Saw It Coming: Top Surgical Bone Saws Reviewed

Why Choosing the Right Bone Saw Matters for Your Practice

Bone saws are specialized surgical instruments designed to cut through bone tissue with precision and control. Whether you're running a funeral home, pathology lab, or medical facility, selecting the right bone saw can make the difference between smooth operations and costly delays.

Key Types of Bone Saws:

- Manual saws - Hand-operated tools like hacksaws and frame saws

- Reciprocating saws - Powered oscillating blades for smooth cuts

- Autopsy saws - Heavy-duty models for pathology work

- Orthopedic saws - Precision instruments for surgical procedures

Primary Applications:

- Autopsy and forensic examination

- Orthopedic surgery and joint replacement

- Veterinary procedures

- Food processing and commercial butchery

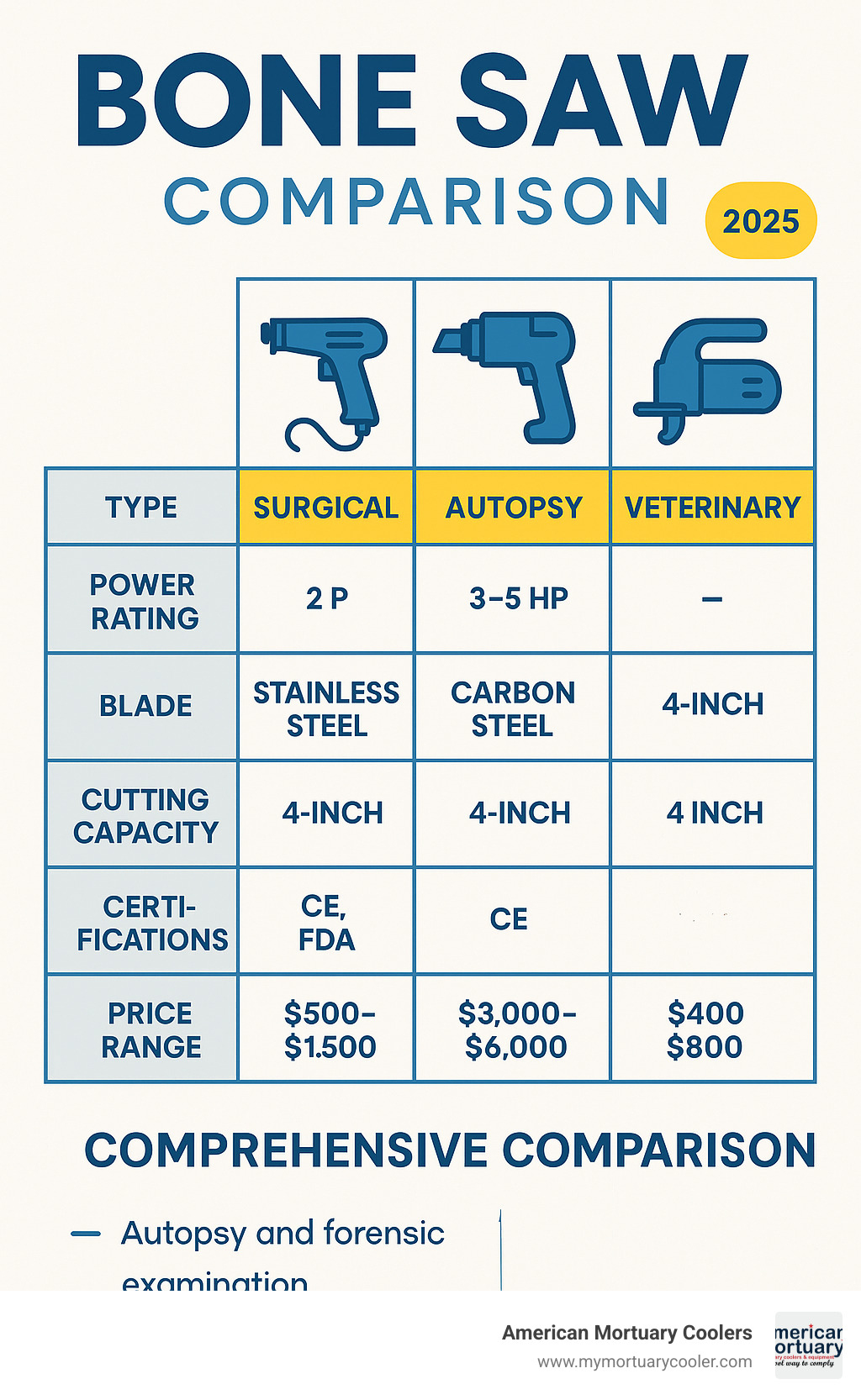

The bone saw market offers everything from $79 manual instruments to $6,700 complete pathology systems with integrated dust collection. Power ratings range from 2 to 5 horsepower, with cutting capacities up to 14 inches thick on industrial models.

