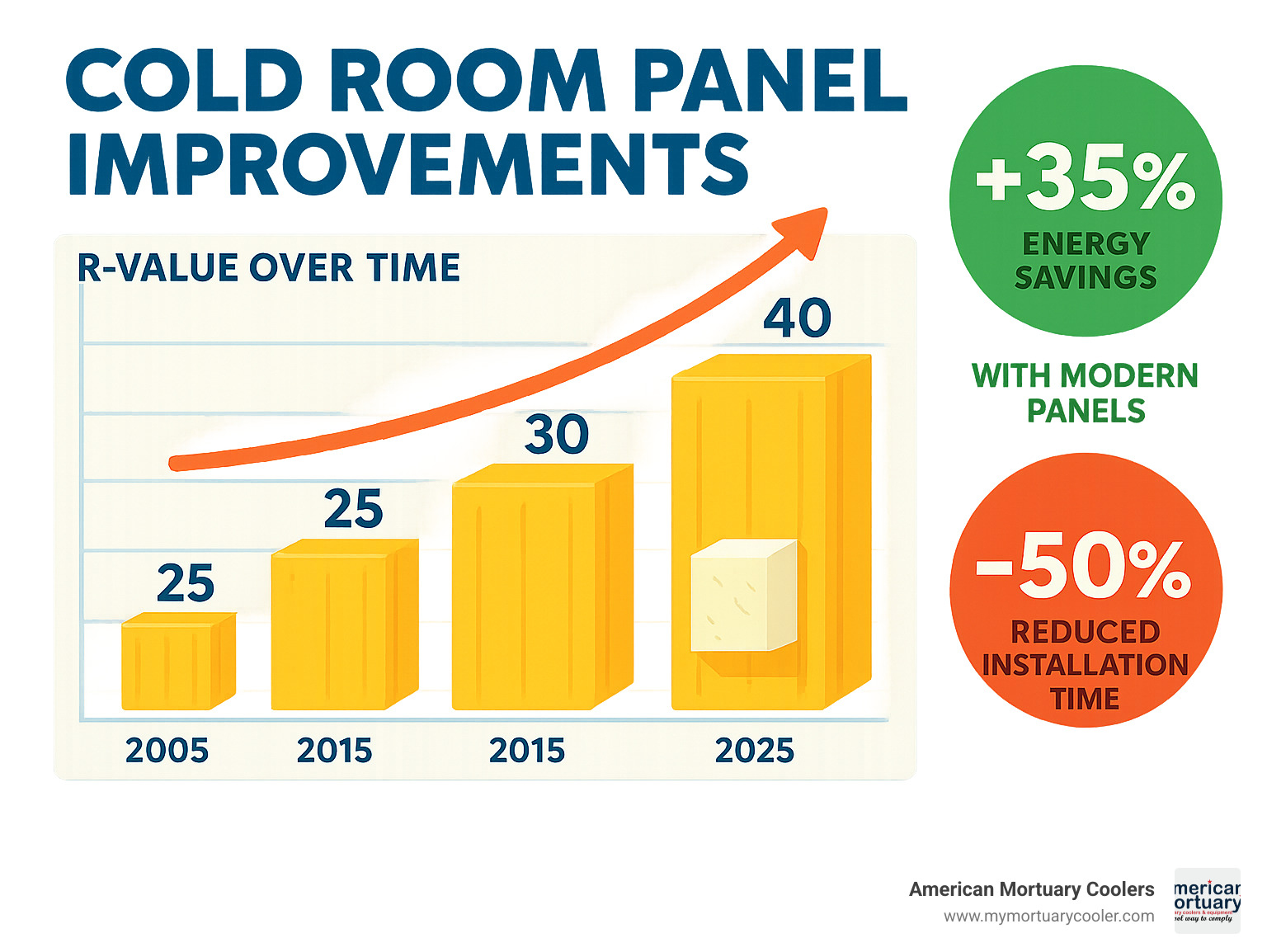

QuadCore technology has already raised the bar with R-values hitting 9.0 per inch, but manufacturers aren't stopping there. The next generation of hybrid foam cores promises to break the R-10 barrier while maintaining the fire resistance that keeps insurance companies happy and building inspectors satisfied.

