The Complete Guide to Buying a Kason Door Handle

Why Kason Door Handles Are Essential for Safe Commercial Refrigeration

Kason door handle systems are industry-standard hardware components designed for commercial refrigeration, walk-in coolers, freezers, and industrial enclosures. Here's what you need to know:

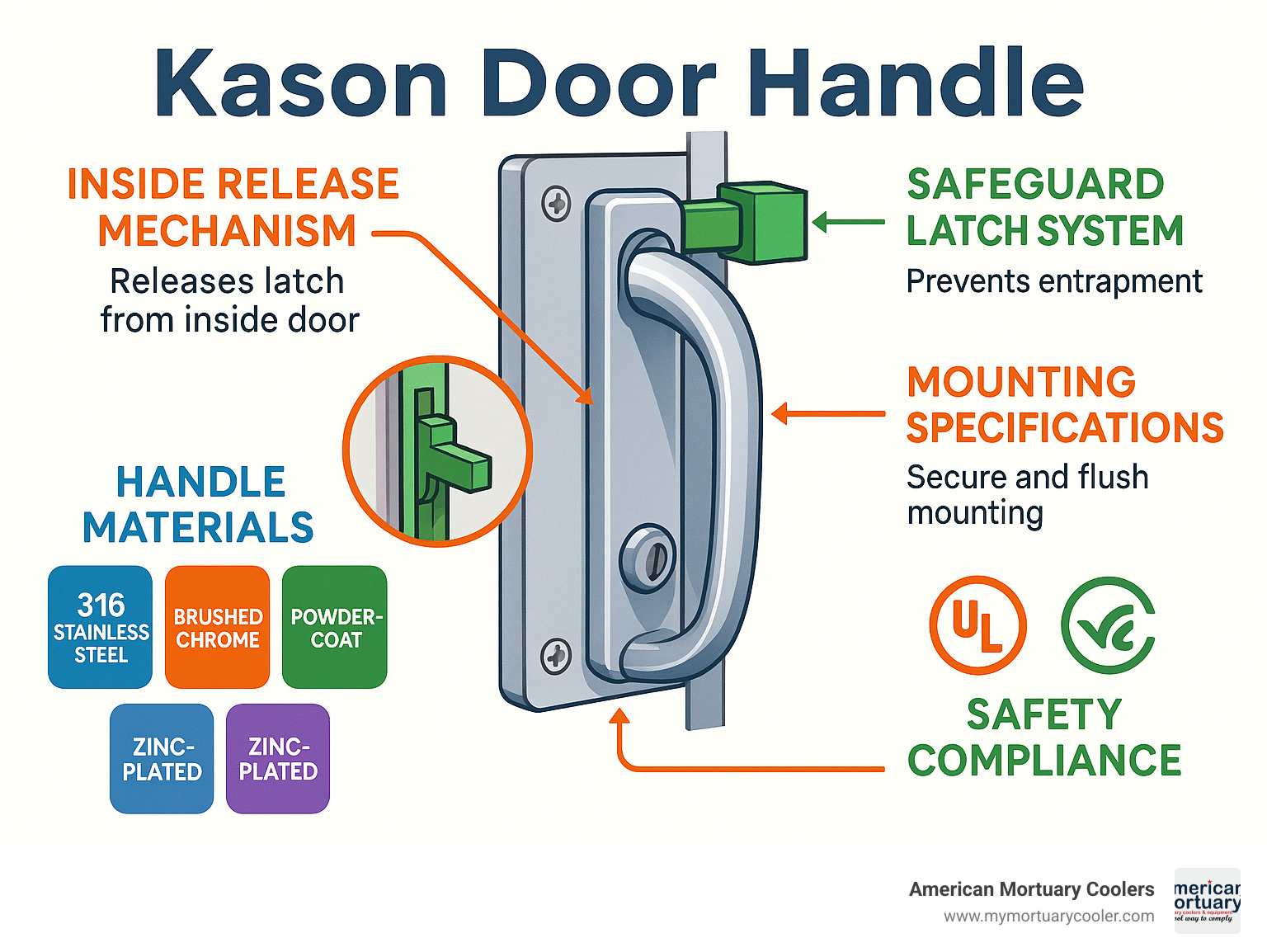

Key Kason Door Handle Types:

- Inside Release Handles - Prevent entrapment with SafeGuard® latch technology

- Pull Handles - Standard exterior handles in multiple finishes

- Panic Bars - Large-contact UL 305 compliant emergency exit hardware

- Truck Body Handles - Heavy-duty latches for mobile refrigeration

Popular Models:

