The Complete Guide to Choosing a Stainless Steel Table

Why Stainless Steel Tables Are Essential for Professional Operations

A stainless-steel-table- is a durable work surface made from corrosion-resistant steel alloy, commonly used in commercial kitchens, laboratories, and mortuary facilities for food preparation, equipment support, and sterile work environments.

Key Features of Stainless Steel Tables:

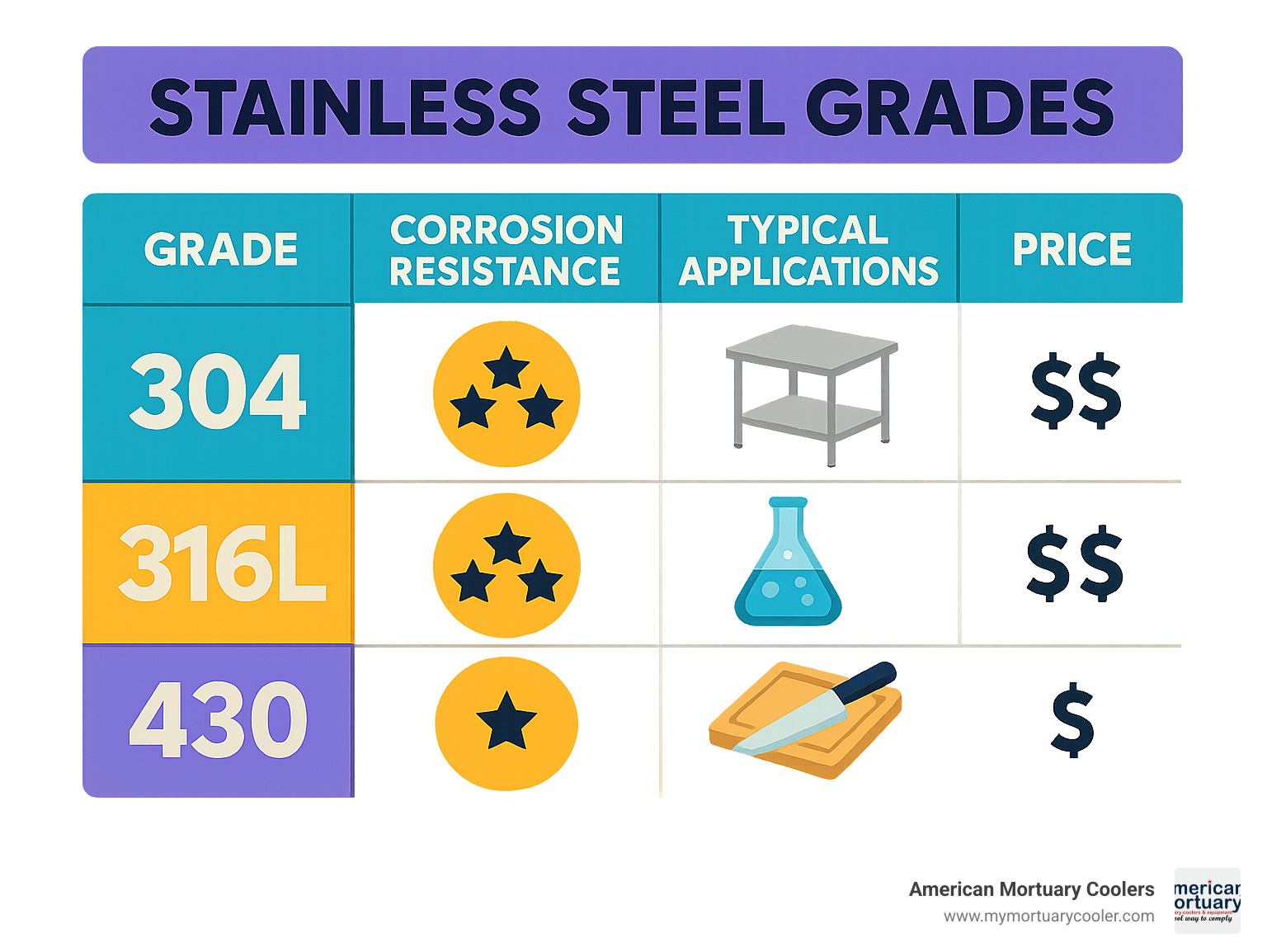

- Grades: 304 (food service), 316L (marine/lab), 430 (budget-friendly)

- Gauges: 14-gauge (heavy-duty), 16-gauge (standard), 18-gauge (light-duty)

- Types: Open base, cabinet base, equipment stands, prep tables

- Sizes: 24"-96" length, 24"-36" depth, standard 34"-36" height

- Weight Capacity: 150-800+ lbs depending on construction

- Certifications: NSF-rated for food service applications

Stainless steel tables have become the industry standard across multiple sectors because they combine best durability with superior hygiene. The non-porous surface resists bacteria, stains, and corrosion while withstanding heavy daily use.

