The Complete Guide to 404A Pressure-Temp Charts

Why Pressure Temp Chart 404A is Critical for Reliable Refrigeration

Pressure temp chart 404a is an essential tool that shows the relationship between refrigerant pressure and temperature at saturation conditions. Here's what you need to know:

Key R-404A Pressure-Temperature Values:

- At 0°F (-17.8°C): 32.6 psi

- At 40°F (4.4°C): 85.4 psi

- At 100°F (37.8°C): 234.6 psi

- Critical temperature: 161.7°F (72°C)

- Critical pressure: 540.8 psi

Common Applications:

- Commercial freezers and coolers

- Supermarket display cases

- Walk-in cold storage

- Mortuary refrigeration systems

Every refrigeration technician working with R-404A systems needs to understand how pressure and temperature work together. When refrigerant reaches its saturation point, it changes from liquid to vapor (or vice versa) at a specific pressure-temperature combination.

This relationship is crucial for:

- System diagnostics - detecting leaks, blockages, or charge issues

- Performance optimization - ensuring proper superheat and subcooling

- Troubleshooting - identifying why a system isn't cooling properly

R-404A is a ternary blend of three refrigerants (R-125, R-143a, and R-134a) commonly used in commercial refrigeration. However, with a Global Warming Potential (GWP) of 3,922, it faces regulatory phase-downs under environmental regulations.

For mortuary applications, understanding these pressure-temperature relationships ensures your cooling systems maintain the precise temperatures needed for proper preservation while operating efficiently and reliably.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes optimize their refrigeration systems using pressure temp chart 404a data for reliable operation. My background includes working with funeral directors across the country to ensure their cooling equipment operates at peak performance through proper pressure-temperature monitoring and maintenance.

Pressure temp chart 404a word guide:

R-404A at a Glance: Composition, Uses & Environmental Impact

When you're working with pressure temp chart 404a data, it helps to understand what makes this refrigerant tick. R-404A is what we call a ternary blend – think of it as a carefully crafted recipe mixing three different refrigerants together. You've got 52% R-143a, 44% R-125, and 4% R-134a all working as a team.

This HFC (hydrofluorocarbon) blend wasn't just thrown together randomly. Engineers developed it specifically to replace older refrigerants like R-502 and R-22 when the industry needed something better for low and medium-temperature applications.

You'll spot R-404A hard at work in supermarket display cases keeping your frozen foods crisp, walk-in freezers in restaurants, commercial ice machines, transport refrigeration trucks, and cold storage warehouses. Here at American Mortuary Coolers, we've seen it perform reliably in mortuary cooling systems across Tennessee, Georgia, Illinois, and throughout our service regions.

The reason R-404A works so well in funeral home applications is its excellent thermodynamic properties. It maintains those precise temperatures that mortuary refrigeration demands – no room for error when it comes to proper preservation.

But here's where things get complicated. R-404A has a Global Warming Potential (GWP) of 3,922, which is pretty hefty from an environmental standpoint. That's why it's facing some serious regulatory pressure from the Kigali Amendment to the Montreal Protocol, the EPA's SNAP program, and the AIM Act.

The good news? R-404A earned an ASHRAE A1 safety classification, meaning it won't catch fire and has low toxicity – that's peace of mind for technicians. Its critical temperature of 161.7°F and critical pressure of 540.8 psi define where this refrigerant reaches its limits.

