The Complete Guide to Turbo Air Parts Replacement

Why Turbo Air Parts Are Critical for Commercial Refrigeration Success

Turbo air parts keep your commercial refrigeration equipment running efficiently and prevent costly downtime. Whether you need compressors, door gaskets, PCB boards, or specialized components for Turbo Air's self-cleaning condenser system, understanding which parts to order and when to replace them is essential for any foodservice operation.

Most Common Turbo Air Replacement Parts:

- Compressors - 7-10 year replacement cycle

- Door gaskets - Replace every 6-12 months

- Fan motors - Last 2-4 years typically

- PCB control boards - Handle temperature regulation

- Condensate drain pans - Prevent water damage

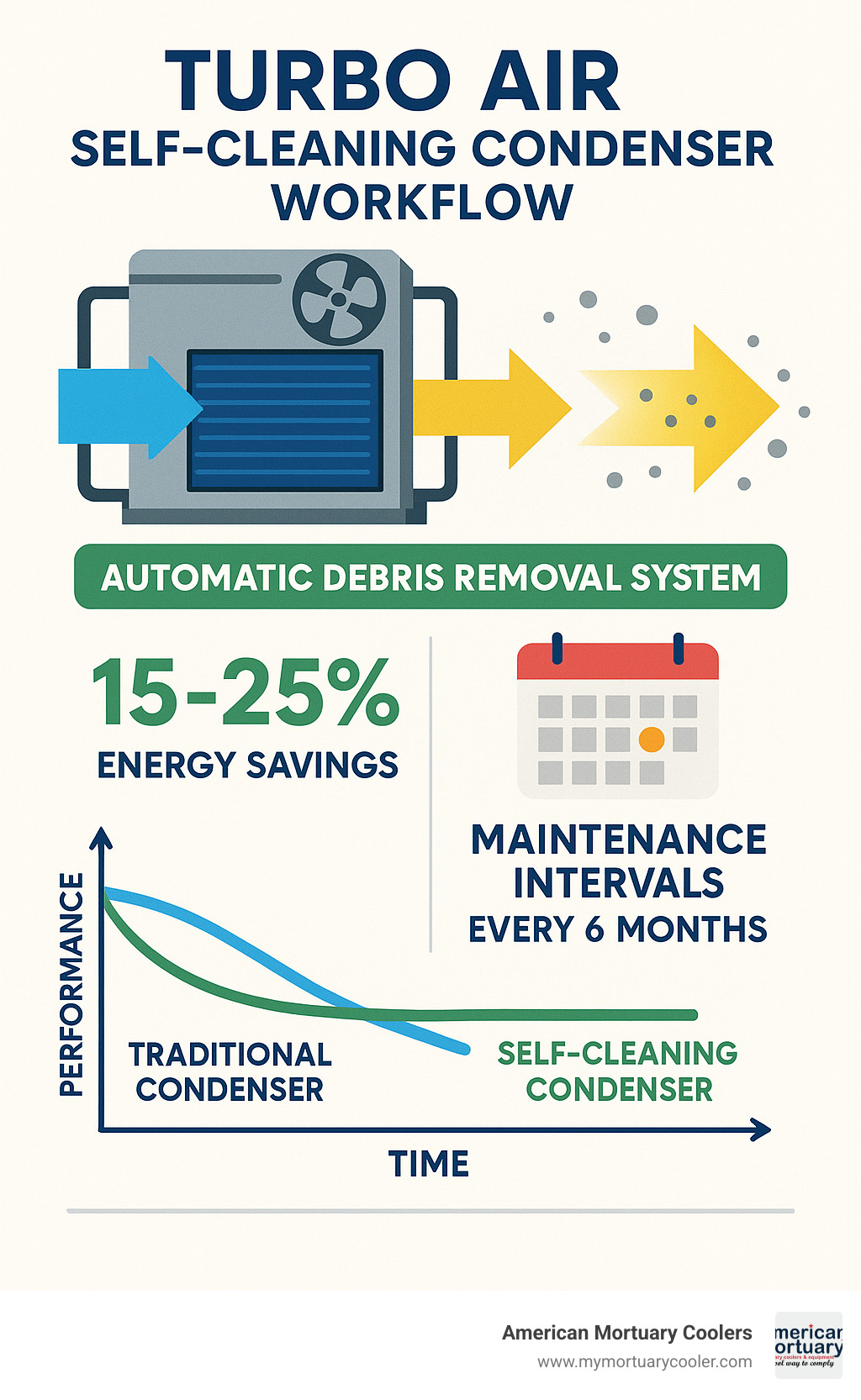

- Self-cleaning condenser components - Deliver 15-25% energy savings

Turbo Air manufactures over 500 refrigeration units across multiple series including reach-ins, prep tables, undercounters, merchandisers, and their innovative Radiance cooking line. With 140+ Energy Star certified models and a patented self-cleaning condenser system, proper parts maintenance becomes even more critical for maximizing performance.

