In Depth Guide to Reefer Trailers: Understanding the Basics

Why Reefer Trailers Are Critical for Temperature-Controlled Transport

A reefer trailer is a refrigerated semi-trailer that maintains precise temperatures during transport of perishable goods. These specialized trailers use diesel-powered refrigeration units to keep cargo between -20°F and 70°F, making them essential for the cold chain supply network.

Key Reefer Trailer Facts:

- Temperature Range: -20°F to 70°F (-29°C to 21°C)

- Fuel Usage: 0.5 to 1.5 gallons per hour

- Load Capacity: 43,000 to 45,000 pounds

- Standard Lengths: 48 feet and 53 feet

- Power Source: Independent diesel engine

The term "reefer" comes from "refrigerated" and represents a $15+ billion industry that moves everything from fresh produce to life-saving pharmaceuticals. Unlike dry vans, reefer trailers feature thick insulation, air circulation systems, and nose-mounted refrigeration units that work independently of the truck's engine.

Modern reefer trailers can operate in single-temperature or multi-temperature zones, allowing different products to share the same trailer while maintaining their specific temperature requirements.

I'm Mortuary Cooler, a national-level supplier of temperature-controlled solutions with experience in refrigeration systems including reefer trailer applications for specialized transport needs.

Easy reefer trailer glossary:

What Is a Reefer Trailer?

Think of a reefer trailer as a giant mobile refrigerator that keeps your groceries fresh while traveling hundreds of miles. These specialized trailers transport everything from strawberries to life-saving vaccines across the country.

The magic happens through heat removal - not just cooling. These trailers actively pull heat away from cargo and keep it out, creating a controlled environment that protects temperature-sensitive goods. Whether it's blazing summer heat or freezing winter cold, the trailer maintains exactly the temperature your cargo needs.

Reefer trailers evolved from horse-drawn ice carriages to today's sophisticated systems. The 1920s brought cooled containers, and by 1939, portable air cooling units appeared - the grandfather of today's systems.

This evolution changed everything. Florida oranges could reach Seattle markets, and Maine lobsters could be enjoyed in landlocked states. Modern reefer trailers don't just cool - they can heat cargo too, preventing paint from freezing during winter transport while keeping ice cream frozen in summer heat.

Reefer Trailer vs Dry Van

Walking into a reefer trailer feels completely different from stepping into a regular dry van. It's like comparing a walk-in freezer to a garage.

The construction tells the whole story. Reefer trailers wrap cargo in foam-in-place insulation that creates a complete thermal barrier with R-29 to R-32 ratings. Dry vans offer minimal insulation. Metal or fiberglass replaces wood construction, creating surfaces that resist moisture and odors.

The real difference is the refrigerant loop system. That nose-mounted unit houses a complete refrigeration system with compressor, condenser, and evaporator coils. Air chutes run along the ceiling, channeling cold air from front to back.

| Feature | Reefer Trailer | Dry Van |

|---|---|---|

| Temperature Range | -20°F to 70°F | Whatever Mother Nature provides |

| Insulation Rating | R-29 to R-32 | Minimal |

| Power Source | Independent diesel engine | None |

| Weight | 2,000+ lbs heavier | Lighter |

| Maintenance | Regular refrigeration service needed | Basic trailer upkeep |

Key Goods Moved in a Reefer Trailer

Reefer trailers are the unsung heroes behind your grocery store's fresh produce section. Those perfect strawberries in December traveled hundreds of miles in temperature-controlled comfort.

Dairy products make up a huge portion of reefer cargo. Milk, cheese, yogurt, and ice cream all need consistent cold temperatures. One temperature spike can turn premium ice cream into expensive soup.

The pharmaceutical industry relies heavily on reefer transport. Vaccines lose effectiveness if they get too warm, and many medications become dangerous if they freeze. The cold chain for medical supplies is literally a matter of life and death.

Fresh flowers are frequent reefer passengers. Those Valentine's Day roses traveled from South America in climate-controlled trailers. Some cargo needs heating - paint and chemicals can become unusable if they freeze during winter transport.

The Science Behind Reefer Trailer Refrigeration

Think of a reefer trailer as a giant refrigerator on wheels, but built to handle the bumps, vibrations, and temperature swings of life on the road.