More info about R-404A properties

Bubble vs. Dew Point Explained

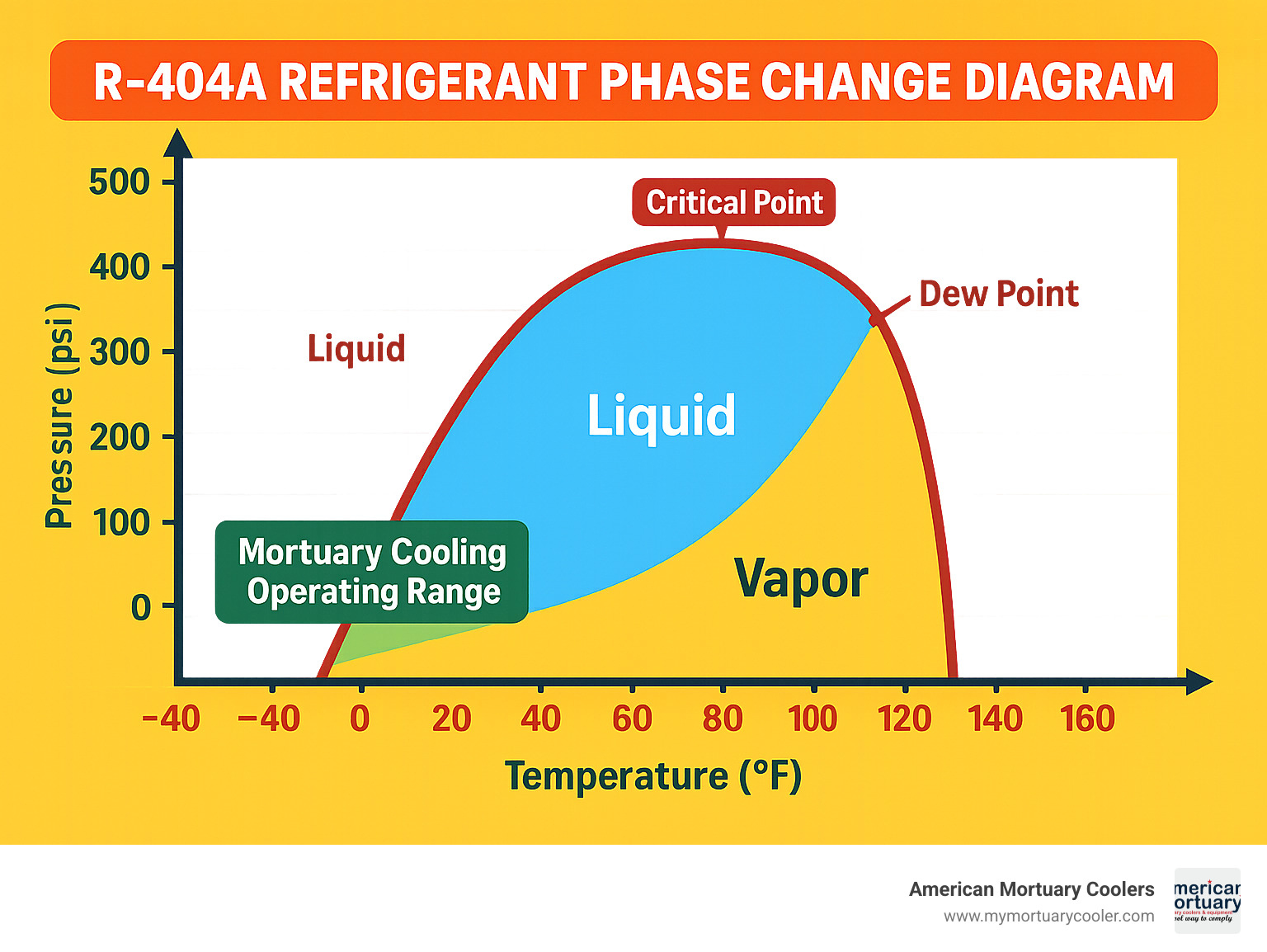

Here's where working with pressure temp chart 404a gets interesting. Since R-404A is a zeotropic blend, it doesn't behave like a single-component refrigerant. Instead, it shows temperature glide during phase changes – kind of like how different ingredients in a soup boil at slightly different temperatures.

Bubble point is the temperature where you'll see the first tiny vapor bubble form when you're heating liquid refrigerant at constant pressure. This is your go-to reference for subcooling calculations – think of it as the liquid side of the equation.

Dew point works the opposite way. It's the temperature where the first liquid droplet appears when you're cooling vapor refrigerant at constant pressure. You'll use this for superheat calculations – the vapor side of things.

The temperature difference between bubble and dew points is called glide. When you're looking at a Sporlan chart or similar reference, you'll notice separate liquid column and vapor column readings. This isn't a mistake – it's accounting for R-404A's blended nature.

Understanding this glide is crucial for accurate system diagnostics. It affects how you read your gauges and interpret what's really happening inside the refrigeration system.

How to Read & Apply a Pressure Temp Chart 404A

Mastering your pressure temp chart 404a is like learning to read a roadmap for your refrigeration system. Once you understand the basics, you'll spot problems before they become expensive headaches.

The chart itself is pretty straightforward. Your temperature readings sit in the left column, usually showing both °F and °C for convenience. The corresponding pressure values appear in the adjacent columns, typically measured in psig (pounds per square inch gauge).

