Manufacturers That Bring Life to Mortuary Equipment

The Essential Guide to Mortuary Equipment Manufacturers

When it comes to the delicate work of caring for the deceased, having the right equipment isn't just about efficiency—it's about dignity. As someone who's spent years in this specialized field, I've seen how quality equipment makes all the difference in providing respectful end-of-life care.

Mortuary equipment manufacturers create the backbone of funeral homes, hospital morgues, and medical examiners' offices nationwide. These companies craft everything from refrigeration systems that preserve remains to the specialized tables and tools that help professionals do their work with precision and care.

I'm with American Mortuary Coolers, where we've built relationships with suppliers across the country while crafting our Tennessee-made coolers. Through these connections, I've gained unique insights into what makes certain manufacturers stand out in our specialized industry.

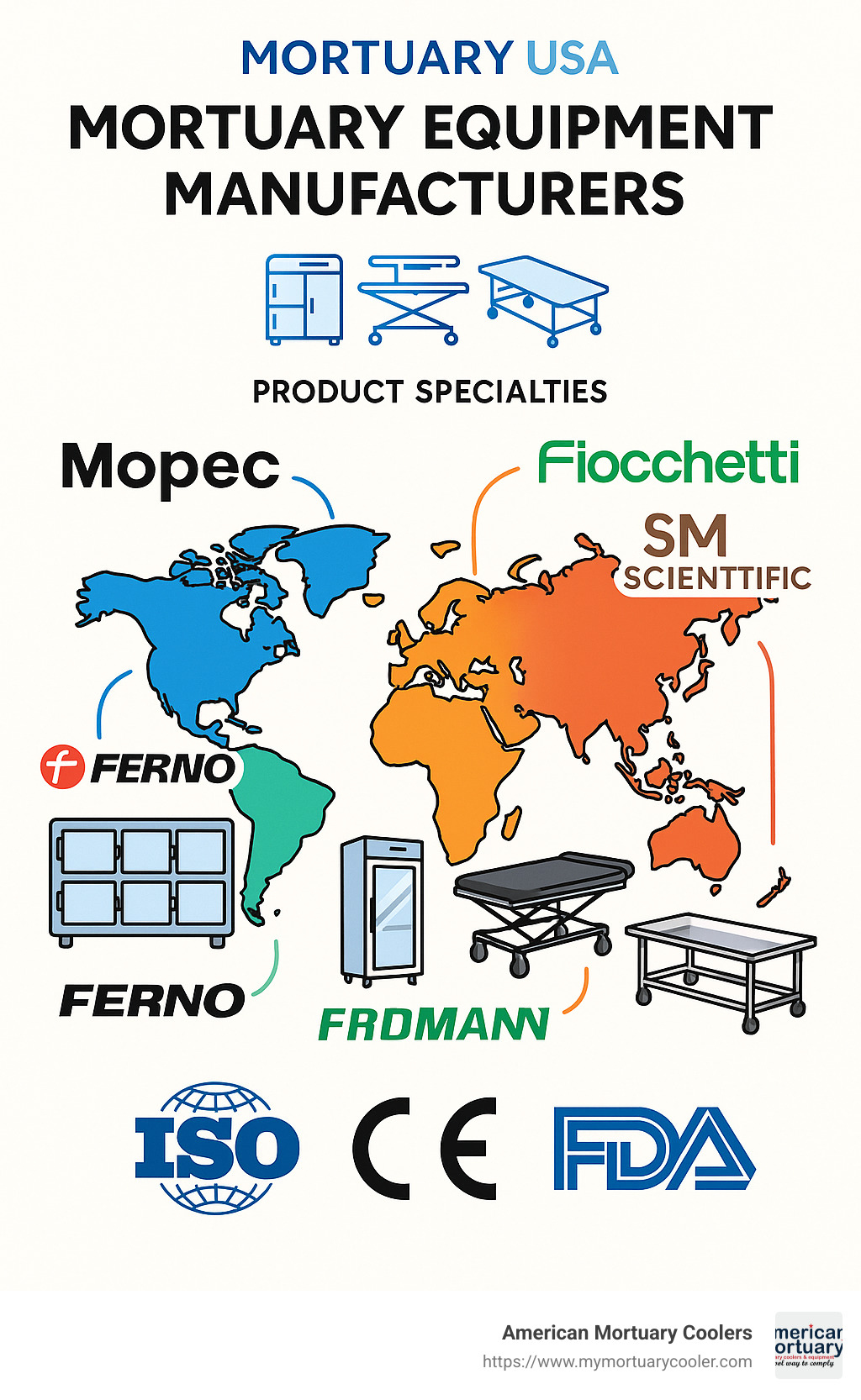

The leading mortuary equipment manufacturers each bring something special to the table:

American Mortuary Coolers proudly crafts refrigeration units and walk-in coolers right here in the USA. Our units ship to all 48 contiguous states, offering funeral homes and medical facilities custom-built solutions that meet their exact needs.

SKMortech (Saikang Medical) has been innovating since 2002 from their base in China. With over 120 patents and comprehensive ISO/CE/FDA certifications, they've established themselves as a global provider of comprehensive mortuary systems.

Mortuary Solutions brings over 55 years of British craftsmanship to their refrigeration units, trolleys, and racking systems. Since 1969, they've offered complete services from design through installation.

William Kenyon serves Europe and the UK with precision-engineered body chambers and autopsy tables. Their bespoke solutions come with a price-match guarantee that gives customers peace of mind.

Shotton Parmed supplies Australia with innovative storage and handling systems, including their signature One Tray System. They understand that equipment purchases are significant investments, which is why they offer helpful financing options.

Two other notable players include MOBI Medical from the USA, which creates built-to-order roller storage systems and cots using industrial-grade materials, and Morquip Industries from New Zealand, which has spent over 30 years developing equipment for everything from funeral homes to veterinary facilities.

Behind each piece of mortuary equipment is a story of innovation and understanding. These manufacturers don't just produce metal and machinery—they create tools that help professionals honor lives with dignity and respect, even after death.

