Preserve & Protect with Prefilled Formalin Containers

Why Formalin Containers Are Essential for Safe Specimen Preservation

Formalin containers are specialized laboratory vessels designed to safely store and transport tissue specimens in 10% neutral buffered formalin (NBF) solution. These containers range from small 5 mL vials to large 1.25-gallon vessels and feature leak-resistant seals, chemical-resistant materials, and safety compliance ratings for pneumatic tube transport.

Key specifications for formalin containers:

- Standard concentration: 10% neutral buffered formalin at pH 7.0

- Common sizes: 20 mL to 120 mL (pneumatic tube compliant), up to 1.25 gallons for bulk storage

- Materials: Polypropylene (most common), PET, or HDPE with polyethylene caps

- Safety features: 95 kPa pressure rating, dual-click seals, ribbed lids for gloved handling

- Fill level: Typically 50% pre-filled to allow specimen placement and prevent overflow

The most critical safety consideration is that formaldehyde is a known human carcinogen that can cause severe pulmonary reactions and skin irritation. Proper storage requires temperatures between 15-30°C, adequate ventilation, and regular inspection for leaks or damage.

As American Mortuary Coolers with experience in mortuary equipment, we've seen how proper formalin containers directly impact both specimen integrity and staff safety in funeral homes and pathology labs. Quality containers with reliable seals prevent costly specimen loss and reduce formaldehyde exposure risks that can compromise your facility's compliance standards.

Formalin containers vocab explained:

What Are Formalin Containers & Their Core Laboratory Roles

When you walk into any histology lab, you'll find formalin containers quietly doing one of the most important jobs in medicine - keeping tissue specimens perfectly preserved for accurate diagnosis. These specialized vessels hold 10% neutral buffered formalin (NBF), which has been the gold standard for tissue fixation for over a century.

