Step-by-Step Guide to R22 Refrigerant Replacement and Purchase

Why R22 Refrigerant Phase-Out Affects Your Cooling Systems

R22 refrigerant is a hydrochlorofluorocarbon (HCFC) that was widely used in air conditioning and refrigeration systems for decades, but it's now being phased out due to environmental regulations.

Key R22 Facts:

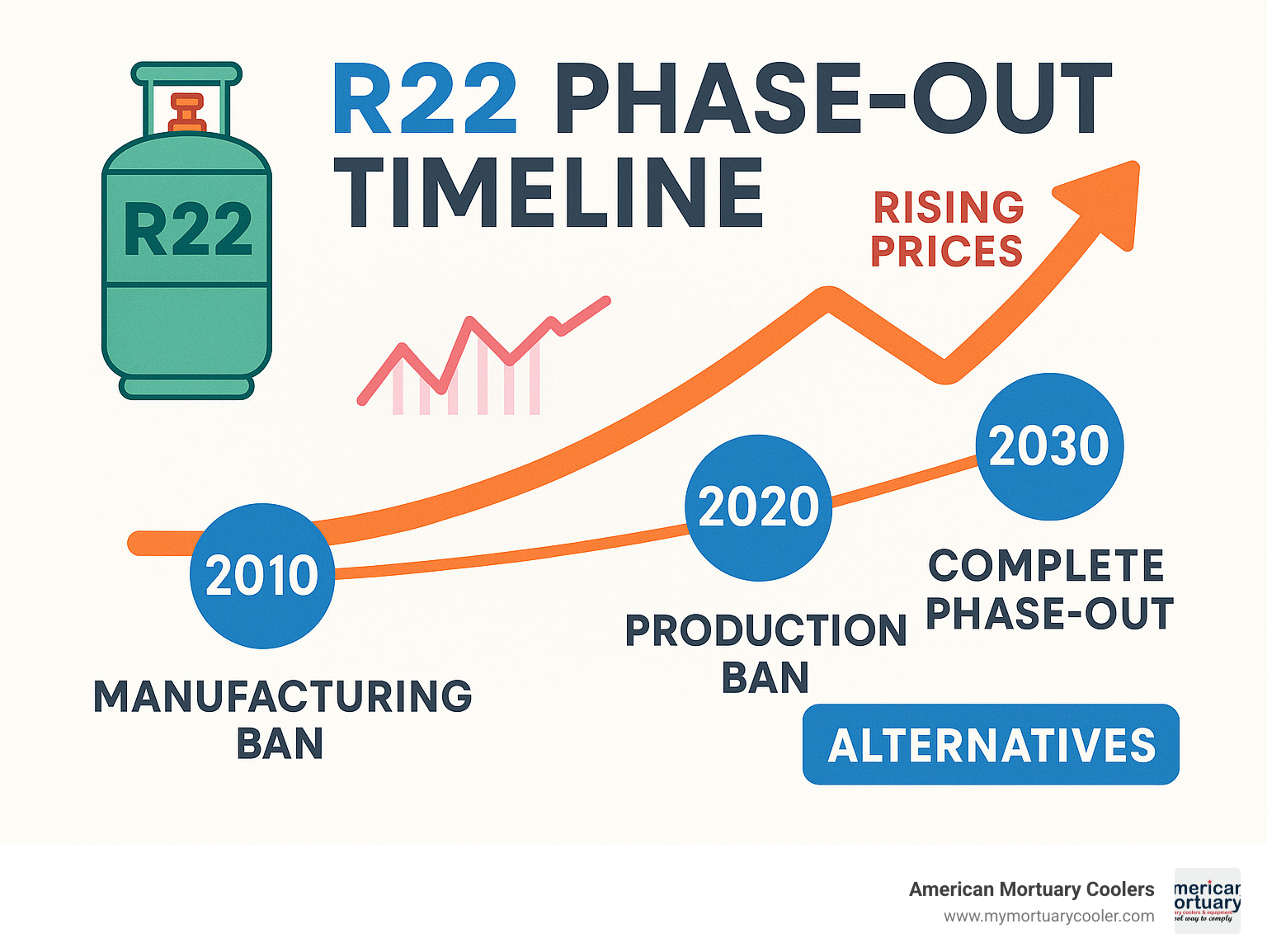

- Production banned: January 1, 2020 in the U.S.