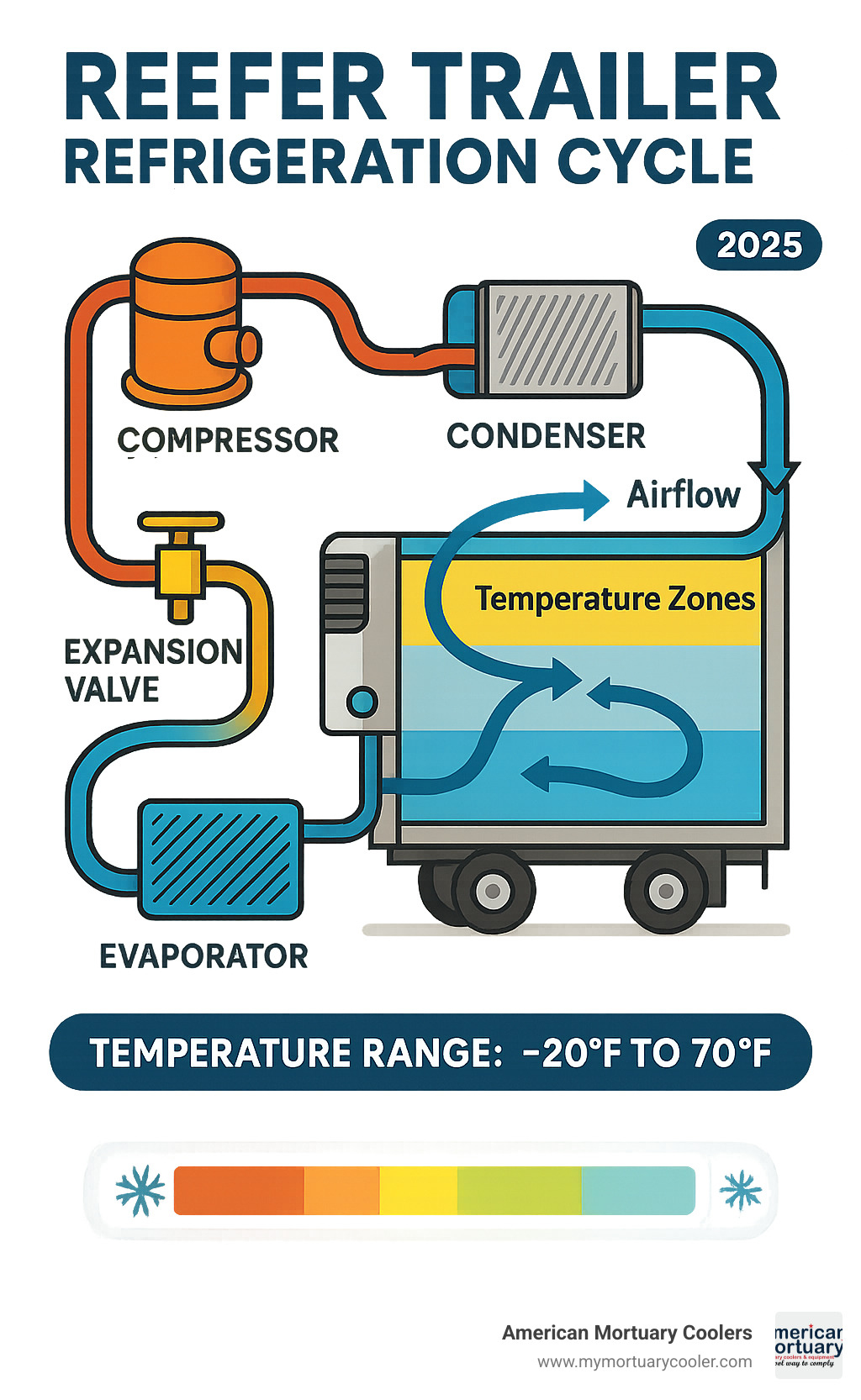

The refrigeration system works through a closed-loop system with four main components. The compressor acts as the heart, powered by its own diesel engine that runs independently from the truck. This compresses refrigerant gas, heating it up and building pressure.

Next, the hot, pressurized refrigerant flows to the condenser mounted outside the trailer, where heat gets dumped into outside air, turning the gas back into liquid. The expansion valve drops both pressure and temperature as refrigerant enters the final component.

