The Complete Guide to Histology Supplies

Why Quality Histology Supplies Are the Foundation of Accurate Diagnostics

Histology supplies are the specialized tools, consumables, and reagents used in laboratories to prepare, process, and examine tissue samples at the microscopic level. These essential materials enable pathologists and researchers to diagnose diseases, conduct medical research, and ensure patient safety through accurate tissue analysis.

Essential histology supplies include:

- Consumables - microscope slides, coverslips, tissue cassettes, paraffin wax, staining reagents

- Equipment - microtomes, tissue processors, embedding centers, cryostats, automated stainers

- Reagents - fixatives (formalin), dehydrants (ethanol), clearing agents (xylene), mounting media

- Ancillaries - labels, markers, storage systems, cleaning supplies, personal protective equipment

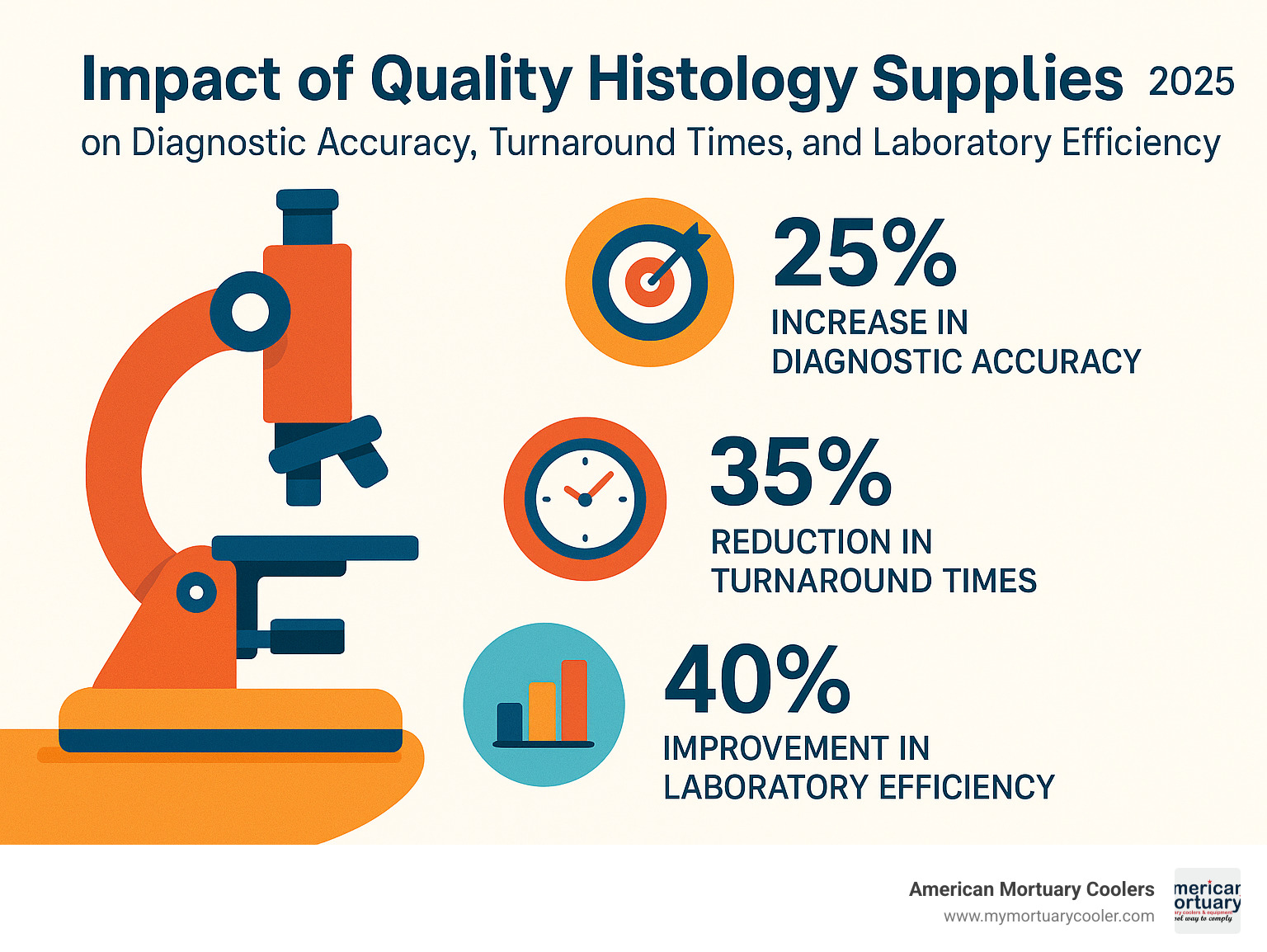

Modern histology labs depend on consistent, high-quality supplies to maintain workflow efficiency and deliver reliable diagnostic results. As one industry expert notes: "The smooth running of any laboratory depends on a consistent supply of high-quality consumables." Poor-quality supplies can lead to processing errors, delayed diagnoses, and compromised patient care.