- Current price: $60-$250 per pound (due to limited supply)

- Environmental impact: Ozone Depletion Potential of 0.055, Global Warming Potential of 1,810

- Still available: Only recycled or reclaimed R22 can be used for existing systems

- Final deadline: Complete HCFC phase-out by January 1, 2030

The phase-out follows the Montreal Protocol and EPA regulations under the Clean Air Act. Systems manufactured before 2010 likely use R22, while newer equipment uses alternatives like R-410A or R-454B.

If your mortuary cooling systems rely on R22, you're facing rising costs and dwindling supply. The EPA's 2012 reduction of R22 by 45% caused prices to jump over 300%, and costs continue climbing as recycled supplies shrink.

Your main options include:

- Continue servicing with expensive recycled R22

- Retrofit to approved alternative refrigerants

- Replace entire systems with modern, efficient units

As American Mortuary Coolers with years of experience helping funeral homes steer refrigeration challenges, we've seen how the R22 refrigerant shortage impacts mortuary operations and budgets. Understanding your options now helps you make smart decisions before emergency repairs force costly rushed choices.

Understanding R22 Refrigerant Phase-Out

R22 refrigerant (chlorodifluoromethane or HCFC-22) became the backbone of cooling systems worldwide due to its A1 safety classification - both non-toxic and non-flammable under normal conditions. However, this refrigerant has an Ozone Depletion Potential (ODP) of 0.055 and a staggering Global Warming Potential (GWP) of 1,810. Every pound of R22 released has the same warming effect as 1,810 pounds of carbon dioxide.

The Montreal Protocol in 1987 recognized the urgent need to protect our ozone layer. The United States incorporated these requirements into the Clean Air Act, setting phase-out deadlines: January 1, 2010 ended new R22 equipment manufacturing, January 1, 2020 banned R22 production and import, and January 1, 2030 will complete the HCFC phase-out.

Why R22 Refrigerant Was the Industry Standard

For over forty years, R22 refrigerant dominated cooling applications through exceptional heat-transfer efficiency and reliability in medium-temperature commercial refrigeration. At American Mortuary Coolers, we've worked with countless R22 systems that delivered the consistency funeral homes depend on for maintaining precise temperatures.

The refrigerant's A1 safety classification gave technicians peace of mind with straightforward handling procedures. This combination of safety, efficiency, and reliability made R22 the obvious choice for everything from residential heat pumps to commercial chillers.

Environmental Impact of R22 Refrigerant

When R22 refrigerant escapes into the atmosphere, its chlorine atoms break down ozone molecules, weakening our planet's protective ozone layer. This allows more harmful UV radiation to reach Earth's surface, contributing to increased skin cancer, cataracts, and immune system problems.

R22 is also a potent greenhouse gas that traps heat far more effectively than carbon dioxide. As R22 use declines and environmentally friendly refrigerants take its place, we're giving our ozone layer a chance to heal while reducing global warming impact.