Whether you're looking for morgue equipment, specialized mortuary tools, or mortuary walk-in coolers, the right manufacturer makes all the difference. In my experience, the best relationships between funeral professionals and mortuary equipment manufacturers are built on trust, reliability, and a shared commitment to excellence in end-of-life care.

American Mortuary Coolers

When it comes to mortuary equipment manufacturers with deep American roots, American Mortuary Coolers stands as a testament to quality craftsmanship and specialized expertise. From our Tennessee manufacturing facilities, we create custom-built mortuary refrigeration solutions that serve funeral homes, hospitals, morgues, and medical examiners across the nation.

What makes our coolers special isn't just where they're made—it's how they're made. Each unit features heavy-duty stainless steel construction, providing the durability and sanitary conditions essential in mortuary settings. Our commitment to energy efficiency means your facility benefits from reliable refrigeration without excessive utility costs.

"We don't just build coolers," shares our lead engineer. "We create solutions that honor both the deceased and the professionals who provide end-of-life care."

Our walk-in and portable morgue refrigeration systems are designed with real-world needs in mind. For funeral homes, we understand that space often comes at a premium, so our units integrate seamlessly with existing preparation areas. Hospital morgues require multi-body capacity with individual access, which our compartmentalized systems deliver beautifully. Coroners and medical examiners rely on our forensic-grade refrigeration that maintains precise temperatures for evidence preservation.

Fast delivery to all 48 contiguous states means you won't face lengthy delays when upgrading your facilities. And because every mortuary setting is unique, we specialize in customization rather than one-size-fits-all solutions.

Compliance matters in this industry, which is why all our refrigeration systems meet or exceed state and federal regulations. This attention to regulatory detail provides peace of mind for facility managers and funeral directors alike.

Whether you need a single-body cooler or a comprehensive walk-in solution, our Tennessee team is ready to craft exactly what your facility requires. For those seeking reliable, American-made mortuary refrigeration backed by people who understand the industry, you can find leading morgue cooler solutions through our nationwide service network.

SKMortech (Saikang Medical)

When it comes to global mortuary equipment manufacturers, SKMortech (the specialized mortuary equipment brand of Saikang Medical) stands as an industry giant. Founded in 2002, this Chinese manufacturer has rapidly expanded to become one of the most comprehensive suppliers of mortuary equipment worldwide.

