In Depth Guide to Understanding Reefer Truck Reefers

Why Reefer Truck Reefers Are the Backbone of Temperature-Controlled Transport

Reefer truck reefer systems are the refrigeration units that keep America's perishable goods fresh during transport. These specialized cooling systems can maintain temperatures from -20°F to 55°F, ensuring everything from fresh produce to life-saving pharmaceuticals arrives in perfect condition.

Key Facts About Reefer Truck Reefers:

- Temperature Range: -20°F to 55°F for different cargo types

- Load Capacity: 43,000 to 45,000 pounds maximum

- Fuel Tank: Roughly 50 gallons for the refrigeration unit alone

- Standard Size: Most trailers are 53 feet long

- Global Scale: 4 million refrigerated road vehicles worldwide

The origins of the reefer date back to the ice cream industry in the 1920s, when inventor Frederick McKinley Jones developed the first successful mechanically refrigerated trucks around 1925. Today, these systems use advanced technology including diesel generators, electric power, or even cryogenic cooling to maintain precise temperatures.

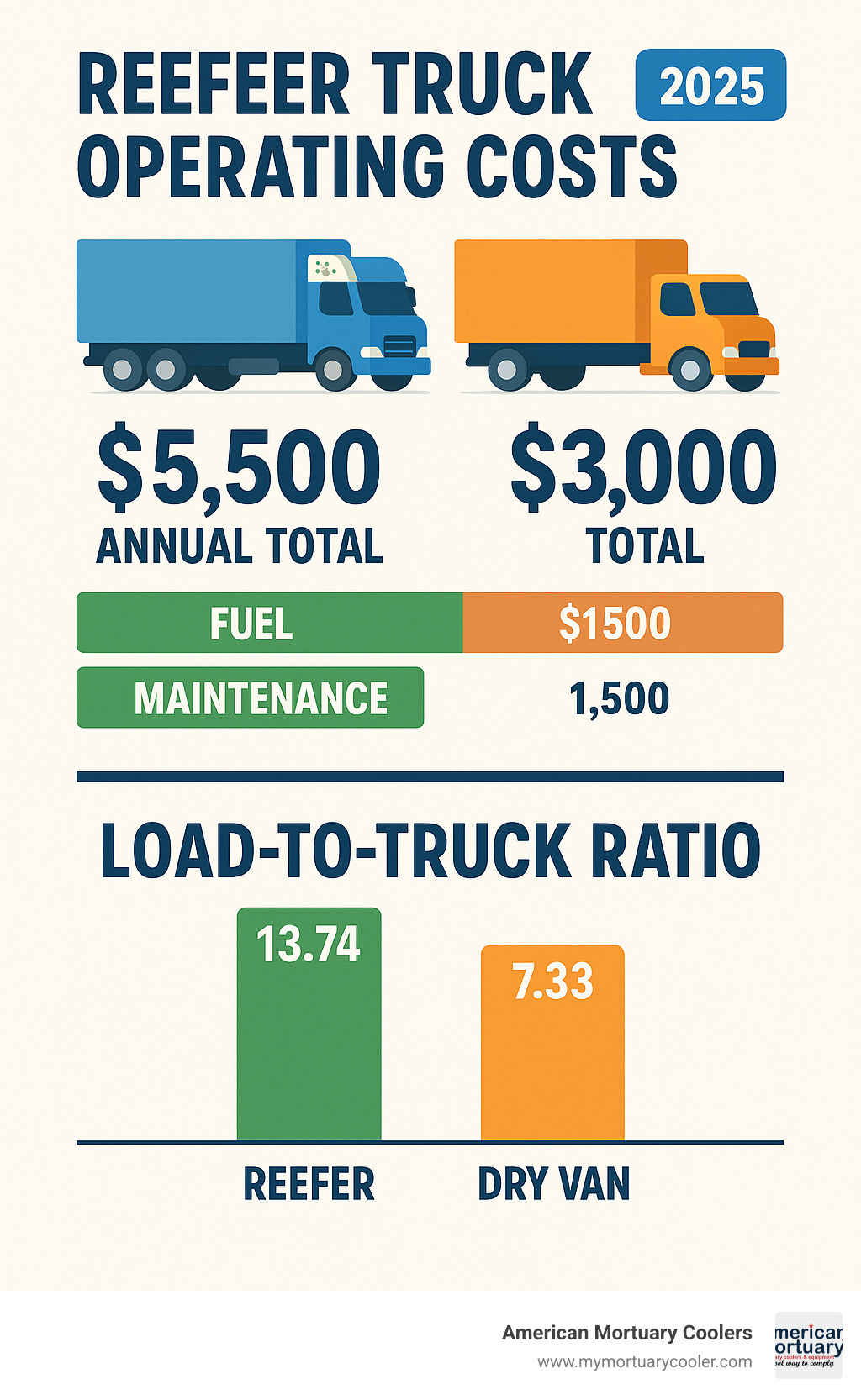

What sets reefer truck reefers apart from regular dry vans is their insulated walls, independent refrigeration systems, and specialized airflow designs. The load-to-truck ratio for reefers was 13.74 in February 2022 - nearly double that of dry vans at 7.33 - showing the high demand for temperature-controlled transport.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in refrigeration systems including reefer truck reefer applications. My expertise spans custom cooling solutions and understanding the critical role temperature control plays across industries from food service to specialized transport needs.

Reefer truck reefer terminology:

What Is a Reefer Truck Reefer?

Think of a reefer truck reefer as a mobile freezer that travels America's highways. It's essentially a refrigerated trailer that hooks up to a semi-truck, designed specifically to keep temperature-sensitive cargo at just the right temperature during transport. The word "reefer" is simply trucker slang for refrigerated – much easier to say over the CB radio than "refrigerated trailer unit."