Antimicrobial coatings represent a game-changer for our industry. These surfaces actively fight bacterial growth, which matters tremendously when you're maintaining the dignity and respect that families deserve during their most difficult times. The technology works around the clock, providing an extra layer of protection beyond regular cleaning protocols.

Smart monitoring systems are becoming standard rather than luxury add-ons. Modern cold room panels can now integrate IoT sensors that track temperature, humidity, and even structural integrity in real-time. Imagine getting a text alert if your cooler starts running warm at 2 AM—that's the kind of peace of mind that helps funeral directors sleep better.

Rapid-lock fastening systems are cutting installation time in half compared to traditional cam-locks. For large installations, this translates to significant labor savings and faster project completion. The systems maintain the same structural integrity while making future modifications much simpler.

Modular expansion capabilities have evolved to the point where adding space feels almost like playing with sophisticated building blocks. Growing funeral homes can start with basic capacity and expand seamlessly as their needs change, without rebuilding from scratch.

Key Standards & Certifications to Watch

Understanding certifications might seem like alphabet soup, but these standards directly impact your cold room panel performance and legal compliance. USDA approval remains essential for any facility handling food products, ensuring surfaces meet sanitary requirements. The familiar white stucco finish isn't just for looks—it provides easy cleaning and visual inspection capabilities that inspectors appreciate.

ASTM E84 (UL 723) fire safety standards measure how quickly flames spread and how much smoke develops. Meeting these requirements isn't just good practice—it's often required by local building codes and can significantly impact insurance premiums. We've seen funeral homes face costly retrofits when panels don't meet current fire safety standards.

FM 4880 certification from Factory Mutual indicates panels can handle serious fire resistance requirements. This certification often determines whether your insurance company considers your facility properly protected. For large installations, this approval can make or break project feasibility.

NSF 7 certification ensures panels meet hygiene requirements for commercial applications. While primarily focused on food service, these standards increasingly apply to mortuary facilities where cleanliness and sanitation are paramount concerns.

ISO 9001 quality management certification tells you the manufacturer maintains consistent production standards and continuously improves their processes. This matters for long-term reliability—the last thing you want is panel failure during a busy period.

The Cold Storage Market insights show steady growth in technology adoption across all temperature-controlled storage sectors. Sustainability initiatives are driving development of more energy-efficient panels and environmentally responsible manufacturing processes.

As the industry moves forward, we expect to see continued integration of smart technologies, improved thermal performance, and manufacturing processes that reduce environmental impact while maintaining the reliability that funeral homes depend on for serving families with dignity and respect.

Frequently Asked Questions about Cold Room Panels

How long do cold room panels last?

Here's the honest truth about cold room panel lifespan: quality panels should serve you faithfully for 20 to 30 years, and we've seen some well-maintained installations still going strong after 40 years. That's a testament to both good manufacturing and proper care.

The secret to longevity lies in a few key factors. Core material quality makes a huge difference—PIR and QuadCore foams maintain their insulating punch far longer than basic PUR options. Think of it like buying a good winter coat versus a cheap one; both keep you warm initially, but only the quality coat still works after years of use.

Steel skin protection is equally important. Pre-painted finishes resist corrosion much better than field-applied coatings that might chip or wear over time. We've seen panels with quality factory finishes look nearly new after decades of service.

Installation quality can make or break your investment. Proper sealing prevents moisture from sneaking in and degrading the foam core—moisture is the enemy of insulation performance. When we install panels correctly the first time, they tend to last their full expected lifespan.

In our mortuary applications, we typically see panels reaching their full lifespan because funeral homes maintain controlled environments and follow professional maintenance practices. The dignity of the families we serve demands nothing less than reliable, long-lasting equipment.

