The Definitive Guide to Buying the Best Aluminum Jacket

The Ultimate Guide to Aluminum Jacketing for Industrial Applications

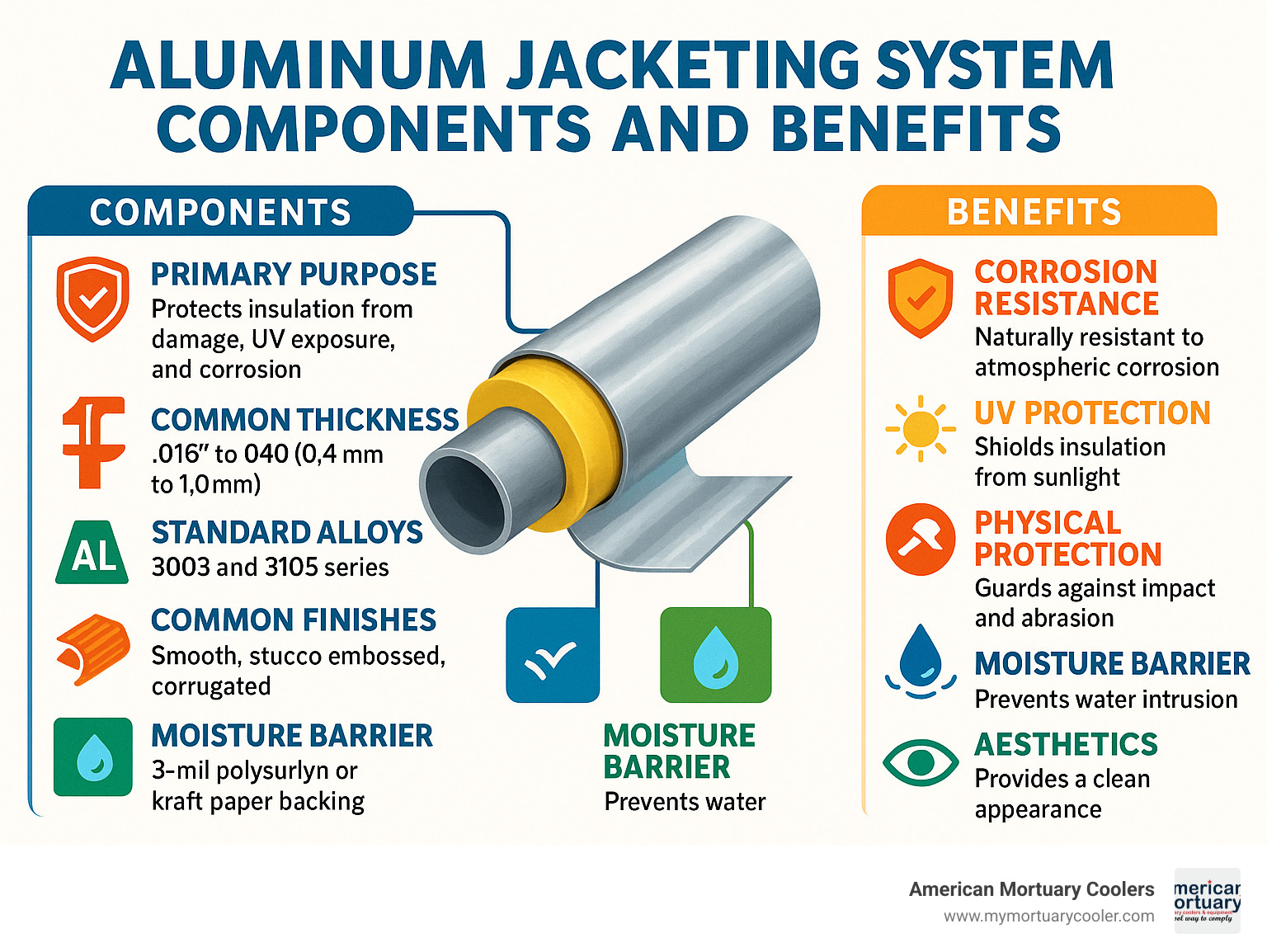

Aluminum jacketing is a protective outer covering designed for mechanical insulation systems, including pipes, vessels, tanks, and equipment. It provides crucial protection against physical damage, UV exposure, corrosive environments, and water intrusion.

If you're looking for information about aluminum jacketing, here's what you need to know:

| Aspect | Details |

|---|---|

| Primary Purpose | Protects insulation from physical damage, UV exposure, water intrusion, and corrosion |

| Common Thickness | .016" (0.4mm) to .040" (1.0mm) depending on application |

| Standard Alloys | 3003 and 3105 series aluminum (ASTM B-209 compliant) |

| Common Finishes | Smooth, stucco embossed, corrugated |

| Moisture Barrier | 3-mil polysurlyn or kraft paper backing to prevent corrosion |

| Applications | Industrial piping, HVAC ducts, vessels, tanks, equipment |

Aluminum jacketing serves as the industry standard for protecting insulation systems in industrial, commercial, and marine environments. Its lightweight yet durable properties make it ideal for both indoor and outdoor applications where protection from the elements is essential.

The primary benefit of aluminum jacketing is its ability to prevent corrosion under insulation (CUI), a serious problem that can compromise system integrity and efficiency. When properly installed with a moisture barrier, aluminum jacketing creates a weatherproof seal that extends the life of both the insulation and the underlying pipe or vessel.

Key features that make aluminum jacketing the preferred choice:

- Corrosion Resistance: Naturally resistant to atmospheric corrosion

- UV Protection: Shields insulation from degradation caused by sunlight exposure

- Physical Protection: Guards against impact damage and abrasion

- Moisture Barrier: Prevents water intrusion and subsequent insulation failure

- Aesthetics: Provides a clean, professional appearance for exposed systems

For industrial applications, aluminum jacketing typically comes in thicknesses ranging from .016" (recommended for pipes up to 24" diameter) to .040" (for heavy-duty applications). The most common alloys used are 3003 and 3105, which offer an optimal balance of strength, formability, and corrosion resistance.