What makes these units truly special is their active cooling and heating systems. Unlike a regular insulated van that just tries to maintain whatever temperature you start with, a reefer truck reefer can actively cool down to -20°F for frozen goods or warm up to 55°F for items that might freeze in cold weather. Some regions call them chiller lorries, but they're the same essential equipment.

The story of refrigerated transport goes back nearly a century. Frederick McKinley Jones, a brilliant inventor, developed the first successful mechanically refrigerated trucks around 1925 for the ice cream industry. His invention literally changed how America eats. Today, there are approximately 4 million refrigerated road vehicles operating worldwide, making the cold chain possible from farm to your dinner table.

You can learn more about the fundamentals in our In-Depth Guide to Reefer Trailers: Understanding the Basics.

Reefer Truck Reefer vs. Dry Van: Key Specs

The main difference between a reefer truck reefer and a regular dry van isn't just the cooling system – it's like comparing a thermos to a cardboard box. Reefer trailers are built with thick insulation panels, specialized air circulation systems, and vent doors that can be opened when the unit isn't being used for refrigerated loads.

| Feature | Reefer Truck Reefer | Dry Van |

|---|---|---|

| Maximum Load Weight | 43,000-45,000 lbs | 47,000-48,000 lbs |

| Wall Construction | Insulated panels (metal/fiberglass) | Standard aluminum/steel |

| Temperature Control | -20°F to 55°F | Ambient temperature only |

| Fuel Requirements | Truck fuel + 50-gallon reefer tank | Truck fuel only |

| Air Circulation | Specialized chutes and fans | Natural airflow |

| Vent Doors | Yes, for ventilation | Standard rear doors |

| Annual Operating Costs | ~$5,500 | ~$3,000 |

The weight difference comes from all that insulation and refrigeration equipment. But here's a bonus: most reefer trailers can double as dry vans when needed. Just power down the cooling unit, open those vent doors, and you've got extra cargo space for non-refrigerated backhauls.

Common Goods Carried by Reefer Truck Reefers

Reefer truck reefers haul far more than just frozen peas and ice cream. The variety of temperature-sensitive cargo might surprise you.

Food products make up the bulk of reefer loads: fresh produce from California farms, frozen meats from processing plants, dairy products, and specialty items like ice cream that need ultra-cold storage at -40°F. But the cargo diversity goes well beyond the grocery store.