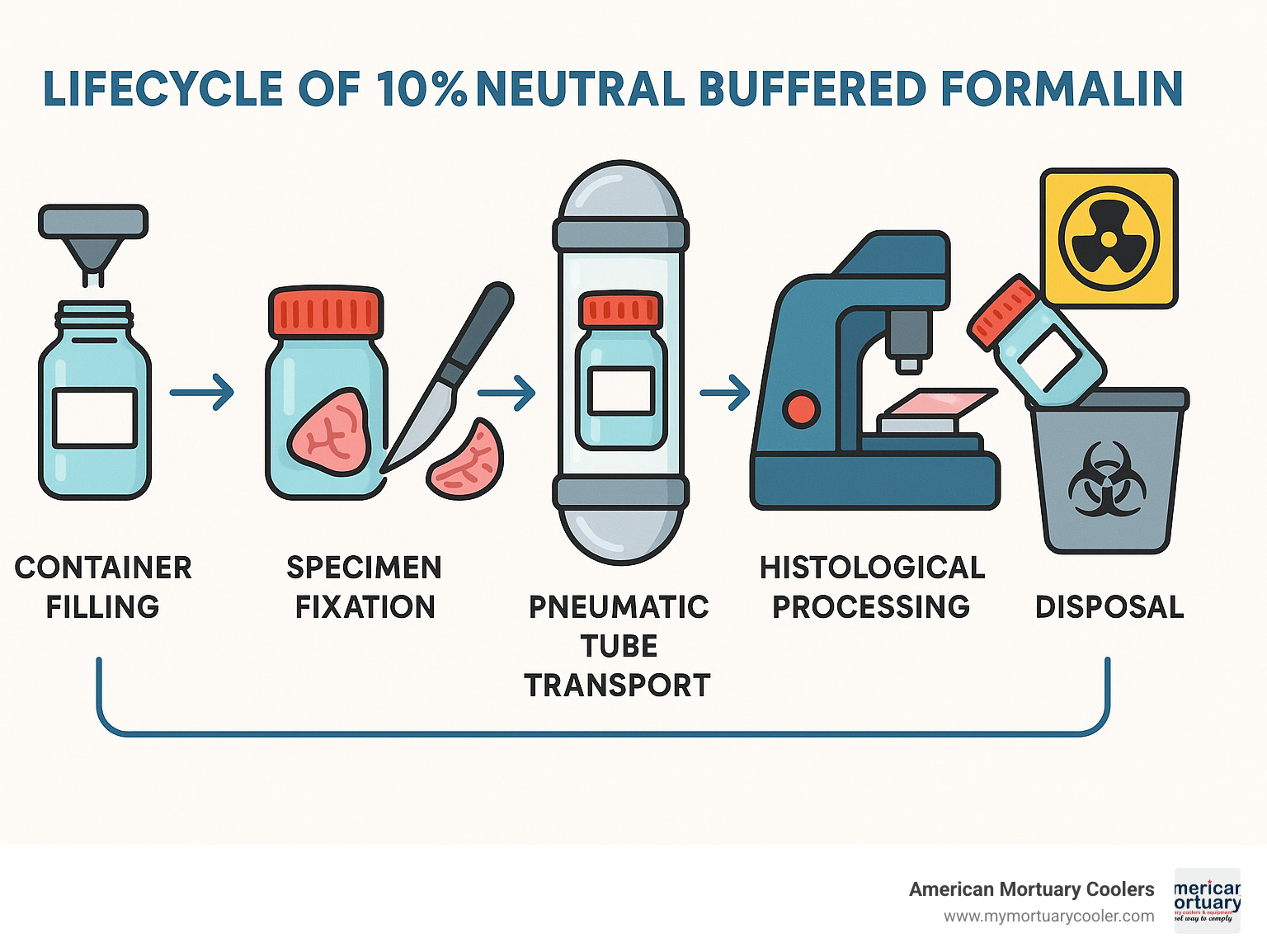

Formalin containers are the guardians of specimen integrity. Once a tissue sample goes into that container, the formaldehyde begins cross-linking proteins and nucleic acids, essentially freezing the tissue's cellular structure in time. This prevents natural breakdown processes that would otherwise make microscopic examination impossible.

The fixation process typically takes 6 to 24 hours depending on tissue thickness. During this critical window, formaldehyde works through every cell, stopping bacterial growth and preventing decomposition. Without proper fixation, even the most skilled pathologist can't make an accurate diagnosis.

Here's where things get serious: Formaldehyde is a known human carcinogen. OSHA has strict rules about exposure limits - you can't have more than 0.75 parts per million in the air over an 8-hour period, and never more than 2 ppm for even 15 minutes. This is why container design matters so much. Those leak-resistant seals aren't just nice to have - they're essential for keeping your staff safe and your facility compliant.

In our years serving funeral homes and pathology labs, we've seen how the right formalin containers make all the difference. Whether you're processing routine biopsies or handling complex forensic cases, specimen integrity starts with that first container choice.

Key Components Inside Every Formalin Container

The 50% fill rule ensures you have enough fixative to completely surround your specimen while leaving room to add tissue without creating a mess. Most labs aim for a 10:1 or 20:1 ratio of fixative to tissue volume.

The pH 7.0 buffer system keeps your specimens looking their best under the microscope. Without proper buffering, formalin naturally becomes acidic over time, forming formic acid that causes nuclear swelling and poor staining results.

Methanol stabilizer prevents formaldehyde from clumping together into useless polymers. This is especially important if specimens sit in transport for extended periods.

The phosphate buffer maintains both pH and the right ionic strength, keeping cells from shrinking or swelling excessively during fixation.

Clarity might seem minor, but cloudy or precipitated formalin is a red flag indicating contamination or improper storage conditions that could compromise your entire specimen.

Buying Guide: Formalin Containers by Size & Material

Choosing the right formalin containers for your facility depends on your specific workflow needs. Formalin containers range from tiny 5 mL vials to massive 1.25-gallon containers. Most facilities find their sweet spot with 60-70 mL containers handling about 80% of their daily needs.