The company's nationwide network includes 10+ branch locations, and 95% of service calls are fulfilled within three business days. However, knowing which genuine parts to stock and when to replace them can save you from emergency repairs and extend equipment life significantly.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in commercial refrigeration systems and turbo air parts replacement across funeral home operations. My background includes helping facility managers optimize their cold storage equipment through proper maintenance and genuine part selection, ensuring reliable temperature control when it matters most.

Turbo air parts terms at a glance:

Why This Guide Matters

Equipment downtime in commercial kitchens can cost operators hundreds of dollars per hour in lost revenue and spoiled inventory. We've seen this in our work with funeral homes, where temperature control failures can have devastating consequences. That's why preventative maintenance through timely turbo air parts replacement isn't just recommended—it's essential for protecting your investment and maintaining operational continuity.

Understanding Turbo Air Parts & Supported Equipment

When you're dealing with commercial refrigeration, understanding your equipment inside and out makes all the difference. Turbo Air has built quite the lineup over the years—reach-in refrigerators and freezers that anchor most commercial kitchens, prep tables that keep ingredients at the perfect temperature while you work, and undercounters that maximize every square foot of kitchen space.

Their merchandisers help display products beautifully while maintaining freshness, and the Radiance cooking line brings together refrigeration and cooking in one integrated system. What really sets Turbo Air apart is how they've standardized many components across their different series. This means the compressor in your reach-in might be the same one used in a prep table, making your parts inventory much simpler to manage.

The real game-changer is their self-cleaning condenser technology, which you'll find in over 140 Energy Star certified models. Instead of manually cleaning condenser coils every few months, this system automatically brushes away debris, keeping your equipment running efficiently with minimal hands-on maintenance.

Common Turbo Air Parts Across All Series

Some turbo air parts show up in nearly every piece of equipment they make, which is great news for keeping your maintenance simple and costs predictable.

Fan motors are the unsung heroes of refrigeration, working around the clock to keep air circulating properly. You can expect them to last about 2-4 years before they start showing signs of wear like unusual noises or weaker airflow. When they go, you'll know it—your temperatures will start fluctuating, and you might hear grinding or squealing sounds.

Door gaskets need attention more often than anything else, typically every 6-12 months depending on how busy your operation is. A worn gasket might not look like much, but it can spike your energy bills by 30% and create temperature swings that put food safety at risk.

Thermostats and temperature controls are your equipment's brain, making sure everything stays at exactly the right temperature. The newer digital versions give you more precision and often include diagnostic features that help you troubleshoot problems before they become emergencies.

Don't overlook casters and legs—they might seem basic, but wobbly equipment creates uneven cooling and puts unnecessary stress on internal components. Condensate pans prevent water damage and keep things sanitary, which is especially important in our line of work where contamination simply isn't an option.

Turbo Air Parts for Specialized Lines

Turbo Air's specialized equipment requires unique turbo air parts that you won't find in standard refrigeration units, and that's where things get interesting.

The Radiance burners are precision-built for consistent heat distribution, requiring specific burner assemblies, controllers, and grates that can handle commercial kitchen demands day after day.

Chef bases combine refrigeration with a sturdy work surface, so they need reinforced drawer slides, cutting boards, and gaskets that won't fail when exposed to heat from overhead cooking equipment.

Beer dispensers operate in their own world with CO2 regulators, specialized beer lines, and temperature controls calibrated to keep beverages at serving temperature without freezing.

Open display merchandisers require specialized lighting systems and anti-fog treatments for the glass, plus unique airflow components that maintain product visibility while preserving freshness.

Milk coolers need agitation systems, precise temperature sensors, and sanitary components that meet strict dairy industry standards—similar to the exacting requirements we face in mortuary refrigeration where temperature control is absolutely critical.

Identifying & Ordering Genuine Turbo Air Parts

Finding the right turbo air parts doesn't have to be a guessing game. Every piece of Turbo Air equipment comes with a serial plate that holds the key to successful parts ordering. This small but mighty plate contains your model number, serial number, and manufacturing date—think of it as your equipment's DNA.