Assessing Your Existing System Before You Buy or Replace

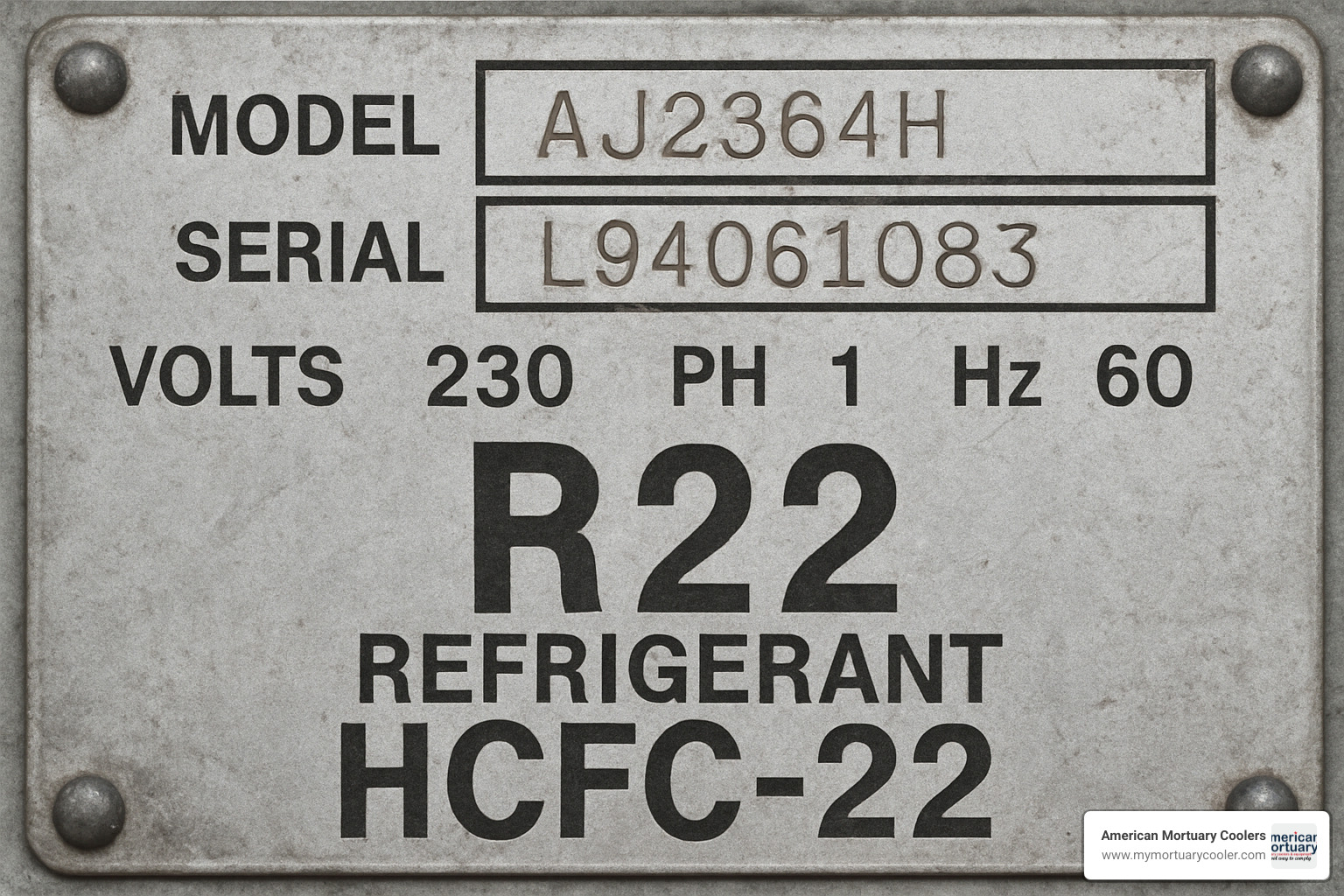

Start by checking your equipment nameplate for R22 refrigerant designation and manufacturing date. Review service records - frequent refrigerant top-offs indicate leaks that now cost serious money with R22 refrigerant running $60 to $250 per pound.

Systems manufactured before 2010 almost certainly use R22. If they're approaching 15-20 years old, continuing repairs might waste money compared to replacement. Document current performance issues like inadequate cooling or constant operation.

EPA Section 608 rules require certified technicians for major refrigerant work, but you can gather information to make informed decisions before service calls.