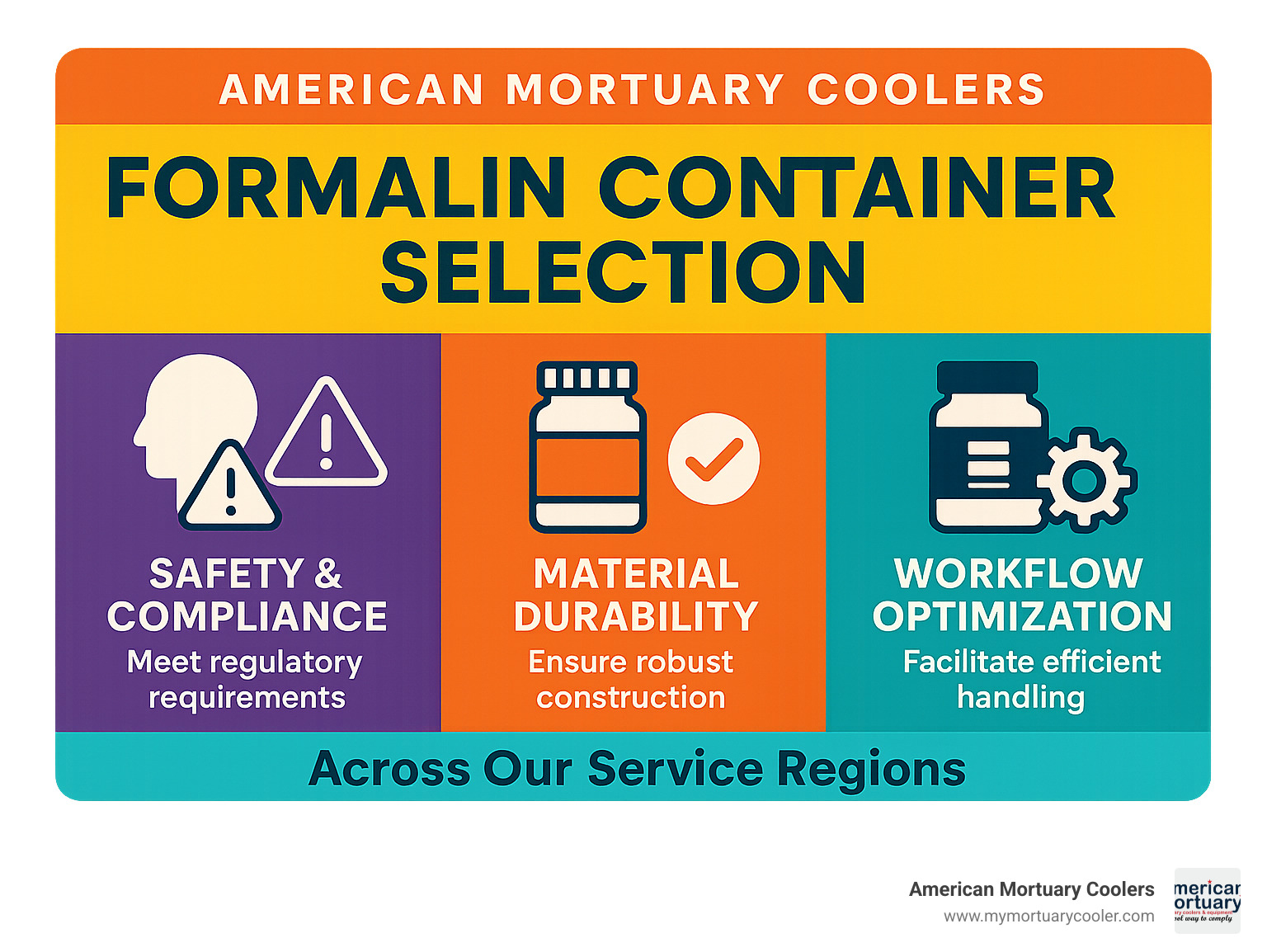

Polypropylene dominates the market for good reason - it's tough, chemical-resistant, and won't crack when dropped. PET offers crystal-clear visibility but can't handle heat if you need to autoclave. HDPE works great for bulk storage but you can't see through it.

The shift away from glass containers has been significant. While glass looks professional, when dealing with formaldehyde - a known carcinogen - the last thing you want is broken glass creating additional hazards. Modern plastic containers are shatterproof and just as chemically resistant.

| Property | Polypropylene | PET | HDPE |

|---|---|---|---|

| Chemical Resistance | Excellent | Good | Excellent |

| Clarity | Translucent | Crystal Clear | Opaque |

| Autoclavable | Yes | No | Yes |

| Crack Resistance | Excellent | Good | Excellent |

| Cost | Low | Medium | Low |

Choosing the Right Capacity for Your Specimen

The 20 mL click-top containers have become popular, especially in facilities using pneumatic tube systems. That satisfying double-click when you seal them confirms the container meets the 95 kPa pressure rating required for safe tube transport.

For most day-to-day work, 60-70 mL containers are the workhorses. They're large enough for typical surgical specimens but small enough for easy handling. Plus, they fit comfortably in most lab storage systems.