Pharmaceuticals and medical supplies represent a critical reefer market. Vaccines, blood products, and temperature-sensitive medications all depend on precise climate control. One degree off specification can mean the difference between life-saving medicine and expensive waste.

Then there are the specialty items that might surprise you: fresh flowers heading to wedding venues, fine art traveling between galleries, cosmetics that would separate in extreme temperatures, and even hazardous materials that require climate control for safety reasons. Some reefer loads include candles (which melt), paint (which can freeze), and tobacco products that need specific humidity levels.

This versatility makes reefer truck reefers valuable across industries you might never consider – from florists to pharmaceutical companies to art dealers. The cold chain touches more of our economy than most people realize.

How Reefer Truck Refrigeration Systems Work

Think of a reefer truck reefer as a giant refrigerator on wheels - because that's essentially what it is. The refrigeration system works just like your kitchen fridge, but it's built tough enough to keep tons of cargo cold while bouncing down the highway at 70 mph.

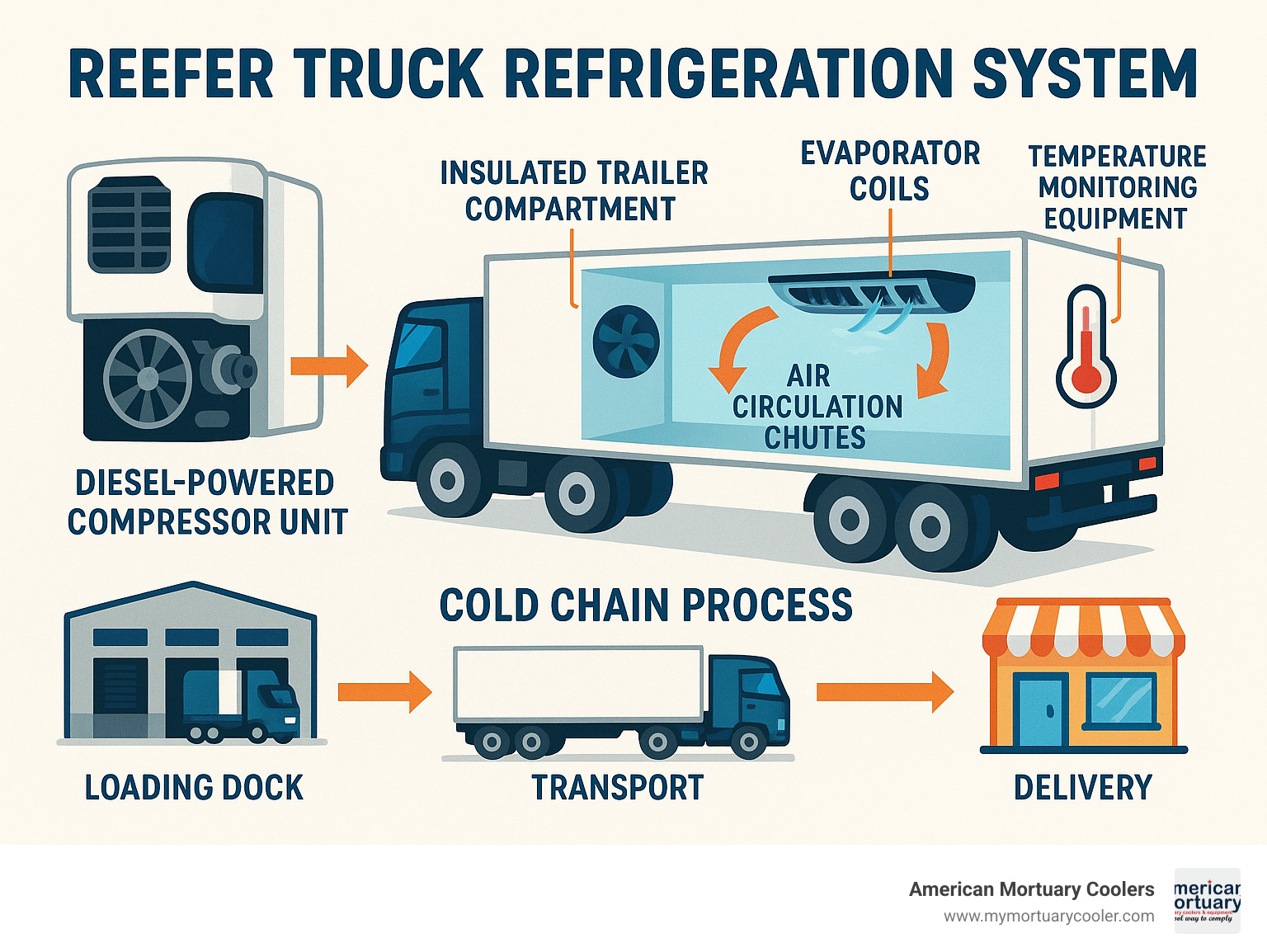

The magic happens through a simple four-step dance that repeats thousands of times during transport. Compressor, condenser, expansion valve, and evaporator - these four components work together in perfect harmony to pull heat out of your cargo and dump it outside the trailer.

Here's the basic cycle: The compressor squeezes refrigerant gas until it gets hot and pressurized. That hot gas flows to the condenser where it cools down and turns into liquid. The liquid then passes through an expansion valve that drops the pressure dramatically, making it super cold. Finally, this cold refrigerant flows through the evaporator inside the trailer, where it absorbs heat from your cargo before heading back to the compressor to start all over again.

Modern systems use environmentally-friendly refrigerants like R-134a for fresh goods and R-452A for frozen items. These newer refrigerants have much lower global warming potential than the older stuff - good news for everyone who breathes air.

The whole system runs on power from either a diesel engine mounted on the front of the trailer or an electric standby system when parked at facilities. Some newer units even experiment with cryogenic CO₂ systems, though these are still pretty rare on the road.

Components & Process Inside a Reefer Truck Reefer

The compressor is the workhorse of any reefer truck reefer system. It's usually powered by its own small diesel engine that sits right on the front of the trailer - that's the noisy box you see humming away at truck stops. This little engine runs independently from the truck's main engine, so your cargo stays cold even when the truck is parked.