Key features to consider include:

- Blade material (high-carbon steel vs stainless steel)

- Frame construction (aluminum alloy vs stainless steel)

- Power source (manual, electric, pneumatic)

- Safety certifications (CE, ETL, NSF)

- Dust collection capabilities

As Mortuary Cooler, I've worked with funeral homes across the country to specify bone saws that meet their exact operational needs and budget constraints. My experience with mortuary equipment has shown that the right bone saw selection directly impacts both efficiency and service quality in funeral operations.

Quick look at bone saw:

What Is a Bone Saw & How Does It Work?

A bone saw is a specialized surgical instrument designed to cut through bone tissue with precision and control. Whether you're working in a hospital operating room, pathology lab, or funeral home, these tools are essential for safely accessing internal structures without damaging surrounding soft tissues.

Think of a bone saw as the surgical equivalent of a carpenter's saw, but engineered to much higher standards. Medical-grade models typically feature frames made from cast aluminum or heavy-duty stainless steel for durability and corrosion resistance. The blades themselves are crafted from high-carbon steel or surgical stainless steel, with hardness ratings around HRC 54° ± 2° for optimal cutting performance.

Unpowered bone saws include traditional hacksaws and frame saws that rely on manual operation. These manual tools are incredibly valuable in procedures like knee surgery where precise, measurable cuts are essential.