- 0489 - Narrow recessed inside release with Safety-Glow™ knob

- 488C - Walk-in push bar with low-effort operation

- 1229S - Rugged 316 stainless steel SafeGuard® series

- 0058E - Electronic security latch with flush strike

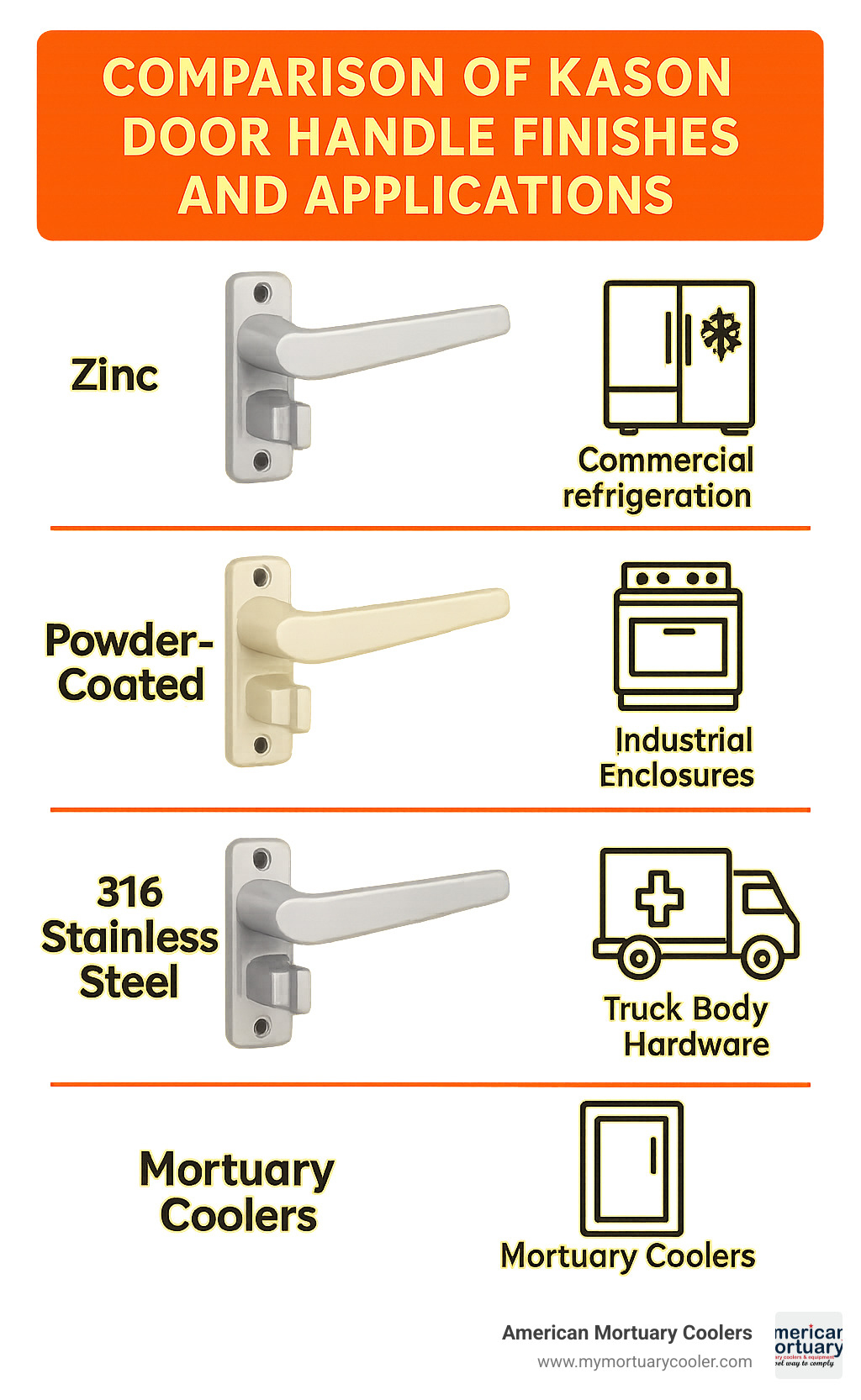

Materials & Finishes:

- 316 stainless steel for maximum corrosion resistance

- Brushed chrome to resist chlorine cleaner damage

- Powder-coat for aggressive environments

- Zinc-plated for standard applications

Kason door handles serve critical safety functions in walk-in environments. Their SafeGuard® latches can be released from inside whether cylinder locked or padlocked, helping prevent dangerous entrapment situations that can occur in commercial refrigeration units.