SKMortech's product range is impressively diverse, covering virtually every aspect of mortuary operations:

- Mortuary refrigerators with single to multi-body capacity

- Hydraulic and electric corpse transportation trolleys

- Advanced autopsy tables with integrated drainage systems

- Body bags and other consumables

What truly distinguishes SKMortech in the global market is their commitment to innovation and quality assurance. The company reinvests approximately 10% of its annual profits into research and development, resulting in over 120 registered technological patents. This dedication to advancement has helped them develop solutions that address both traditional needs and emerging challenges in mortuary operations.

Their quality standards are equally impressive. SKMortech holds more than 20 quality certifications, including ISO-9001/13485/14001/18001, European CE marking, and FDA approval from the USA. These certifications ensure their products meet stringent international standards for safety, performance, and reliability.

The company's global reach is remarkable, having served more than 1,000 medical entities across more than 100 countries. Their 30,000 m² manufacturing facility and 2,000 m² showroom space provide ample capacity for producing and showcasing their extensive product line.

"We adhere strictly to a 'quality first' principle in product development," states SKMortech's company materials, reflecting their commitment to excellence that has helped them build trust with both new and returning customers worldwide.

Mortuary Solutions

When it comes to trusted mortuary equipment manufacturers in the United Kingdom, Mortuary Solutions stands tall with an impressive 55-year legacy dating back to 1969. They've grown to become a cornerstone of the British mortuary industry, serving both NHS facilities and private funeral homes with equal dedication and expertise.

What makes Mortuary Solutions special is their comprehensive approach to mortuary equipment. Rather than just selling products, they guide clients through the entire process—from initial design concepts to manufacturing and final installation. This end-to-end service ensures every piece of equipment fits perfectly into the client's space and workflow.

Their product range covers everything a modern mortuary facility might need. Their expertly-crafted cold rooms maintain precise temperatures for dignified preservation. Their stainless steel racking systems maximize storage capacity while ensuring easy access. The specialized mortuary trolleys they produce make transportation respectful and efficient. And their hygienic preparation surfaces create safe, functional workspaces for mortuary professionals.

The team at Mortuary Solutions believes that no two facilities are exactly alike. That's why they offer complimentary, no-obligation design surveys for every potential client. Their experts visit your space, understand your needs, and create custom solutions that work specifically for you. This commitment to personalization, backed by their ISO 9001 certification, shows how seriously they take quality and client satisfaction.

Perhaps most refreshingly, they take a uniquely transparent approach to financing. Unlike many competitors who mark up financing arrangements, Mortuary Solutions connects clients directly with leasing companies without taking a penny in commission. As they plainly state: "Mortuary Solutions don't make a single penny from finance arrangements, giving you full transparency and importantly the best deal!"

The proof of their excellence comes from those who know their work best—their clients. A representative from Asian Funeral Home Leeds shared: "We would like to thank the staff at Mortuary Solutions—they have been brilliant, they know what they are doing." This practical knowledge, developed over more than five decades in the industry, makes them a trusted partner for organizations of all sizes.

From your first inquiry through installation and beyond, Mortuary Solutions remains committed to supporting your facility's needs. Their dedication to both technical excellence and compassionate service makes them a standout among mortuary equipment manufacturers in the UK market.

William Kenyon

Across Europe and the UK, William Kenyon has quietly built a reputation that speaks volumes in mortuary equipment manufacturers. Their impressive catalog covers everything essential to modern mortuary operations—from carefully designed body chambers to state-of-the-art autopsy equipment and specialized supplies for funeral homes.

What makes William Kenyon truly stand out is their holistic approach to creating mortuary solutions. Rather than outsourcing different stages of production, they handle everything in-house—from initial design concepts through manufacturing to final installation. This hands-on philosophy ensures exceptional quality control at every step and allows them to craft truly personalized solutions that fit each client's unique space and workflow needs.