With over 350 different models available from major retailers and weight capacities ranging from 150 to 800+ pounds, these tables adapt to virtually any professional workspace.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in stainless-steel-table- selection and customization for funeral homes and medical facilities. My background in mortuary equipment helps facilities choose tables that meet strict hygiene standards while maximizing operational efficiency.

Know your stainless-steel-table- terms:

What Makes Stainless Steel Tables Stand Out

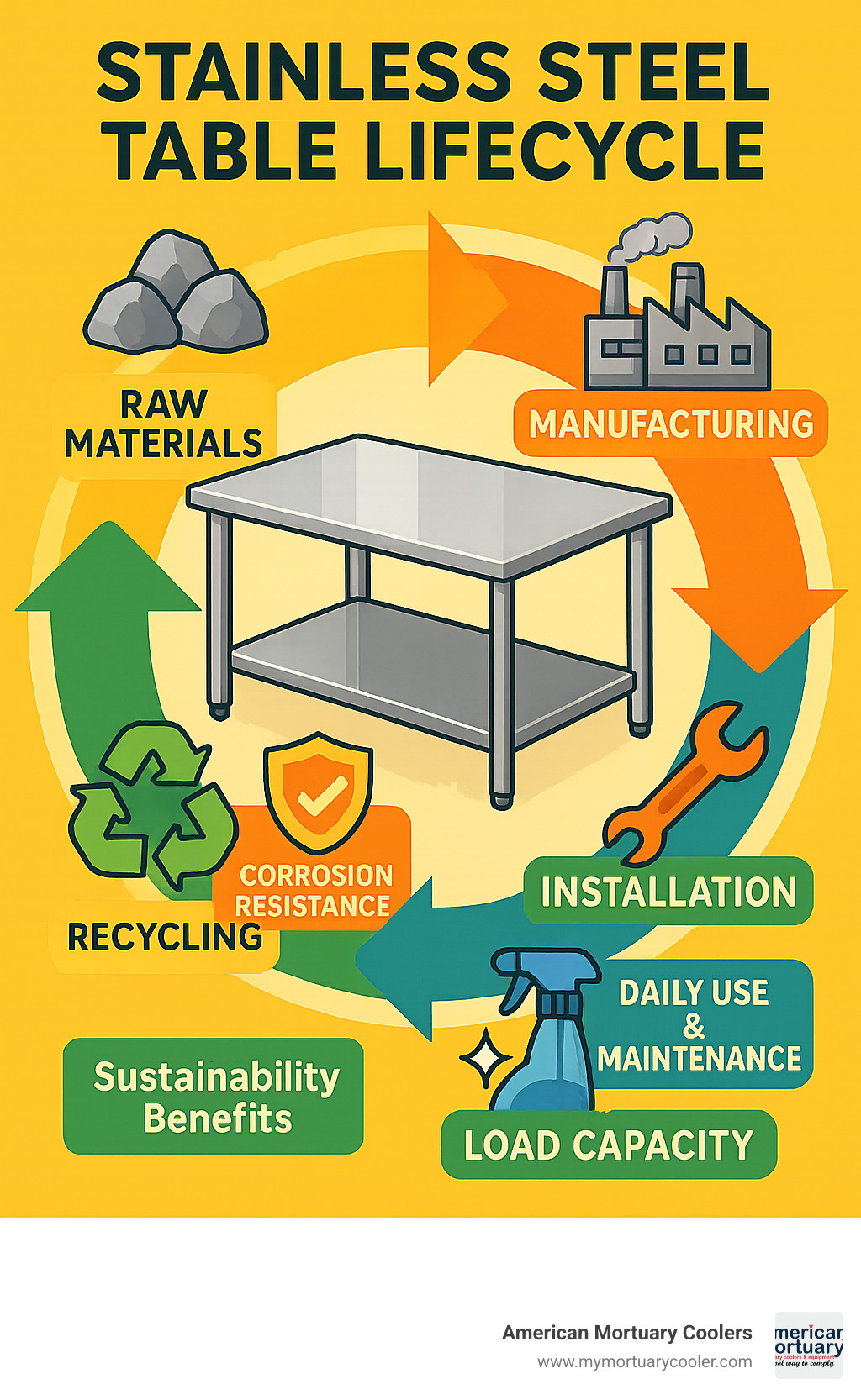

When you're investing in a stainless-steel-table-, you're getting much more than just a work surface. The magic happens at the molecular level, where chromium makes up at least 10.5% of the steel's composition. This creates an invisible chromium oxide layer that acts like a superhero shield against rust and corrosion.