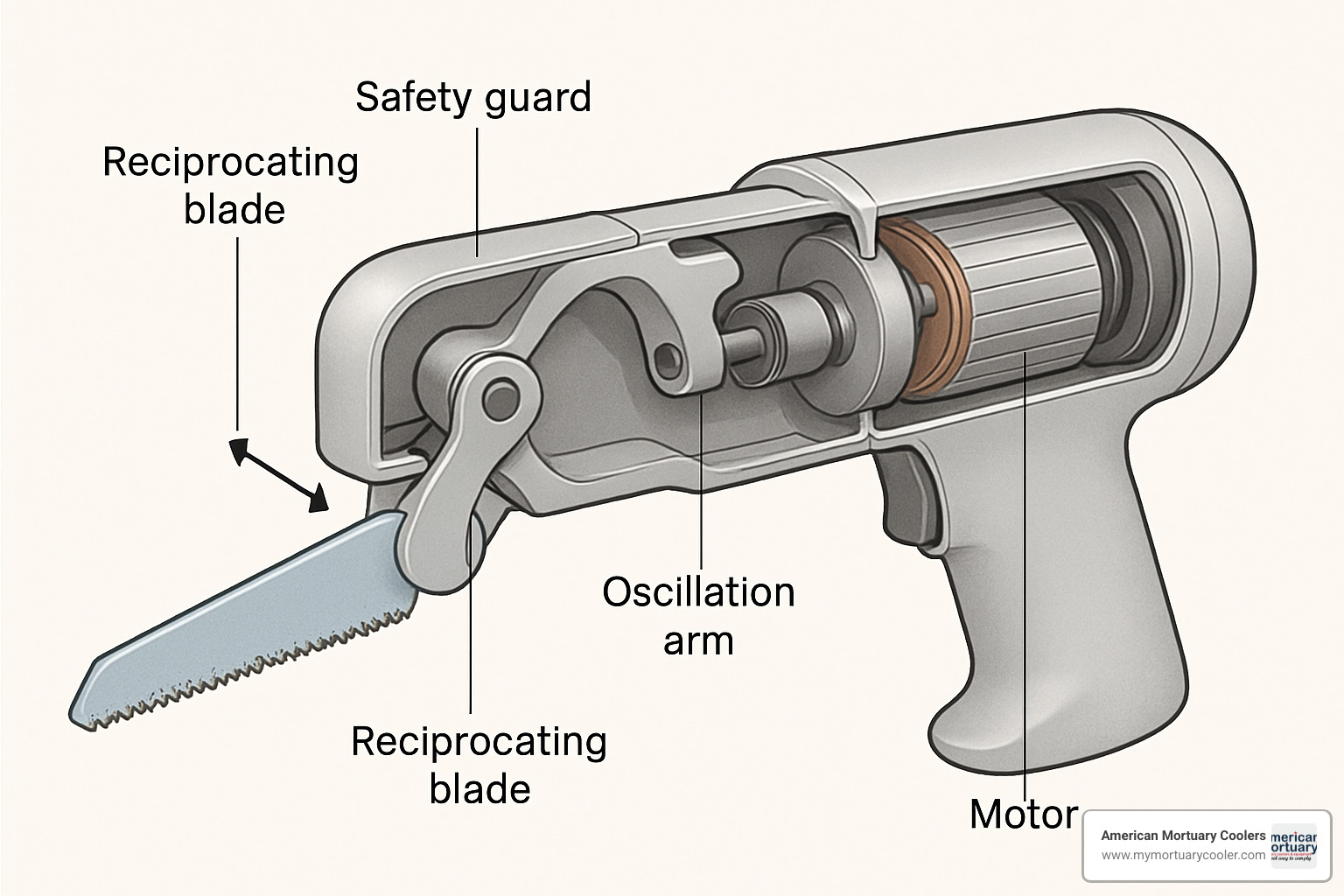

Reciprocating bone saws bring power to the equation with their oscillating motion. Instead of spinning like a circular saw, these electric models use a back-and-forth motion that delivers smooth, controllable cuts. This reciprocating mechanism is particularly useful for procedures like craniotomies and rib cutting, where the oscillating motion minimizes bone splintering.

The newest technology includes sonic bone saws, which use high-frequency sound waves to remove bone material. While still experimental, this technology shows real promise for reducing trauma to surrounding tissues. Research from scientific studies on sternal saw innovation continues to drive improvements in bone saw design and safety.

One specialized tool worth mentioning is the costotome - a dual-lever rib cutter that provides controlled access to the thoracic cavity during surgical procedures.

Power & Motion Fundamentals

The effectiveness of any bone saw comes down to how it delivers power and cutting motion. Reciprocating saws operate through powered rotary oscillation, where the blade moves back and forth at high frequency rather than spinning continuously. This oscillating motion typically spans only a few degrees but occurs at very rapid rates.

Most electric bone saws operate at speeds around 1400 RPM, providing consistent cutting power for extended procedures. Sonic micro-vibration technology takes a different approach, using ultrasonic frequencies to shake bone material apart at the molecular level.

Materials & Build Quality

Surgical stainless steel is the gold standard for medical applications, offering superior corrosion resistance and the ability to withstand repeated sterilization cycles. German surgical stainless steel provides even better rust resistance compared to standard grades.

Frame alloy selection typically comes down to cast aluminum for lighter weight or stainless steel for maximum durability. Blade steel varies based on application - high-carbon steel blades offer excellent edge retention, while surgical stainless steel blades provide the necessary corrosion resistance and biocompatibility required for patient safety.

At American Mortuary Coolers, we understand that the right bone saw can make all the difference in your daily operations, which is why material quality and build construction are never areas to cut corners.

Best Surgical Bone Saws of 2024

Finding the right bone saw for your facility can feel overwhelming with so many options on the market. After working with funeral homes and pathology labs across the country, I've seen which models deliver reliable performance when it matters most.

The bone saw landscape in 2024 offers something for every budget and application. Whether you're running a small funeral home or managing a high-volume pathology lab, there's a tool that fits your needs perfectly.

| Model | Blade Length | Power Source | Max Cut | Price Range | Certifications |

|---|---|---|---|---|---|

| Mopec 1000 | Variable | 110V Electric | N/A | $2,399.95 | Medical Grade |

| Epredia Shandon | Dual Blade | Manual | 7" x 9" | $500-1000 | Laboratory |

| LZQ Orthopedic | Variable | Electric | N/A | $300-500 | ISO Compliant |

| YNR Manual Set | 6"-12" | Manual | Variable | $49-118 | CE Marked |

| EFI SA-BS65 | 65" | Electric | 7" thick | $1000-2000 | ETL/NSF |

Mopec 1000 Autopsy Bone Saw

When funeral directors tell me they need a bone saw that won't let them down during critical procedures, I often point them toward the Mopec 1000. At $2,399.95, it's not the cheapest option, but it's built like a tank.