When you need serious capacity, 1-gallon bulk containers with rectangular F-style design make storage more efficient than round containers. Many come with built-in spigots that make dispensing controlled and reduce spill risk.

If you're using pneumatic tubes, you're limited to containers under 120 mL. Anything larger can't maintain the pressure requirements for safe transport.

Material Matters: Polypropylene vs PET vs HDPE

Chemical resistance is essential when containers will sit in formalin for weeks or months. Polypropylene handles this beautifully, staying flexible and crack-free even with long-term exposure.

Transparency needs vary by workflow. Pathology labs often prefer crystal-clear PET containers because they can inspect specimens without opening the container and releasing formaldehyde vapors.

The shatterproof nature of modern plastic containers has been a safety game-changer, eliminating dangerous situations with formaldehyde spills and glass fragments.

Weight becomes important with larger containers. Plastic makes handling much safer for your staff compared to heavy glass alternatives.

Safety & Compliance Features That Matter

When it comes to formalin containers, safety features aren't just extras - they're life-savers. Working with formaldehyde daily means every seal, cap design, and safety rating matters for protecting your staff.

Leak-resistant seals form your first defense against formaldehyde exposure. The 95 kPa pressure rating is the difference between a container that survives pneumatic tube transport and one that fails catastrophically.

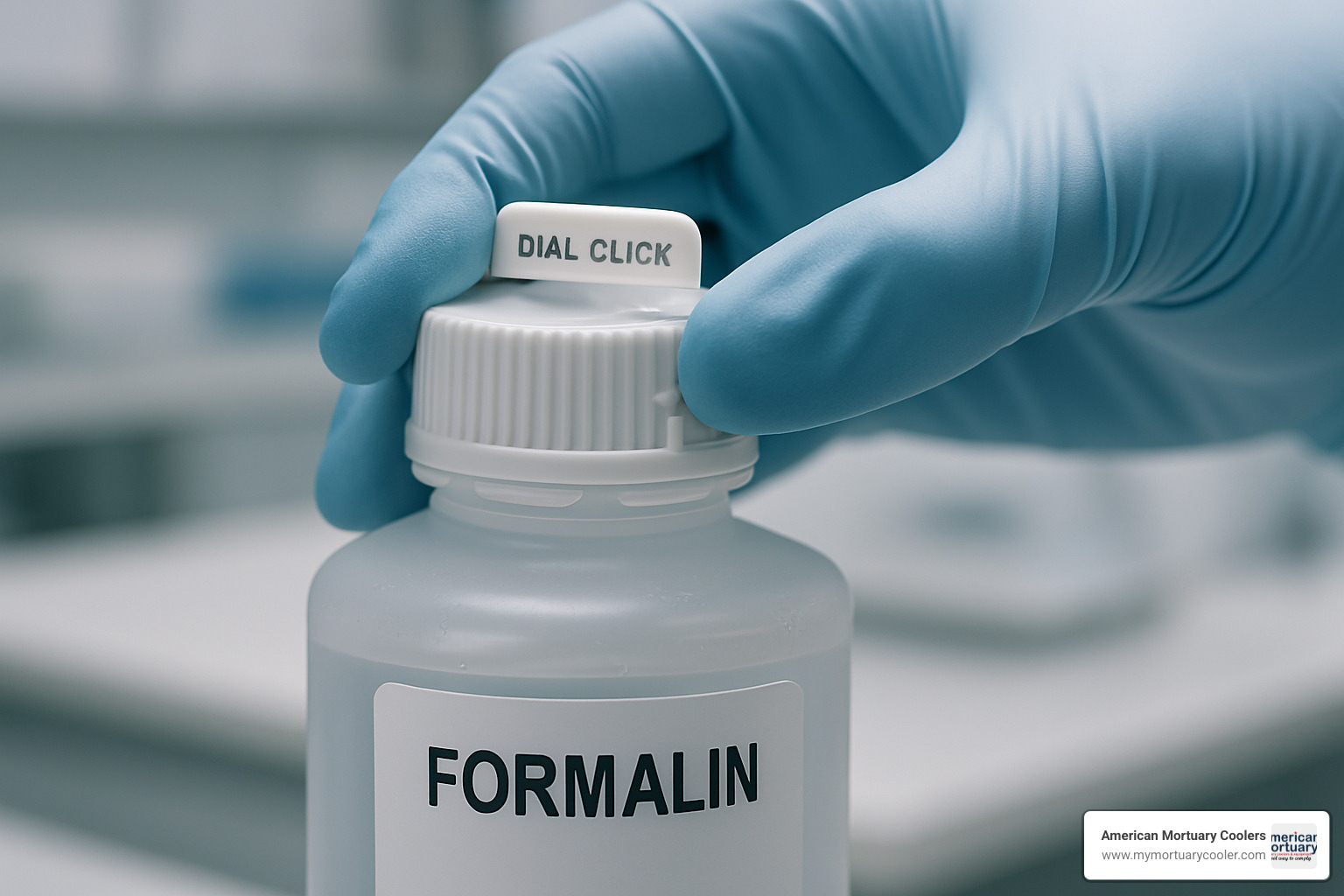

Dual-click lids provide that satisfying sound that tells you the container is properly sealed. This simple feature prevents most transport spills that could expose your team to dangerous vapors.

Ribbed caps give you reliable grip with wet gloves, reducing dropped containers and improving efficiency when processing multiple specimens.

PPE requirements for formalin work include chemical-resistant gloves, safety glasses, and lab coats as minimum protection. Well-designed containers reduce direct formalin exposure, making your protective equipment more effective.

Temperature storage between 15-30°C keeps formalin stable and prevents cloudy precipitates that can ruin specimen quality.

Ventilation systems need to maintain negative pressure around formalin storage areas. Poor ventilation is the number one OSHA violation we've seen in our years serving funeral homes.

Spill kits designed specifically for formalin must include neutralizing agents, not just regular absorbents. The carcinogenic nature of formaldehyde means you need proper cleanup materials that neutralize the chemical.

For detailed guidance on safe storage practices, check out Special Storage Considerations for Formalin Containers in Laboratories. You'll also find helpful information in our guide to anatomic pathology equipment.

Handling, Transport & Labeling Best Practices