The condenser sits right behind that diesel engine, and it's basically a big radiator that dumps heat into the outside air. Ever walked past the front of a reefer trailer and felt that blast of hot air? That's the condenser doing its job, getting rid of all the heat it pulled out of the cargo area.

Inside the trailer, the evaporator does the actual cooling work. It's mounted up front near the refrigeration unit, and it uses fans to blow cold air through a specialized airflow chute system. This chute runs along the ceiling of the trailer, ensuring cold air reaches all the way to the back doors evenly.

The expansion valve might be small, but it's incredibly important. This precision component controls exactly how much refrigerant flows into the evaporator, and getting this right makes the difference between perfect temperatures and spoiled cargo.

Most systems can run in two different modes. Cycle mode turns the compressor on and off to save diesel fuel - perfect for frozen goods that can handle small temperature swings. Continuous mode keeps the compressor running constantly for temperature-sensitive fresh produce that generates its own heat as it ripens.

The defrost cycle kicks in automatically when ice starts building up on the evaporator coils. This happens more often when hauling fresh produce or in humid conditions, and the system briefly reverses the refrigeration cycle to melt away any ice buildup.

Many modern units can even handle multi-temperature zones, keeping frozen items at -10°F in one section while maintaining fresh produce at 35°F in another part of the same trailer.

Temperature Control & Monitoring Tech

Gone are the days when drivers had to guess if their reefer truck reefer was working properly. Today's systems feature digital controls that would make a NASA engineer proud, and they're getting smarter every year.

Telematics systems now connect reefer units to the internet, sending real-time data about temperatures, fuel levels, and system performance directly to fleet managers' computers. If something goes wrong at 2 AM on a lonely stretch of highway, the dispatcher knows about it before the driver does.

Data loggers continuously record every detail about the cargo environment, creating an unbreakable chain of documentation that meets strict FDA requirements for food transportation. This data can literally save a load from being rejected if there are any questions about temperature control during transit.

Remote monitoring takes the stress out of temperature-sensitive loads. Fleet managers can check on their reefers from anywhere with an internet connection, and they'll get instant alerts if temperatures drift outside acceptable ranges. Some systems even send text messages to drivers' phones when action is needed.