The evaporator coil inside the trailer is where cooling happens. Cold, low-pressure refrigerant absorbs heat from inside the trailer, cooling your cargo. The system relies on thick insulation and air chutes that circulate cold air from front to back.

How a Reefer Trailer Works

The refrigeration cycle starts when the compressor squeezes refrigerant gas, making it hot and high-pressure. This heated gas travels to the condenser, where outside air pulls heat away, turning gas back into liquid.

The liquid refrigerant hits the expansion valve, which reduces pressure and temperature as refrigerant enters the evaporator coil. Here, cold refrigerant absorbs heat from the cargo area while turning back into gas. That cooled air gets pushed through the air chute system.

Reefer trailers operate in two modes. Continuous mode keeps refrigeration running non-stop, perfect for fresh produce that generates its own heat. Cycle mode runs intermittently to save fuel, allowing slight temperature swings that work fine for frozen goods.

The temperature range from -20°F to 70°F covers everything from ice cream to fresh flowers. Fuel consumption typically runs 0.5 to 1.5 gallons per hour, depending on outside temperatures and how often doors get opened.

Temperature Monitoring & Control in a Reefer Trailer

Modern reefer trailers feature digital temperature sensors throughout the trailer giving real-time readings from multiple zones. Data logging continuously records temperature, humidity, and system performance - essential for meeting FSMA (Food Safety Modernization Act) requirements.

Telematics integration allows fleet managers to track trailer conditions from anywhere using smartphones. Systems like Thermo King's ConnectedSuite™ provide 24/7 monitoring and automatic alerts for temperature spikes, equipment malfunctions, or low fuel levels.

Alarm systems prevent disasters by providing immediate notifications when temperatures drift outside acceptable ranges. This early warning system can save thousands in product loss and protect customer relationships.

Types, Sizes & Capacities of Reefer Trailers

Reefer trailers come in different lengths to match hauling needs. Common lengths are 28 feet for regional deliveries, 48 feet for regional and some long-haul, and 53 feet for heavy-duty long-haul transport. The 53-footer can hold up to 30 standard pallets, making it the industry workhorse.

Reefer trailers can't carry as much weight as dry vans. The refrigeration unit and insulation add about 2,000 pounds, dropping maximum payload to 43,000 to 45,000 pounds. However, this trade-off enables transport of high-value perishable goods that command premium freight rates.

Standard dimensions are 8 feet 6 inches wide externally, shrinking to 8 feet 1.5 inches inside after insulation. External height hits 13 feet 6 inches, while door opening provides 9 feet 2 inches of clearance.

