The Complete Guide to Walk In Freezer Door Parts and Replacements

Why Walk In Freezer Door Parts Are Critical for Temperature Control

Walk in freezer door parts are the essential components that keep your freezer sealed, energy-efficient, and operating at proper temperatures. When any of these parts fail, you'll face rising energy costs, temperature fluctuations, and potential equipment damage.

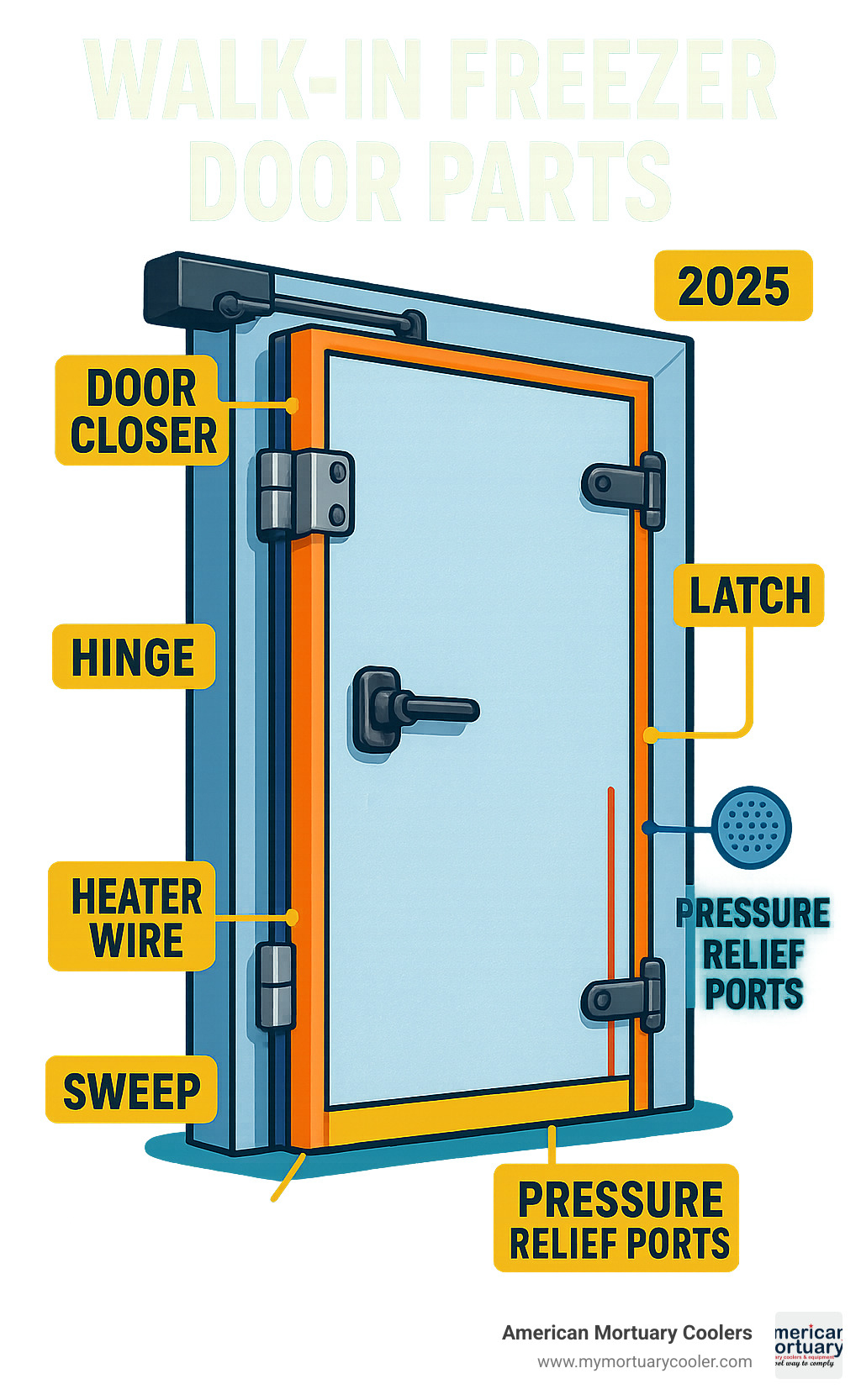

The main walk-in freezer door parts include:

- Gaskets and seals - Create airtight barrier to prevent warm air infiltration

- Hinges - Support door weight and ensure proper alignment

- Latches and strikes - Secure door closure and maintain compression

- Door closers - Automatically close doors to prevent air leaks

- Sweeps - Seal the bottom gap between door and threshold

- Heater wire - Prevents ice buildup on door frames (freezer applications)

- Pressure relief ports - Allow safe pressure equalization

Research shows that aging insulation panels, especially those over 10 years old, can lose effectiveness and contribute to air leaks and ice build-up. Door hardware failures account for many of these issues, with over 200 different door hardware options available from specialized suppliers to address specific problems.

Ice build-up due to air leaks or component failure can lead to increased compressor workload, reducing its lifespan and increasing energy costs. The most common failure points are hinges, latches, door closers, and magnetic gaskets - components that experience constant use and wear.

We're American Mortuary Coolers, a national-level mortuary cooler supplier with extensive experience helping funeral homes maintain their walk in freezer door parts for reliable temperature control. Our work across Tennessee, Atlanta, Chicago, and nationwide has shown us how proper door component maintenance can prevent costly breakdowns and extend equipment life.

Walk in freezer door parts further reading:

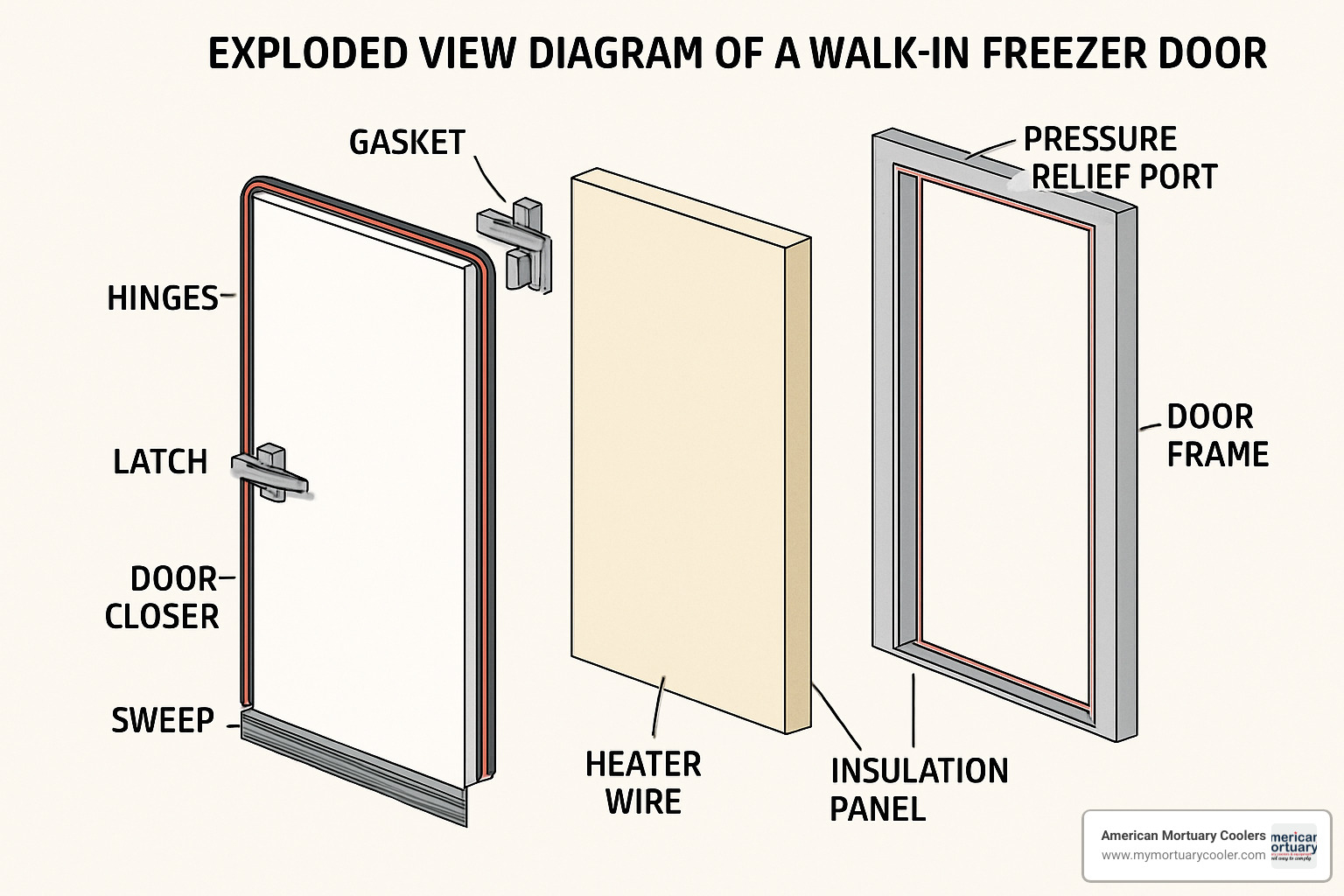

Anatomy of a Walk-In Freezer Door

Think of your walk in freezer door parts as a well-orchestrated team - each component has a specific job, but they all work together to keep your freezer running efficiently. When you understand how these parts function as a system, you'll be better equipped to spot problems before they become expensive headaches.

The core panel serves as your door's backbone, packed with high-density insulation that typically delivers an R-factor between 28.8 and 32 for 4-inch thick walls. This isn't just foam stuffed in a frame - it's engineered insulation that must maintain its integrity year after year to keep your energy bills reasonable.

Wrapped around that insulated core is the door frame, which does much more than just hold things together. It's the mounting platform for your hinges, the anchor point for your latches, and the foundation that keeps everything aligned properly. When this frame gets damaged or warped, it throws off the entire door system.

Here's where freezer doors get interesting - they need heater wire running along all four sides of the frame, plus around the pressure-relief port. This UL-approved heating element prevents ice buildup that would otherwise freeze your door shut or compromise the seal. It's one of those "invisible" components that you never think about until it stops working.