This protective layer is self-healing. Scratch it, and it automatically reforms when exposed to oxygen. It's like having a table that repairs itself while you work.

The non-porous surface is where hygiene really shines. Unlike wood or plastic that can harbor bacteria in tiny cracks, stainless steel gives germs nowhere to hide. This is why you'll find these tables in mortuary coolers, prep kitchens, hospitals, and anywhere cleanliness is critical.

A properly built stainless-steel-table- can handle serious weight, from 150 pounds on lighter models up to 800+ pounds on heavy-duty units. That load capacity comes from smart engineering like gusset reinforcements and the steel's natural toughness.

Heat resistance means you can set hot equipment directly on the surface without worry. The aesthetic appeal doesn't hurt either—that clean, professional look brightens any workspace and never goes out of style.

From an environmental standpoint, stainless steel tables are champions of sustainability. They're 100% recyclable and last for decades, making them an eco-friendly choice that reduces waste over time.

Scientific research on stainless steel durability backs up what professionals already know—these materials maintain their strength and appearance even under heavy commercial use.

Durability & Hygiene Benefits

The chromium oxide layer creates a surface that's naturally antimicrobial and incredibly easy to sanitize. Easy sanitizing becomes second nature with stainless steel. A quick wipe with standard disinfectants is all it takes.

Food-grade safety is built right into the material. Grade 304 stainless steel meets all FDA requirements for direct food contact.

Commercial vs Residential Advantages

Restaurants put stainless steel tables through the ultimate stress test. They resist stains from acidic ingredients, won't absorb odors, and can be cleaned quickly between prep tasks.

Laboratories need surfaces that won't react with chemicals or compromise sterile environments. Home kitchens are catching on to what professionals have known for years.

Weight Capacity & Safety Features

Gusset reinforcements distribute weight evenly across the entire structure. Rounded edges prevent cuts and bruises during busy work periods. Adjustable feet solve the problem of wobbly tables on uneven floors.

Types, Sizes & Grades Explained

Choosing the right stainless-steel-table- becomes simpler once you understand the basic categories.

Open-base tables are the workhorses of most professional kitchens. They give staff plenty of legroom and you can see the floor underneath for easy cleaning.

Cabinet-base tables combine a table and storage unit in one package. The enclosed base hides supplies and gives you a cleaner look for front-of-house areas.

Equipment stands are built specifically to handle heavy machinery. They're usually shorter at 24" height and reinforced to handle weight and vibration.

Prep tables are designed with food preparation in mind, often featuring cutting boards, ingredient bins, or integrated sinks.

The grade determines how well your table handles different environments:

304 grade is your reliable everyday choice with 18% chromium and 8% nickel. It's the standard for food service because it handles acidic foods and frequent cleaning.

316L grade is the premium option that adds molybdenum for extra protection against harsh chemicals and salt water.

430 grade is the budget-friendly option with 17% chromium but no nickel. It's less corrosion-resistant but works for basic prep work.

Gauge thickness works backward - smaller numbers mean thicker, stronger tables. 14-gauge at 0.0781" thick is built for heavy-duty use. 16-gauge at 0.0625" thick handles standard commercial work. 18-gauge at 0.05" thick works for light-duty prep.

Standard depths include 24", 30", and 36" to fit different layouts. Lengths range from 24" to 96" or longer for custom applications.

Core Table Types

Open-base tables with undershelves give you legroom plus storage space below. Mobile tables with casters turn any workspace into a flexible operation with four-inch swivel casters and brakes.

Grade & Gauge Breakdown

304 stainless steel for foodservice dominates commercial kitchens with excellent corrosion resistance at reasonable cost. 316L for marine and lab environments justifies higher cost with superior resistance to chlorides and acids. 430 for budget applications offers practical compromise for controlled environments.