This electric model runs on standard 110V power and uses interchangeable BD101 blades. What really sets it apart is the modular blade system - you can swap blades quickly without tools, which saves precious time during procedures.

The dust vacuum option is where this saw really shines. Bone dust isn't just messy - it's a health hazard and makes it hard to see what you're doing. The integrated vacuum system keeps your workspace clean and your staff safe. Yes, the complete system with vacuum can run up to $6,712.95, but think of it as an investment in both efficiency and safety.

I've installed these in busy funeral homes that handle dozens of cases monthly, and they keep running year after year with minimal maintenance.

Epredia Shandon Dual-Blade Manual Bone Saw

Here's something you don't see every day - a bone saw that makes two parallel cuts simultaneously. The Epredia Shandon is perfect for labs that need consistent bone slices for analysis.

This manual saw handles specimens up to 7 x 9 inches in cross-section, and there's no limit on length. The dual-parallel-cuts feature means you get uniform samples every time, which is crucial for accurate pathology work.

One of the biggest advantages is aerosol reduction. Unlike electric saws that can spray particles everywhere, this manual design keeps things controlled. Your staff stays safer, and your lab stays cleaner. It comes with both coarse and fine blade sets, so you can match the blade to the bone type you're cutting.

The hacksaw mechanism is rock-solid and easy to clean - important when you're dealing with biological materials. For labs prioritizing precision over speed, this is a smart choice in the $500-1000 range.

LZQ Reciprocating Orthopedic Bone Saw

The LZQ stands out with its ergonomic handpiece design. When you're holding a tool for extended periods, comfort isn't luxury - it's necessity. This bone saw gets that right.

Built from ultra-high anti-rust stainless steel with HRC 54° ± 2° hardness, it's designed to last. The five blade positions give you incredible flexibility for different cutting angles. Whether you need a straight cut or something more complex, this saw adapts to your needs.

The stationary blade shaft is a safety win. It dramatically reduces the chance of accidentally damaging soft tissue - something that keeps surgeons and funeral directors sleeping better at night.

LZQ offers both reciprocating and oscillating versions, plus custom OEM kits. If you have specific procedures or need to match existing equipment, they'll work with you to get it right.

YNR Stainless Manual Bone Saw Set

Sometimes the best tool is the simplest one. The YNR manual bone saw set proves this point beautifully. At around $62 for the complete three-piece set, it's hard to beat the value.

You get 6", 9", and 12" sizes with straight, wide, and round blade options. The CE-marked certification means it meets European safety standards, and being autoclave-safe makes sterilization straightforward.

These hand-crafted stainless steel saws are popular with veterinarians and smaller funeral homes. They're portable, reliable, and won't leave you stranded if the power goes out. Sometimes that peace of mind is worth more than all the bells and whistles.

EFI SA-BS65 Pathology Bone Saw

The EFI SA-BS65 brings industrial strength to pathology work. With a 65-inch blade running at 1400 RPM, it handles thick cuts up to 7 inches with ease.

The cast aluminum body keeps weight manageable at 89.5 pounds while maintaining durability. Being ETL-NSF certified means it meets strict safety and sanitation standards - important for both pathology labs and commercial applications.

The stainless steel table and high-carbon steel blade combination delivers consistent results. The blade tension knob lets you fine-tune performance, and the compact footprint (18.3" W × 24.4" D × 34.4" H) fits in smaller spaces.

With a one-year parts and labor warranty backing it up, this mid-range option offers solid performance without breaking the budget.

How to Choose the Right Bone Saw for Your Practice

Finding the right bone saw for your facility comes down to understanding your specific needs and matching them with the right features. After years of helping funeral homes and pathology labs across the country, I've learned the key factors that matter most.

Motor power is your foundation for electric models. Heavy-duty work requires systems with 2-5 horsepower motors that can cut through materials up to 14 inches thick. However, many smaller facilities find that 1-2 horsepower models handle their routine work perfectly while saving thousands of dollars upfront.

Blade specifications matter significantly. A 6-inch blade works beautifully for precision veterinary work, while pathology labs often need something in the 65-inch range. Going too big means paying for unused capacity, while going too small creates frustrating limitations.