I'm Mortuary Cooler, a national supplier of mortuary refrigeration equipment with experience in thermal insulation systems including aluminum jacket applications for temperature-controlled environments. My background in insulation materials has taught me how proper aluminum jacketing can significantly extend equipment lifespan while improving energy efficiency.

Aluminum jacket terms explained:

Understanding Aluminum Jacketing Basics

The story of aluminum jacketing is a fascinating one that's evolved right alongside modern industrial insulation. What began as a lightweight alternative to heavier metal claddings has become the gold standard for protecting insulation systems in countless industries.

Think of aluminum jacketing as the raincoat for your insulation - it creates a protective weather barrier that shields everything underneath from rain, snow, UV rays, and physical damage. This isn't just any metal sheet, though. To ensure quality and consistency, proper aluminum jacketing must meet specific industry standards including ASTM B209 (for the aluminum material itself), ASTM C1729 (for jacketing systems), and ASTM C585 (which governs dimensional requirements).

Most aluminum jacketing you'll encounter is crafted from either 3003 or 3105 alloys with H14 or H12 temper designations. Don't worry about the technical jargon - these specifications simply ensure your jacketing has the perfect balance of strength, flexibility, and corrosion resistance. The typical thickness ranges from .016" to .040", with .016" being the most common choice for everyday applications. You'll generally find it in widths of 36" or 48" and roll lengths between 50' and 300'.

One element you should never overlook is the moisture barrier - typically made from either polysurlyn or kraft paper. This layer is absolutely crucial for preventing galvanic corrosion between the aluminum and any underlying metal pipes or vessels.

What Is an Aluminum Jacket and Why Use It?

An aluminum jacket isn't just a metal wrapper - it's a specially engineered protective system designed specifically for insulation applications. Unlike standard sheet metal, these jackets have been carefully designed with the right thickness, flexibility, and protective properties to shield insulation from harm.

Why should you consider using an aluminum jacket? The benefits are substantial:

First, it provides excellent mechanical protection, creating a durable shield against physical impacts that might otherwise damage your insulation. When properly installed with a moisture barrier, an aluminum jacket also helps prevent Corrosion Under Insulation (CUI) - a serious and costly problem in many industrial settings.

Unlike many insulation materials that quickly degrade in sunlight, aluminum naturally stands up to UV exposure, making it perfect for outdoor applications. Its impact resistance protects softer insulation materials from punctures and compression damage. Plus, aluminum jacketing performs beautifully across temperatures ranging from cryogenic applications all the way up to systems running at 400°F (204°C).

Moisture Barriers: Polysurlyn vs. Kraft Paper

The unsung hero of any aluminum jacket system is definitely the moisture barrier. This thin but mighty layer on the interior surface prevents moisture from getting trapped between the jacket and pipe - a situation that would rapidly accelerate corrosion.

You'll typically encounter two main types of moisture barriers:

The premium option is the Polysurlyn Moisture Barrier - a 3-mil polyfilm that's heat-laminated to the interior surface of the aluminum. The heat lamination creates a strong bond that won't separate during installation or service. For most industrial applications, especially in humid or wet environments, polysurlyn is the gold standard. According to industry Data Sheets, this 3-mil polyfilm is now the preferred choice for quality aluminum jacketing products.

The more traditional and economical option is Kraft Paper - a treated paper backing adhered to the aluminum. While it costs less upfront, kraft paper typically offers less robust protection and may deteriorate more quickly in challenging environments.

Either way, these barriers serve a critical purpose: preventing galvanic corrosion that occurs when dissimilar metals (like aluminum and steel) make contact in moist conditions. Without this protective layer, both your jacketing and the underlying pipe could face a significantly shortened lifespan.

Standard Dimensions & When to Upsize

Choosing the right thickness for your aluminum jacket is a bit like picking the right coat for the weather - you need enough protection without going overboard. Fortunately, industry standards provide clear guidance:

For most applications, .016" (0.4mm) thickness works perfectly for pipelines up to 24" in outside diameter (including insulation). As your pipes get larger, consider stepping up to .020" (0.5mm) for lines up to 36" in diameter. Need extra strength for demanding environments? That's when .024" (0.6mm) comes into play. The heaviest options - .032" to .040" (0.8-1.0mm) - are reserved for heavy wear areas, large vessels, or custom fabrication needs.

When it comes to format, you have two main choices: roll jacketing or precut sections. Roll jacketing offers more economy for larger projects and flexibility in cutting lengths, but requires more field work. Precut jacketing, which typically comes in standard 3-ft sections to match common insulation lengths, reduces field cutting and ensures consistent sizing.

Don't try to guess the right size - diameter charts are essential tools that cross-reference pipe size with insulation thickness to determine the appropriate jacketing dimension. For example, a 3" pipe with 1" insulation would typically need a #6 aluminum jacket, while that same pipe with 1.5" insulation would call for a #7 jacket.

At American Mortuary Coolers, we understand how proper insulation and jacketing contribute to the efficiency and longevity of temperature-controlled environments - knowledge that directly translates to our work with mortuary refrigeration systems across the country.

Choosing the Right Aluminum Jacket: Alloys, Finishes & Sizes

When it comes to selecting the perfect aluminum jacket for your insulation system, you're not just picking a metal covering—you're choosing a protective shield that needs to perform in specific environments for years to come. Let's break down the key factors that will help you make the right choice.

Think of aluminum alloys as recipes—each with slightly different ingredients that create unique properties. For jacketing applications, you'll typically encounter:

1100 Series aluminum contains at least 99.0% pure aluminum, giving it excellent corrosion resistance, though it's not as strong as other options. Its cousin, the 1200 Series, offers similar properties with slight variations in trace elements.

The workhorse of industrial applications is the 3003 Series, which includes manganese for added strength while maintaining good corrosion resistance. This is why it's the most commonly used alloy you'll see in the field.

For applications needing extra durability, the 3105 Series includes both manganese and magnesium, creating a jacket with improved strength and excellent formability.