Size & Custom Dimension Guide

24" to 96" length options increment by 12 inches. Most commercial kitchens use 48", 60", or 72" tables. 24", 30", and 36" depths accommodate different workflow patterns. Custom height beyond standard 34-36" helps with ergonomics and equipment clearance.

Choosing the Perfect stainless-steel-table-

Finding the right stainless-steel-table- isn't just about picking the biggest one in your budget. It's about understanding how your team actually works.

Workflow analysis starts with watching your team work. Where do they spend most of their time? What supplies do they reach for constantly? These observations reveal whether you need mobile tables with casters for flexibility, or if integrated storage would eliminate trips to the supply room.

Space planning goes beyond measuring the table footprint. You need clearance for doors and drawers to open fully. Staff need room to move around comfortably during busy periods.

Budget in terms of total cost, not just the sticker price. Shipping can add hundreds of dollars. A higher-quality table that lasts 20 years often costs less per year than a cheaper one needing replacement in 5 years.

Assessing Your Application for a stainless-steel-table-

Different industries have completely different needs.

Butchery operations need the toughest tables with 14-gauge tops and maximum reinforcement because cleavers create constant impact. Easy cleaning is critical for food safety.

Bakery applications benefit from wood-laminate tops combined with stainless steel bases. Mortuary prep requires specialized features like fluid drainage systems and height adjustability.

Feature & Accessory Checklist

Undershelves add 50-75% more storage without taking extra floor space. Drawers keep frequently used tools within arm's reach. Casters transform static tables into flexible workstations when you need mobility.

Backsplashes protect walls and make cleanup easier. Marine edges prevent spills from running off the table surface. Integrated sinks combine prep and cleanup functions when space is tight.

Customize for Maximum Efficiency

Modern configuration software lets you design custom tables with precise specifications. Fully-welded options cost more upfront but eliminate mechanical fasteners that can loosen over time.

More info about workspace optimization provides additional guidance on maximizing efficiency.

Price Factors & Budgeting

Material grade significantly impacts pricing. 316L costs 20-30% more than 304, while 430 offers 10-15% savings. Gauge thickness affects both price and durability - 14-gauge costs about 25% more than 16-gauge but provides substantially more durability.

Shipping logistics vary dramatically by location. Commercial addresses with loading docks typically cost much less than residential locations requiring liftgate service.

Care, Maintenance & Certifications

Taking care of your stainless-steel-table- is surprisingly simple. Unlike wood surfaces that need special oils or laminate tops that chip and peel, stainless steel practically takes care of itself with basic maintenance.

Daily cleaning prevents buildup of grease and grime. The non-porous nature means bacteria can't hide in microscopic cracks. Rust removal is rare on quality stainless steel, and simple household items often work when needed.

NSF certification isn't just paperwork - it's your assurance that the table meets strict standards for food safety and sanitation. If you're running a commercial kitchen, this certification often isn't optional.

Scientific research on stainless steel sanitation backs up what professionals have known - properly maintained stainless steel surfaces resist bacterial growth and clean up beautifully.

Daily Cleaning Routine for stainless-steel-table-

Your daily cleaning routine should be straightforward. Start with mild detergent and warm water - the same dish soap you use at home works perfectly. Skip harsh chemicals like bleach unless absolutely necessary.

Microfiber cloths grab particles without scratching and don't leave lint. Always wipe with the grain when you can see the directional pattern. Dry thoroughly after cleaning, especially with hard water.

Removing Rust & Scratches

Baking soda paste works like magic on surface rust. Mix with just enough water to make thick paste, spread over the spot, and let sit for hours. For tougher stains, oxalic acid cleaners like Bar Keepers Friend are specifically made for stainless steel.

Stick with non-abrasive pads when scrubbing. Steel wool creates scratches that become homes for bacteria.

Industry Standards & Compliance

NSF certification separates professional-grade tables from consumer products. Many health departments won't let you operate without NSF-certified equipment. OSHA guidelines focus on keeping workers safe with proper ergonomic heights and stable construction.

Frequently Asked Questions about Stainless Steel Tables

What grade of stainless steel should I choose for a humid environment?

When dealing with humidity, your stainless-steel-table- grade choice can make or break your investment. For most humid environments like commercial kitchens or food processing facilities, 304 stainless steel provides excellent protection with its 18% chromium and 8% nickel content.