The threshold creates that crucial bottom seal where your door meets the floor. This spot takes a beating from foot traffic, spills, and constant temperature changes, making it one of the most vulnerable points for air leaks.

Key Walk In Freezer Door Parts Explained

Walk in freezer door parts break down into two main families: the structural foundation and the working hardware. Your structural components - the insulated panel, frame assembly, and threshold - provide the bones of the system. These rarely fail catastrophically, but when they do, you're usually looking at a complete door replacement.

The hardware is where most of your maintenance headaches live. Based on what we see in the field, hinges, latches, and door closers are the usual suspects when doors start acting up. With over 200 different door hardware options available from specialized suppliers, getting the right replacement part can feel overwhelming.

Common specifications you'll encounter include Keil W19 latches for standard applications and Keil W38 latches when you need heavy-duty performance. W60 satin chrome reversible lift-off hinges come in single or double configurations, while W94 concealed mount hydraulic door closers provide that smooth, controlled closing action that prevents door slamming.

The complexity isn't just for show - each component is engineered to handle specific loads, temperatures, and usage patterns. Using the wrong part might work initially, but it'll likely fail prematurely.

How Gaskets & Seals Maintain Performance

Your gaskets and seals are the unsung heroes of temperature control. They create that critical air-infiltration barrier that maintains your freezer's R-value and prevents condensation problems. These aren't just rubber strips - they're precision-engineered sealing systems using tongue-and-groove joints with double-barreled NSF-approved gaskets.

When you close the door, these gaskets compress to form an airtight seal around the entire perimeter. It's like a giant zipper that seals shut every time. When this system fails, warm humid air sneaks in, condenses on cold surfaces, and creates ice buildup that can damage other components.

The industry standard for measuring gaskets is outside-to-outside (OA) dimensions unless specified otherwise. This standardization helps ensure you get the right fit when ordering replacements, though it's always smart to double-check your measurements.

More info about replacement gaskets

Most Common Walk-In Freezer Door Parts That Fail

After years of servicing mortuary coolers across the country, we've seen the same walk in freezer door parts fail over and over again. It's not random - certain components take a beating and wear out faster than others.

Hinges are probably the biggest troublemakers. Think about it - they're supporting the full weight of that heavy insulated door every single time someone opens it. Day after day, month after month, those hinge pins start wearing down. When they do, your door starts sagging and won't seal properly against the gasket.