Single-Temp vs Multi-Temp Reefer Trailer

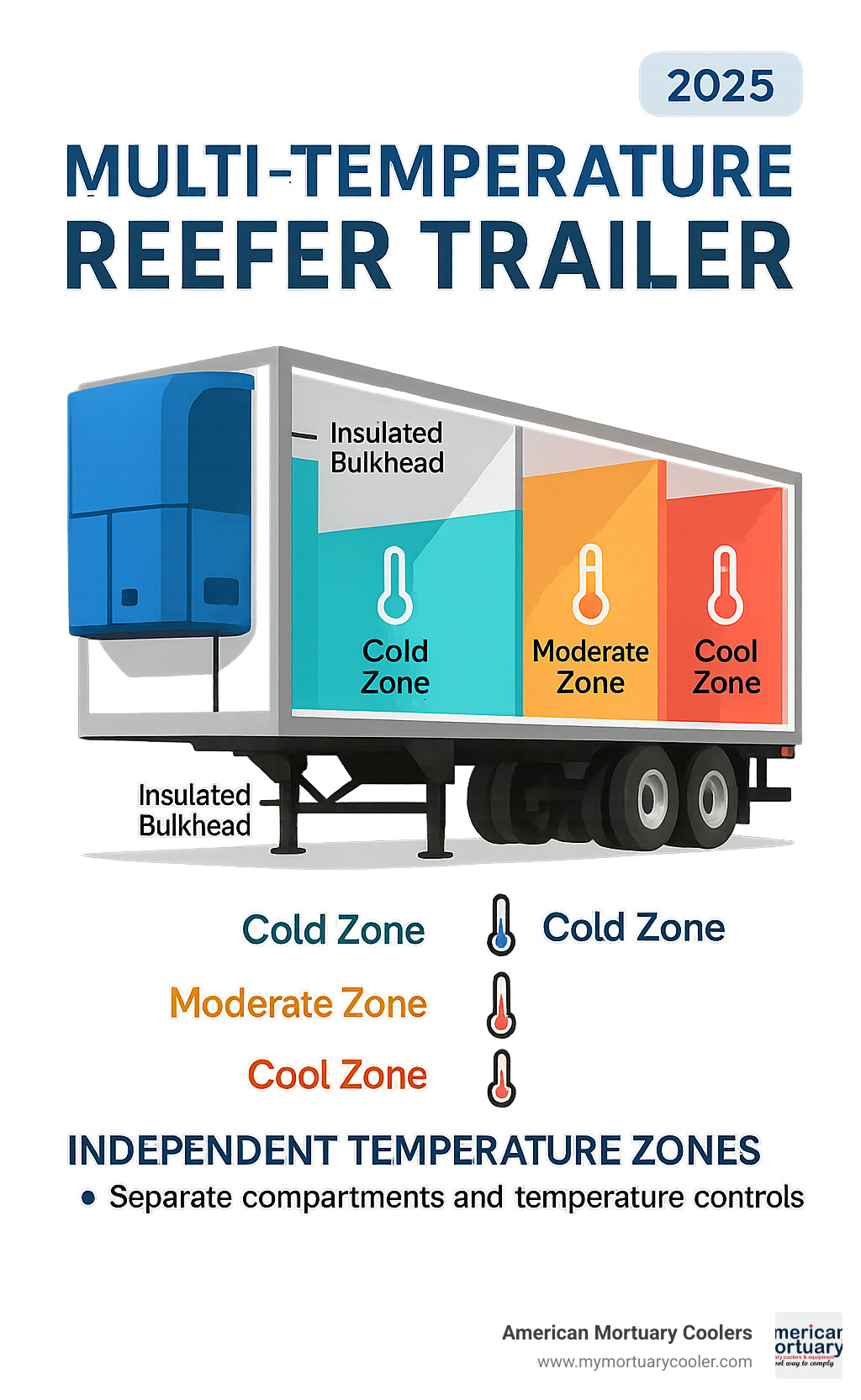

Single-temperature reefer trailers keep everything at one consistent temperature from front to back. Perfect when hauling frozen pizzas or fresh lettuce that all need the same climate.

Multi-temperature trailers use insulated bulkheads to create separate climate zones within the same trailer. You might have fresh produce at 35°F in front while frozen goods stay at -10°F in back.

Systems like Utility Trailer's CenterSeal® partition device create airtight separations between zones. Each compartment gets independent air circulation and separate temperature controls - essentially two refrigerators in one trailer.

This multi-zone capability is a game-changer for efficiency. Instead of running two separate trailers for mixed loads, you can consolidate everything into one shipment.

Dimensions & Weight Breakdown

A standard 53-foot reefer trailer provides about 52 feet of usable cargo space inside. Width shrinks to 8 feet 1.5 inches inside, with roughly 8 feet 7 inches of height. The door opening is 9 feet 2 inches high and 8 feet wide.

The trailer weighs about 12,455 pounds, and the refrigeration unit adds another 2,000 pounds. With standard GVWR of 80,000 pounds for the entire rig, maximum payload runs 43,000 to 45,000 pounds - less than dry vans but enabling transport of high-value perishables that command premium rates.

Operating, Loading & Efficiency Best Practices

Running a reefer trailer efficiently starts before loading. Pre-cooling is critical - set your trailer to target temperature 2-3 hours before loading begins. Your cargo should also be at proper temperature before loading.

Modern reefer trailers include efficiency features that impact your bottom line. Side skirts and low rolling-resistance tires save up to 6% in fuel costs according to EPA estimates. Automatic tire inflation systems keep tires at optimal pressure for fuel efficiency and safety.

Understand your cargo for efficient operation. Fresh produce generates its own heat through respiration, requiring continuous cooling mode. Frozen goods can handle cycle mode, where the unit runs intermittently to save fuel.