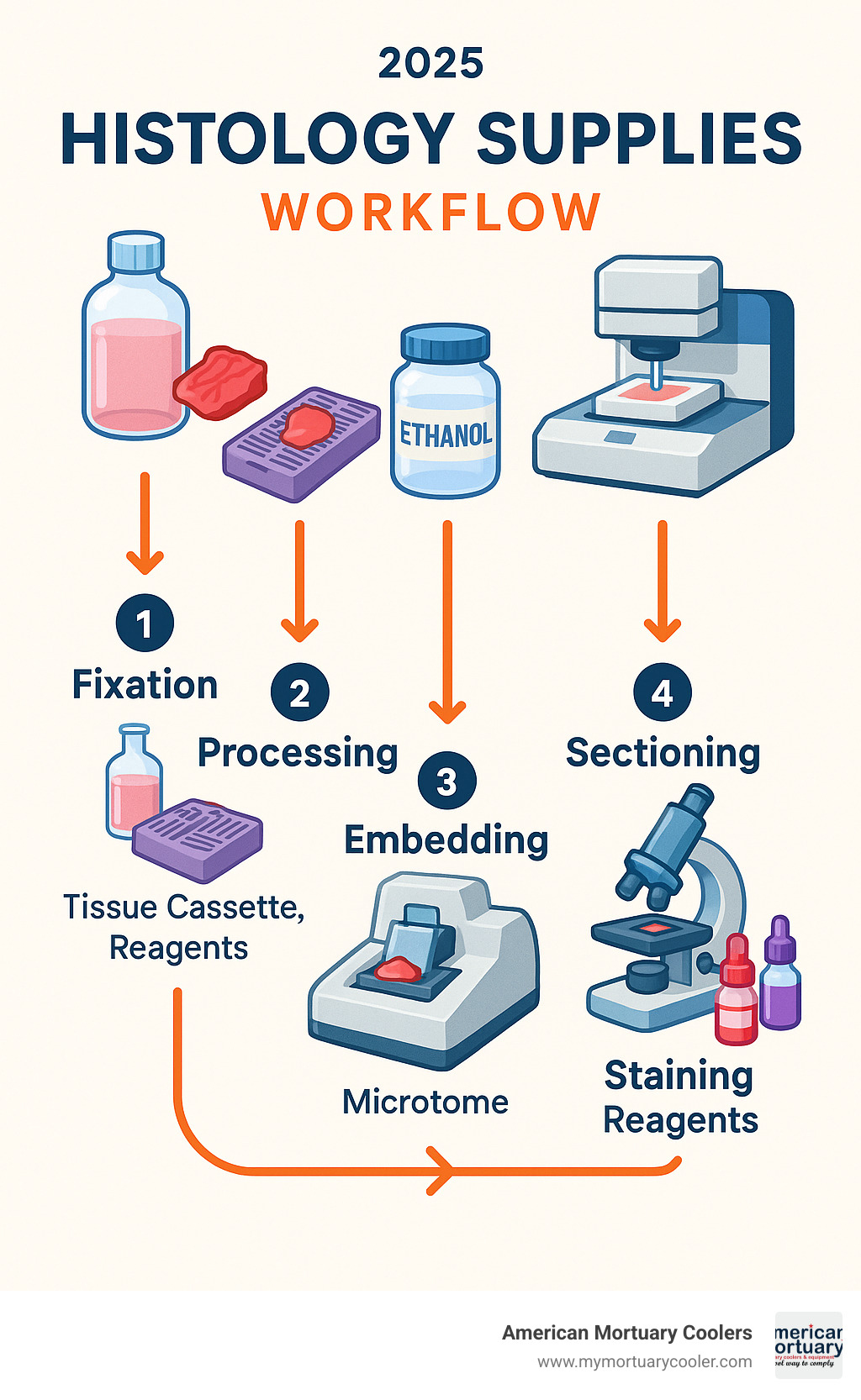

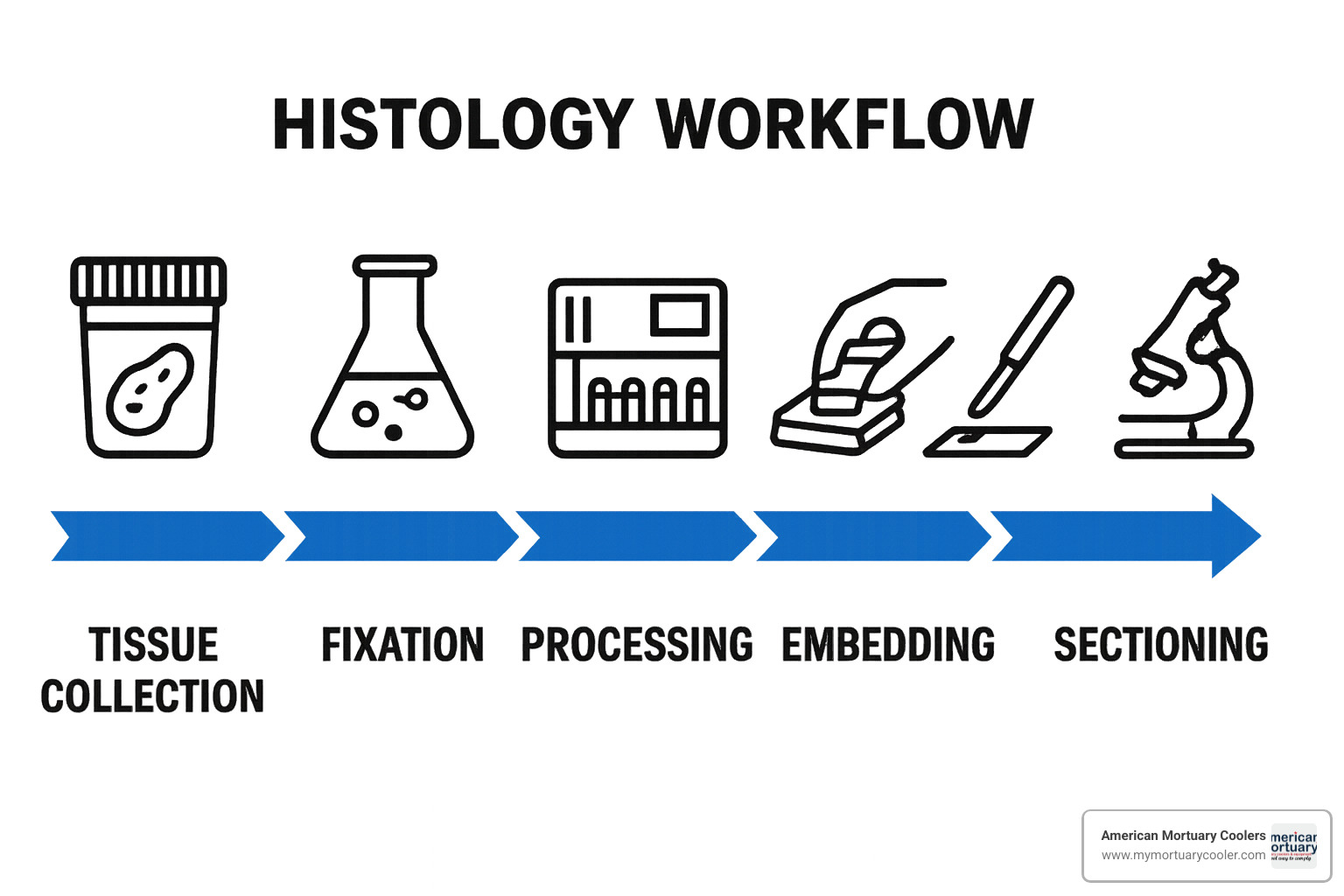

The histology workflow follows five critical steps: fixation, processing, embedding, sectioning, and staining. Each stage requires specific supplies that must meet strict quality standards to ensure accurate results. Labs serving funeral homes and medical facilities need reliable suppliers who understand the urgency of diagnostic work and can provide consistent product availability.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience providing specialized equipment to funeral homes and pathology labs. My background in mortuary equipment has given me deep insight into how quality histology supplies directly impact diagnostic accuracy and operational efficiency in healthcare facilities.