When it comes to materials, William Kenyon refuses to compromise. Their body trays and critical components are crafted from premium 304 or 316 stainless steel—materials chosen specifically for their outstanding durability, resistance to corrosion, and ease of sanitization. These qualities aren't just nice-to-haves in mortuary settings; they're absolute necessities for maintaining proper hygiene and extending equipment lifespan.

"We pride ourselves on the quality and precision of these products," the company notes—a statement backed by their confident price-match guarantee. This straightforward promise to match any comparable written quote from competitors speaks volumes about their commitment to delivering exceptional value alongside superior craftsmanship.

Their diverse clientele includes everything from major hospital systems requiring comprehensive autopsy facilities to independent funeral directors in need of reliable body chambers and preparation equipment. Even private sector organizations with specialized mortuary needs turn to William Kenyon for thoughtfully designed solutions.

The company's dedication to precision engineering shines through in every piece they create. Their presentation trolleys incorporate smart design elements that improve both safety and efficiency, while their lifting equipment demonstrates careful attention to ergonomics—protecting both the dignity of the deceased and the well-being of operators.

For mortuary professionals throughout Europe and the UK seeking equipment that marries old-world craftsmanship with modern innovation, William Kenyon delivers a compelling blend of customization, quality, and value that's increasingly rare in today's market.

Shotton Parmed

Australia's contribution to the global landscape of mortuary equipment manufacturers comes notably through Shotton Parmed, a company that has established itself as a leader in innovative mortuary storage and handling systems. Their Australian-owned, designed, and manufactured products reflect a deep understanding of the unique needs of facilities in the region and beyond.

What truly sets Shotton Parmed apart is their "One Tray System," an integrated approach that enables seamless transfer of bodies between racks, trolleys, post-mortem stations, embalming rooms, and viewing areas—all using a single tray. This system eliminates the need for multiple transfers, reducing both physical strain on staff and maintaining the dignity of the deceased.

Their product range encompasses:

- Mortuary racking systems in various configurations

- Specialized body lifters and transfer equipment

- Dedicated veterinary post-mortem and storage solutions

- Comprehensive mortuary facility design services

Shotton Parmed goes beyond simply manufacturing equipment to offer turnkey facility design services. Their team provides professional hazard and risk assessments, workflow efficiency consultations, and bespoke equipment design for both new facilities and modernization projects. This holistic approach ensures that clients receive not just quality equipment but optimized mortuary spaces that improve both efficiency and safety.

To increase accessibility, the company offers finance options on equipment purchases, making it easier for smaller facilities to acquire high-quality mortuary systems without prohibitive upfront costs. Their commitment to long-term client relationships extends to comprehensive service maintenance plans that keep equipment functioning optimally throughout its lifespan.

For Australian facilities—and increasingly those in neighboring regions—Shotton Parmed represents a combination of innovative design thinking, practical functionality, and ongoing support that addresses the complete spectrum of mortuary equipment needs.

How to Choose the Right Mortuary Equipment Manufacturers

Selecting the appropriate mortuary equipment manufacturers requires careful consideration of multiple factors. The right choice can lead to decades of reliable service, while the wrong one may result in costly replacements, compliance issues, or compromised dignity in care for the deceased.

Key Considerations When Evaluating Manufacturers

Product Quality and Materials: Look for industrial-grade stainless steel (preferably 304 or 316 grade), seamless welding, and corrosion-resistant finishes. These elements ensure longevity and ease of sanitization.

Manufacturing Experience: Companies with longer histories in the mortuary sector typically have refined their designs through years of feedback and improvements. At American Mortuary Coolers, we've seen how our decades of specialized experience translate into more thoughtful design features.

Customization Capabilities: Every facility has unique spatial constraints and workflow requirements. The best manufacturers offer customization rather than one-size-fits-all solutions.

Geographic Relevance: Regional manufacturers often better understand local regulations and climate considerations. For example, refrigeration requirements differ significantly between Arizona and Maine.