Here's where Turbo Air really shines in customer support. Many of their newer units feature QR codes that link directly to digital manuals and exploded diagrams. No more squinting at tiny print or trying to describe a mysterious widget to a parts supplier. Just scan, and you'll see exactly what you're looking for with clear part numbers.

The company has built an impressive support network through their Parts Distributors program. With over 10 branch locations and multiple authorized distributors nationwide, they back up their bold promise that 95% of service calls are fulfilled within three business days. That's the kind of reliability that keeps your operation running smoothly.

For complex refrigeration components, our Complete Guide to Walk-In Cooler Compressors and Evaporators offers additional technical insights that work hand-in-hand with Turbo Air's systems.

Step-by-Step: Finding the Right Part

The process starts with detective work, but it's easier than you might think. Locate the serial plate first—it's usually tucked inside the unit or mounted on the back panel. Once you've got those model and serial numbers recorded, you're halfway home.

Turbo Air's online parts catalog is surprisingly user-friendly. You can filter by model to narrow down your options, then cross-reference with their compatibility charts to make sure you're getting exactly what fits your unit. The system organizes turbo air parts into logical categories, so whether you need compressors, door gaskets, or those specialized self-cleaning condenser components, you won't be hunting around aimlessly.

The exploded diagrams are particularly helpful when you're dealing with a part that's seen better days. Sometimes a picture really is worth a thousand words, especially when you're trying to identify a component that's been mangled by years of hard use.

The Ordering Process & Shipping Tips

Smart ordering starts with good documentation. Your purchase orders should include complete model information, quantities, and shipping preferences. Most distributors offer expedited shipping for those "oh no, it's down again" moments, though your wallet will feel the rush charges.

Don't get caught off guard by minimum quantities on smaller items like gaskets or hardware. While it might seem like overkill to order six door gaskets when you only need one, having spares on hand beats waiting for parts when your refrigeration goes down during the dinner rush.

Warranty registration is one of those boring but crucial tasks that pays off later. Keep your documentation organized by equipment serial number—future you will thank present you when you need to track coverage periods or process warranty claims.

Most distributors offer return policies ranging from 30 to 60 days for unused parts. It's worth understanding these policies upfront, because ordering the wrong part happens to the best of us. At least you won't be stuck with an expensive paperweight if you accidentally order a part for the wrong model.

The key to success with turbo air parts ordering is preparation and patience. Take the time to identify components correctly, and you'll save yourself headaches down the road.

Maintenance, Troubleshooting & Performance Boosts

Taking care of your turbo air parts doesn't have to be complicated, but it makes a huge difference in how long your equipment lasts and how well it performs. Think of it like taking care of your car—a little attention now saves you from big headaches later.

Turbo Air's self-cleaning condenser system is pretty impressive. It automatically brushes away debris that would normally clog up the system, which can boost your energy efficiency by 15-25%. But even with this smart technology, you'll still want to give it a deeper cleaning from time to time to keep everything running smoothly.

When your equipment starts acting up, the PCB diagnostics are your best friend. Modern Turbo Air units show error codes on their displays that tell you exactly what's wrong. It's like having a conversation with your refrigerator—and trust me, it's usually more helpful than talking to some people.

Watch out for temperature drift, which is often the first sign that sensors or control boards are starting to fail. If you notice temperatures creeping up or down over time, it's worth investigating before you end up with spoiled inventory.

Every good maintenance person needs the right tools. A digital multimeter helps diagnose electrical problems, while refrigerant manifold gauges check system pressures. Don't forget temperature probes for accuracy checks, basic hand tools for swapping parts, and a stash of spare fuses and relays for those quick fixes that save the day.

Routine Replacement Intervals for Key Turbo Air Parts

Here's the reality about turbo air parts—they all have a lifespan, and knowing when to replace them keeps you ahead of the game.

Compressors are the workhorses that typically last 7-10 years with good care. When they start getting noisy, using more energy, or struggling to keep things cold, it's time to start shopping for a replacement. For units under 8 years old, a new compressor usually makes financial sense.

Door gaskets take the most abuse and need replacing every 6-12 months, especially in busy kitchens where doors are constantly opening and closing. Here's a simple test: close the door on a dollar bill and try to pull it out. If it slides out easily, your gasket isn't sealing properly and needs replacement.

Fan motors generally keep going for 2-4 years, though dusty environments or 24/7 operation can shorten their life. When you start hearing unusual noises or feeling excessive vibration, those bearings are probably wearing out.