Histology supplies terms simplified:

What Are Histology Supplies & Why They're Essential

Think of histology supplies as the essential toolkit that transforms tissue into a microscopic window revealing disease, health, and healing. These specialized materials include everything from microscope slides to complex reagents that bring cellular structures into sharp focus.

Every day, pathologists rely on these supplies to make life-changing diagnoses. When a surgeon removes a suspicious lump during a biopsy, it's the quality of histology supplies that determines whether that tissue can tell its story clearly under the microscope.

Tissue diagnostics wouldn't exist without this intricate dance of chemistry and precision. Each reagent, slide, and processing step must work in perfect harmony to preserve the delicate architecture of cells and tissues.

Lab accuracy depends on consistency at every level. The formalin that fixes tissue samples must be fresh and properly buffered. The paraffin that embeds specimens needs the right temperature and consistency. Even microscope slides must be perfectly clean and free from scratches that could obscure critical diagnostic features.

Patient safety hangs in the balance with every tissue sample processed. A cancer diagnosis missed because of poor tissue preparation, or a false positive result due to contaminated reagents, can derail a patient's entire treatment plan.

Regulatory compliance isn't just paperwork - it's a safety net. Organizations like CLIA set strict standards because shortcuts in histology can have devastating consequences. These regulations ensure every lab maintains high standards, whether processing samples in a major medical center or small community hospital.

The Role of Histology in Modern Labs

Microscopic anatomy reveals secrets the naked eye cannot see. While a surgeon might notice tissue looks "suspicious," only histological examination can definitively identify cancer cells, measure their aggressiveness, and determine if they've spread.

Modern disease diagnosis relies heavily on pattern recognition at the cellular level. Pathologists spend years learning to distinguish subtle differences in cell shape, size, and arrangement that separate one disease from another.

In our work with funeral homes and medical facilities, we've seen how critical timing can be. During frozen section procedures, surgeons wait in operating rooms while pathologists race to provide diagnoses that guide immediate surgical decisions. There's no room for equipment failures or supply shortages when someone's life hangs in the balance.

Main Categories of Histology Supplies

Understanding the three main categories of histology supplies makes all the difference in successful lab management. Each category plays a unique role in keeping your diagnostic workflow running smoothly.

Consumables are your daily essentials, equipment represents major investments that form the backbone of operations, and reagents are specialized chemicals that make the magic happen at each processing step.

| Category | Examples | Typical Cost | Replacement Frequency |

|---|---|---|---|

| Consumables | Slides, cassettes, reagents | $5,000-15,000/month | Daily to weekly |

| Equipment | Microtomes, processors | $50,000-200,000 | 5-15 years |

| Reagents | Formalin, xylene, stains | $2,000-8,000/month | Monthly to quarterly |

Smart budget planning means balancing these three categories. While equipment costs hit hard upfront, consumables and reagents create ongoing expenses that add up over time.

Consumable Histology Supplies

Consumables are the workhorses of your histology lab - items you'll order most frequently and go through fastest. These include microscope slides, coverslips, tissue cassettes, paraffin blocks, staining solutions, adhesives, and labels.

Microscope slides and coverslips might seem simple, but they're precision instruments. Quality slides need consistent thickness, smooth surfaces, and proper adhesive coatings. Poor-quality slides cause tissue sections to float off during staining.

Tissue cassettes are your specimen's home throughout processing. Modern cassettes feature ventilation slots for fluid flow, secure locking mechanisms, and chemical-resistant materials.

Paraffin wax quality makes a huge difference in sectioning performance. High-grade paraffin melts consistently at 55-57°C, provides excellent tissue support, and ribbons beautifully during microtomy.

Staining reagents need lot-to-lot consistency for reliable results. Hematoxylin and eosin (H&E) stains remain the gold standard, with eosin working best at pH 4.5-5.