Here's where it gets interesting - and where many techs make mistakes. Since R-404A is a blend, you'll see separate columns for liquid and vapor pressures. At 32°F, for example, your liquid pressure reads about 73.8 psig while vapor pressure shows 72.4 psig. This small difference matters when you're doing precise calculations.

Watch out for negative pressures when working with freezer applications. Temperatures below -18°F or so will show readings in inches of mercury below atmospheric pressure. Your gauges need to handle these conditions, especially in mortuary freezers where we often operate at -10°F or lower.

When you need a pressure reading between chart values, simple math works fine. Say you need the pressure at 35°F, but your chart only shows 32°F (72.4 psig) and 40°F (85.4 psig). Split the difference proportionally - you'll get roughly 77.5 psig at 35°F.

Gauge calibration is absolutely critical. We recommend checking your gauges annually, minimum. In mortuary work, where temperature precision can mean the difference between proper preservation and problems, accuracy isn't optional.

| Temperature (°F) | Liquid Pressure (psig) | Vapor Pressure (psig) |

|---|---|---|

| -10 | 23.8 | 23.6 |

| 0 | 33.0 | 32.6 |

| 32 | 73.8 | 72.4 |

| 40 | 86.2 | 85.4 |

Field Method: Using a Pressure Temp Chart 404A for Superheat

Calculating superheat with your pressure temp chart 404a becomes second nature once you've done it a few times. The process tells you whether your evaporator is doing its job properly.

Start by measuring your suction line pressure right at the evaporator outlet. This reading goes straight to your pressure chart - but here's the key detail many techs miss. Use the dew point column (vapor pressure) to convert that pressure into saturation temperature.

Next, grab your thermometer and measure the actual temperature of that same suction line. Make sure you get good contact and wait for a stable reading.

The math is simple: Actual Temperature minus Saturation Temperature equals Superheat. Let's say your suction pressure reads 23.6 psig. Looking at your chart, that corresponds to -10°F saturation temperature. If your actual suction line temperature measures 5°F, you've got 15°F of superheat (5°F - (-10°F) = 15°F).

Most systems run happily with 8-12°F of superheat. Too little suggests you're flooding the compressor with liquid refrigerant - never good. Too much means your evaporator isn't getting enough refrigerant to do its job effectively.

In mortuary applications, we often run tighter tolerances depending on the specific cooling requirements and ambient conditions around the unit.

Field Method: Using a Pressure Temp Chart 404A for Subcooling

Subcooling calculations follow the same logic as superheat, but we're working on the high-pressure side of your system. This measurement tells you about your refrigerant charge and condenser performance.

Measure your liquid line pressure at the condenser outlet. This time, you'll use the bubble point column (liquid pressure) on your pressure chart to find the saturation temperature.

Take your liquid line temperature reading at the same spot where you measured pressure. Good contact matters here too - you want the real temperature of that refrigerant, not the ambient air around the line.

The calculation flips from superheat: Saturation Temperature minus Actual Temperature equals Subcooling. If your liquid pressure shows 200 psig (about 85°F saturation) and your actual liquid line temperature reads 75°F, you've got 10°F of subcooling.

Healthy subcooling typically runs 10-15°F for most systems. Too little subcooling often means you're low on refrigerant charge. Excessive subcooling might indicate overcharge, or possibly restricted airflow across your condenser coils.

The subcooling reading also helps you cross-check your sight glass if your system has one. Clear sight glass with proper subcooling confirms adequate charge. Bubbles in the sight glass with low subcooling points to refrigerant shortage.

Operating Pressures, Troubleshooting & Best Practices

Understanding normal operating pressures helps identify system problems quickly. For R-404A systems:

Typical Operating Ranges:

- Cooler applications (34-40°F): 80-90 psig suction pressure

- Freezer applications (-10°F): approximately 23 psig suction pressure

- Head pressure: 200-270 psig at 90-110°F ambient conditions

These values come from our extensive field experience and align with industry standards. However, actual pressures depend on:

- Ambient temperature

- System load

- Airflow conditions

- Refrigerant charge level

Negative Pressure Considerations: At very low temperatures, R-404A can operate below atmospheric pressure. At -49°F, the system operates at only 0.3 psig vapor pressure. This creates unique challenges for oil return and system design.