Sensors and controls typically last 3-5 years before they start drifting out of calibration. Regular temperature checks help catch these issues before they become problems.

DIY vs Professional Service: Minimizing Downtime

Some turbo air parts are easy enough to replace yourself, while others definitely need a professional touch. Knowing the difference can save you time, money, and frustration.

You can handle door gaskets and handles, casters and legs, basic electrical components like fuses, condensate drain pans, and interior lighting without breaking a sweat. These are straightforward swaps that don't require special tools or certifications.

But when it comes to compressor replacement, refrigerant system work, PCB board programming, electrical panel modifications, or anything covered under warranty, call in the pros. Turbo Air's branch technicians know their stuff and can get you back up and running quickly.

The smart move is keeping spare-part kits for common turbo air parts so you can make temporary fixes while waiting for professional service. It's like having a first-aid kit—you hope you won't need it, but you're glad it's there when you do.

Safety always comes first when working with commercial refrigeration. Always disconnect power before starting any work, and never mess with refrigerant systems unless you're properly certified. For more technical details about how these systems work, check out our Complete Guide to Fridge Compressor Function and Operation.

OEM Turbo Air Parts vs Aftermarket Alternatives

When your Turbo Air equipment needs repairs, you'll face a choice that can make or break your investment. Should you go with genuine turbo air parts or save money with aftermarket alternatives? It's a decision that affects more than just your immediate budget.

I've seen operators try to cut corners with generic parts, only to face bigger headaches down the road. The upfront savings rarely justify the long-term costs. Here's why genuine parts usually win the day.

Warranty protection disappears the moment you install aftermarket components. Turbo Air's warranty terms are crystal clear—they require genuine turbo air parts to keep coverage intact. Lose that warranty on a major component like a compressor, and you could be looking at thousands in uncovered repairs.

Safety certifications matter more than you might think. Genuine parts carry UL and NSF compliance stamps that aftermarket alternatives often skip. In commercial foodservice, these aren't just nice-to-have certificates. They're your protection against liability issues and health code violations that can shut down operations.

Performance reliability shows its true colors over time. OEM turbo air parts are engineered to work perfectly with your existing system. Generic parts might fit, but they create stress points that can cause other components to fail early. It's like putting the wrong size tire on your car—it works until it doesn't.

| Component | OEM Lifespan | Aftermarket Lifespan | Warranty Impact | Energy Efficiency |

|---|---|---|---|---|

| Compressors | 7-10 years | 3-5 years | Voids warranty | Maintains rated efficiency |

| Fan Motors | 2-4 years | 1-2 years | Voids warranty | May reduce airflow |

| Control Boards | 5-7 years | 2-3 years | Voids warranty | Programming issues possible |

| Door Gaskets | 12-18 months | 6-9 months | Usually acceptable | Seal quality varies |

The numbers tell the story. Compressors with genuine parts last twice as long as aftermarket versions. Fan motors and control boards show similar patterns. Even door gaskets, where aftermarket options are more acceptable, still don't match OEM quality and lifespan.

How OEM Turbo Air Parts Support Sustainability & Energy Efficiency

Turbo Air didn't just design their self-cleaning condenser system to impress—they built it to save energy and reduce environmental impact. But those 15-25% energy savings only happen when you maintain the system with genuine turbo air parts.

The company's move toward natural refrigerants like R-290 creates another layer of complexity. These eco-friendly refrigerants operate at different pressures and temperatures than traditional ones. Generic parts simply aren't designed for these conditions, potentially creating safety hazards that no operator wants to face.

Forced-air cold bunker technology represents another area where precision matters. This system improves temperature distribution throughout refrigerated spaces, but it requires exactly the right fan motors and control systems. Install a generic fan motor, and you might lose the precise airflow characteristics that make the system work efficiently.

Turbo Air's sustainability commitment extends beyond just using natural refrigerants. Their entire parts ecosystem is designed to maximize equipment lifespan and minimize waste. When you choose genuine turbo air parts, you're supporting a circular approach that keeps equipment running longer and reduces the need for premature replacements.

For detailed information about Turbo Air's sustainability initiatives and their complete parts catalog, visit Turbo Air's official website. Their commitment to environmental responsibility shows in every component they manufacture.

Frequently Asked Questions about Turbo Air Parts

How do I cross-reference my model number to the correct Turbo Air replacement part?

Finding the right turbo air parts starts with that little metal plate inside your unit—the serial plate. This contains your complete model number and manufacturing date, which are like fingerprints for your equipment. Every Turbo Air unit has a unique identifier that tells you exactly which parts will fit.