Latches and strike plates are next on the failure list. All that grabbing and releasing action eventually wears down the metal surfaces. When a latch can't create proper compression anymore, you've lost your airtight seal - and that's when your energy bills start climbing.

Door closers contain hydraulic mechanisms that eventually leak or fail completely. When this happens, doors don't close properly - or worse, they stay open. In a busy funeral home, staff might not notice right away, and that open door is costing you money every minute.

Magnetic gaskets lose their grip over time. The rubber cracks, the magnetic strip weakens, and suddenly you don't have that tight seal around the door frame. Sweeps at the bottom of the door get hit with floor moisture and cleaning chemicals, causing them to deteriorate faster than other components.

Heater wire can fail from electrical issues or getting damaged during cleaning. When it stops working, ice builds up around the door frame, and eventually you can't even get the door open. The pressure relief port sometimes gets clogged or its heating element fails, creating pressure problems inside the unit.

Signs Your Walk In Freezer Door Parts Need Attention

Your freezer will tell you when walk in freezer door parts are starting to fail - you just need to know what to look for. The good news is that catching these problems early can save you from expensive emergency repairs.

Frost on the door frame is usually the first red flag. When you see ice crystals forming around the edges of your door, that's warm humid air sneaking in through compromised gaskets. Don't ignore this - it's your freezer's way of crying for help.

Door drag is another dead giveaway. If you're having to put your shoulder into opening the door, or if it's making grinding noises, your hinges are probably worn out. A healthy door should swing open and closed smoothly without any wrestling matches.

Rising utility bills without any change in your usage patterns often point to air leaks. Even tiny gaps can force your compressor to work overtime trying to maintain temperature. We've seen funeral homes cut their energy costs by 20% or more just by replacing worn door components.

Watch for doors that don't close completely on their own, ice buildup around the threshold, or condensation appearing where it shouldn't. These are all signs that your door system needs some attention before small problems become big headaches.

Ice Build-Up & Component Failure

Ice buildup isn't just annoying - it's a symptom of walk in freezer door parts that aren't doing their job. Understanding why ice forms helps you fix the root cause instead of just scraping it off every few days.

When door seals fail, moisture migration becomes a serious problem. Warm, humid air from outside infiltrates through those tiny gaps and immediately hits the cold interior surfaces. That moisture has nowhere to go except freeze solid, and it builds up fast.

This creates what we call a cascade effect. Ice accumulates on panels and creates even more air leak paths. Your compressor has to work harder to fight against the constant influx of warm air, which puts compressor strain on the entire system. We've seen compressors fail prematurely just from overwork caused by leaky door seals.

Panel saturation becomes a real concern as your freezer ages. Research shows that insulation panels over 10 years old can become waterlogged, dramatically reducing their effectiveness. When panels fail, even perfect door seals can't maintain proper temperature control.

Scientific research on insulation longevity

The ice doesn't just sit there looking ugly - it actively damages your equipment. It can crack interior panels, jam door mechanisms, and create additional leak points. We've seen funeral homes spend thousands on repairs that could have been prevented with timely door maintenance.

Choosing, Installing & Maintaining Replacement Parts

When it's time to replace walk in freezer door parts, the decisions you make can affect your equipment's performance for years to come. Getting the right parts and installing them properly isn't just about fixing today's problem—it's about preventing tomorrow's headaches.