OSHA labeling requirements aren't suggestions - they're the law. Every formalin container needs proper hazard warnings, including carcinogen designations that won't fade during extended formalin exposure.

UN3373 classification applies when shipping formalin-preserved specimens as biological substances. This requires specific packaging and documentation that keeps everyone safe during transport.

Secondary containment becomes your safety net during transport. Leak-proof transport bags mean that if your primary container fails, you won't have formaldehyde spreading through your facility.

Pneumatic tube transport has specific requirements: verify 95 kPa compliance, ensure caps are properly engaged, never overfill containers, and keep containers under 120 mL capacity.

Disposal & Decontamination Protocols

Neutralization of leftover formalin requires specific chemical treatments that convert formaldehyde into safer compounds. Simply diluting with water doesn't work and can make exposure risks worse.

Hazardous waste pickup services need proper qualifications to handle formaldehyde materials. Regular waste generators need EPA identification numbers and manifesting procedures.

Sink disposal restrictions prohibit dumping formalin down drains in most areas. Even "neutralized" solutions often contain residual formaldehyde that overwhelms wastewater treatment plants.

Workflow Innovations: Prefilled, Click-Top & Isoparaffin Barrier Solutions

Modern formalin containers have evolved far beyond basic glass jars. Today's innovative designs focus on making lab work safer and faster while protecting the people who handle specimens every day.

The biggest game-changer has been prefilled containers with 10% NBF that arrive ready to use. No more measuring, mixing, or worrying about getting the concentration right. These containers eliminate guesswork and reduce exposure risks that come with handling bulk formalin solutions.

Formallock technology brings a simple but brilliant innovation - containers that actually click when properly sealed. You'll hear that satisfying click sound that tells you the container is secure, even in a busy lab environment.

Pressure-sensitive seals add another protection layer by creating barriers that activate under normal handling. These seals work quietly in the background, reducing formaldehyde vapors that escape during storage and transport.

One interesting innovation is the isoparaffin barrier - a floating layer that sits on top of the formalin surface. When you open a container, this barrier dramatically cuts down on vapor release, making specimen handling much safer for lab staff.

For facilities preferring bulk purchasing, the Ultrasafe filling station offers the best of both worlds. This enclosed dispensing system captures vapors while you fill containers, letting you save money on bulk formalin while protecting your team. Learn more about this system through the Milestone Ultrasafe system.