Scientific research on PT diagnostics

Troubleshooting With the 404A Pressure-Temp Chart

Common issues we encounter in mortuary applications include:

Frosted Evaporator with High Superheat:

- Check for restricted TXV or low refrigerant charge

- Compare actual pressures to chart values

- Verify proper airflow across evaporator

Compressor Short-Cycling:

- High head pressure may indicate dirty condenser

- Low suction pressure suggests refrigerant leak

- Use chart to verify pressure-temperature relationships

Poor Cooling Performance:

- Compare operating pressures to expected values from chart

- Check for line restrictions or blockages

- Verify proper superheat and subcooling

At American Mortuary Coolers, we've found that systematic pressure-temperature analysis solves most cooling issues efficiently. Our technicians across regions from the Northeast to the Pacific use these diagnostic methods daily.

A Practical Guide to Finding a PT Chart for R404A Refrigerant

Maintenance Tips for Stable Pressures & Temperatures

Consistent maintenance ensures reliable operation and accurate pressure-temperature relationships:

Monthly Tasks:

- Record pressure and temperature logs

- Clean condenser coils for proper heat rejection

- Verify fan operation and airflow

- Check sight glass for proper charge level

Annual Tasks:

- Replace filter driers

- Calibrate gauges and thermometers

- Inspect and clean evaporator coils

- Verify control settings

Best Practices:

- Always use dry nitrogen when brazing to prevent oxidation

- Monitor ambient conditions that affect head pressure

- Keep detailed service records for trend analysis

- Focus on energy efficiency through proper maintenance

Regular maintenance not only ensures proper operation but also contributes to sustainability by maximizing system efficiency and extending equipment life.