Value vs. Cost: The lowest upfront price rarely represents the best long-term value. Consider operational efficiency, durability, and warranty terms in your total cost calculation.

| Certification | What It Means | Typical Warranty |

|---|---|---|

| ISO 9001 | Quality management systems | 1-5 years |

| ISO 13485 | Medical devices quality management | 2-5 years |

| CE Marking | European health, safety, environmental protection | 2-3 years |

| FDA Registration | US Food & Drug Administration compliance | 1-3 years |

| UL Certification | Safety standards compliance | 1-5 years |

Compliance & Certifications

When evaluating mortuary equipment manufacturers, certifications serve as critical indicators of quality and regulatory compliance. These formal recognizations demonstrate a manufacturer's commitment to meeting established standards.

The most relevant certifications to look for include:

ISO 9001: This certification verifies that the manufacturer follows consistent quality management processes. It doesn't specifically address mortuary equipment but ensures systematic quality control.

ISO 13485: More specific to medical devices, this certification indicates adherence to quality management systems particular to medical equipment manufacturing.

CE Marking: Required for products sold in the European Economic Area, this marking signifies compliance with health, safety, and environmental protection standards.

FDA Registration: For US facilities, equipment with FDA registration indicates compliance with American regulatory requirements.

Beyond these international standards, mortuary equipment must also comply with local building codes and health department regulations, which vary significantly by region. Reputable manufacturers will be familiar with these requirements in their service areas.

Risk assessments are another crucial component of compliance. Quality manufacturers conduct thorough evaluations to identify potential hazards in their equipment and implement appropriate mitigation measures. These assessments should cover electrical safety, mechanical risks, ergonomic considerations, and infection control.

At American Mortuary Coolers, we ensure all our refrigeration units meet or exceed relevant national and local standards, providing peace of mind for facilities facing regulatory inspections.

Support & After-Sales

The relationship with mortuary equipment manufacturers shouldn't end at delivery. Quality support services are essential for maximizing equipment lifespan and performance.

Key after-sales considerations include:

Installation Services: Professional installation ensures equipment functions correctly from day one. Look for manufacturers who offer comprehensive installation rather than just delivery.

Staff Training: Proper training on equipment operation and maintenance prevents damage and extends service life. The best manufacturers provide thorough training sessions for facility staff.

Spare Parts Availability: Even the highest quality equipment eventually needs replacement parts. Manufacturers should maintain adequate spare parts inventories for at least 10 years after model discontinuation.

Warranty Terms: Standard warranties typically range from 1-5 years, but coverage details matter more than duration. Examine what's covered (parts, labor, travel) and exclusions.

Emergency Service Response: In mortuary settings, equipment failure can create immediate crises. Responsive service departments with 24/7 emergency support demonstrate a manufacturer's commitment to client operations.

"We simply stand behind each and every purchase," is how one American manufacturer describes their support philosophy, reflecting the industry's best practices.

For facilities seeking reliable equipment partners, you can find more info about suppliers through industry resources and networking.

Emerging Trends Driving Mortuary Equipment Design

The world of mortuary care is evolving in fascinating ways, with mortuary equipment manufacturers responding thoughtfully to new technologies and changing expectations. Gone are the days when mortuary equipment was simply functional – today's innovations blend respect, efficiency, and cutting-edge design.

Automation and Digital Integration

Remember when checking cooler temperatures meant physically walking to each unit with a clipboard? Those days are rapidly disappearing. Today's mortuary refrigeration systems often feature smart monitoring that sends alerts directly to your phone when temperatures fluctuate outside safe ranges.

Digital tracking systems now help funeral homes and morgues maintain perfect records of remains in their care. Rather than relying on paper logs that can be misplaced, these systems create automatic digital footprints of who accessed storage units and when – providing peace of mind for families and bulletproof chain-of-custody documentation.

Many of our clients at American Mortuary Coolers tell us these digital features aren't just convenient – they're becoming essential for modern operations where staff may be stretched thin but accountability remains paramount.

Ergonomic Innovations

We've all heard the jokes about morticians having bad backs, but there's truth behind the humor. The physical demands of mortuary work can take a serious toll, which is why ergonomic design has become a major focus in equipment development.

Height-adjustable autopsy tables now accommodate technicians of different statures, reducing strain during long procedures. Power-assisted trolleys have transformed body transport, requiring just gentle guidance rather than brute strength. And those heavy cooler trays that once required significant muscle? Many now feature smooth-gliding systems that a single person can operate without strain.