I'm Mortuary Cooler, and as a national-level mortuary cooler supplier, I've specified and installed countless Kason door handle systems for funeral homes across America. My experience with commercial refrigeration hardware helps funeral directors choose the right components for their specific needs while ensuring safety compliance and long-term durability.

Key terms for Kason door handle:

Understanding Kason Door Handles: Basics & Applications

Let's be honest - when you're running a funeral home, the last thing you want to worry about is whether your cooler door handle will work when you need it. That's exactly why Kason door handles have become the go-to choice for professionals who can't afford equipment failures.

These aren't your everyday door handles. Kason Industries has spent decades perfecting hardware that works flawlessly in the most demanding environments - from blazing hot commercial kitchens to sub-zero mortuary coolers. Their commitment to safety and quality shows in every detail, and their Resources for Kason hardware provide the technical documentation that installers and facility managers need.

What makes Kason special is their focus on safety compliance. Every handle meets strict NSF and UL 305 standards, which means they've been tested and certified for commercial use. When we install these systems in funeral homes across Tennessee and beyond, we know they'll perform when it matters most.

What Is a Kason Door Handle?

A Kason door handle is purpose-built hardware designed for commercial and industrial applications where lives literally depend on proper function. While a residential door handle might fail after a few years of normal use, Kason handles are engineered to work reliably for decades in harsh conditions.

The magic is in the details. These handles resist corrosion from cleaning chemicals, operate smoothly in extreme temperatures, and maintain their strength even after thousands of open-close cycles. That's why you'll find them on walk-in coolers and freezers in restaurants, grocery stores, and food processing facilities nationwide.

Commercial refrigeration represents the largest market for Kason handles, but they're also standard equipment for OEM equipment manufacturers who build commercial kitchen gear. Truck body hardware is another major application - those refrigerated delivery trucks need handles that won't fail on the road.

For our work at American Mortuary Coolers, we specify Kason handles for mortuary coolers because funeral directors need absolute reliability. When you're serving families during their most difficult times, equipment problems are simply not acceptable.

Industrial enclosures round out the major applications. Generator rooms, acoustic chambers, and material handling equipment all benefit from Kason's robust construction and safety features.

How Kason Door Handles Improve Safety Inside Walk-Ins

Here's where Kason really shines - inside release mechanisms that prevent the nightmare scenario of someone getting trapped inside a cooler or freezer. We've all heard those terrifying stories, and Kason's SafeGuard® latches are specifically designed to prevent them.

The brilliance of the SafeGuard® system is its simplicity. No matter how the door is locked from the outside - whether with a cylinder lock or padlock - the inside release always works. Always. The person inside can push, pull, or activate the release mechanism and get out safely.

Panic bars like the 488C model take this concept even further. These large-area push bars require minimal effort to operate, which is crucial when someone might be weakened by cold exposure or panic. Even if your hands are numb or you're not thinking clearly, you can still activate the release by pushing against the large contact surface.

The 0489 recessed model includes something really clever - glow-in-the-dark knobs that remain visible even when the lights go out. In a true emergency, being able to find the release handle immediately could save a life.

We've installed these safety systems in mortuary coolers from coast to coast, and the peace of mind they provide is invaluable. No funeral director should have to worry about staff safety when accessing refrigeration equipment. With proper Kason hardware, they don't have to.

The entrapment prevention features aren't just good engineering - they're required by code in many jurisdictions. Kason's UL 305 certification ensures that their handles meet or exceed these safety requirements, giving facility owners confidence that they're fully compliant with local regulations.

Choosing the Right Kason Door Handle

Choosing the right Kason door handle is like picking the right tool for the job - get it wrong, and you'll be dealing with headaches for years to come. After decades of installing these systems in mortuary coolers across the country, I've learned that the devil is truly in the details.

The good news? Once you understand what to look for, the selection process becomes much clearer. Let me walk you through the key factors that will determine which handle system will serve you best.

| Finish Type | Best For | Corrosion Resistance | Sanitation | Cost |

|---|---|---|---|---|

| 316 Stainless Steel | Mortuary coolers, medical facilities | Excellent | Superior | High |

| Brushed Chrome | Chlorine-cleaned environments | Very Good | Good | Medium |

| Powder Coat | Aggressive environments | Excellent | Good | Medium |

| Zinc Plated | Standard applications | Good | Fair | Low |

Kason Door Handle Materials & Finishes

Here's where many people make costly mistakes - they choose a Kason door handle finish based on appearance rather than performance. Trust me, you'll regret that decision when you're replacing corroded hardware two years down the road.