The finish you choose affects both how your aluminum jacket performs and how it looks. A basic mill finish gives you that natural metallic appearance, while a stucco embossed texture cleverly hides scratches and minor damage—perfect for high-traffic areas where bumps and scrapes are inevitable.

For larger applications, corrugated finishes add rigidity and help accommodate the natural expansion and contraction that occurs with temperature changes. When covering massive vessels, deep corrugated finishes provide the structural strength needed to span greater distances.

Some specialized finishes include painted jackets for color-coding or aesthetics, clear-coated options for improved corrosion protection, and Alclad material that sandwiches a stronger core between layers of highly corrosion-resistant aluminum.

Alloys & Tempers Explained

Understanding alloys and tempers might seem technical, but it's actually quite straightforward. Think of the alloy as the recipe and the temper as how the metal has been treated to achieve certain properties.

The 3003 alloy is the trusted standard in the industry. With about 1.2% manganese mixed in, it hits that sweet spot between being strong enough to protect your insulation while remaining flexible enough to work with during installation. It's like the all-purpose flour of the aluminum jacket world—reliable and suitable for most applications.

When you need something with a bit more muscle, the 3105 alloy steps up to the plate. By adding magnesium to the mix, manufacturers create a stronger jacket that still bends where you need it to. This is particularly valuable when your system faces more physical stress or needs additional structural integrity.

For environments where corrosion is your biggest enemy (think coastal installations or chemical processing facilities), Alclad material offers the best defense. This clever sandwich of materials combines a core of strong 3004 alloy with outer layers of ultra-pure 7072 alloy. The result? Superior corrosion resistance without sacrificing strength—the best of both worlds.

The temper designation tells you how the metal has been processed:

H14 means the aluminum has been strain-hardened to about half its maximum hardness. This creates a material with good strength that can still be worked with during installation.

H32 indicates the metal has been strain-hardened and then stabilized, resulting in a balance of strength and formability that makes it ideal for creating complex shapes like fitting covers.

For harsh marine environments where salt spray is a constant threat, Alclad or 3105 alloys will serve you best. If you're dealing with high-temperature applications, 3003-H14 offers better strength retention when things heat up. And when you need to wrap your aluminum jacket around complex shapes, 3003-H32 gives you the flexibility to make it happen.

Finish Options for Varying Environments

The finish on your aluminum jacket isn't just about looks—it's a practical choice that affects performance in different environments.

A smooth finish gives you that clean, reflective surface that's easy to wipe down and maintain. It's the simplest option and works beautifully for indoor applications or anywhere appearance matters. The downside? It shows every scratch and dent, which can make your installation look worn before its time.

Most contractors prefer stucco embossed finishes for outdoor and industrial applications. That distinctive textured pattern isn't just decorative—it's functional. The raised pattern cleverly disguises minor scratches and dents, helping your installation look newer longer. It also adds rigidity to the material without increasing thickness or weight, and reduces glare from sunlight. If you're installing in an area with foot traffic or occasional impacts, stucco embossing is your friend.

For larger pipes and vessels, 3/16" corrugated finishes offer significant advantages. The wavy pattern dramatically increases rigidity, allowing the jacket to span greater distances without sagging. These corrugations also create natural channels for water runoff and accommodate thermal expansion and contraction—a smart choice for outdoor installations subject to changing weather conditions.

Box rib finishes feature rectangular raised sections that provide maximum rigidity. They're primarily used on large vessels and flat surfaces where structural support is needed over spans. The distinctive pattern also creates an attractive industrial appearance that many architects and designers appreciate.

When you're jacketing truly massive vessels (over 8 feet in diameter), deep corrugated finishes become essential. Available in 1.25" × 0.25" or 2.5" × 0.5" profiles, these deep waves provide the structural integrity needed to prevent sagging and resist wind loads. They follow standard sine-wave patterns for consistent performance and create a self-supporting structure that protects your insulation system for decades.

Your environment should guide your finish selection. In coastal areas, stucco embossed finishes tend to maintain their appearance better despite salt exposure. For food processing facilities where regular cleaning is required, smooth finishes might be preferred. And in areas with extreme temperature fluctuations, corrugated finishes help your system expand and contract gracefully with the weather.

Sizing Your Aluminum Jacket Correctly

Getting the size right is crucial for your aluminum jacket installation. Too small, and you'll struggle to secure it properly; too large, and you'll create gaps where moisture can penetrate.

The sizing process takes into account three key measurements:

First, consider your pipe size—the nominal diameter of the pipe being insulated. Next, factor in your insulation thickness—how much insulating material surrounds the pipe. Together, these give you the total outside diameter (OD) of your insulated pipe system.

Thankfully, you don't need to do complex math in the field. Jacketing charts make this process simple by cross-referencing pipe size with insulation thickness. For example, if you're working with a 3" pipe wrapped in 1" of insulation, you'll need a #6 aluminum jacket. Bump that insulation up to 1.5" thick, and you'll need to move up to a #7 jacket.

When ordering, you'll also need to specify your lap preference:

A 2" lap is standard for smaller diameter pipes, providing adequate overlap for a secure closure.

For larger diameters or installations where extra weather protection is needed, a 3" lap gives you additional sealing surface.

Don't overlook edge treatment options. Hemmed edges cost a bit more but provide significant benefits: they're safer to handle (no sharp edges to cut installers), add rigidity to the jacket, and create a cleaner finished appearance. Raw edges save money but require careful handling during installation.

Standard aluminum jacket sizing differs from what you'll need for elbow covers and other fittings. These specialty pieces must be ordered separately using their own sizing systems.

For unusual applications where standard charts don't apply, you can calculate the circumference yourself: multiply π (3.14159) by the sum of your pipe's outside diameter plus twice your insulation thickness, then add your desired lap allowance.

Taking the time to size your aluminum jacket correctly ensures a proper fit, adequate overlap at seams, and ultimately, a protective system that will perform as expected for years to come.

Installation & Accessories for an Aluminum Jacket System

Installing an aluminum jacket system isn't just about having the right materials—it's about putting them together correctly. Even the highest quality jacketing won't protect your insulation if it's installed improperly. Think of it like putting together a puzzle where all the pieces need to fit just right to create a weatherproof shield for your insulation.