Loading & Unloading a Reefer Trailer

Loading a reefer trailer requires strategic gaps for air circulation. The magic numbers are 2 inches from sidewalls, 4 inches from doors, and 9 inches of overhead clearance. These aren't suggestions - they're requirements for proper air circulation.

The nose-mounted refrigeration unit pushes cold air through ceiling-mounted channels. If you block those channels with stacked cargo, cold air can't reach the trailer's back.

E-track systems make securing cargo easier than ropes. Verta-Lock vertical shoring bars spring-load between floor and ceiling to prevent load shifting.

Always turn off refrigeration during loading and unloading. When doors open, warm air rushes in and can cause ice formation on evaporator coils. Strip curtains reduce temperature loss during partial unloading.

Fuel, Sustainability & Cost Controls

Fuel costs can make or break reefer trailer operations. Thermo King's Diesel Direct Electric (DDE) architecture delivers double-digit fuel savings by eliminating mechanical belt drives and optimizing power delivery.

Shore power capability is a game-changer for extended parking. Instead of burning diesel, you can plug into electrical power at docks or warehouses, eliminating emissions and saving fuel costs.

CARB compliance requirements drive innovation toward cleaner, more efficient technology. S-Series units maintain "evergreen" CARB compliance, avoiding expensive future retrofits.

Advanced insulation reduces thermal load on refrigeration systems, meaning less work to maintain temperature. Better insulation equals lower fuel consumption and less equipment wear.

The Refrigerated Vans, Reefers, Multi-Temp Trailers – Utility Trailer website provides detailed specifications on efficiency features and compliance standards.

Maintenance, Compliance & Future Technology

Keeping your reefer trailer running smoothly protects valuable cargo and ensures regulatory compliance. Regular maintenance follows manufacturer recommendations, with major service intervals every three to five years.

The refrigeration system needs attention to refrigerant levels, air filter cleaning, and belt inspection. Electrical systems require special attention since road vibration can loosen connections. Many manufacturers offer impressive warranties - Utility Trailer provides 5-year coverage on their 3000R series.

Modern telematics systems provide predictive analytics, alerting you before problems occur rather than after cargo spoils.

Regulations & Documentation for a Reefer Trailer

Operating a reefer trailer means navigating multiple regulations focused on safety and food protection. The Food Safety Modernization Act (FSMA) requires continuous temperature logging for food transport, documenting every minute to prove cold chain integrity.

DOT regulations cover basics - proper CDL licensing, regular vehicle inspections, and hours of service rules. CARB compliance affects California operations with emission standards that keep getting stricter.

Temperature documentation serves multiple purposes beyond compliance. Insurance companies want proof of proper handling for claims. Customers demand transparency about their products' journey. The More info about x services provides additional regulatory compliance insights.

Emerging Tech & Innovations

The reefer trailer industry is experiencing a technology revolution. Electric and hybrid systems lead the charge toward sustainability. Electric standby units let trailers plug into shore power during loading, eliminating diesel emissions at distribution centers.

Solar assistance represents exciting development. Solar panels on trailer roofs supplement diesel power, reducing fuel consumption significantly. While solar can't replace diesel entirely yet, technology continues improving rapidly.

Smart technology integration transforms trailers into connected devices. IoT sensors monitor everything from door openings to refrigerant pressure. Predictive maintenance uses AI to analyze performance patterns, scheduling service before failures occur.

Electric refrigeration systems show promise for urban delivery routes where noise and emission regulations grow stricter. The cold chain IoT revolution connects every link from farm to consumer, providing unprecedented visibility into product handling.

Frequently Asked Questions about Reefer Trailers

What temperature ranges can a reefer trailer maintain?

Most reefer trailers are surprisingly versatile when it comes to temperature control. Standard units can maintain temperatures anywhere from -20°F (-29°C) to 70°F (21°C), which covers the vast majority of temperature-sensitive cargo needs.

For everyday hauling, most operators work within the -13°F to 55°F range. This handles everything from frozen pizzas that need to stay rock-solid to fresh lettuce that requires gentle chilling. The beauty of this wide range means one trailer can handle completely different loads depending on what's needed.

When you get into specialized pharmaceutical transport, that's where things get really interesting. Some units can reach ultra-low temperatures of -85°F (-65°C) for vaccine transport and critical medical supplies. These specialized units are essentially mobile laboratories on wheels.