316 stainless steel is what we recommend for virtually every mortuary cooler installation. The 1229S Stainless Steel SafeGuard® Handle Series might cost more upfront, but it's built from rugged, sanitary 316 stainless steel that laughs at cleaning chemicals and bodily fluids. We offer it in both locking and non-locking models, depending on your security needs.

Brushed chrome has a secret superpower that most people don't know about - it actually prevents gunk buildup better than polished chrome. More importantly, it resists pitting from chlorine-based cleaners. If your facility uses bleach solutions regularly, this finish will keep looking professional while others start showing wear.

Kasonized finish is Kason's own proprietary coating that gives you excellent corrosion resistance without the premium price tag. It's their sweet spot for standard applications where you need reliability but don't face extreme conditions.

Powder coat finishes create an armor-like barrier against aggressive environments. Kason specifically recommends these for maximum life in corrosive conditions - think coastal areas with salt air or facilities that use harsh cleaning protocols.

Zinc plated options like the 0489 model offer the most economical solution for standard applications. The zinc-plated steel rod and plate with plastic housing work fine when corrosive exposure is minimal.

Kason Door Handle Compatibility & Customization

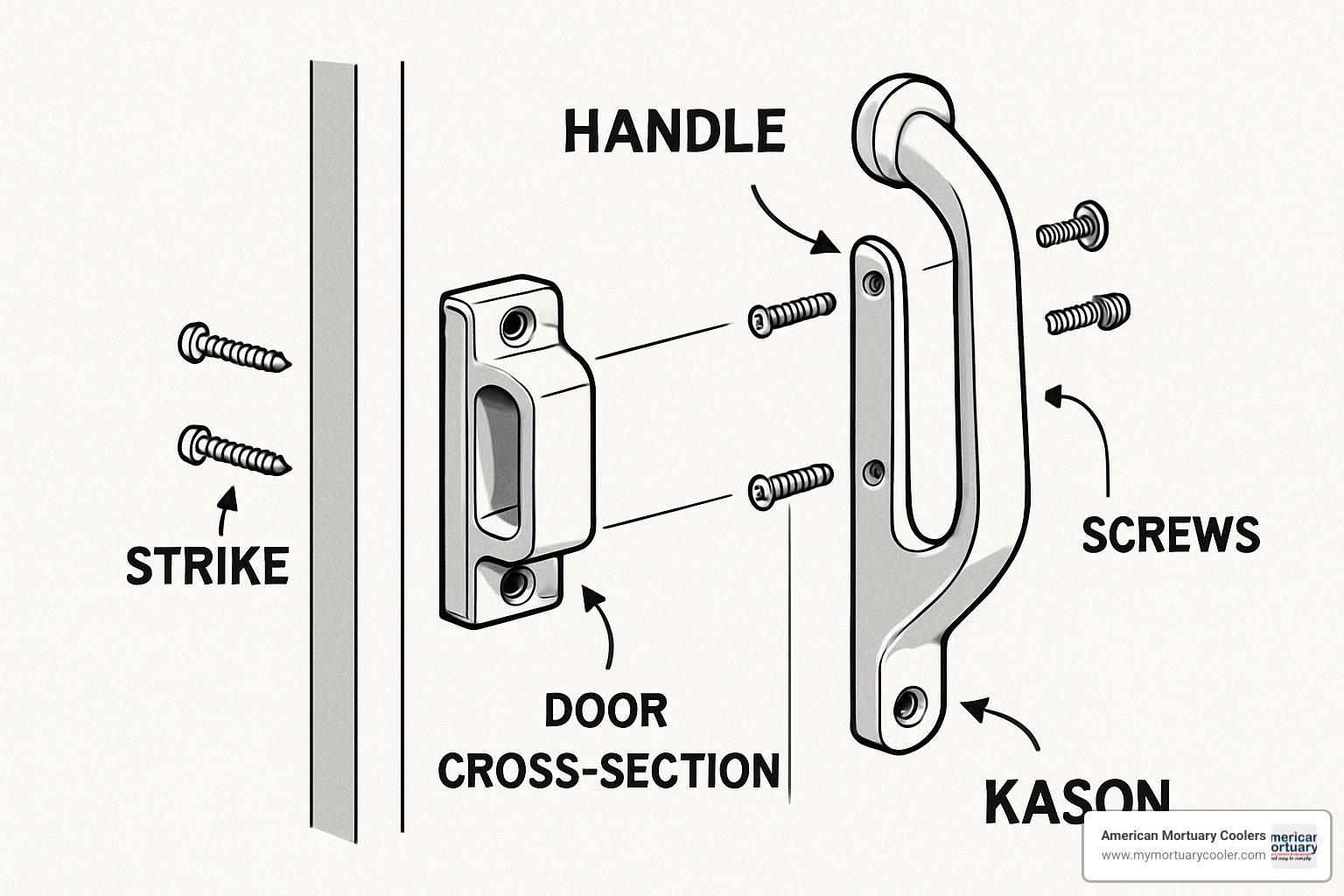

This is where we see the most confusion - and the most expensive mistakes. A Kason door handle isn't just a handle; it's part of a complete system that needs to work together perfectly.

Door thickness matters more than you might think. Different handle models accommodate different door thicknesses, and the offset measurement is absolutely critical. You measure from the door jamb to the door face when the door is closed - get this wrong, and your door won't seal properly.

Latch pairings can't be mixed and matched randomly. The SafeGuard® system requires specific latch models to function properly. Try to pair incompatible components, and you'll lose the safety features that make these handles worth having.

Strike types come in flush and offset varieties. The K58 series offers both ½ inch and 1½ inch offset options to ensure your door seals properly. Poor sealing means higher energy costs and potential temperature fluctuations that could compromise your facility's operation.

Foam door compatibility is crucial for modern cooler installations. Kason designs their hardware specifically to avoid damaging foam insulation during installation or operation. This isn't just about preventing immediate damage - it's about maintaining the door's thermal performance over time.

If you're retrofitting an older system, I strongly recommend checking our Ultimate Checklist for Choosing a Walk-In Freezer Door Handle Replacement before making any decisions. It covers all the compatibility factors that could save you from costly mistakes.

Comparing Kason Door Handle Models

Let me break down the most popular Kason door handle models based on real-world applications we've installed across the country.