Equipment Histology Supplies

Equipment represents your biggest upfront investment, but these workhorses serve your lab faithfully for years when properly maintained. This includes microtomes, tissue processors, embedding centers, cryostats, slide stainers, and imaging systems.

Microtomes slice tissues into incredibly thin sections - 0.5 to 10 microns thick. Modern microtomes feature ergonomic designs, precise thickness controls, and safety mechanisms.

Tissue processors handle dehydration, clearing, and infiltration steps automatically. These systems process dozens of cassettes simultaneously while ensuring consistent results.

Embedding centers maintain precise temperature control for optimal paraffin handling. Quality stations feature heated forceps, temperature-controlled dispensers, and cold plates for rapid cooling.

Cryostats are specialized microtomes working at sub-zero temperatures, enabling rapid frozen sectioning for intraoperative consultations.

Reagents & Ancillaries

Reagents include chemical solutions that make tissue processing possible, along with ancillary supplies like fixatives, dehydrants, clearing agents, mounting media, cleaning wipes, and personal protective equipment.

Fixatives like formalin stabilize tissue proteins and prevent degradation. Pre-filled containers reduce handling risks and ensure proper ratios.

Dehydrating agents - primarily graded ethanol solutions - systematically remove water from tissues. Clearing agents like xylene remove alcohol and make tissues compatible with paraffin.

Mounting media preserve stained sections and provide optical clarity for microscopic examination. Modern media resist fading and maintain transparency during storage.

Learn More about routine stains to explore specialized staining options.

Histology Workflow & the Supplies Needed at Each Stage

The histology workflow transforms fresh tissue specimens into diagnostic slides through six sequential stages. Each step requires specific supplies and careful attention to quality control.

Understanding this workflow helps laboratories optimize supply inventory, reduce processing errors, and maintain consistent turnaround times. We've worked with pathology labs that reduced their slide turnaround time by 47% through workflow optimization and proper supply management.

Step 1: Fixation

Fixation preserves tissue architecture and prevents bacterial decomposition. Formalin remains the gold standard fixative, typically used as 10% neutral buffered formalin.

Pre-filled formalin containers eliminate mixing errors and reduce formaldehyde exposure risks. These containers ensure proper fixative-to-tissue ratios and include safety features like tamper-evident caps.

Formalin neutralizers help laboratories manage chemical hazards and comply with environmental regulations. Green chemistry alternatives reduce formaldehyde exposure while maintaining excellent tissue preservation.

Proper fixation timing is critical - under-fixation leads to poor morphology while over-fixation can mask antigen sites needed for immunohistochemistry.

Step 2: Processing

Processing removes water from tissues and replaces it with paraffin wax through automated tissue processors. This involves sequential treatment with graded alcohols, clearing agents, and molten paraffin.

Graded ethanol solutions (70%, 80%, 95%, 100%) gradually dehydrate tissues without causing excessive shrinkage. High-purity solvents filtered to remove particulates ensure cleaner processing results.

Xylene or xylene substitutes clear alcohol from tissues and make them compatible with paraffin. Proper ventilation and safety equipment are essential when handling these volatile solvents.

Modern tissue processors can handle 200+ cassettes per run, with programmable cycles optimized for different tissue types and sizes.

Step 3: Embedding

Embedding orients tissues in paraffin blocks for optimal sectioning. This requires embedding centers with temperature-controlled paraffin dispensers and precision molds.

Paraffin dispensers maintain wax at optimal temperatures (typically 60-65°C) and deliver consistent amounts without air bubbles. Quality dispensers feature heated forceps to prevent paraffin solidification during handling.

Base molds come in various sizes to accommodate different tissue types. Proper tissue orientation in molds ensures diagnostic areas are accessible during sectioning.

Embedding centers often include cold plates for rapid block cooling, reducing processing time and improving workflow efficiency.