The most advanced units now offer remote diagnostics that can predict maintenance needs before breakdowns happen. When your reefer unit starts showing signs of trouble, the system can automatically schedule maintenance appointments and even order parts.

For businesses dealing with equipment breakdowns, professional help is available through specialized commercial refrigeration repair services that understand the unique challenges of keeping these mobile refrigeration systems running smoothly.

Types, Sizes & Power Sources of Reefer Equipment

When it comes to reefer truck reefers, one size definitely doesn't fit all. These temperature-controlled workhorses come in a variety of configurations, each designed to tackle specific transportation challenges.

The most common sight on America's highways is the 53-foot reefer trailer - the heavyweight champion that can haul up to 30 standard pallets while keeping everything at the perfect temperature. But don't overlook the smaller players. 28-foot trailers excel in tight urban deliveries where maneuverability beats maximum capacity every time.

Straight trucks (those familiar box trucks you see around town) bring refrigeration right to your neighborhood. They're perfect for local grocery deliveries, restaurant supplies, or any situation where you need to steer city streets without the hassle of a full semi-trailer setup.

Here's where things get really interesting: multi-temperature trailers can maintain different climate zones within the same unit. Imagine hauling frozen ice cream at -10°F in the front compartment while keeping fresh lettuce at a crisp 35°F in the back. It's like having multiple trucks in one.

Most modern reefer truck reefers feature deep-channel floors with T-shaped decking that creates pathways for cold air to flow throughout the cargo area. This design eliminates those dreaded hot spots that can turn a perfect load into an expensive mistake.

The industry leaders each bring something special to the table. Great Dane's Everest series is renowned for superior insulation that keeps operating costs down. Utility's 3000R has earned a reputation for going the distance with minimal maintenance headaches. Meanwhile, Hyundai's ThermoTech units pack advanced temperature control technology that makes precise climate management almost effortless.

Main Power Sources for Reefer Units

The heart of any reefer truck reefer needs power, and there are several ways to keep that cooling system humming along the highway.

Diesel gensets remain the workhorse of the industry. These separate small engines run independently from the truck's main motor, burning untaxed red diesel from their own 50-gallon tanks. The cost savings on fuel make these units particularly attractive for long-haul operations.

Direct-drive systems take a different approach by tapping into the truck's main engine through a power take-off (PTO) connection. While they only work when the truck is running, they're perfect for shorter routes where the engine rarely shuts down.

Electric stand-by power is becoming increasingly popular, especially for urban operations. These units can plug into dock power during loading or extended stops, cutting fuel costs and reducing emissions in city environments where every bit of clean air matters.

Hybrid systems offer the best of both worlds, automatically switching between diesel and electric power based on what's available and most efficient. It's like having a smart assistant managing your energy consumption.

For specialized applications, cryogenic systems using liquid nitrogen or frozen carbon dioxide provide whisper-quiet cooling with zero emissions during operation. These units are particularly valuable for pharmaceutical transport or urban deliveries where noise restrictions apply.

The newest innovation is solar-assisted units that use roof-mounted panels to supplement the refrigeration system's power needs. While still emerging, this technology promises significant fuel savings for operators willing to invest in green solutions.

Leading Manufacturers and Models

The reefer truck reefer market is shaped by several manufacturers who've built their reputations on keeping America's food supply fresh and safe.

Thermo King leads the pack with decades of innovation and a reputation for bulletproof reliability. Their units range from compact truck applications to massive trailer systems that can handle any cooling challenge.

Carrier Transicold brings comprehensive refrigeration solutions with some of the most advanced temperature monitoring and control systems available. Their units practically think for themselves when it comes to maintaining perfect conditions.

Great Dane specializes in integrated trailer-refrigeration combinations designed for maximum efficiency. Their approach focuses on the entire system working together rather than just bolting a cooler onto a trailer.

Utility Trailer has built their name on durability and low total cost of ownership. When you need equipment that keeps working year after year with minimal fuss, their units deliver.

Hyundai Translead brings innovative designs with a sharp focus on fuel efficiency and meeting increasingly strict environmental regulations.