The 0489 Narrow Recessed Inside Release Handle is our go-to choice for mortuary coolers. The recessed design prevents snagging in tight spaces - important when you're maneuvering equipment or gurneys. It comes packaged 24 per carton with a total weight of about 18 pounds, making it easy to stock spares. The Safety-Glow™ plastic knob provides visibility in low-light conditions, and there's a frost-resistant fiberglass rod option for freezer applications.

The 488C Walk-In Push Bar Inside Release features a large contact area that requires minimal effort to operate. This is particularly valuable in emergency situations where someone might be weakened by cold exposure or panic. The large surface area means it can be activated even by someone wearing heavy gloves or protective equipment.

Our premium recommendation is the 1229S Stainless Steel SafeGuard® Handle Series. Made from rugged, sanitary 316 stainless steel, it's available in both locking and non-locking models. For mortuary applications where sanitation and durability are non-negotiable, this is worth every penny of the premium price.

For facilities requiring electronic access control, the 0058E Security Latch with Electronic Flush Strike integrates with security systems while maintaining the critical inside release function. It's perfect for facilities that need to track access or restrict entry to certain areas.

The key to choosing the right model is understanding your specific needs. Mortuary coolers benefit from the sanitary properties of stainless steel models, while standard commercial applications might work fine with zinc-plated options. But remember - this is safety-critical hardware, so it's usually worth investing in the better option.

Installation, Maintenance & Troubleshooting for a Kason Door Handle

Proper installation and maintenance of your Kason door handle is crucial for safety and longevity. We've developed our installation and maintenance protocols through years of field experience across all our service regions.

The basic installation involves drilling patterns sized for No. 10 (5.0 mm) screws, but there's much more to consider for a professional installation. Torque specifications, strike alignment, and inside release testing are all critical steps that can't be overlooked.

For ongoing maintenance, we recommend regular lubrication schedules, gasket inspections, and checking for frost-resistant rod function in freezer applications. Our maintenance guide How to Improve Your Mortuary Cold Room Doors Service & Maintenance in 7 Days provides detailed procedures for keeping your door hardware in optimal condition.

Step-by-Step Installation of a Kason Door Handle

Here's our proven installation process for Kason door handle systems:

1. Template Marking: Use the manufacturer's template to mark mounting hole locations. Double-check measurements - drilling mistakes in cooler doors are expensive to fix.

2. Drilling: Drill holes for No. 10 (5.0 mm) screws. For foam doors, use sharp bits and steady pressure to avoid tearing the foam core.