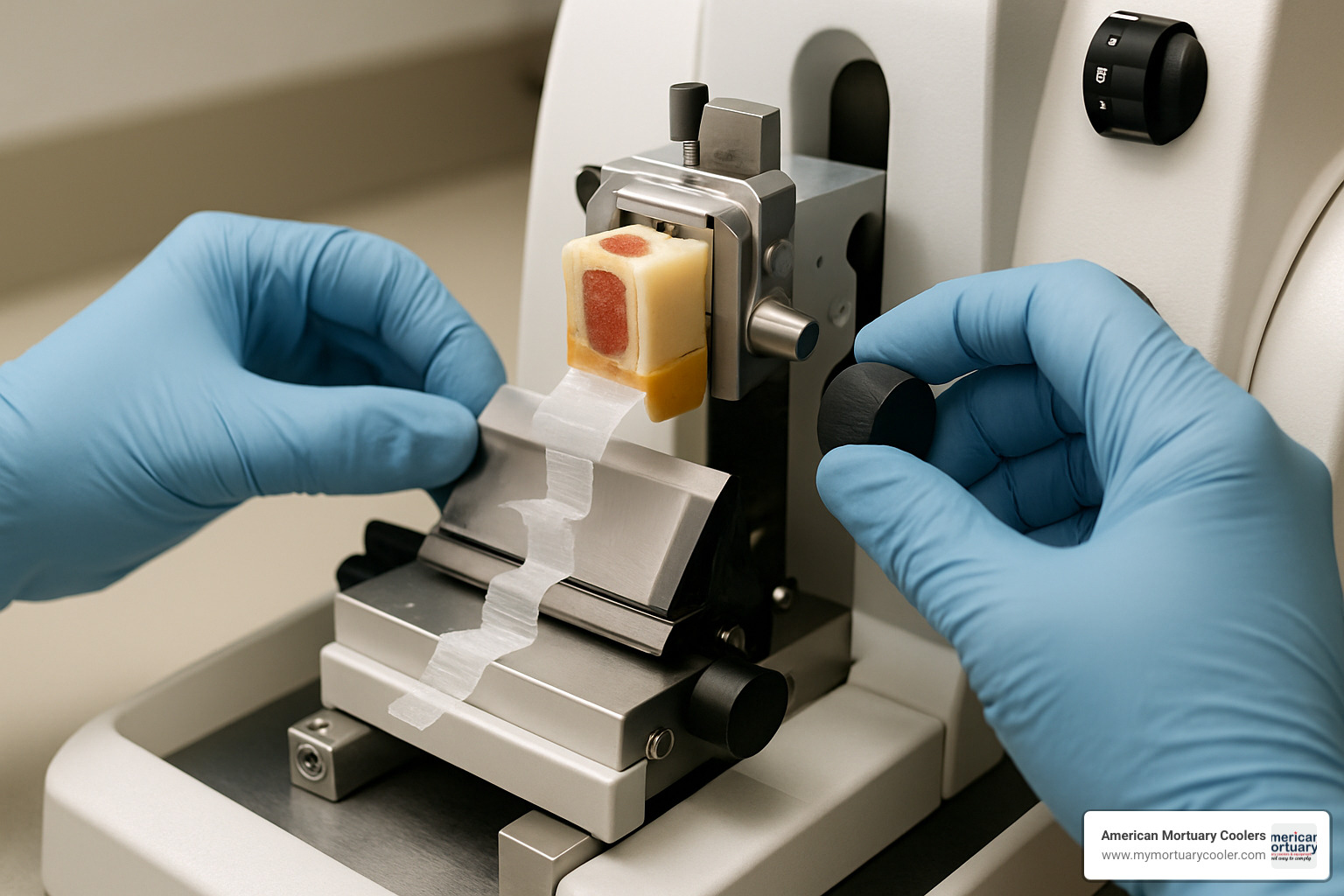

Step 4: Sectioning

Sectioning produces thin tissue sections (typically 3-5 microns) suitable for microscopic examination. This requires sharp microtome blades, properly maintained equipment, and skilled technique.

Microtome blades must be extremely sharp and free from nicks or damage. Disposable blades ensure consistent cutting performance and eliminate sharpening requirements.

For frozen sections, cryostat media like OCT (Optimal Cutting Temperature) compound supports tissues during sub-zero sectioning. These water-based media wash away easily and don't interfere with staining.

Anti-roll plates prevent sections from curling during cutting, ensuring smooth ribbon formation and easier slide mounting.

Scientific research on section thickness provides detailed guidelines for optimal sectioning parameters.