The heating capability is often overlooked but incredibly valuable. During winter months, reefer trailers can actually warm cargo to prevent freezing damage. This makes them year-round workhorses rather than just summer cooling machines.

How much fuel does a reefer trailer use per hour?

Fuel consumption for reefer trailers typically runs between 0.5 to 1.5 gallons of diesel per hour. But like most things in trucking, the real answer is "it depends."

The biggest factor is temperature differential. Running a unit at -10°F when it's 95°F outside works that diesel engine much harder than maintaining 35°F on a mild spring day. Fresh produce also creates its own heat through natural respiration, so hauling a load of bananas requires more cooling power than frozen french fries.

Door openings are fuel killers. Every time those doors swing open, all that carefully maintained cold air rushes out, and the unit has to work overtime to recover. Frequent stops for deliveries can easily push fuel consumption toward the higher end of the range.

A standard 50-gallon fuel tank typically lasts 4-5 days under normal conditions. However, extreme weather or poor maintenance can cut that time significantly. Modern units with diesel direct electric systems and better insulation help stretch those fuel dollars further.

Can a reefer trailer both cool and heat cargo?

Absolutely! Reefer trailers are essentially heat pumps on wheels, meaning they can move heat in either direction. This dual capability makes them incredibly versatile for different cargo needs and seasonal conditions.

Cooling applications are what most people think of first - keeping fresh produce crisp, dairy products safe, frozen goods solid, and pharmaceuticals within their required temperature ranges. The system removes heat from inside the trailer and dumps it outside.

Heating applications are equally important, especially for fleets operating in northern climates. The system can reverse its operation to pump heat into the trailer, protecting cargo from freezing damage. This is crucial for certain chemicals that become unusable if frozen, electronics that could be damaged by condensation, and liquids that need to maintain proper viscosity.

This heating capability transforms reefer trailers from seasonal equipment into year-round assets. A trailer that hauls ice cream in July might be protecting paint shipments from freezing in January. For fleet operators, this versatility means better equipment utilization and more consistent revenue streams throughout the year.

At American Mortuary Coolers, we understand the critical importance of reliable temperature control across various industries. Our experience with specialized cooling systems gives us unique insight into how temperature management affects different types of sensitive cargo.

Conclusion

The world of reefer trailers might seem far from our specialty at American Mortuary Coolers, but reliable temperature control is universal. Whether keeping produce fresh on cross-country hauls or maintaining proper conditions in our custom mortuary coolers, the same principles apply: precision, reliability, and unwavering performance.

These remarkable mobile refrigeration systems have revolutionized modern commerce. From the Utility 3000R's 30-year reign as North America's top-selling reefer to Thermo King's fleet of over 200,000 units, reefer trailers are the unsung heroes of global commerce.

The technology keeps improving. New diesel direct electric systems cut fuel costs while advanced telematics let fleet managers monitor cargo from thousands of miles away. It's the same innovation we bring to our mortuary cooling solutions.

Regulatory changes drive positive improvements. CARB compliance requirements make units cleaner and more efficient, while FSMA documentation ensures food safety from farm to table.

At American Mortuary Coolers, we've perfected temperature-controlled solutions across Tennessee, Georgia, Illinois, and beyond. While our heart is in crafting custom mortuary coolers that funeral directors can count on, we respect the engineering that goes into reefer trailers. Both require the same commitment to never failing when people depend on you.

Our Mobile Chill: Your Guide to Portable Morgue Refrigeration guide explores many of the same mobile refrigeration principles that make reefer trailers effective.

Looking ahead, electric and hybrid systems coming online fascinate us. Solar-assisted units and battery backup systems aren't just environmentally friendly - they're smart business. The same innovative thinking drives our approach to custom solutions.

The cold chain that reefer trailers make possible touches every aspect of modern life. From strawberries in your morning smoothie to vaccines that keep communities healthy, these mobile refrigeration systems are essential infrastructure we rarely consider until something goes wrong.

That's exactly why we do what we do. Whether it's a reefer trailer maintaining the cold chain or one of our custom mortuary coolers serving families during difficult times, reliable temperature control isn't just about technology - it's about trust, dignity, and doing right by the people who depend on us.