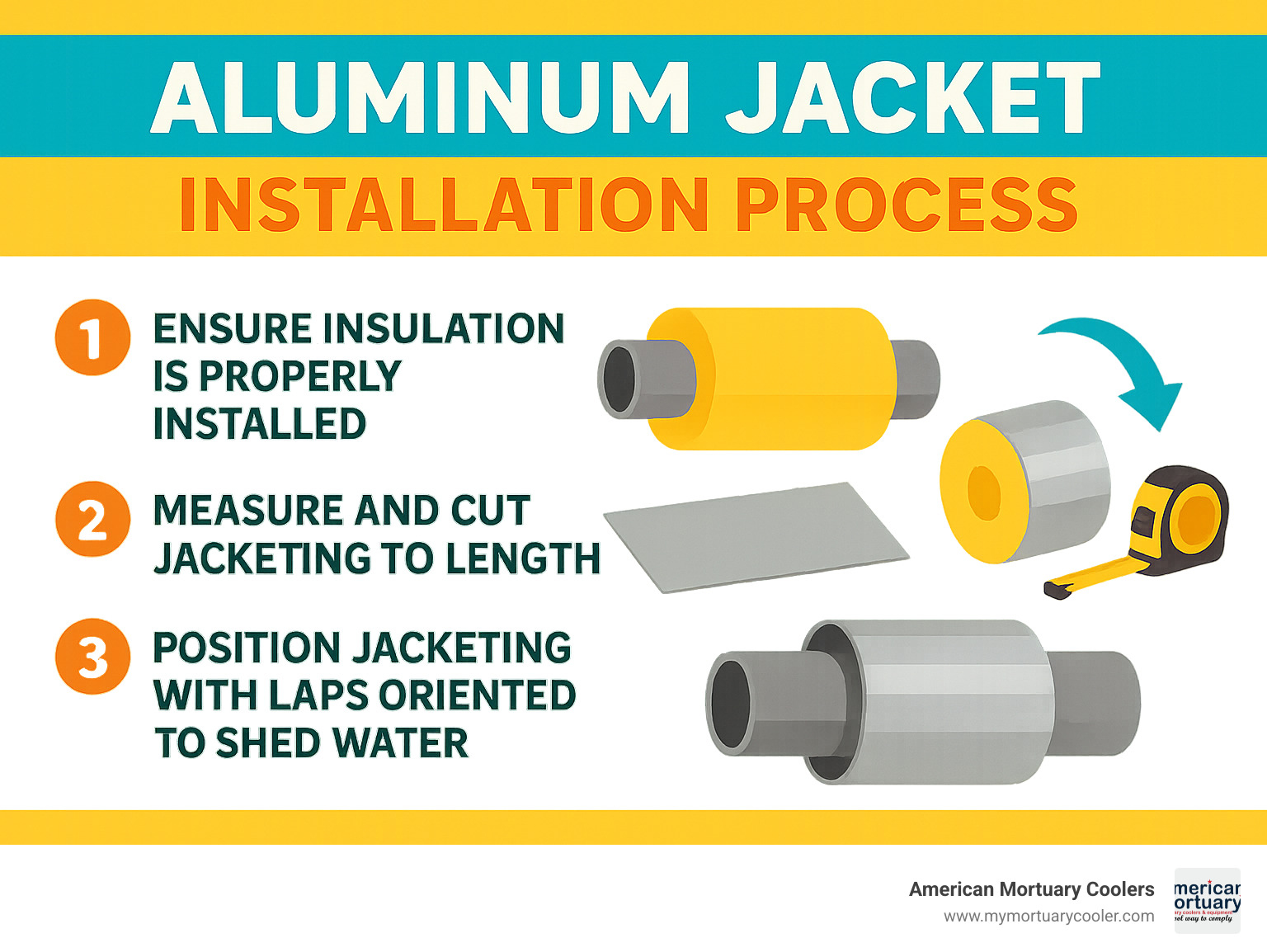

The basic installation process follows a logical sequence that starts with preparation and ends with a complete protective system. First, make sure your insulation is properly installed, secured, and completely dry—moisture trapped under jacketing is a recipe for disaster. Next, carefully measure and cut your jacketing to the right length (especially important if you're using roll stock).

When positioning the jacketing, water should always flow away from seams—just like shingles on a roof. Secure everything with appropriate fasteners like fabstraps, wing seals, or screws, making sure they're tight enough to hold but not so tight they damage the material. A good weatherproof caulking at all seams completes the basic installation, followed by fitting covers for those tricky elbows, tees, and terminations.

The accessories you choose can make or break your aluminum jacket system. Fabstraps (those stainless steel or aluminum bands) are like the belts that hold everything together. Wing seals lock those bands in place, while expansion springs allow for natural movement as temperatures change. Don't forget quality silicone caulk—it's the unsung hero that creates those critical weatherproof seals. Many installers also appreciate safety hems (factory-folded edges) that prevent nasty cuts during handling.

You'll need the right tools in your toolbox too. Good metal snips make clean cuts, proper banding tools ensure fabstraps are tensioned correctly, and a quality caulking gun helps apply sealant evenly. Simple measuring tools prevent wasteful mistakes and ensure precise fitting.

At American Mortuary Coolers, we've learned through experience that proper insulation jacketing directly impacts the energy efficiency of our cooling systems. When your mortuary cooler has properly installed jacketing, it maintains optimal temperature with less energy—saving you money while ensuring reliable performance.

Straight Runs, Elbows, Tees & End Caps

While straight sections make up most insulation systems, it's often the fittings and transitions that cause the most headaches—and leaks—if not properly protected. That's why specialized aluminum jacket components for these areas are worth their weight in gold.

Preformed elbows take the guesswork out of covering those tricky 45° and 90° bends. They typically come as two-piece "half shells" that join at the throat and back, manufactured to ASTM C450 standards to ensure they'll fit just right. The best ones feature clever weather seals at the joints to keep water out. They're available in numbered sizes that match your pipe and insulation combinations, making selection straightforward.