3. Strike Alignment: This is where many installations go wrong. The strike must align perfectly with the latch mechanism. Use the offset measurements (½ inch or 1½ inch for K58 series) to ensure proper door sealing.

4. Handle Installation: Mount the handle assembly, ensuring all designated parts are installed correctly. The inside release mechanism won't function properly if components are missing or incorrectly positioned.

5. Cylinder Lock Setup: If using locking models, install the cylinder lock according to manufacturer specifications.

6. UL 305 Testing: This is the most critical step. Test the inside release mechanism multiple times to ensure it functions whether the door is locked or open uped. Someone's life may depend on this mechanism working properly.

7. Final Adjustment: Adjust strike position if necessary to ensure proper door sealing and latch engagement.

Preventive Maintenance to Maximize Longevity

Your Kason door handle will provide years of reliable service with proper maintenance:

Cleaning Protocols: Use appropriate cleaning agents for your finish type. Stainless steel handles can tolerate stronger chemicals than zinc-plated models. Avoid abrasive cleaners that can damage protective finishes.

Corrosion Checks: Inspect regularly for signs of corrosion, especially around mounting points where moisture can accumulate. Early detection prevents major problems.

Glow Knob Replacement: Safety-Glow™ knobs gradually lose their luminescence over time. Replace them every 2-3 years to maintain visibility in emergency situations.

Spring Tension Calibration: The inside release mechanism relies on proper spring tension. Test monthly and adjust as needed to ensure reliable operation.

Lubrication Schedule: Use food-grade lubricants on moving parts. Avoid over-lubrication, which can attract dirt and debris.

Troubleshooting a Kason Door Handle

Common issues we encounter with Kason door handle systems and their solutions:

Latch Misalignment: Usually caused by door settling or thermal expansion. Adjust strike position or shim as needed to restore proper alignment.

Frozen Rods: In freezer applications, moisture can cause inside release rods to freeze. The frost-resistant fiberglass rod option prevents this problem. For existing installations, ensure proper sealing around rod penetrations.

Loose Mounting: Thermal cycling can loosen mounting screws over time. Check and retighten quarterly, but don't over-torque as this can strip threads in foam doors.

Replacement Parts Sourcing: Always use genuine Kason replacement parts. Generic substitutes may not maintain the safety certifications that could be required by local codes or insurance policies.