Do I need an insulated floor panel in my walk-in?

This question comes up constantly, and the answer depends on your specific situation. Let me walk you through the decision-making process we use with our clients.

Insulated floors become essential when you're installing over unheated spaces like basements or crawl spaces. Ground contact installations in areas with seasonal frost also need floor insulation to prevent ground freeze from affecting your cooler's performance. For extreme temperature applications like blast freezers, insulated floors aren't optional—they're mandatory for proper operation.

You might skip insulated floors when installing over heated building space where the floor below stays warm year-round. Moderate temperature applications between +2°C to +10°C can sometimes get away without floor insulation, especially when budget constraints require prioritizing wall and ceiling insulation.

For our mortuary applications, we typically recommend insulated floors because they provide thermal stability that ensures consistent temperatures regardless of what's happening in the building's foundation or basement. When families trust you with their loved ones, that consistency matters more than saving a few dollars upfront.

Can panels be relocated or expanded later?

One of the most beautiful aspects of modern cold room panels is their flexibility for future changes. Life happens, businesses grow, and sometimes you need to move or expand your facility.

Expansion planning should start during your initial design phase. We always recommend thinking about where you might want to expand and ensuring your panel layout accommodates future growth. Keeping a few spare panels in storage can save you headaches later when you need to modify your setup.

Relocation is absolutely possible with properly installed cam-lock systems. These mechanical fasteners allow complete disassembly and relocation with minimal panel damage. We've successfully moved entire mortuary cooler installations when funeral homes expand or relocate their facilities.

The key is using cam-lock systems rather than permanent adhesive installations if you think relocation might be in your future. Gaskets may need replacement during disassembly, and we always recommend professional installation to maintain warranty coverage, but the modular nature of quality panels makes them surprisingly portable.

We've helped funeral homes grow from small operations to large facilities by expanding their original panel installations, and we've moved complete systems when families relocate their businesses. The flexibility of modular cold room panels provides real practical value that goes far beyond their initial installation.

Conclusion

Making the right cold room panel choice doesn't have to feel overwhelming once you understand the basics. Whether you're installing a single mortuary cooler or planning a massive cold storage warehouse, the fundamentals remain the same—proper insulation, quality joints, and professional installation make all the difference.

We've walked alongside countless funeral directors through this decision-making process, from the mountains of Tennessee to the busy funeral homes of New York and California. What we've learned is that investing in quality cold room panels upfront saves headaches and money down the road. Nobody wants to explain to a grieving family why their loved one couldn't be properly preserved because of equipment failure.

The numbers speak for themselves. Modern panels with PIR or QuadCore insulation can slash your energy bills by 30-50% compared to older systems. That's real money back in your pocket every month, money that adds up to thousands over the panel's 20-30 year lifespan. Plus, you get the peace of mind that comes with reliable temperature control—something you simply can't put a price on in our industry.

The technology keeps getting better too. Smart monitoring systems now alert you to potential problems before they become expensive emergencies. Antimicrobial coatings help maintain the hygienic standards that families expect and deserve. Even the installation process has improved, with new fastening systems that cut setup time in half.

For funeral directors ready to take the next step, our comprehensive guide How to Master Walk-In Cooler Design in 5 Simple Steps walks you through the entire process from initial planning to final commissioning. It's the same systematic approach we've used successfully across all 48 states we serve.

Cold room panels are just one piece of the puzzle. The refrigeration equipment, door systems, controls, and accessories all need to work together seamlessly. That's where having an experienced partner makes the difference. Our team provides technical consultation and connects you with Technical Services insights to ensure every component of your system works perfectly together.

The funeral industry continues evolving, and so does cold storage technology. By understanding these fundamentals, you're prepared to evaluate new innovations and make smart decisions that will serve your families well for decades to come. After all, that's what this business is really about—serving families with dignity, respect, and reliability when they need it most.