Pressed tees are another time-saver that eliminate frustrating field fabrication at pipe junctions. Factory-formed for consistent fit and appearance, these components include alignment features that help ensure proper positioning. The superior weather sealing at these complex junctions means fewer callbacks and longer system life.

Don't forget about end caps—those critical termination points where water can easily find its way in. Available in flat, beveled, or contoured designs, quality end caps create weather-tight seals at system endpoints. Many include small drain holes to prevent condensation buildup inside—a thoughtful detail that prevents problems down the road.

For larger vessels (over 8' in diameter), deep corrugated sheets provide the structural rigidity needed over expansive curved surfaces. Available in 1.25" × 0.25" or 2.5" × 0.5" corrugation profiles, these sheets are typically fastened with self-drilling screws rather than banding. They accommodate thermal expansion while maintaining solid weather protection—essential for large tanks and equipment.

Using these factory-fabricated components instead of trying to field-fabricate everything saves time, reduces frustration, and results in a more reliable system. They're designed to work together seamlessly, creating an aluminum jacket system that provides complete protection from end to end.

Essential Tools & Consumables

Having the right tools and supplies on hand makes installing an aluminum jacket system much smoother—like having the right ingredients before starting a recipe. These items not only speed up installation but also ensure your jacketing will perform well for years to come.

Fastening systems keep everything secure and in place. Fabstraps (those stainless steel or aluminum bands) come in different widths—typically ½" or ¾"—to match your project needs. If you're looking to save time, QuickStraps® with their pre-formed design and built-in locking mechanisms can be a real time-saver. Wing seals make securing banding simpler without needing specialized crimping tools, while professional banding tools help achieve just the right tension for a secure fit. For large vessels and tanks, self-drilling screws often work better than banding.

Sealing materials are your first line of defense against moisture. Aluminum-colored silicone caulk creates weather-tight seals while blending in visually with your jacketing. Butyl tape works well for sealing overlaps in horizontal applications, while specialized expansion joint compounds allow for movement without compromising weather protection. In critical areas, vapor barrier mastic ensures those all-important vapor-tight seals.

Don't overlook safety equipment—those sharp metal edges aren't forgiving! Cut-resistant gloves protect your hands, safety glasses shield your eyes from metal particles during cutting, and appropriate protective clothing prevents painful cuts and scrapes. Safety isn't just about avoiding injuries; it also leads to better quality work when you're not worried about getting hurt.

Basic installation tools round out your toolkit. Quality aviation snips make cutting straight sections and simple curves easier, while folding tools help create field-formed hems and bends when needed. A good measuring tape and marking tools ensure accurate cutting and fitting, preventing wasteful mistakes.

At American Mortuary Coolers, we've installed systems across diverse climates, from our New York facility to our Los Angeles location. This experience has taught us that proper tools and installation techniques directly impact cooling performance—especially important when maintaining precise temperatures is essential, as it is in mortuary refrigeration.

Field Tips to Prevent Leaks & CUI

The main enemy of any insulation system is water intrusion, which leads to the dreaded Corrosion Under Insulation (CUI). These battle-tested techniques will help keep your aluminum jacket system dry and your pipes protected for years to come.

Lap orientation is your first line of defense against water. Think of your jacketing like roof shingles—water should always flow over the seams, not into them. On horizontal piping, always orient laps downward so water naturally sheds away. For vertical piping, make sure the upper section overlaps the lower section (not the other way around). Maintain at least 2" overlaps at all seams, and consider going to 3" in areas with severe weather conditions.

Horizontal and vertical piping need different approaches. Horizontal runs require more frequent support bands to prevent sagging that could create water traps. Vertical runs need special attention to those overlaps to prevent water from working its way in. Even your sealant application changes—the bead placement varies depending on whether you're working horizontally or vertically.

Don't forget about movement! Thermal expansion and contraction can break seals if not accommodated. Install expansion joints with 6"–8" overlap wherever pipes cross building expansion joints, and place them every 20-30 feet on long straight runs. The trick is to never band directly over these expansion joints, and to apply sealant in a way that allows movement while still keeping water out.

Choosing and applying the right sealant makes a huge difference. Aluminum-colored silicone caulk works well for most applications and blends in visually. Apply a continuous, even bead at all overlaps—skimping here is false economy. Make sure your sealant is compatible with both the jacketing and insulation materials, and pay extra attention to complex fittings and terminations where leaks often start.

Some final field wisdom: never install jacketing over wet insulation (it needs to be completely dry), remove any oils or contaminants from the jacketing before installation, use temporary banding during installation to ensure everything lines up correctly, and always check that your moisture barrier is intact before proceeding. Adding identification markers outside the jacketing helps with future maintenance and system identification.

These field-proven techniques might seem like extra work now, but they'll significantly extend the life of your insulation system by preventing moisture infiltration—saving you from costly repairs and replacements down the road.

Comparing Aluminum Jacket to Alternative Jacketing Materials

When it comes to protecting your insulation, you've got options. While aluminum jacket systems remain the industry standard (and for good reason), several alternatives exist that might be better suited for specific situations. Let's compare these materials to help you make the best choice for your project.

| Feature | Aluminum | Stainless Steel | PVC/Vinyl | FlexClad® |

|---|---|---|---|---|

| Weight | Lightweight | 2-3× heavier | Very lightweight | Medium |

| Initial Cost | Moderate | High | Low | Moderate-High |

| Corrosion Resistance | Good | Excellent | Excellent | Very Good |

| Max Temperature | 400°F | 1000°F+ | 150°F | 250°F |

| UV Resistance | Excellent | Excellent | Poor-Moderate | Good |

| Impact Resistance | Good | Excellent | Poor | Moderate |

| Installation Speed | Moderate | Slow | Fast | Very Fast |

| Recyclability | Excellent | Excellent | Limited | Limited |

| Color Options | Limited | Limited | Extensive | Moderate |

| Maintenance | Low | Very Low | Moderate | Low |

Aluminum jacketing hits that sweet spot that makes it ideal for most applications. It's light enough for easy handling (your installation team will thank you), yet durable enough to stand up to the elements year after year. The natural ability of aluminum to resist corrosion and UV damage means it performs beautifully in outdoor settings without needing extra treatments or fancy coatings.