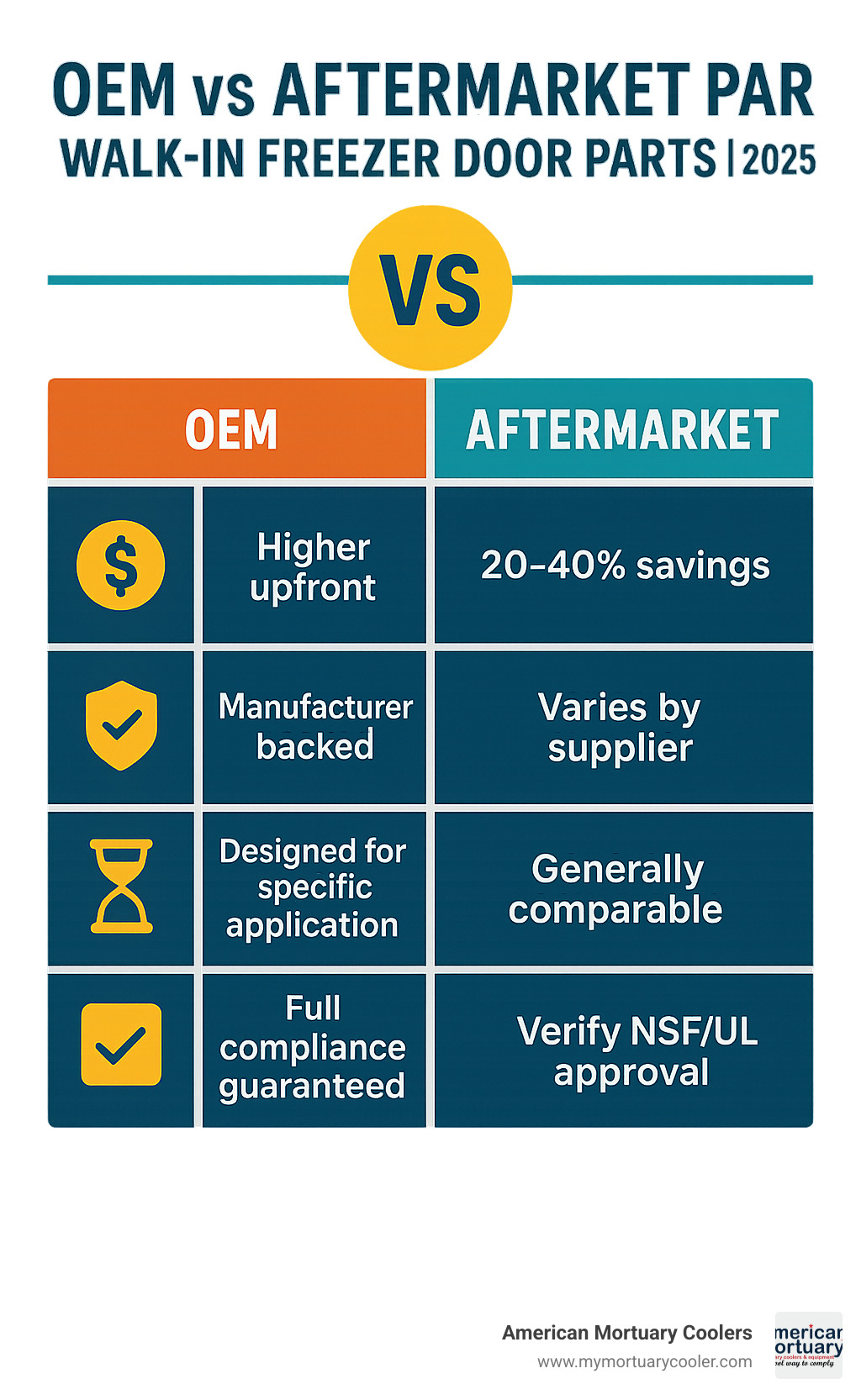

We always start with OEM part numbers when they're available. These manufacturer-specified parts guarantee the fit and performance your equipment was designed for. But here's the thing: high-quality aftermarket options can deliver the same reliability while saving you money. The key is knowing which suppliers have earned their reputation through consistent quality.

Before you touch any walk in freezer door parts, safety comes first. Put on your safety glasses and work gloves—no exceptions. Make sure your freezer is properly shut down and any electrical components are completely de-energized. Trust us, a few extra minutes of safety prep beats a trip to the emergency room every time.

Here's something we've learned from years of servicing mortuary coolers nationwide: preventive maintenance costs a fraction of emergency repairs. When you catch wear early through regular inspections, you can plan replacements during convenient maintenance windows instead of scrambling at 2 AM when something fails.

Selecting the Right Hardware

Choosing the right hardware feels overwhelming when you're staring at hundreds of options, but understanding a few key differences makes the decision much clearer. More info about walk-in cooler door hardware

Offset hinges versus cam-rise hinges serve completely different purposes, and picking the wrong one creates problems. Offset hinges give you clearance when doors need to swing past obstacles—perfect for tight spaces. Cam-rise hinges actually lift the door slightly as it opens, which helps overcome uneven floors and ensures your door wants to close on its own.

Lift-off designs are a maintenance person's best friend. These hinges let you remove the entire door without disconnecting anything from the frame. In mortuary applications where thorough cleaning sometimes requires door removal, this feature saves hours of work.