How to Tell If Your HVAC Uses R22

Check the equipment nameplate for labels saying "HCFC-22," "R-22," or "Freon-22". Systems manufactured before January 1, 2010 almost certainly use R22, as that's when EPA banned new R22 equipment production.

If nameplates are unreadable, check owner's manuals or call manufacturers with model numbers. Ask certified technicians during service visits - they can identify refrigerant types instantly.

Phase-Out Effects on Homeowners & Businesses

The R22 refrigerant phase-out creates multiple challenges beyond higher prices. Service delays occur when R22 isn't available, and retrofit modifications without manufacturer approval can void warranties.

Aging R22 systems often work harder to maintain temperatures, driving up electric bills. For mortuary facilities needing 24/7 cooling, efficiency losses cost thousands annually. Planning transitions while systems work gives you control over timing and costs.

More info about R22 system options can help you understand alternatives for your cooling needs.

Replacement Options, Retrofits, and Drop-In Alternatives

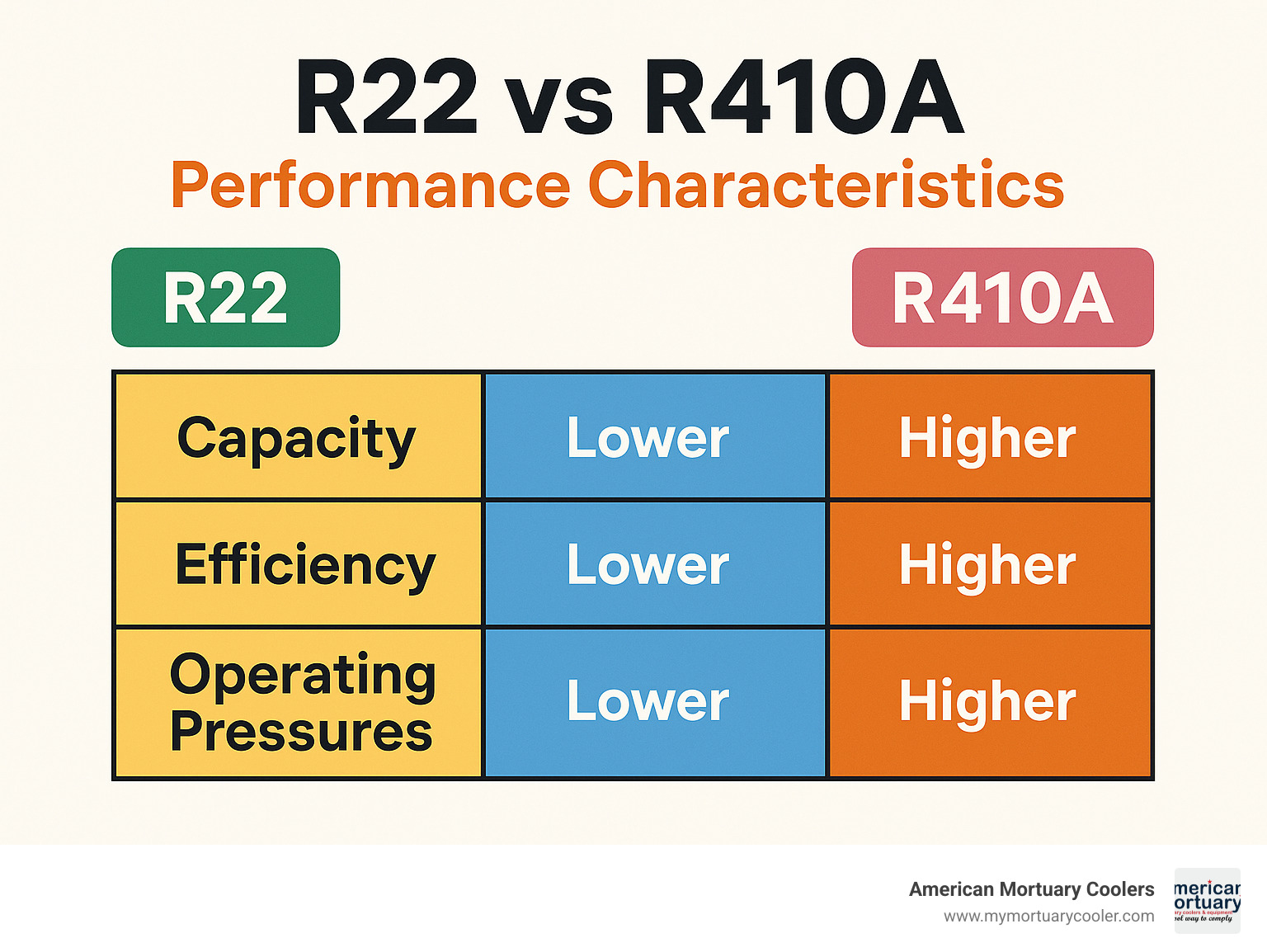

R-410A has become the cooling industry workhorse, eliminating ozone depletion while boosting energy efficiency. However, it runs at much higher pressures than R22, usually preventing safe conversion of existing equipment.

R-454B represents the industry's future with a Global Warming Potential of just 466 (compared to R22's 1,810), delivering similar cooling power while meeting stricter environmental standards.

For extending current system life, R-449A (Opteon XP40) and R-438A (MO99) were designed as R22 refrigerant replacements. These retrofit blends work with existing equipment after modifications. R-422B (NU-22B) offers another retrofit path, particularly for medium-temperature applications like mortuary cooling systems.

Oil compatibility matters significantly. Most R22 systems use mineral oil, but many alternatives need POE (polyolester) oil, requiring complete oil changes and system flushing. Pressure and temperature characteristics vary between refrigerants, often requiring thermostatic expansion valve (TXV) adjustments.

Opteon™ refrigerants Regulations provides detailed specifications for approved alternatives.

Full System Replacement vs Retrofit