For those tricky installations with complex shapes, hybrid systems like FlexClad® combine flexible membranes with aluminum facing. They go on faster and wrap around odd shapes more easily, but you'll pay more for that convenience and may sacrifice some temperature resistance compared to traditional metal jacketing.

Pros & Cons of Stainless Steel, Vinyl & Hybrid Systems

Let's take a closer look at each alternative to see where they shine and where they fall short.

Stainless Steel Jacketing is the heavy-duty champion in the lineup. It laughs in the face of extreme temperatures (handling up to 1000°F and beyond) and shrugs off corrosive environments that would destroy lesser materials. The downside? Your wallet will definitely feel it—expect to pay 2-3 times more than aluminum. It's also significantly heavier, making installation more labor-intensive and potentially requiring additional support structures. Your installers might grumble about how difficult it is to cut and form compared to aluminum, too.

PVC/Vinyl Jacketing is the budget-friendly option that comes in a rainbow of colors. It's feather-light and snaps into place with minimal effort, making installation a breeze. The chemical resistance is impressive, and you never have to worry about water getting through the material itself. However, it's a bit like sending a paper boat into a rock fight—impact resistance is poor, and temperatures above 150°F will cause problems. Leave it out in the sun too long, and UV degradation becomes an issue. It's simply not built for the long haul like metal jacketing.

Hybrid Membrane Systems like FlexClad® offer some interesting advantages for specific situations. The self-adhesive backing makes installation almost as simple as applying a giant sticker—just peel and stick. It hugs complex shapes beautifully and creates self-sealing barriers around penetrations. Available in several colors, it looks good while providing solid weatherproofing. But there are tradeoffs: higher costs than traditional aluminum jacketing, temperature limitations (typically maxing out around 250°F), less resistance to impacts, and limited repairability if damaged.

Your choice ultimately depends on your specific needs:

- Working with high-temperature steam lines? Stainless steel might be your only viable option.

- Need something colorful for an indoor, low-temperature application where looks matter? PVC could be perfect.

- Dealing with a retrofit project full of odd shapes where speed matters? A hybrid system could save the day.

For most standard industrial applications, though, aluminum jacketing remains the go-to choice because it offers the best balance of performance and value.

Long-Term Value & Sustainability

Looking beyond the price tag to consider the full lifecycle costs and environmental impact is increasingly important—and this is where aluminum jacketing really shines.

A properly installed aluminum jacket system typically provides 20+ years of reliable service under normal conditions. Add a quality polysurlyn moisture barrier, and you might see 25-30 years even in moderately corrosive environments. This impressive longevity means fewer replacements and lower lifetime costs.

Once installed, aluminum jacketing asks very little of you. Unlike some alternatives that need regular painting or coating renewal, aluminum requires minimal maintenance beyond occasional visual inspections. Its natural oxide layer continuously renews itself, maintaining corrosion resistance without any help from you.

From an environmental perspective, aluminum jacketing is a responsible choice. It's 100% recyclable with no loss of properties—meaning today's jacket could become tomorrow's window frame or soda can. Recycling aluminum requires just 5% of the energy needed to produce new aluminum, and most aluminum jacketing already contains a significant percentage of recycled content. When it's finally time for replacement, the scrap value helps offset some of your costs.

While aluminum production does require significant energy initially, its long service life and recyclability result in a lower environmental impact over time. Its lightweight nature means lower transportation energy compared to heavier alternatives like stainless steel. And let's not forget the bigger picture—the energy savings from properly jacketed insulation systems far outweigh the embodied energy of the jacketing itself.

Here at American Mortuary Coolers, we've seen how proper insulation jacketing contributes to energy efficiency in temperature-controlled environments. Our mortuary coolers rely on well-jacketed insulation to maintain precise temperatures while minimizing energy consumption, whether they're operating in the humid heat of our Southern facilities or the variable climate of our Midwest locations.

For more information about insulation efficiency and how it relates to temperature-controlled environments, check out our guide to comparing R-value insulation charts.

Maintenance, Cleaning & Cost Considerations

Taking care of your aluminum jacket system doesn't have to be complicated, but a little attention goes a long way in extending its life. Unlike many other building materials that demand constant upkeep, aluminum jacketing is relatively low-maintenance – which is one of the reasons it's so popular in industrial settings.

When it comes to cleaning your aluminum jacket, simplicity is key. A solution of mild detergent and warm water usually does the trick nicely. Grab a soft cloth or brush to prevent scratching that beautiful surface, and make sure to rinse thoroughly afterward – leftover soap residue can actually attract more dirt over time. For those stubborn stains that won't budge, there are specialized aluminum cleaners available, but always test in an inconspicuous spot first.

I've seen plenty of well-intentioned maintenance crews damage their jacketing systems by using the wrong cleaning products. Always avoid chloride-containing cleaners – they're aluminum's worst enemy and can trigger corrosion faster than you can say "replacement budget." Similarly, steer clear of abrasive tools that might scratch through the protective oxide layer that naturally forms on aluminum surfaces.

Regular visual inspections are your best defense against developing problems. For standard environments, an annual once-over is typically sufficient, but if your facility is near the coast or exposed to chemical environments, bump that up to twice yearly. I also recommend taking a good look after any extreme weather events or if the jacketing takes a physical hit from equipment or materials.

When it comes to dents and damage, not everything requires immediate attention. Minor dents where the moisture barrier remains intact can often be left alone – the jacket is still doing its job. For more significant damage, you might need to replace sections, though temporary repairs using aluminum tape and sealant can buy you some time until a proper fix is scheduled.