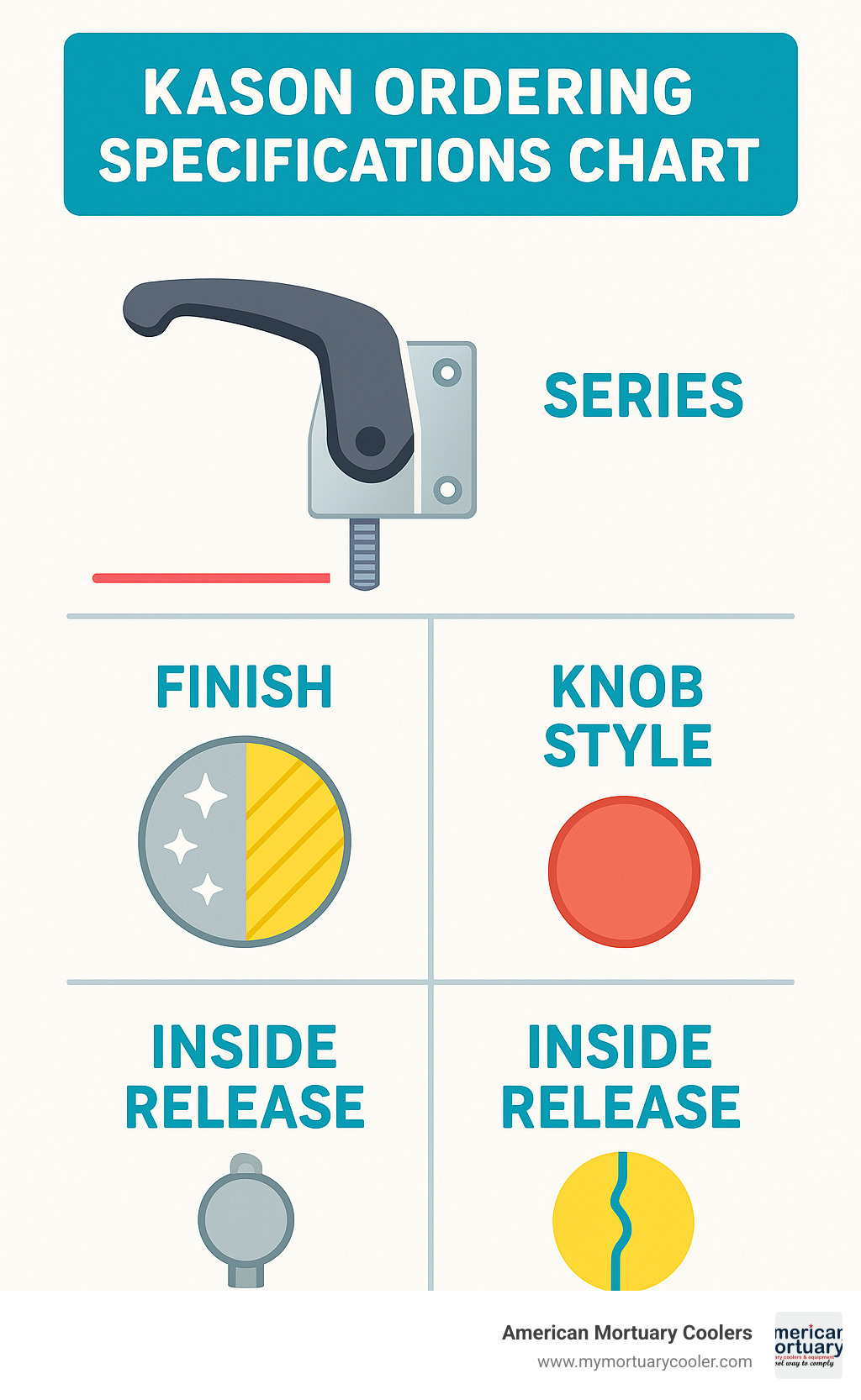

Ordering & Support Resources for Your Kason Door Handle

Getting your Kason door handle order right the first time makes everyone's life easier. After years of ordering these handles for mortuary coolers across the country, I've learned that having your specifications ready upfront prevents delays and costly mistakes.

The good news is that Kason has streamlined their ordering process significantly. Their Ordering Guide :: Kason Industries walks you through everything you need to know, but let me share what really matters from our field experience.

When we place orders, we always double-check the model/quantity/finish specs because these are the details that can't be changed once production starts. Lead times vary depending on what you're ordering - standard models like the 0489 ship quickly, while custom finishes might take several weeks.

Carton weights matter more than you might think, especially for freight shipping. The 0489 model ships 24 units per carton at about 18 pounds total, which keeps shipping costs reasonable. But when you're ordering larger quantities or heavier models like the 1229S stainless steel series, those weights add up fast.

For custom orders, you'll work directly with Kason's design team. They have excellent Kason Design Tools that help visualize how your specific configuration will look and function before you commit to the order.

Where to Buy and What Information You'll Need

Here's what trips up most first-time buyers: you need more than just a model number to place a Kason door handle order correctly.

Part numbers are your starting point, but they don't tell the whole story. You'll need to specify the door offset measurement - that's the distance from your door jamb to the door face when closed. Get this wrong, and your handle won't seal properly.

Hand operation specification catches people off guard too. Stand outside your cooler facing the door - does it swing left or right? This determines which way your handle mechanism needs to be oriented.

Don't forget your shipping instructions. We've learned to be very specific about delivery requirements, especially for funeral homes where receiving docks might not be available or accessible during service hours.

At American Mortuary Coolers, we maintain relationships with authorized Kason distributors from our Tennessee headquarters all the way to our service areas in California and New York. This network helps us get competitive pricing and faster delivery times for our customers nationwide.

Additional Help & Documentation

Kason doesn't leave you hanging after you place your order. Their support resources are genuinely helpful, not just marketing fluff.

The instruction sheets that come with each Kason door handle are actually readable - no tiny fonts or confusing diagrams. They include proper mounting templates and the torque specifications you need for professional installation.

Their Spanish catalog has been a lifesaver for many of our installation teams. Clear communication during installation prevents safety issues later.

YouTube installation videos show you exactly what proper installation looks like. The 488C Walk-in Push Bar video, for example, demonstrates the correct way to test the inside release mechanism - something that's literally life-or-death important.

When you do run into problems, Kason's tech support contacts actually know their products. We've called them for tricky retrofit situations, and they've always provided practical solutions.

For funeral home applications specifically, our The Complete Guide to Walk-In Cooler Doors covers the unique considerations for mortuary environments that standard commercial guides often miss.