New equipment brings immediate benefits: modern systems meet minimum SEER 13 requirements, typically providing 10-40% better energy efficiency than older R22 systems. For funeral homes running cooling equipment continuously, efficiency gains translate to monthly savings plus full manufacturer warranties and readily available parts.

Replacement costs range from several thousand for smaller units to tens of thousands for complex walk-in systems. Retrofitting costs less initially and can extend system life several years if equipment is well-maintained.

Retrofits have compromises - aging components may fail, and efficiency gains are modest compared to new equipment. Heat pump systems add complexity as some retrofit refrigerants behave differently in heating mode.

Consider available incentives and rebates from utility companies and federal programs, which can significantly improve replacement economics.

Step-by-Step Retrofit Guide for R22 Refrigerant Systems

Retrofit work requires EPA Section 608 certification and specialized equipment. The process starts with system assessment - documenting current operation including pressures, temperatures, superheat, and subcooling values.

R22 recovery uses certified equipment to remove every bit of existing refrigerant. System inspection includes leak testing and filter drier replacement. Oil evaluation determines if complete oil changes are necessary for compatibility.

Evacuation and charging requires precision - systems get evacuated to 400 microns or less, then charged with new refrigerant at 95-105% of original R22 weight. System startup includes TXV adjustments and pressure control resetting.

Final documentation and labeling ensures future service goes smoothly with clear refrigerant identification and updated service records.

Everything You Need to Know About R452A Refrigerant offers insights into modern refrigerant alternatives.

Buying & Handling R22 or Approved Alternatives Safely

Since January 2020, only recycled or reclaimed R22 refrigerant is available, creating shrinking supply with prices from $60 to $250 per pound. EPA-certified reclaimed stock maintains original R22 quality, but finding legitimate suppliers with proper documentation is challenging due to counterfeit refrigerant containing harmful contaminants.

Cylinder sizes range from 2 to 30 pounds - smaller containers work for minor top-offs while larger cylinders suit major repairs. Shipping rules classify refrigerants as hazardous materials, requiring special packaging and higher costs.