But here's where it gets interesting - if you're working in coastal areas, around swimming pools, or anywhere with salt air exposure, you'll want to step up to 316L stainless steel. That extra molybdenum content acts like armor against chlorides and acids that love to attack regular 304 steel.

I've seen too many facilities try to save money with 430 grade steel in humid conditions, only to find surface rust appearing within months. The lack of nickel in 430 grade makes it vulnerable to moisture, so avoid it for humid environments unless budget absolutely demands it.

The bottom line? 304 grade for most humid conditions, 316L for extreme humidity or coastal locations. Your table will thank you with decades of rust-free service.

How much weight can a standard 16-gauge table support?

A typical 16-gauge stainless steel table handles 150-300 pounds per shelf, with total capacities ranging from 300-600 pounds. But don't just go by the numbers - construction details matter enormously.

Fully welded tables always outperform bolted assemblies because there are no mechanical connections to loosen over time. Add gusset reinforcements at the corners and stress points, and you're looking at significantly higher weight capacity.

The leg design tells the whole story too. Heavier gauge legs with proper cross-bracing create a rock-solid foundation that won't wobble under load. Larger tables actually distribute weight better across their frame, though they might have lower per-square-foot ratings.

For heavy-duty work like butchering or supporting mixers and grinders, consider upgrading to 14-gauge construction. That extra thickness provides about 25% more weight capacity - often the difference between a table that lasts 5 years versus 20 years under heavy use.

Always check the manufacturer's specific weight ratings for your exact model. Construction methods vary between suppliers, and you want to know exactly what you're getting.

Do stainless steel tables require special cleaners?

Here's some good news - your stainless-steel-table- doesn't need expensive specialty cleaners for daily maintenance. Mild dish soap and warm water handle 90% of your cleaning tasks perfectly.

The secret is using microfiber cloths instead of paper towels or rough sponges. Microfiber grabs particles without scratching and leaves no lint behind. Always wipe with the grain direction when you can see grain patterns - this prevents scratches and keeps your table looking professional.

For stubborn stains or water spots, stainless steel cleaners containing oxalic acid (like Bar Keepers Friend) work wonders. These products actually help restore the protective oxide layer while removing discoloration and heat stains.

What you should never use: chlorine bleach, hydrochloric acid, or abrasive cleaners that attack the protective chromium layer. Steel wool is also a no-go - it creates scratches where bacteria can hide.

For sanitizing, standard food-service sanitizers work perfectly. The non-porous surface doesn't absorb chemicals, making sanitization straightforward and effective. That's why stainless steel remains the gold standard in commercial kitchens and medical facilities where hygiene is non-negotiable.

Conclusion

Finding the perfect stainless-steel-table- doesn't have to be overwhelming when you understand what matters most for your specific situation. Think of it like choosing a reliable work partner - you want something that'll show up every day, handle whatever you throw at it, and still look professional years down the road.

The beauty of stainless steel tables lies in their versatility. Whether you're running a busy restaurant kitchen, managing a laboratory, or operating a mortuary facility, these tables adapt to your needs while maintaining the same high standards of durability and hygiene.

Grade 304 handles most everyday applications beautifully, while 316L steps up when you're dealing with harsh chemicals or coastal environments. The 16-gauge thickness hits that sweet spot between strength and affordability for most operations, though heavy-duty work might call for the extra muscle of 14-gauge construction.

At American Mortuary Coolers, we've seen how the right table transforms a workspace. Our custom mortuary solutions go beyond standard offerings because we understand that funeral homes and medical facilities can't compromise on quality or compliance. Every table we deliver meets strict NSF certification standards while providing the specialized features your operation demands.

Our sustainability focus means you're not just buying equipment - you're investing in a solution that'll serve your facility for decades while minimizing environmental impact. With contiguous US delivery from our strategic locations in Tennessee, Atlanta, Chicago, Columbia, Dallas, Los Angeles, New York, and Pittsburgh, we make it easy to get quality equipment where you need it.

The numbers speak for themselves: properly maintained stainless steel tables often serve facilities for 20+ years, making them one of the smartest long-term investments you can make. When you factor in reduced maintenance costs, improved efficiency, and improved safety, quality tables practically pay for themselves.

The cheapest option upfront isn't always the most economical choice. A well-built stainless-steel-table- that handles your daily workload without breaking down saves money, time, and frustration over its lifetime.

Ready to explore your options? More info about our custom stainless solutions provides detailed insights into our specialized offerings for mortuary and medical applications, helping you make the best choice for your facility's unique needs.