The easiest approach is using Turbo Air's online parts catalog with your model number in hand. Their system automatically filters compatible parts once you enter your equipment details. If you're more of a phone person, any authorized distributor can walk you through the process—they deal with turbo air parts cross-referencing all day long.

Here's a helpful tip from our experience: Turbo Air's model numbers follow a logical pattern. The series designation tells you the equipment type, while capacity and configuration details determine which specific parts you need. Newer units even have QR codes that link directly to parts diagrams, making the whole process much simpler.

Will using aftermarket parts void my Turbo Air warranty?

This is probably the most important question we get about turbo air parts, and the answer is straightforward: yes, aftermarket parts will void your warranty. Turbo Air's warranty terms are crystal clear about requiring genuine OEM parts to maintain coverage.

We've seen this play out in our own industry. A funeral home saves fifty dollars on an aftermarket fan motor, then faces a $3,000 compressor replacement that's no longer covered under warranty. The aftermarket part didn't even cause the compressor failure, but its presence voided the entire warranty.

This applies to both your original equipment warranty and any extended service agreements you might have purchased. Even if you're handy with repairs, using non-genuine turbo air parts can turn a covered repair into an expensive out-of-pocket expense.

What innovative technologies are unique to Turbo Air equipment?

Turbo Air has developed some genuinely clever solutions that set them apart from other manufacturers. Their patented self-cleaning condenser system is the standout innovation—it automatically brushes away debris buildup while the unit runs normally. This isn't just a convenience feature; it delivers real 15-25% energy savings while reducing your maintenance headaches.

The forced-air cold bunker technology might sound technical, but it solves a common problem: hot spots and cold spots inside refrigerated spaces. This system ensures even temperature distribution throughout the unit, which is crucial for food safety and product quality.

Their digital temperature controllers go beyond basic temperature monitoring. These systems provide precise control and diagnostic capabilities that help identify potential turbo air parts failures before they cause complete breakdowns. Error codes appear on the display, giving you advance warning when components need attention.

Turbo Air's commitment to natural refrigerants like R-290 also deserves mention. While this might seem like an environmental feel-good measure, it actually requires sophisticated engineering to handle different operating pressures and temperatures safely. This forward-thinking approach ensures their equipment meets evolving environmental regulations.

Conclusion

When it comes to keeping your commercial refrigeration running smoothly, genuine turbo air parts aren't just a recommendation—they're your best insurance policy against costly downtime and equipment failures. We've seen this at American Mortuary Coolers, where temperature control failures simply aren't an option.

Turbo Air has built something impressive with their network of 10+ branch locations and their promise to fulfill 95% of service calls within three business days. But here's the thing—waiting for emergency service calls is like closing the barn door after the horse has bolted. The real magic happens when you stay ahead of problems with scheduled maintenance and genuine parts replacement.

Over our years serving funeral homes across the contiguous 48 states from our Tennessee base, we've learned that reliable refrigeration systems share one common trait: they're maintained with the right parts at the right intervals. Whether it's a compressor lasting its full 7-10 years or door gaskets getting replaced every 6-12 months, consistency with genuine components makes all the difference.

The math on genuine turbo air parts is actually pretty straightforward. You might save a few dollars upfront with aftermarket alternatives, but those savings evaporate quickly when you factor in voided warranties, reduced energy efficiency, and shorter component lifespans. Turbo Air's self-cleaning condenser system delivering 15-25% energy savings only works properly with genuine components—that's real money staying in your pocket month after month.

What really impresses us about Turbo Air's approach is their commitment to sustainability through natural refrigerants like R-290 and Energy Star certification on 140+ models. This isn't just good for the environment—it's good for your operating costs too. But these advanced systems need genuine parts to function as designed.

At American Mortuary Coolers, we understand that every piece of refrigeration equipment in your facility has a job to do, and it needs to do that job reliably. That's why we recommend the same approach to turbo air parts that we bring to our custom mortuary cooler solutions: use quality components, maintain them properly, and they'll serve you well for years to come.

For operators managing multiple refrigeration units, our guide on Top Refrigeration Units for Your Walk-In Cooler Needs provides additional insights into selecting and maintaining commercial refrigeration systems that complement your Turbo Air equipment.

Your refrigeration equipment works around the clock to protect your inventory and maintain food safety standards. Giving it the genuine turbo air parts it was designed to use isn't just smart business—it's the foundation of a reliable operation that keeps running when you need it most.