Certifications aren't just paperwork - they're your protection. ETL Listed, ETL Sanitation Listed, and NSF Certified models meet strict requirements for medical and food service applications. CE Mark approval is essential for European markets, while ISO compliance shows international quality standards.

Cut thickness capacity varies dramatically between models. Manual saws typically handle specimens up to 7-9 inches, covering most routine work. Industrial electric models can power through materials up to 14 inches thick.

Ergonomics matter for extended use. Features like balanced weight distribution, comfortable grips, and proper height adjustment prevent fatigue and improve safety. Budget considerations go beyond the sticker price - factor in operating costs like power consumption and blade replacement frequency.

For detailed guidance on selection criteria, review our comprehensive equipment selection guide.

Bone Saw Buying Checklist

When evaluating bone saw options, start with power and performance specs. Motor horsepower rating should match your workload, with most facilities finding the 1-5 HP range adequate. Operating RPM around 1400 works well for most applications, while maximum cutting thickness capability and blade length options should align with your typical specimen sizes.

Build quality separates good saws from great ones. Frame construction in aluminum alloy offers lighter weight, while stainless steel provides maximum durability. Blade material and hardness rating around HRC 54° ± 2° gives you the sweet spot between sharpness and longevity.

Safety and compliance can't be compromised. Required certifications like ETL, NSF, CE Mark, or ISO aren't optional. Dust collection capabilities protect your staff and maintain workspace cleanliness. Safety guards and ergonomic design prevent accidents and reduce fatigue.

Consider long-term support including warranty duration, local service availability, blade replacement support, and vendor reputation. Budget considerations extend beyond initial purchase price to include operating costs and maintenance requirements.

Innovations & Trends to Watch

Sonic technology represents the most exciting advancement - using high-frequency vibrations to remove bone material with incredible precision and minimal tissue damage. Integrated vacuum systems are becoming standard for serious operations, capturing bone dust right at the source.

Quick-swap blade systems are gaining popularity because they let operators change blade configurations rapidly without tools. The focus on ergonomic improvements continues advancing with lighter materials, better balance, and improved grip designs.

Safe Operation, Cleaning & Maintenance

When it comes to bone saw safety, there's no room for shortcuts. Proper safety protocols and maintenance can mean the difference between smooth operations and serious problems.

Personal protective equipment isn't optional - every operator needs safety glasses, cut-resistant gloves, and a protective apron as absolute minimums. For electric models, add hearing protection. Most importantly, bone dust masks or respirators are essential unless you have a top-notch vacuum system running.

OSHA takes bone saw safety seriously, covering everything from dust control to operator training. Your facility needs proper ventilation, the right PPE for every team member, and comprehensive training programs.

Sterilization requirements vary by application. Medical and veterinary bone saws need full autoclaving between uses, while pathology work might allow chemical sterilization. Always follow your manufacturer's guidelines exactly to avoid damaging blade temper or warping frame materials.

Bone dust vacuum systems are game-changers for any electric bone saw operation. These systems grab particles right at the source, protecting your operators and cutting cleanup time dramatically.

For complete safety protocols, check out our detailed mortuary tool safety guide.

Bone Saw Maintenance 101

Daily cleaning should become second nature. Remove every bit of bone debris from the blade and frame, wipe down all surfaces with the right disinfectants, and always check blade tension and alignment. For electric models, ensure safety guards are positioned correctly.

Weekly maintenance digs deeper. Disassemble removable components for thorough cleaning, check blade sharpness honestly, and lubricate moving parts according to manufacturer specs using only approved lubricants.

Monthly inspections catch problems early. For powered models, check electrical connections and verify smooth motor operation. Inspect the frame carefully for any cracks or unusual wear patterns.

Record keeping documents every maintenance activity, blade replacement, and operational issue. This paperwork protects your warranty coverage and helps you spot patterns that might signal bigger problems.

Troubleshooting & Repairs

Most bone saw problems follow predictable patterns with straightforward solutions.

Blade wandering during cuts usually means dull blades, improper blade tension, or worn blade guides. Start with a fresh blade, then check and adjust tension according to manufacturer specifications.

Motor overheating typically means someone's pushing too hard, ventilation is blocked, or internal components are wearing out. Back off cutting pressure first, then ensure air can flow freely around the motor.

Motor stalling points to electrical issues, mechanical binding, or excessive load. Clear any debris from the cutting mechanism, double-check blade installation, and verify your electrical supply meets requirements.