Legal Requirements for Purchasing R22 Refrigerant

EPA Section 608 certification is mandatory for purchasing controlled refrigerants. Most mortuary applications need Type II certification covering high-pressure refrigerants. Record-keeping requirements document every purchase with quantities, dates, suppliers, and intended use.

The venting ban is absolute - no refrigerant can be intentionally released to atmosphere. Violations carry fines up to $37,500 per day. Some states add requirements beyond federal EPA rules.

Safe Storage, Transport & Disposal

Personal protective equipment includes safety glasses and chemical-resistant gloves. Work in well-ventilated areas since vapors can displace oxygen. Cylinder labeling must clearly identify refrigerant type, purity level, and safety warnings.

Recovery machines must meet EPA standards with regular maintenance. Use separate cylinders for different refrigerants to prevent cross-contamination. Recycling centers certified for refrigerant handling provide proper disposal services.

Hazmat transport regulations apply when moving cylinders. Storage areas should stay cool, dry, and well-ventilated with cylinders secured to prevent tipping.

EPA Homeowner FAQ provides additional regulatory guidance.

Frequently Asked Questions About R22 Phase-Out

When did the R22 ban start and what's next?

The R22 refrigerant phase-out rolled out in stages. January 1, 2010 stopped new R22 equipment manufacturing. January 1, 2020 halted all new R22 production and import. We're now in the "service phase" where existing systems can be repaired using only recycled refrigerant.

The final deadline is January 1, 2030 for complete HCFC phase-out. After that, even recycled R22 becomes extremely scarce. Every repair using R22 refrigerant reduces remaining supply, making each service call more expensive.

Can my old R22 system be converted to another gas?

Many R22 refrigerant systems can be converted, but it's not simple gas swapping. R-410A operates at much higher pressures than R22, making it unsuitable for old systems without major modifications that could cause failures.

"Drop-in" alternatives like R-438A (MO99), R-449A, and R-422B are engineered for R22 systems, operating at similar pressures and temperatures. However, conversions typically require oil changes from mineral oil to POE oil, expansion valve adjustments, and pressure control resets.

Conversion success depends on system age and condition. Well-maintained 15-year-old equipment might retrofit well, while 25-year-old units with multiple previous repairs are better replaced entirely.

Why is R22 so expensive now?

Basic economics: supply and demand. The 2020 production ban created limited supply from recycling only. The 2012 EPA reduction of R22 by 45% caused 300% price increases, previewing current market conditions.

Limited recycling capacity, contractor hoarding, hazmat shipping costs, and counterfeit product concerns all drive prices higher. Quality contaminated refrigerant must be destroyed rather than recycled, further reducing supply.

Prices will keep climbing toward the 2030 deadline, making early replacement often more economical than continued repairs.

Conclusion & Next Steps

The R22 refrigerant phase-out doesn't have to be a crisis with proper planning and support. At American Mortuary Coolers, we've helped funeral homes across Tennessee, Atlanta, Chicago, Columbia, Dallas, Los Angeles, New York, Pittsburgh, and throughout all regions successfully steer this transition.

Start by realistically assessing your current equipment and expected service life. If systems are showing age, replacement might save money versus expensive R22 refrigerant repairs. Budget planning becomes crucial as costs won't decrease before 2030.

Consult certified technicians for professional insight on retrofit viability versus replacement economics. Explore available incentives from utilities and government programs to offset upgrade costs.

Modern systems provide better temperature control, improved energy efficiency, and more reliable operation - critical for mortuary applications. We focus on helping you plan transitions during slower periods rather than emergency scrambling.

The R22 refrigerant phase-out timeline isn't negotiable, but your response strategy can be flexible and smart. Whether choosing retrofitting, replacement, or combination approaches, start the conversation now.

More info about refrigeration controls can help optimize systems during and after transition, ensuring maximum benefit from your chosen approach.

This industry-wide transition offers opportunities for improved operations and long-term savings with proper planning.