When you're dealing with larger doors or high-traffic areas, heavy-duty latches like the Keil W38 series provide the extra strength you need. These latches feature reinforced construction and often include adjustable strike plates that accommodate door settling or frame movement over time.

DIY Installation of Gaskets, Hinges & Latches

Many walk in freezer door parts replacements are well within reach of facility maintenance staff who have basic tools and pay attention to details. However, always check manufacturer specifications and local codes before starting any repair work.

Your essential tool list includes a drill with appropriate bits, a socket set or adjustable wrenches, a level for alignment verification, measuring tape for accurate positioning, and a torque wrench for proper fastener tension. Having the right tools makes the difference between a professional job and a frustrating struggle.

Gasket replacement requires patience more than skill. Remove the old gasket completely and clean all mounting surfaces thoroughly—any debris will create leak paths. Install the new gasket starting at one corner and working around the perimeter, ensuring even compression with no gaps or overlaps.

Hinge installation demands precise alignment to prevent door binding or poor sealing. Use your level to ensure the door hangs properly, then check that it closes evenly against the gasket around the entire perimeter. A door that seals well in one spot but gaps in another will leak air and waste energy.

After any installation, perform a simple leak test by placing a thin piece of paper between the door and gasket, then closing the door. You should feel consistent resistance when pulling the paper out at all points around the perimeter. No resistance means no seal.

Routine Maintenance Checklist

Regular maintenance prevents most walk in freezer door parts failures and extends component life significantly. We recommend monthly inspections for high-use doors and quarterly checks for moderate-use applications—a schedule that catches problems before they become emergencies.

Monthly inspections should cover gasket condition and compression, door closer operation and adjustment, hinge wear or looseness, latch engagement and strike alignment, plus cleaning door surfaces and hardware. These quick checks take minutes but prevent hours of downtime.

Quarterly maintenance goes deeper with lubricating hinge pins and moving parts, checking heater wire continuity in freezer applications, testing pressure relief port operation, inspecting door sweep condition, and verifying door alignment with adjustments as needed.

Keep essential supplies on hand including food-grade lubricant for hinges and latches, NSF-approved silicone caulk for sealing, cleaning supplies suitable for food service areas, basic hand tools for adjustments, and replacement gaskets and hardware as needed. Having these items ready means you can address small issues immediately instead of waiting for parts to arrive.

Cost, Sourcing, and OEM vs Aftermarket Comparison

Understanding the cost implications of walk in freezer door parts replacement helps you budget effectively and make informed decisions about repair versus replacement. Based on industry data, common replacement costs range from $30 for door sweeps to over $100 for heavy-duty latches.

Typical price ranges include:

- Door sweeps: $30-45 depending on length

- Basic latches: $84 for W19 series

- Heavy-duty latches: $114 for W38 series

- Hydraulic door closers: $76 for concealed mount units

- Hinge sets: $23-50 depending on configuration

Lead times vary significantly between OEM and aftermarket suppliers. OEM parts may require 14-21 business days for custom or less common components, while aftermarket parts are often available for immediate shipment.

Where to Buy High-Quality Parts

Specialized distributors often provide the best combination of product knowledge, availability, and competitive pricing for walk in freezer door parts. These suppliers focus exclusively on commercial refrigeration components and understand the critical nature of proper part selection.

Replacement Hardware at WalkinCoolerParts

Online catalogs make it easier to identify correct parts using model numbers, dimensions, or photos. Many suppliers offer technical support to help verify compatibility before ordering.

Bulk discounts may be available for facilities with multiple units or those planning comprehensive maintenance programs. Consider stocking commonly needed parts to minimize downtime during repairs.

OEM vs Aftermarket: Pros & Cons for Walk In Freezer Door Parts

OEM parts provide performance guarantees and ensure regulatory compliance, but come with higher costs and potentially longer lead times. These parts are engineered specifically for your equipment and typically include comprehensive warranty coverage.

Aftermarket options can provide significant cost savings, often 20-40% less than OEM equivalents. However, you must verify that aftermarket parts meet NSF and UL certification requirements for food service applications.

Walk in freezer door parts availability often favors aftermarket suppliers, especially for older equipment where OEM parts may be discontinued. Quality aftermarket manufacturers often improve upon original designs, incorporating lessons learned from field experience.