For operators looking to explore different reefer configurations and their specific applications, our guide on reefer lorries provides detailed insights into how these systems work across various industries.

Operations, Maintenance, Challenges & Insurance

Running a reefer truck reefer is like managing a mobile refrigerator that travels thousands of miles. It's more complex than regular trucking, but the rewards can be worth it. The annual operating cost averages around $5,500, with fuel eating up about $4,000 and maintenance taking another $1,500. Yes, it's pricier than dry van operations, but reefer freight rates are typically higher too.

The biggest challenge? Everything has to work perfectly. One breakdown can mean thousands of dollars in spoiled cargo. That's why successful reefer operators become obsessed with maintenance and proper procedures.

Best Practices for Loading a Reefer Truck Reefer

Loading a reefer truck reefer properly can make or break your delivery. It's not just about cramming as much cargo as possible into the trailer - it's about creating the right environment for your refrigeration system to work efficiently.

Pre-cooling is absolutely critical. Never load warm product into your trailer. Run the reefer unit for at least 30 minutes before loading to bring the interior to the right temperature. Check that your refrigeration system completes a full cycle without issues, and make sure you have enough fuel in that 50-gallon reefer tank.

The spacing rules are known as 1-2-9-4 in the industry. Leave 1-2 inches between cargo and sidewalls, maintain 9 inches of clearance from the ceiling, and keep 4 inches from the rear doors. This isn't just busy work - it ensures cold air can circulate properly around your cargo.

Pallet placement matters more than you might think. Use a checkerboard pattern when possible, with pallets oriented to allow maximum airflow. Install bulkheads for partial loads to prevent air from short-cycling. Place your most temperature-sensitive items away from the doors, where temperature fluctuations are most likely.

The golden rule? Never block the air return vents. Your refrigeration system depends on proper airflow to function. Block those vents, and you'll create hot spots that can spoil an entire load.

Maintenance & Cleaning Requirements

A reefer truck reefer demands respect when it comes to maintenance. These aren't set-it-and-forget-it systems - they're complex machines that need daily attention and regular care.

Daily inspections become second nature for experienced reefer drivers. Check your temperature readings first thing every morning. Listen for unusual noises or vibrations that might signal trouble. Inspect those door seals and gaskets - a small tear can let in warm air and work your system harder than necessary.

Fuel management is different with reefer operations. You're not just watching your main tank - that separate reefer diesel tank needs attention too. Most units burn about a gallon per hour, so plan accordingly for long hauls.

Regular maintenance keeps you rolling. Replace fuel filters every 500 hours of operation. Those drive belts need inspection and replacement as they wear. Clean the condenser coils regularly - dirty coils make your system work harder and use more fuel.

FDA sanitation requirements add another layer of complexity for food haulers. You'll need to clean and sanitize between loads to prevent cross-contamination. Document your cleaning procedures - inspectors want to see paper trails. Use approved sanitizers and follow proper protocols.

Defrost cycles prevent ice buildup, especially important when hauling fresh produce that generates moisture. Modern systems handle this automatically, but older units might need manual defrosting.

For complex repairs and maintenance beyond basic driver tasks, professional help is essential. Our guide on commercial refrigeration repair covers finding qualified technicians who understand these specialized systems.

Insurance and Driver Certification

Insurance for reefer operations goes way beyond standard trucking coverage. You're not just protecting against accidents - you're covering the value of temperature-sensitive cargo that can spoil in hours.

Reefer cargo liability coverage protects you when your refrigeration system fails and cargo spoils. Temperature excursion coverage handles those borderline situations where temperatures drift outside acceptable ranges. Equipment breakdown insurance covers expensive repairs to your refrigeration system. Contamination coverage protects against cross-contamination claims between loads.

These specialized policies cost more than standard truck insurance, but they're essential. One load of spoiled pharmaceuticals or premium seafood can cost tens of thousands of dollars.

Driver certification requirements include your standard CDL for vehicles over 26,000 pounds. But reefer operations often require additional training. The FMCSA-approved Reefer Endorsement typically costs $100-$300 and takes a few days to a week to complete.