These improvements aren't just about comfort – they're helping funeral homes and morgues comply with workplace safety regulations while extending the careers of valued staff members who might otherwise face injury.

Sustainability Focus

Green practices have finally reached the mortuary industry, and they're making a real difference. Energy-efficient refrigeration systems with smart temperature management can reduce power consumption by up to 30% compared to older models – something we've prioritized in our cooler designs at American Mortuary Coolers.

The refrigerants themselves are changing too. Newer eco-friendly coolants have significantly lower global warming potential than their predecessors. Even water usage is being addressed, with newer autopsy tables featuring improved drainage systems that conserve this precious resource.

These sustainability improvements offer a double benefit: they reduce environmental impact while simultaneously lowering monthly utility bills – a win-win that's hard to ignore.

Antimicrobial Materials and Surfaces

Infection control has always been critical in mortuary settings, but recent innovations have taken protection to new levels. Antimicrobial surfaces with built-in protection help prevent bacterial colonization between cleanings. Some manufacturers are incorporating nano-coatings that actively resist pathogens, while others are integrating UV-C disinfection systems directly into storage units.

Touch-free operation – once considered a luxury – is increasingly becoming standard for frequently used equipment. These features protect both staff and the dignity of the deceased by maintaining the highest standards of hygiene, a concern that's only grown more prominent in recent years.

Modular and Adaptable Design

If there's one thing we've learned from working with hundreds of funeral homes, it's that needs change over time. That's why modular design has become a cornerstone of modern mortuary equipment.

Expandable refrigeration units allow facilities to start with what they need today while having the flexibility to grow tomorrow. Mobile equipment pieces can be reconfigured for different procedures or moved between rooms as needed. Even components are becoming more standardized, making future upgrades simpler and more cost-effective.

This adaptability helps facilities maximize their space and investment, avoiding the need for complete replacements when circumstances change – something particularly valuable for smaller funeral homes with limited square footage.

For those interested in staying current with these and other industry innovations, industry publications regularly feature News & Trends highlighting the latest developments from leading manufacturers.

Frequently Asked Questions about Mortuary Equipment Manufacturers

What financing or leasing options are available?

Let's talk money – because even in the mortuary business, budgets matter. Most mortuary equipment manufacturers understand that their specialized equipment represents a significant investment for any facility. That's why many offer flexible financing solutions to make high-quality equipment more accessible to businesses of all sizes.

Equipment leasing is particularly popular, giving you fixed monthly payments over 2-5 years with the option to purchase when the lease ends. This approach lets you preserve capital for other business needs and might even offer some tax advantages – always worth discussing with your accountant!

If you prefer ownership from day one, installment purchase plans work similarly to traditional financing, allowing you to spread payments over time while taking immediate ownership of the equipment. For temporary needs or if you want to "try before you buy," some manufacturers even offer short-term rental programs.

Here at American Mortuary Coolers, we've built relationships with financing partners who truly understand the specialized nature of mortuary equipment. Rather than marking up financing like some companies do, we connect customers directly with these partners to secure the most favorable terms possible. As one of our UK colleagues puts it: "We don't make a single penny from finance arrangements, giving you full transparency and importantly the best deal!"

The application process is typically straightforward – most require basic business information and can provide approval within just a few days. Need help with budgeting? Just ask, and we can provide quick financing quotes to help with your planning.

How do manufacturers ensure hygiene and operator safety?

When you're working in mortuary services, hygiene isn't just important – it's absolutely essential. Reputable mortuary equipment manufacturers build safety and sanitation into every aspect of their designs.

It starts with material selection. That industrial-grade stainless steel you see in quality equipment isn't just about looking professional – those 304 or 316 grade surfaces provide non-porous, easily sanitized work areas that stand up to chemicals, bodily fluids, and harsh cleaning agents day after day.

Look closely at well-made equipment and you'll notice seamless welding and rounded corners. These aren't just aesthetic choices – they eliminate the tiny crevices where contaminants could hide, making thorough cleaning possible. On autopsy tables and preparation surfaces, those deep troughs (typically 3 inches or deeper) and efficient drainage systems direct fluids away from work areas, protecting both the operator and the dignity of the deceased.