Budget impact considerations include not just initial cost, but also installation time, warranty coverage, and expected service life. Sometimes spending more initially on OEM parts provides better long-term value through reduced maintenance and longer service intervals.

Frequently Asked Questions about Walk-In Freezer Door Parts

We get a lot of questions about walk in freezer door parts from funeral homes across the country. Here are the three most common concerns we hear from our customers, along with practical answers based on our years of experience.

What is the typical lifespan of door gaskets and sweeps?

Door gaskets usually last 3-5 years with normal use, but don't be surprised if they need replacement sooner in busy facilities. High-traffic funeral homes might see gasket failure in as little as 2-3 years, especially if staff are frequently moving equipment in and out.

Sweeps have a shorter lifespan - typically 2-3 years - because they take a beating from floor moisture, cleaning chemicals, and constant contact with the threshold. It's honestly one of the hardest-working parts on your door.

You'll know it's time for replacement when gaskets start cracking, getting hard and inflexible, or losing their magnetic grip. Sweeps will show fraying, separation from the door, or gaps that let cold air escape. Don't wait until complete failure - replacing these parts early saves energy costs and prevents bigger problems.

How do I measure accurately for a replacement hinge or latch?

Getting the right measurements is crucial for walk in freezer door parts replacement. For hinges, you'll need to measure the distance between mounting holes from center to center. Also note your door thickness and check the weight capacity requirements - mortuary cooler doors are often heavier than standard commercial doors.

Latch measurements require the backset distance (from the door edge to the center of the latch mechanism) and door thickness. This seems simple, but getting it wrong means the latch won't align properly with the strike plate.

Here's a pro tip from our installation team: take clear photos of your existing hardware from multiple angles and look for any part numbers stamped on the components. When you're unsure, remove the old part and bring it to your supplier for matching. It's worth the extra effort to avoid ordering the wrong parts.

Can upgrading my door closer really cut energy costs?

Absolutely - and the savings can be dramatic. A quality hydraulic door closer ensures your door closes completely every single time, which is critical for maintaining temperature control. We've seen facilities cut their energy costs significantly just by installing proper door closers.

The numbers are eye-opening: leaving a door open for just 5-10 minutes introduces enough humidity to cause serious icing problems. That forces your compressor to work overtime, driving up electricity bills and shortening equipment life.

A quality hydraulic door closer typically pays for itself within 6-12 months in high-use applications. For funeral homes with multiple staff members accessing the cooler throughout the day, this upgrade is almost always worth the investment. Plus, you'll have peace of mind knowing the door will close properly even when everyone's focused on serving families during difficult times.

Conclusion

Taking care of your walk in freezer door parts isn't just about fixing things when they break—it's about protecting your investment and keeping your operation running smoothly. When you stay on top of regular inspections and preventive maintenance, those components will serve you well for years to come, saving you from those dreaded middle-of-the-night emergency repair calls.

The money you save on energy bills alone makes proper door maintenance worthwhile. Think about it: even tiny air leaks make your compressor work overtime, driving up electricity costs and wearing out your equipment faster. It's like leaving a window cracked open while running your air conditioning—small problems create big expenses over time.

Here's the exciting part: upgrading your door components can actually make your freezer work better than when it was new. Today's gasket materials are more durable, modern hinge designs last longer, and newer door closers operate more smoothly than older models. These improvements don't just fix problems—they prevent future ones while cutting your maintenance workload.

At American Mortuary Coolers, we've seen how crucial reliable temperature control is in mortuary applications. There's simply no room for error when it comes to preservation, which is why we focus exclusively on custom mortuary walk-in solutions that meet the highest standards. We deliver nationwide from our Tennessee headquarters, serving funeral homes everywhere from Atlanta and Chicago to Columbia, Dallas, Los Angeles, New York, and Pittsburgh.

Our coverage spans the entire contiguous United States, including the Midwest, Northeast, Rocky Mountain, Southeast, Southwest, and Pacific regions. Whether you're dealing with worn-out door parts on existing equipment or planning a completely new custom installation, we understand the unique challenges funeral homes face and we're here to help.

The bottom line is this: your mortuary cooler needs to work perfectly, every single time. That reliability starts with properly functioning door components that maintain consistent temperatures and keep energy costs under control.