The bottom line is this: Kason backs up their hardware with real support. When you're dealing with safety-critical equipment like door handles, that support makes all the difference.

Frequently Asked Questions about Kason Door Handles

When you're considering a Kason door handle for your mortuary cooler or commercial refrigeration application, you probably have questions about safety certifications, compatibility, and performance. We've been answering these questions for funeral directors across the country for years, so let's tackle the most common ones.

How do I confirm my Kason door handle meets NSF and UL 305?

The good news is that Kason door handle models meeting NSF and UL 305 standards clearly display the appropriate markings right on the product and in the documentation. You don't have to guess or dig through fine print.

For example, the 0489 Narrow Recessed Inside Release Handle carries NSF component approval, which is crucial for mortuary applications where sanitary design standards matter. The 488L Panic Bar Inside Release and Latch Assembly specifically meets UL 305 requirements for emergency egress hardware.

Here's why these certifications matter for your facility: NSF certification ensures the hardware meets sanitary design standards that are often required by health departments for mortuary operations. UL 305 certification confirms the panic hardware meets safety requirements for emergency egress - basically, it guarantees someone can get out in an emergency.

Always double-check that the certifications match your local code requirements. Some jurisdictions have specific requirements for mortuary facilities that go beyond standard commercial applications.

Can I retrofit a Kason door handle onto an older mortuary cooler door?

Absolutely! We've successfully retrofitted hundreds of older mortuary coolers with modern Kason door handles, and the safety improvements are always worth the effort. However, compatibility isn't automatic - it depends on several key factors.

Door thickness and construction matter most. Solid doors are easier to work with than foam core doors, but both can usually accommodate Kason hardware with proper planning. Existing hardware mounting patterns sometimes align with new Kason templates, which makes the job much simpler.

Door frame design - whether it's flush mount or overlap style - affects which strike options you can use. The available space for strike installation is often the limiting factor, especially on older units with tight clearances.

The reality is that most older mortuary coolers can be upgraded, but sometimes you need minor door modifications to accommodate the new hardware. We've found that the safety benefits of modern inside release mechanisms make retrofitting worthwhile even when it requires some extra work.

If you're considering a retrofit, our experience shows it's usually more cost-effective than replacing the entire door, and you get the peace of mind that comes with modern safety features.

What finish is best for chlorine-cleaned environments?

If your facility uses chlorine-based cleaners regularly - and most mortuary facilities do - brushed chrome finish is your best bet for Kason door handles. This isn't just our opinion; research shows that brushed chrome actively deters gunk build-up and prevents the pitting that chlorine chemical cleaners can cause on other finishes.

Brushed chrome outperforms polished finishes because the textured surface doesn't show water spots and minor scratches the way mirror finishes do. It maintains its appearance longer and requires less maintenance in high-cleaning environments.

However, if your facility uses particularly aggressive cleaning protocols or deals with other corrosive conditions, you might want to step up to 316 stainless steel or powder-coat finishes. Kason specifically recommends these for maximum life in corrosive or aggressive environments.

The 1229S series uses 316 stainless steel that offers superior resistance to chemical attack while maintaining the sanitary properties essential for mortuary applications. It costs more upfront, but if you're dealing with harsh cleaning chemicals daily, it pays for itself in longevity and reduced maintenance.

Conclusion

Choosing the right Kason door handle is about more than just hardware - it's about ensuring the safety of your staff and the reliability of your operations. Whether you're specifying handles for a new mortuary cooler installation or retrofitting existing equipment, the investment in quality Kason hardware pays dividends in durability, safety compliance, and peace of mind.

At American Mortuary Coolers, we've built our reputation on delivering custom mortuary refrigeration solutions nationwide, and that includes specifying the right door hardware for each application. From our Tennessee headquarters to our service regions across the contiguous 48 states, we understand that funeral directors need equipment they can rely on completely.

The safety features built into every Kason door handle - from SafeGuard® latch technology to Safety-Glow™ knobs - represent decades of engineering focused on preventing the kind of accidents that can turn routine operations into tragedies. When you're dealing with the sensitive nature of mortuary operations, having hardware you can trust isn't optional.

For more detailed guidance on mortuary cooler door selection and specifications, check out our comprehensive resource: An Essential Guide to Mortuary Cold Room Doors and Your Best Options.

When it comes to Kason door handles, proper specification, installation, and maintenance aren't just about equipment longevity - they're about ensuring that your facility operates safely and efficiently for years to come. That's the kind of reliability that American Mortuary Coolers delivers to funeral homes across America.