Modern equipment often includes thoughtful features like connection points for ventilation systems to remove potentially harmful vapors, and ergonomic designs that prevent staff injuries through hydraulic height adjustment, power-assisted movement, and strategically placed controls. Many pieces are also designed to accommodate disposable barriers and personal protective equipment, further improving infection control.

Beyond the equipment itself, good manufacturers provide detailed cleaning and disinfection protocols specific to their products. These guidelines ensure facilities can maintain proper sanitation standards throughout the equipment's lifecycle, protecting staff and maintaining the highest standards of care.

How is regional regulation affecting equipment choices?

Working with mortuary equipment means navigating a complex web of regulations that can vary dramatically depending on where you're located. These regional differences significantly impact both equipment design and selection decisions.

Here in North America, equipment typically needs to comply with OSHA workplace safety standards, UL electrical safety certifications, and a patchwork of state-specific health department regulations. At American Mortuary Coolers, we design with these specific requirements in mind, ensuring our Tennessee-manufactured units will pass inspection anywhere in the 48 contiguous states we serve.

Cross the Atlantic, and you'll find European Union requirements centered around the mandatory CE marking, which indicates compliance with health, safety, and environmental protection standards. Europe also tends to have more stringent energy efficiency requirements, influencing how refrigeration systems are designed.

Down under in Australia and New Zealand, unique workplace health and safety regulations shape ergonomic features, while specific energy efficiency standards affect cooling system designs. Throughout Asia, regulations vary widely, with some countries adopting international standards and others maintaining distinct national requirements.

Beyond these broad regional differences, local building codes, electrical standards, and health department requirements create additional compliance considerations. This regulatory complexity is precisely why working with manufacturers familiar with your local regulations is so valuable – they can help ensure your equipment will sail through inspection and approval processes.

Climate considerations also play a surprising role in equipment design, particularly for refrigeration systems. A unit designed for the humid conditions of Florida requires different condensation management than one headed for the dry climate of Arizona – highlighting the value of working with manufacturers who understand your specific regional needs.

Conclusion

The world of mortuary equipment manufacturers is truly a specialized one, where innovation meets compassion in service of a profound purpose. These companies don't just build products—they create the foundation for dignified end-of-life care while protecting those who provide these essential services.

Throughout our exploration, we've seen how different manufacturers bring their unique strengths to the table. From the precision-crafted stainless steel coolers made in Tennessee by American Mortuary Coolers to the globally-certified innovations from SKMortech, each company offers something special. Regional leaders like Mortuary Solutions, William Kenyon, and Shotton Parmed round out the landscape with their specialized expertise and local knowledge.

What's particularly exciting is how the industry continues to evolve. Today's mortuary equipment increasingly incorporates sustainable materials, smart digital monitoring, and thoughtful ergonomic design. These aren't just fancy features—they're meaningful improvements that improve both operational efficiency and the dignity of care provided to families during their most vulnerable moments.

For those in charge of selecting equipment for funeral homes, hospitals, or medical examiner offices, the decision factors remain consistent. Look for quality construction that will stand the test of time. Verify appropriate certifications that ensure compliance with regulations. Seek customization capabilities that address your specific needs. And perhaps most importantly, confirm the availability of robust after-sales support that will keep your operation running smoothly for years to come.

Here at American Mortuary Coolers, we take immense pride in our Tennessee-built refrigeration systems. We understand that our coolers aren't just appliances—they're essential tools that support the meaningful and sensitive work performed by mortuary professionals across the country. When you choose our equipment, you're not just getting a cooler; you're gaining a partner committed to supporting your mission with quality, sustainability, and ongoing service.

We're ready to help you find the perfect solution for your facility's unique needs. Whether you're expanding an existing operation or building something new, our team understands the nuances of creating environments that balance technical requirements with respectful care.

For those ready to explore high-quality mortuary refrigeration options that ship directly to all 48 contiguous states, you can find leading morgue cooler solutions through our nationwide service network. We're just a call away, ready to bring our decades of expertise to your doorstep.