BiopSafe containers combine multiple safety features into one package. They're sterilizable for use in sterile fields and have specialized sealing systems that minimize vapor release every time you open them.

All these innovations come with ISO 13485 certification, meaning manufacturing meets medical device quality standards. This certification provides traceability and quality assurance that helps with regulatory compliance in clinical settings.

How Prefilled Formalin Containers Save Time & Reduce Exposure

Ready-to-use containers eliminate one of the most time-consuming and risky parts of specimen processing. Instead of spending 15-20 minutes measuring and mixing formalin from bulk solutions, you simply grab a container and get to work.

The 50% volume fill is carefully calculated to provide the right fixative-to-specimen ratio while leaving room for your specimen without overflow. This precise filling means less waste and consistent fixation quality.

No bulk mixing means fewer exposure chances. Every eliminated step - opening bulk containers, measuring, mixing, cleanup - reduces cumulative formaldehyde exposure your staff faces throughout the day.

Fewer spills happen naturally when you don't have to pour and measure. Prefilled containers arrive sealed and stay that way until needed, eliminating the most common source of formalin accidents.

Next-Gen Seals & Vapor Barriers

Dual-thread closure systems provide backup protection beyond what single-thread designs offer. These systems often use different thread pitches that create more secure mechanical connections.

Heat-sealed closures on larger containers provide tamper-evident protection that prevents leakage during shipping and storage. This technology becomes especially important for containers that might get rough handling during transport.

95 kPa testing protocols ensure containers can handle pneumatic tube transport without failing. This testing simulates real-world conditions your containers face during routine transport.

Top Prefilled Formalin Containers to Buy in 2024

Finding the right formalin containers can feel overwhelming with so many options available. After years of working with pathology labs and funeral homes, we've seen which products actually deliver on their promises. Here's our honest take on the containers making labs safer and more efficient in 2024.

Fisher Healthcare PROTOCOL containers lead our recommendations for facilities prioritizing specimen visibility. Their 480 mL crystal-clear PET construction lets you inspect specimens without opening the container, reducing formaldehyde exposure. At $154.34 for a case of 32, they offer solid value for medium-volume operations.

Globe Scientific Tite-Rite containers have earned our respect for their leak-resistant design. Available in 20 mL, 30 mL, 50 mL, and 120 mL sizes, they cover the full range of pneumatic tube applications. Since they come prefilled with 10% neutral buffered formalin, you eliminate the messy mixing process entirely.

Cardinal Health's prefilled options shine in high-temperature environments thanks to their autoclavable polypropylene construction. The pressure-sensitive inner seals minimize vapor exposure during opening - a feature our funeral home clients particularly appreciate.

VWR's click-top containers bring serious engineering to the table. Their dual-click confirmation system gives you that satisfying "snap" that confirms proper sealing. The 95 kPa pneumatic tube compliance covers sizes from 20 mL to 120 mL.

Azer Scientific Formalock containers deserve special mention for their patented audible sealing technology. The two-click confirmation system works even in noisy environments, and their size range from 20 mL up to massive 3840 mL containers covers every conceivable application.

Formalin Containers Under 120 mL: Best for Pneumatic Tubes

20 mL containers are the workhorses of small biopsy processing. Their compact size makes them perfect for skin samples and needle biopsies, while dual-click sealing ensures they'll survive pneumatic tube transport.

40 mL containers hit the sweet spot for routine surgical specimens. They're large enough for most tissue samples but small enough that staff won't struggle with handling.

60 mL containers dominate hospital pathology departments for good reason. They handle about 80% of routine specimens while staying pneumatic-tube friendly.

The dual-click mechanisms on pneumatic-compatible sizes aren't just clever engineering - they're essential safety features. When container failure happens in a pneumatic system, contamination can spread throughout the tube network.

Bulk Formalin Containers for High-Volume Labs

1-gallon F-style containers make perfect sense for busy facilities needing reliable bulk storage. The rectangular design maximizes shelf space utilization, while wide-mouth opening makes dispensing straightforward.

5-gallon cubitainer systems with integrated spigots transform bulk formalin handling from a messy chore into a controlled process. The spigot control reduces spillage dramatically compared to pouring from rigid containers.

Cost efficiency analysis shows impressive savings with bulk containers, but don't let numbers overshadow safety considerations. The increased handling risks and potential for larger spills must factor into your decision.