Let's talk dollars and cents. The total cost of ownership for an aluminum jacket system includes several factors that smart facility managers consider:

Initial material costs typically run between $3-8 per square foot, varying based on thickness and finish choices. The labor to install it often exceeds the material costs, especially for systems with lots of fittings and complex geometries. The good news? The minimal maintenance requirements and long service life (often 20+ years) significantly reduce lifetime costs compared to alternatives.

Most quality aluminum jacketing products come with 1-5 year material warranties, though installation warranties vary by contractor. Just remember that proper maintenance is usually required to keep those warranties valid, so keep records of all inspections and maintenance work.

At American Mortuary Coolers, we've seen how properly maintained insulation jacketing extends the life of our cooling systems. Across our service regions – from chilly Chicago to humid Dallas – well-maintained jacketing translates directly to lower operating costs and more reliable performance. When your business depends on consistent temperature control, these details matter.

Budgeting Your Project

Planning the budget for your aluminum jacket system requires looking beyond the simple price-per-square-foot calculation. Let me walk you through the factors that will affect your bottom line.

Material thickness makes a significant difference in your wallet. Standard .016" thickness material typically costs 20-30% less than the heavier .020" option. While it might be tempting to always go with the thinner, less expensive option, sometimes the heavier gauge is necessary for larger pipes or areas prone to physical impact.

The finish you choose affects both appearance and price. That attractive stucco embossed finish adds approximately 10-15% to your base material cost, but many facility managers find the aesthetic improvement and scratch-hiding properties worth the premium. Similarly, moisture barriers add 15-20% to your costs, but they're one of the best investments you can make – they dramatically extend system life by preventing corrosion.

One of my favorite budget tips involves considering the labor-material tradeoff. Precut jacketing costs more upfront but can reduce installation labor by 15-25%. Similarly, those factory-fabricated fitting covers might make you wince at 2-3 times the material cost of field-fabricated alternatives, but they can slash labor costs by 50-75% at complex fittings. In most cases, the labor savings more than offset the increased material costs.

Don't forget about freight considerations. One of aluminum's advantages is its lightweight nature, which reduces shipping costs compared to heavier alternatives like stainless steel. Whenever possible, consolidate orders to meet minimum freight requirements – this simple planning step can yield significant savings.

For larger projects exceeding 5,000 square feet, bulk roll material typically offers 10-15% savings over cut-to-length options. However, smaller projects might actually benefit from cut-to-length material despite the higher unit costs, simply because you'll have less waste. Always consider your material handling capabilities when choosing between formats – those big rolls aren't much help if you don't have the equipment to manage them safely.

Remember to budget for the little things that add up: accessories like bands, seals, and caulk typically add 8-12% to material costs. Specialized tools might require an upfront investment but pay for themselves through reduced labor time. And always factor in a waste allowance – typically 10-15% for complex systems and 5-10% for simpler installations.

By thinking through these factors during your budgeting process, you'll develop more accurate cost projections and identify opportunities to maximize your investment in aluminum jacketing.

When to Replace or Upgrade an Aluminum Jacket

Even the most durable aluminum jacket eventually reaches the end of its useful life. Knowing when to replace or upgrade your system helps prevent costly insulation damage and efficiency losses.

Visible corrosion is your most obvious warning sign. If you notice white powder (aluminum oxide) accumulating on the surface, that's aluminum's way of telling you something's wrong. Pitting or perforation of the jacketing surface means moisture is already getting through, while staining or discoloration, especially at seams and terminations, suggests water intrusion. Rust bleeding through from underlying components is a particularly urgent sign – it means corrosion has already reached your piping or equipment.

Pay close attention to signs of a compromised moisture barrier, which is often the first component to fail. Water stains on the insulation beneath the jacketing are a dead giveaway, as is mold or mildew growth. If you notice the moisture barrier delaminating from the aluminum or see bubbling and blistering of the jacketing surface, water is getting where it shouldn't be.

Physical damage often necessitates replacement sooner than expected. While minor dents might be cosmetic, punctures or tears that can't be effectively sealed are serious problems. Severe denting that affects water shedding capabilities, damaged or missing fastening systems, or separation at seams exceeding 1/8" all warrant prompt attention.

Smart facility managers look for insulation upgrade opportunities that coincide with other work. When you're already replacing insulation due to damage, during system modifications, or during scheduled maintenance shutdowns, that's the perfect time to upgrade your jacketing as well. The incremental cost is often minimal compared to doing it as a standalone project later.

Environmental changes might also trigger the need for replacement. Perhaps your facility has changed processes, resulting in higher ambient humidity or chemical exposure. New code requirements or standards might necessitate upgrades to remain compliant. Even facility repurposing that changes system requirements can be a good time to reassess your jacketing needs.

The good news is that replacement doesn't always mean a complete system overhaul. Often, localized damage can be addressed without full system replacement, especially if the original installation used high-quality materials and proper techniques. Selective replacement of damaged sections is often the most cost-effective approach.

At American Mortuary Coolers, we've learned that proactive replacement of deteriorating jacketing prevents much costlier repairs down the road. Our mortuary coolers operate in environments from humid Atlanta to dry western climates, and we've seen how timely maintenance prevents energy losses that directly impact operating costs. When your business depends on precise temperature control, keeping your insulation system in top shape isn't just maintenance – it's protecting your bottom line.

Frequently Asked Questions about Aluminum Jacketing

What Makes an Aluminum Jacket Different?

When people ask me what makes an aluminum jacket special compared to regular sheet metal, I like to explain it's like the difference between a raincoat and a regular jacket. They might look similar, but one is specifically designed to keep water out!

Aluminum jacketing is purpose-built for protecting insulation systems. Unlike ordinary aluminum sheets you might find at a hardware store, jacketing material is engineered with specific properties that make it ideal for industrial applications.

The alloys used in aluminum jacketing are carefully selected—typically 3003 or 3105 series that meet strict ASTM B-209 standards. These aren't random choices; these particular alloys offer that perfect sweet spot of corrosion resistance, strength, and formability that you need when wrapping insulated pipes and equipment.

Look closely at aluminum jacketing and you'll notice special finishes like stucco embossing or corrugation patterns. These aren't just for looks! These finishes add rigidity to the material and cleverly hide scratches and dents that inevitably happen in industrial environments. It's a practical touch that extends the visual appeal of your installation for years.