This specialized training covers refrigeration system operation, proper temperature monitoring, loading and unloading procedures, and regulatory compliance. You'll learn how to troubleshoot basic problems, understand when to call for help, and maintain proper documentation.

The extra training and certification requirements might seem like a hassle, but they pay off. Reefer drivers typically earn higher rates than dry van drivers, and the specialized knowledge makes you more valuable to carriers and shippers who depend on temperature-controlled transport.

Costs, Acquisition Options & Industry Outlook

The reefer truck reefer market offers various acquisition options to meet different business needs and budgets. Understanding the costs and financing alternatives helps businesses make informed decisions about entering the refrigerated transport market.

Purchase Prices:

- Used reefer trucks: $10,000 to $35,000

- New reefer trailers: $60,000 to $100,000+

- Straight truck reefers: $45,000 to $80,000

Rental Rates:

- Full-sized reefer trailer: ~$190 per day or $800 per week

- Smaller reefer trucks: ~$160 per day or $680 per week

- Cargo van reefers: ~$150 per day or $650 per week

Operating Costs: Annual operating costs for a reefer truck reefer average $5,500, including:

- Fuel costs: ~$4,000 annually

- Maintenance: ~$1,500 annually

- Insurance: Additional $800-1,200 annually

The strong demand for reefer services is evident in the load-to-truck ratio data from Statista, which showed reefer ratios of 13.74 compared to just 7.33 for dry vans in February 2022.

Buying, Renting, or Leasing a Reefer Truck Reefer

Decision Criteria for Acquisition:

Buy New When:

- You have strong cash flow and credit

- Planning long-term operations (5+ years)

- Need latest technology and fuel efficiency

- Want full warranty coverage

Buy Used When:

- Limited capital but need ownership

- Comfortable with higher maintenance risks

- Have mechanical expertise in-house

- Testing the reefer market

Lease When:

- Want predictable monthly payments

- Need to preserve capital for other investments

- Prefer maintenance included in payments

- Planning to upgrade equipment regularly

Rent When:

- Seasonal or short-term needs

- Testing market demand

- Need backup equipment

- One-time special shipments

For detailed leasing information, consult our Ultimate Guide to Refrigerated Truck Lease options.

ROI Analysis Factors:

- Average reefer rates vs. dry van rates

- Fuel efficiency and operating costs

- Maintenance and repair expenses

- Insurance premium differences

- Driver training and certification costs

Future Tech & Sustainability Trends in Reefer Truck Reefers

The reefer truck reefer industry is evolving rapidly with new technologies focused on efficiency, sustainability, and compliance:

Electric and Hybrid Systems:

- All-electric reefer units for urban deliveries

- Hybrid diesel-electric systems for long-haul efficiency

- Shore power connectivity for dock operations

- Battery backup systems for emergency cooling

Environmental Compliance: The AIM Act regulations are driving adoption of low-GWP (Global Warming Potential) refrigerants, moving away from traditional HFC refrigerants to more environmentally friendly alternatives.

Smart Technology Integration:

- IoT sensors for predictive maintenance

- AI-powered route optimization for fuel efficiency

- Blockchain integration for cold chain transparency

- Advanced telematics with real-time analytics

Alternative Cooling Technologies:

- Solar-assisted refrigeration panels

- Cold-plate systems for extended cooling without engine operation

- Cryogenic systems using liquid nitrogen or CO₂

- Thermoelectric cooling for smaller applications

Fuel Efficiency Improvements:

- Aerodynamic trailer designs

- Variable-speed compressors

- Advanced insulation materials

- Heat recovery systems

These innovations are making reefer truck reefers more efficient, environmentally friendly, and cost-effective to operate.

Frequently Asked Questions about Reefer Truck Reefers

Let's tackle the most common questions people ask about reefer truck reefers. These are the real-world concerns I hear from folks considering getting into the refrigerated transport business.

How cold can a reefer truck reefer get?

A reefer truck reefer can get seriously cold - we're talking as low as -20°F for most standard units. The typical operating range runs from -13°F all the way up to 55°F, which gives you incredible flexibility for different types of cargo.