Beyond R-404A: Regulations, Retrofits & Alternative Refrigerants

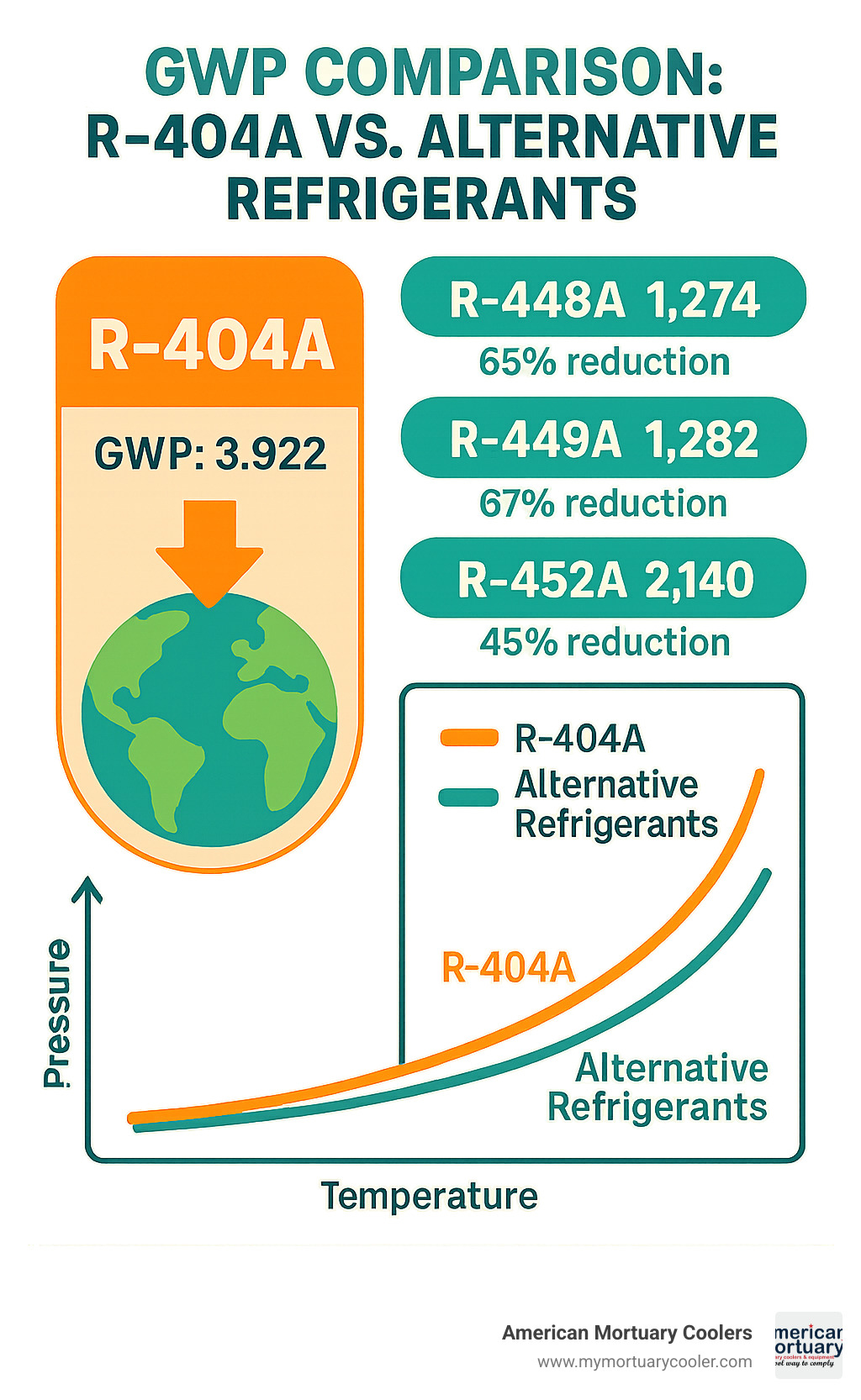

The writing is on the wall for R-404A. With its sky-high GWP of 3,922, this workhorse refrigerant is facing serious regulatory pressure that's reshaping our industry.

F-Gas quotas in Europe and the AIM Act here in the United States are driving the phase-down of high-GWP refrigerants like R-404A. These aren't distant regulations—they're happening right now and affecting refrigerant availability and pricing across the country.

The good news? We have solid alternatives that can keep your mortuary cooling systems running reliably. R-448A offers a GWP of just 1,274—that's a whopping 65% reduction from R-404A. R-449A is even better with a GWP of 1,282, giving you a 67% improvement. For a more conservative transition, R-452A provides a 45% GWP reduction at 2,140.

Here's what's interesting about these alternatives: each one has different comparative PT curves from your familiar pressure temp chart 404a. R-448A, for instance, operates at slightly higher pressures than R-404A but often delivers improved capacity—something we've seen in our mortuary installations.

When you're ready to make the switch, your retrofit checklist needs to cover several critical areas. Most importantly, you'll likely need a lubricant swap to POE oils for compatibility. Your pressure controls will need adjustment, and that trusty TXV will probably need recalibration. Don't forget the basics either—proper system leak-checking, thorough evacuation, and clear labeling so future technicians know what they're working with.

The infographic above shows just how dramatic the GWP drop can be with these alternatives. It's not just about compliance—it's about doing right by the environment while maintaining the reliable cooling your funeral home depends on.

Everything You Need to Know About R452A Refrigerant

Preparing for the Transition in Commercial & Mortuary Applications

At American Mortuary Coolers, we're not just watching this transition happen—we're actively helping funeral homes across Tennessee, Georgia, and our entire service area prepare for what's coming.

Timeline planning is everything. We recommend assessing your current equipment's age and condition now, then planning replacements around your natural equipment lifecycle. Nobody wants to be caught scrambling when R-404A becomes scarce or prohibitively expensive. Smart budgeting for retrofit costs and technician training pays dividends down the road.

Stock management requires a delicate balance. You need adequate R-404A inventory to maintain existing systems, but you also need to source alternative refrigerants and compatible components before demand spikes. We're working with our suppliers to ensure smooth transitions for our customers, and we always emphasize proper reclaim and recycle procedures—it's the responsible thing to do.

Technician training can't be an afterthought. Your service team needs updated PT chart references for new refrigerants, hands-on practice with retrofit procedures, and solid understanding of any new safety considerations. The fundamentals remain the same, but the details matter.

Equipment compatibility checks are crucial. Will your existing compressor work with the alternative refrigerant? Does your expansion valve have the capacity and adjustment range needed? Are you selecting the right lubricant? These aren't questions you want to answer during an emergency service call.

The transition timeline varies by region and specific application, but one thing's certain: planning now ensures your mortuary cooling systems keep running smoothly throughout the entire phase-down period. We've seen too many facilities caught off-guard by regulatory changes, and it's never pretty when you're dealing with critical cooling applications like mortuary refrigeration.

Frequently Asked Questions about Pressure Temp Chart 404A

After working with funeral homes across the country for years, we get the same questions about pressure temp chart 404a readings over and over. Let me share the answers that matter most for keeping your mortuary cooling systems running smoothly.

What are the normal suction & discharge pressures for R-404A?

The "normal" pressures depend entirely on what temperature you're trying to maintain. Think of it this way - colder storage means lower pressure on the suction side.