Perhaps the most important feature—and one you won't find on standard sheet metal—is the moisture barrier on the inside surface. This 3-mil polysurlyn or kraft paper layer prevents galvanic corrosion between the aluminum and the metal pipe beneath it. Think of it as insurance for your insulation system, often doubling its effective lifespan.

These thoughtful design elements make aluminum jacketing far more effective than just wrapping your pipes in standard metal sheets—and why professionals choose proper jacketing for serious insulation protection.

How Do I Determine the Correct Jacket Size?

Sizing an aluminum jacket correctly is a bit like buying a suit—get the measurements right, and everything fits perfectly. Get them wrong, and you'll have problems down the road!

Start with the actual outside diameter (OD) of your pipe. This is the measured diameter, not the nominal pipe size (which can be confusing since a "2-inch pipe" doesn't actually measure 2 inches across).

Next, consider your insulation thickness. Since insulation wraps all the way around, you'll need to add twice this thickness to your pipe OD. For example, if you have a pipe with a 4-inch OD and you're using 1.5-inch thick insulation, your total outside diameter would be 7 inches (4 + 1.5 + 1.5).

The simplest approach is to use a jacketing sizing chart, which does the math for you. These charts cross-reference pipe sizes with insulation thicknesses and give you a standardized "jacketing number." For instance, a 3-inch pipe with 1-inch insulation typically needs a #6 aluminum jacket, while that same pipe with 1.5-inch insulation would need a #7 jacket.

For those one-off situations where standard charts don't apply, you can calculate the circumference yourself: Circumference = π × (Pipe OD + 2 × Insulation Thickness) + Lap Allowance. The lap allowance (typically 2-3 inches) provides enough overlap for a proper seal.

One common mistake I see is using the same sizing system for straight runs and fittings. Elbow covers and other fitting covers have their own sizing systems and need to be ordered separately.

Can Aluminum Jackets Be Used in Coastal or Marine Environments?

"Can I use aluminum jacketing near the ocean?" is a question I hear often, and I'm happy to say the answer is yes—with some important considerations.

Coastal environments can be tough on metal with all that salt spray and humidity, but aluminum jackets actually hold up quite well when properly specified and installed. The standard 3003 and 3105 alloys provide good corrosion resistance in most coastal settings. Aluminum naturally forms a protective oxide layer that acts as a shield against atmospheric corrosion.

For particularly harsh marine environments—think direct ocean spray or offshore platforms—I recommend considering Alclad jacketing. This clever material features a high-purity aluminum surface layer (7072 alloy) bonded to a stronger core (3004 alloy). It's like getting the best of both worlds: superior corrosion resistance with maintained structural strength.

The moisture barrier becomes even more critical in coastal installations. Always specify jacketing with a polysurlyn moisture barrier rather than kraft paper when working near saltwater. The polymer barrier provides much better protection against the persistent moisture that defines coastal environments.

To get the most life from your coastal aluminum jacketing, follow these practical maintenance tips:

- Inspect the jacketing twice yearly rather than the standard annual check

- Give the jacketing an occasional freshwater rinse to remove salt deposits

- Be extra thorough when sealing joints and penetrations

- Consider using slightly heavier gauge material (.020" minimum) for added durability

- Use stainless steel banding and fasteners to prevent problems from dissimilar metals

With these precautions, your aluminum jacketing can provide excellent service even with the ocean as your neighbor. The salt air might be tough on some materials, but with proper selection and care, aluminum stands up to the challenge beautifully.

At American Mortuary Coolers, we understand how important proper insulation is for temperature-controlled environments, whether you're near the coast or inland. The right jacketing makes all the difference in the efficiency and longevity of cooling systems.

Conclusion

Aluminum jacketing has earned its place as the gold standard for protecting mechanical insulation systems across countless applications. There's a good reason professionals keep choosing it—nothing else quite matches its perfect balance of being lightweight yet durable, standing up to corrosion, and delivering excellent value for your investment.

When I talk with clients about insulation protection, I always highlight what makes aluminum jacketing so special:

Its remarkable durability means it stands strong against physical impacts, doesn't degrade in sunlight, and naturally resists atmospheric corrosion. This translates to fewer replacements and repairs over time. From a budget perspective, the cost-effectiveness is clear—you get reasonable upfront costs paired with minimal maintenance requirements down the road.

The lifecycle performance of a properly installed aluminum jacket system is impressive, often providing decades of reliable service. I've seen systems in industrial facilities still performing beautifully after 20+ years when they've been correctly installed and maintained. The versatility of aluminum means you can use it confidently indoors or outdoors, from cryogenic applications all the way up to 400°F systems.

For environmentally conscious projects, the sustainability aspect is significant too. Aluminum jacketing is 100% recyclable, and most products already contain substantial recycled content—something that matters more every year as sustainability requirements increase.

When selecting your aluminum jacket system, quality really does matter. Taking time to choose the right alloy, thickness, finish, and moisture barrier for your specific environment pays dividends through extended service life and better performance. Equally crucial is proper installation—even the finest materials will fail if poorly installed. Using appropriate accessories and proven techniques creates a weathertight system that truly protects your insulation investment.

At American Mortuary Coolers, we've seen how proper insulation protection directly impacts temperature-controlled environments. Our experience crafting custom mortuary coolers throughout the United States has shown that thoughtfully designed and correctly installed insulation systems make all the difference in energy efficiency and equipment longevity. Whether we're serving customers from our Johnson City TN headquarters or supporting clients across the country, we remain committed to providing durable, custom solutions that the funeral industry can rely on.

The bottom line is simple: whether you're protecting industrial process piping, commercial HVAC systems, or specialized equipment like our mortuary coolers, investing in quality aluminum jacketing delivers real long-term value. You'll see it in improved system performance, reduced energy costs, and fewer maintenance headaches.

For more information about our mortuary cooler solutions and how proper insulation systems contribute to their efficiency, visit our mortuary cooler solutions page.