Frequently Asked Questions about Formalin Containers

What is 10% neutral buffered formalin and why is it standard?

10% neutral buffered formalin contains about 4% formaldehyde in a phosphate-buffered water solution kept at pH 7.0. Think of it as the goldilocks of tissue preservation - not too acidic, not too basic, but just right for keeping cellular structures intact.

The "neutral" part is what makes this formula special. Without that phosphate buffer system, regular formalin turns acidic over time and creates formic acid. That's bad news because formic acid makes cell nuclei swell and creates staining problems that can throw off diagnostic results.

This particular recipe became the standard in histology labs because it works consistently across all tissue types. The phosphate buffer also maintains stable pH during long-term storage, which means your formalin containers will perform the same whether they're used today or six months from now.

How do I store formalin containers safely?

Storing formalin containers safely starts with good ventilation. Keep them in areas with exhaust fans or fume hoods that can actually move air around. Formaldehyde vapors are heavier than air, so they'll settle in low spots without proper air circulation.

Temperature control matters too. Keep your storage area between 15-30°C (roughly 59-86°F). Too hot and you'll get increased vapor formation. Too cold and the formalin might develop precipitates that mess with fixation quality.

Label everything with chemical-resistant labels that won't fade when exposed to formalin vapors. Include contents, concentration, and preparation date. Store containers in designated areas with proper hazard signage, and make sure only trained staff can access them.

Regular container inspections should be part of your routine. Look for cracks, leaks, or compromised seals during every shift change. If you find a damaged container, remove it immediately and follow your hazardous waste disposal protocols.

What regulations govern transport of formalin containers?

Formalin containers with preserved specimens fall under UN3373 "Biological Substance, Category B" classification when shipping them. This comes with specific packaging, labeling, and paperwork rules.

For pneumatic tube systems, containers must handle 95 kPa pressure without failing. This limits pneumatic transport to containers of 120 mL or smaller. Anything bigger needs alternative transport methods with secondary containment.

OSHA regulations set workplace exposure limits at 0.75 ppm as an 8-hour time-weighted average, with short-term spikes not exceeding 2 ppm over 15 minutes. These numbers are designed to protect staff from the carcinogenic effects of formaldehyde exposure.

The key is understanding that these regulations exist because formaldehyde is a known human carcinogen. Following the rules isn't just about avoiding fines - it's about protecting the health of everyone who handles these materials.

Conclusion

After serving funeral homes and pathology labs across the country for years, we've learned that choosing the right formalin containers isn't just about finding the cheapest option. It's about protecting your staff, preserving specimens properly, and keeping your facility compliant with regulations.

The landscape of specimen preservation has evolved dramatically. Prefilled formalin containers with advanced sealing systems aren't luxuries anymore - they're essential safety tools that reduce formaldehyde exposure while ensuring consistent results. Whether you're handling delicate biopsy samples in 20 mL click-top containers or processing large specimens in bulk systems, the fundamentals remain the same: quality materials, leak-resistant seals, and proper capacity matching.

From our Tennessee headquarters, we've seen facilities transform their workflows by investing in the right container systems. A pathology lab in Georgia reduced their formaldehyde exposure incidents by 80% after switching to dual-click sealed containers. A funeral home in California streamlined their specimen transport using pneumatic-tube-compatible containers under 120 mL.

The key is matching your container choice to your actual needs. High-volume labs benefit from bulk formalin systems with integrated spigots, while smaller facilities often find that 60-70 mL prefilled containers handle most specimens efficiently. The upfront investment in quality formalin containers pays for itself through reduced waste, fewer exposure incidents, and improved diagnostic reliability.

At American Mortuary Coolers, we understand that specimen preservation is just one piece of your facility's complex puzzle. That's why we've built our reputation on delivering durable, custom solutions that work reliably day after day. Our direct delivery across all 48 contiguous states means you get the equipment you need, when you need it, backed by expertise from years of serving the funeral industry.

Ready to upgrade your specimen handling capabilities? Start with quality formalin containers that prioritize safety and compliance, then build from there. Your staff's health and your specimens' integrity depend on making the right choice.

For comprehensive guidance on related equipment that supports safe specimen handling, explore our detailed guide to essential embalming equipment and find how American Mortuary Coolers continues delivering innovative solutions nationwide.