Now, if you're hauling ice cream (lucky you!), you'll need something even colder. Specialized units can hit -40°F to keep that Rocky Road from turning into Rocky Soup. The exact temperature your unit can achieve depends on a few factors: the specific refrigeration system, how hot it is outside, and the quality of your trailer's insulation.

Think of it this way - your reefer truck reefer is basically a giant freezer on wheels that can also warm things up when needed. Pretty impressive when you consider it's doing all this while bouncing down the highway at 70 mph.

What is the average lifespan of a reefer truck reefer?

Here's the straight answer: a well-maintained reefer truck reefer typically lasts about 8 years. But here's the thing - that's just the average. With some TLC, you can stretch that lifespan significantly.

The secret sauce for longevity? Keep those annual operating hours under 4,000. Follow your preventive maintenance schedule religiously. Use quality fuel and lubricants - your reefer unit will thank you for it. Don't skip the cleaning and sanitation routine, and when something breaks, get it fixed by professionals right away.

I've seen some units still chugging along happily after 10-12 years because their owners treated them right. It's like any relationship - show it some love and attention, and it'll stick around longer than you expect.

Can a reefer truck reefer double as a dry van?

Absolutely! This is one of the best-kept secrets in trucking. Your reefer truck reefer can absolutely work as a regular dry van - just power down that refrigeration unit and you're good to go.

Smart operators use this flexibility all the time. They'll haul frozen foods on the main run, then reduce empty miles by hauling dry freight on backhauls. It's a great way to maximize equipment utilization and keep money coming in both directions.

You can take advantage of available loads regardless of type, which means more opportunities and better profitability. Many drivers will open the vent doors to air out the trailer between refrigerated loads, keeping everything fresh and clean.

This versatility is exactly why reefer equipment often makes more money than specialized dry vans. You're not limited to just one type of freight - you can adapt to whatever the market demands.

Conclusion

Reefer truck reefers have come a long way since Frederick McKinley Jones first developed mechanically refrigerated trucks for the ice cream industry back in 1925. Today, these sophisticated temperature-controlled systems are the backbone of America's cold chain, moving everything from fresh strawberries to life-saving vaccines across the country with precision and reliability.

The numbers tell the story of just how essential these systems have become. With a load-to-truck ratio of 13.74 compared to just 7.33 for dry vans, reefer truck reefers are in incredibly high demand. That's nearly double the freight availability, which translates to better earning potential for operators and more reliable service for shippers who need their temperature-sensitive cargo delivered in perfect condition.

What makes these systems truly special is their versatility. A reefer truck reefer can maintain temperatures from -20°F for ice cream runs to 55°F for delicate flowers, and when the refrigeration unit is powered down, it works perfectly as a regular dry van. This flexibility helps operators maximize their equipment utilization and reduce those costly empty miles that eat into profits.

At American Mortuary Coolers, we've built our reputation on understanding exactly what it takes to keep things at the right temperature. Based here in Tennessee with delivery capabilities across all 48 contiguous states, we specialize in crafting custom cooling solutions that meet the unique demands of specialized industries. Our experience with precision temperature control gives us deep respect for the engineering excellence that goes into modern reefer truck systems.

The future looks bright for the reefer truck reefer industry. New technologies like electric stand-by power, solar-assisted cooling, and IoT monitoring systems are making these units more efficient and environmentally friendly than ever before. The AIM Act regulations are pushing the industry toward cleaner refrigerants, while advances in insulation and airflow design continue to improve fuel efficiency.

For businesses considering entering the refrigerated transport market, the combination of strong demand, premium freight rates, and proven technology makes reefer truck reefers a smart investment. With proper maintenance, driver training, and operational best practices, these systems deliver reliable performance and solid returns for years to come.

Whether you're hauling fresh produce from California farms to East Coast markets, delivering pharmaceuticals that could save lives, or transporting specialty cargo that demands precise climate control, reefer truck reefers ensure your goods arrive exactly as they should - fresh, safe, and ready for their next destination.

Ready to explore your refrigerated transport options? Check out our comprehensive Ultimate Guide to Refrigerated Truck Options to find the perfect solution for your specific transportation needs.