Step 5: Staining & Coverslipping

Staining provides contrast that enables cellular visualization and diagnostic interpretation. H&E staining remains the routine standard, while special stains highlight specific tissue components.

H&E staining kits must provide consistent color balance and reproducible results. Hematoxylin stains cell nuclei blue-purple, while eosin stains cytoplasm various shades of pink.

Automated stainers ensure consistent timing, temperature, and reagent application. These systems reduce variability and free technologists for other tasks.

Coverslippers apply coverslips and mounting media automatically, ensuring bubble-free mounting and consistent results. Automated systems can process hundreds of slides per hour.

Learn More about slides & coverglass for detailed specifications and selection criteria.

Step 6: Imaging, Archiving & Transport

Final steps include microscopic examination, digital imaging, and long-term storage. This requires microscopes, digital scanners, and archival storage systems.

Research-grade microscopes enable brightfield, darkfield, phase contrast, and fluorescence examination. Digital imaging systems capture high-resolution images for documentation and consultation.

Slide storage boxes protect finished slides during transport and archival storage. These boxes feature secure closures, clear labeling areas, and slots sized for standard slides.

Cassette storage cabinets organize processed tissue blocks for long-term retention. Many institutions maintain tissue blocks for decades to enable future testing if needed.

More info about slide storage solutions provides comprehensive storage recommendations.

How to Choose and Maintain High-Quality Histology Supplies

Choosing the right histology supplies focuses on three key areas: quality consistency, reliable vendor support, and total cost of ownership.

The cheapest supplies often become the most expensive mistakes. When slides break during processing or reagents give inconsistent results, you face delayed diagnoses, repeat procedures, and frustrated staff. Smart labs invest in proven suppliers who understand that consistent availability matters as much as product quality.

Look for vendors offering comprehensive support beyond product delivery. The best suppliers provide technical assistance, training programs, and rapid problem resolution when facing deadlines.

Quality & Consistency Impact on Results

Lot-to-lot consistency can make or break diagnostic accuracy. Labs often struggle with staining variations caused by switching reagent lots without proper validation.

Smart quality control starts with testing new reagent lots against established standards before routine use. This prevents concerning moments when H&E staining suddenly looks different.

Accreditation requirements from organizations like CAP aren't just paperwork. They're designed to catch problems before affecting patient care. Labs must demonstrate consistent performance through proficiency testing and internal quality assurance.

More info about nitrile gloves covers important safety considerations.

Safety, Environmental & Compliance Considerations

Formalin safety presents unique challenges requiring specialized handling procedures and environmental controls. OSHA regulations are mandatory requirements protecting staff and facilities.

Many labs find green chemistry alternatives offer benefits beyond environmental protection. Safer reagents often reduce insurance costs, simplify waste disposal, and create better working conditions.

Waste disposal regulations vary by location. Work with licensed disposal contractors who understand local requirements and help manage costs effectively.

Digital Solutions & Automation Trends

The future of histology is digital. Digital-ready workflows require compatible supplies and integrated systems working together seamlessly.

Cassette printers eliminate illegible handwritten labels. Barcode tracking systems maintain chain of custody and prevent specimen mix-ups.

AI-ready slides position labs to leverage artificial intelligence for diagnostic assistance. These specially prepared slides are optimized for digital scanning and computer analysis.

Learn more about histology automation to explore advanced workflow solutions.

Vendor Services & Support

Your supply vendor relationship should feel like a partnership. Comprehensive vendor support makes the difference between smooth operations and constant firefighting.

Training programs ensure staff understands proper product use and safety procedures. Maintenance contracts minimize downtime through scheduled preventive maintenance and rapid repair response.

Remote troubleshooting capabilities keep labs operational during critical periods, especially valuable for smaller communities.

More info about grossing stations provides insights into equipment selection and vendor evaluation.

Frequently Asked Questions about Histology Supplies

When working with pathology labs across the country, we hear the same questions about histology supplies time and again. These concerns usually center around efficiency, quality, and safety - the three pillars that keep diagnostic labs running smoothly.

Let me share the most common questions we encounter and the practical answers that have helped countless labs improve their operations.

Why do histology labs prefer dedicated "plug-and-play" consumables?

The beauty of dedicated plug-and-play consumables lies in their simplicity and reliability. When you're processing dozens of tissue samples under tight deadlines, the last thing you need is compatibility headaches or unexpected variables throwing off your results.