For medium-temperature coolers running around 35-40°F (like body holding coolers), you'll typically see suction pressures between 80-90 psig. This is the most common range we work with in mortuary applications.

Low-temperature freezers operating at -10 to 0°F will show much lower suction pressures, usually 15-35 psig. If you're running an ultra-low temperature application at -20°F, expect suction pressures around 10-20 psig.

On the high side, discharge pressures typically run 200-270 psig, but this varies with ambient temperature. On a hot summer day with 100°F ambient conditions, you might see head pressures around 235 psig - that's perfectly normal.

These are guidelines based on our field experience. Your specific system might run slightly different pressures depending on the equipment design and local conditions.

How can the PT chart help detect low refrigerant charge?

A pressure temp chart 404a is like a detective's tool for finding refrigerant leaks. When a system is low on charge, it tells a very specific story through the pressures.

Lower than normal suction pressure is usually the first clue. If your chart says you should see 85 psig at 40°F but you're only reading 65 psig, that's a red flag. The system can't maintain proper pressure because there's simply not enough refrigerant circulating.

You'll also notice superheat climbing above 15°F - sometimes way above. This happens because the evaporator isn't getting enough liquid refrigerant to absorb heat properly. The refrigerant vapor gets much hotter than it should before reaching the compressor.

On the liquid side, subcooling drops below 8°F or might disappear entirely. This tells you the condenser isn't getting enough refrigerant to build up a proper liquid seal.

Here's the key: compare your actual readings to what the pressure-temperature chart says they should be. If pressures are consistently low across different operating conditions and load scenarios, you're almost certainly dealing with an undercharged system.

What's the difference between bubble point and dew point on a PT chart 404A?

This is where R-404A gets a bit tricky compared to single-component refrigerants. Since it's a blend of three different refrigerants, it doesn't change phase at one exact temperature like older refrigerants did.

Bubble point is the temperature where your liquid refrigerant first starts to boil at a given pressure. Think of it as the moment the first tiny bubble appears in the liquid. This is the number you'll use when calculating subcooling on the liquid line.

Dew point is the opposite - it's the temperature where refrigerant vapor first starts to condense back into liquid at a given pressure. Picture the first droplet forming from the vapor. You'll use this temperature for superheat calculations on the suction line.

The difference between bubble point and dew point temperatures is called "glide" - typically just 1-2°F for R-404A. It's not huge, but it's important enough that quality pressure-temperature charts show separate liquid and vapor columns.

This is why you can't just grab any old refrigerant chart and expect accurate readings. R-404A's blended nature requires charts specifically designed for zeotropic refrigerants that account for this temperature glide.

When we're training technicians on mortuary systems, we always emphasize using the right column for the right calculation. It might seem like a small detail, but it makes the difference between accurate diagnostics and chasing phantom problems.

Conclusion

Working with a pressure temp chart 404a might seem technical at first, but it's really just about understanding the relationship between pressure and temperature in your refrigeration system. Once you get the hang of it, these charts become your best friend for keeping mortuary cooling systems running smoothly.

We've seen thousands of funeral homes across the country benefit from proper pressure-temperature monitoring. It's the difference between catching a small problem early and dealing with a complete system failure during a busy weekend. Nobody wants to explain to a grieving family why their loved one can't be properly preserved because the cooler went down.

The reality is that R-404A systems won't be around forever. With environmental regulations tightening, we're all heading toward lower-GWP alternatives. But here's the thing - the principles you learn from working with pressure temp chart 404a data will serve you well with any refrigerant. Pressure and temperature relationships are fundamental to how refrigeration works.

At American Mortuary Coolers, we design our custom units with these transitions in mind. Whether you're in Tennessee, Georgia, Illinois, or anywhere across the lower 48, we build systems that can adapt as the industry evolves. Our engineers understand both the current R-404A landscape and what's coming next.

The best advice we can give? Start keeping detailed pressure and temperature logs now. Train your staff on proper chart reading. Build relationships with qualified technicians who understand mortuary applications. These steps will pay dividends whether you're running R-404A today or transitioning to alternatives tomorrow.

Reliable refrigeration isn't just about the equipment - it's about understanding how that equipment works. Pressure temp chart 404a knowledge gives you that understanding, turning you from someone who just operates the system into someone who truly manages it.

Ready to optimize your mortuary cooling setup? Our team delivers custom solutions nationwide, backed by the technical expertise to help you make the most of your refrigeration investment. We're here to help you keep families' trust through reliable, precise temperature control.