For complex repairs or warranty work, stick with authorized service centers to protect your warranty coverage and ensure repairs are done right the first time.

Frequently Asked Questions about Surgical Bone Saws

When I talk with funeral directors and pathology lab managers across the country, the same questions about bone saws come up again and again. Let me share the answers that matter most for your daily operations.

How do medical bone saws differ from food-service or industrial models?

The difference between medical and commercial bone saws goes far beyond just the price tag. Medical bone saws must meet incredibly strict biocompatibility standards that food-service models simply don't address.

Every component that touches tissue needs to be made from surgical-grade stainless steel that can handle repeated sterilization cycles without breaking down or corroding. I've seen facilities try to save money with food-service models, only to face compliance issues during inspections.

Medical saws also feature specialized blade designs that minimize tissue damage and reduce the aerosol particles that can spread contamination. Food-service models focus on cutting speed and easy cleanup, which is fine for processing meat but not appropriate when precision and sterility matter.

The certification requirements tell the whole story. Medical bone saws need FDA approval and ISO compliance, while food-service models only require NSF certification for sanitation. Industrial models may not have any medical certifications at all.

What certifications should my bone saw meet for hospital use?

For hospital applications, your bone saw absolutely must carry FDA medical device approval as the baseline requirement. Beyond that, look for ISO 13485 certification, which covers quality management systems for medical devices.

If you're working with international facilities or equipment, CE marking is mandatory for European markets. Canadian facilities need Health Canada approval before they can use any medical bone saw.

Don't forget about electrical safety either. ETL listing ensures your powered bone saw meets electrical safety standards. Some specialized applications may require additional biocompatibility certifications depending on how the saw will be used.

My advice? Always check with your facility's risk management and purchasing departments before ordering. They'll know exactly which certifications your state and accreditation bodies require. It's much easier to get this right the first time than to deal with compliance issues later.

How often should I replace or sharpen a surgical bone saw blade?

Bone saw blade life depends heavily on how often you use it and what quality blade you started with. High-quality surgical blades typically give you 50 to 100 cutting procedures before they need replacement or professional sharpening.

But don't just count procedures - pay attention to performance. If you notice the saw requiring more pressure to cut, or if the cut quality starts looking rough, it's time for a new blade. Dull blades are not only inefficient, they're actually dangerous because operators tend to apply more force.

Manual saw blades can usually be professionally sharpened 2 to 3 times before replacement becomes necessary. Electric saw blades are different - they typically get replaced rather than sharpened because the precision balance required for safe operation is hard to maintain after resharpening.

Here's a tip from my years in the industry: always keep spare blades in stock. Nothing disrupts operations like finding your blade is dull right when you need to use the saw. A simple blade inventory system will save you headaches and keep your facility running smoothly.

Conclusion

Finding the perfect bone saw for your facility doesn't have to be overwhelming. We've covered everything from budget-friendly $79 manual sets that work beautifully for smaller practices to robust $6,700 Mopec systems that power busy pathology labs.

The secret isn't buying the most expensive model - it's matching your actual needs with the right capabilities. Manual saws deliver excellent value and reliability for lower-volume work, while electric models with their consistent power and speed advantages can transform busy facility operations.

Today's bone saw technology offers impressive safety and effectiveness improvements. Integrated vacuum systems capture bone dust at the source, advanced blade technologies cut cleaner with less effort, and ergonomic designs reduce operator fatigue - these features are becoming the standard.

Here at American Mortuary Coolers, we've spent years helping facilities across all 48 contiguous states steer these equipment decisions. We know that investing in mortuary and pathology equipment represents a significant commitment to your practice's future. That's why we take time to understand your specific workflow, volume requirements, and budget constraints before making recommendations.

Our custom solutions approach means we consider how your new bone saw fits into your overall operational picture. Plus, our direct delivery capability across the continental United States means you can count on professional installation support and prompt service when you need it.

Whether you're upgrading existing equipment or setting up a new facility, we're here to help you make the right choice. Every facility is different, and the best equipment decisions come from understanding those unique differences.

Ready to explore beyond bone saws? Our complete mortuary equipment solutions include specialized cooling systems and all the related equipment you need to keep your facility running smoothly. We'd love to show you how our Tennessee-crafted, custom-built approach can support your facility's success for years to come.