These pre-matched supply systems eliminate the guesswork entirely. The reagents work perfectly with the equipment, the timing is already optimized, and the quality control is built right in. As one lab manager told us, "We used to spend hours troubleshooting staining inconsistencies. Now we just load the cartridge and trust the results."

Beyond convenience, these systems actually improve diagnostic accuracy by removing human error from the equation. When everything is designed to work together seamlessly, your technologists can focus on what they do best - preparing perfect slides for accurate diagnoses.

The time savings alone often justify the investment. Instead of mixing reagents, calibrating equipment, and troubleshooting problems, your team can process more samples and deliver faster results to patients who are waiting for answers.

How often should microtome blades be changed for optimal section quality?

This question doesn't have a one-size-fits-all answer, and that's actually good news - it means you can optimize blade changes based on your specific workload and quality standards.

Hard tissues like bone or heavily calcified specimens are absolute blade killers. You might need fresh blades after just a few sections when working with these challenging samples. Soft tissues, on the other hand, are much gentler and can allow a single blade to last through dozens of sections.

The real answer lies in watching your section quality rather than following a rigid schedule. When you start seeing compression artifacts, chatter marks, or uneven thickness, it's time for a new blade. Quality indicators include smooth ribbon formation, consistent section thickness, and complete absence of knife marks or tissue tears.

High-volume labs often change blades daily as a preventive measure, while smaller labs might stretch blade life for several days. The key is developing a routine that matches your volume and quality requirements. A dull blade doesn't just affect section quality - it can also damage valuable tissue samples that can't be replaced.

What's the safest way to store large volumes of xylene in the lab?

Xylene storage is one of those topics that keeps lab managers awake at night, and for good reason. This essential clearing agent is both highly flammable and potentially harmful to human health, making proper storage absolutely critical.

Start with approved safety cabinets designed specifically for flammable liquids. These cabinets should be located away from any heat sources, electrical equipment, or potential ignition risks. The investment in proper storage equipment pays for itself the first time it prevents an accident.

Secondary containment systems are your backup plan when things go wrong. Spill containment trays or berms prevent xylene from spreading across your lab floor if a container leaks or breaks. We've seen too many labs learn this lesson the hard way.

Many forward-thinking labs are transitioning to xylene substitutes that provide similar clearing performance with significantly reduced safety risks. These alternatives often cost slightly more but eliminate many storage headaches and reduce liability concerns.

Don't forget about inventory rotation - xylene can degrade over time, especially when exposed to light or temperature fluctuations. Proper ventilation in storage areas protects your staff from vapor exposure, while regular safety training ensures everyone knows how to handle emergencies.

The bottom line? Invest in proper storage equipment, maintain good ventilation, and consider safer alternatives when they become available. Your staff's safety and your lab's reputation are worth the extra effort.

Conclusion & Next Steps

Building a successful histology lab starts with understanding that histology supplies aren't just products on a shelf - they're the backbone of every accurate diagnosis that helps save lives. When a pathologist examines tissue under a microscope to determine if a patient has cancer, the clarity of that diagnosis depends entirely on the quality of supplies used throughout the entire process.

The future of histology is exciting, with automation making workflows smoother, digital integration connecting labs like never before, and improved safety measures protecting the dedicated professionals who do this critical work. Labs that invest wisely in quality supplies today are setting themselves up to handle whatever diagnostic challenges tomorrow brings.

As someone who's spent years working with funeral homes and pathology labs across Tennessee and beyond, I've seen how the right equipment makes all the difference. At American Mortuary Coolers, we understand that quality isn't just a nice-to-have - it's essential for the families and patients who depend on accurate results.

Whether you're starting fresh with a new histology lab or breathing new life into an existing facility, remember this: your supplier relationship matters just as much as the supplies themselves. Look for partners who understand your daily challenges, respond quickly when problems arise, and genuinely care about helping you succeed.

The investment in quality histology supplies might seem significant upfront, but it pays for itself through fewer processing errors, faster turnaround times, and most importantly, the confidence that comes from knowing your diagnoses are rock-solid. Your patients deserve nothing less.

More info about anatomic pathology equipment provides additional insights into creating comprehensive pathology facilities that serve both clinical and research needs.