How to Quick-Deploy a Morgue: 3 Methods That Guarantee Results

Why Quick-Deploy Morgue Solutions Are Critical for Emergency Response

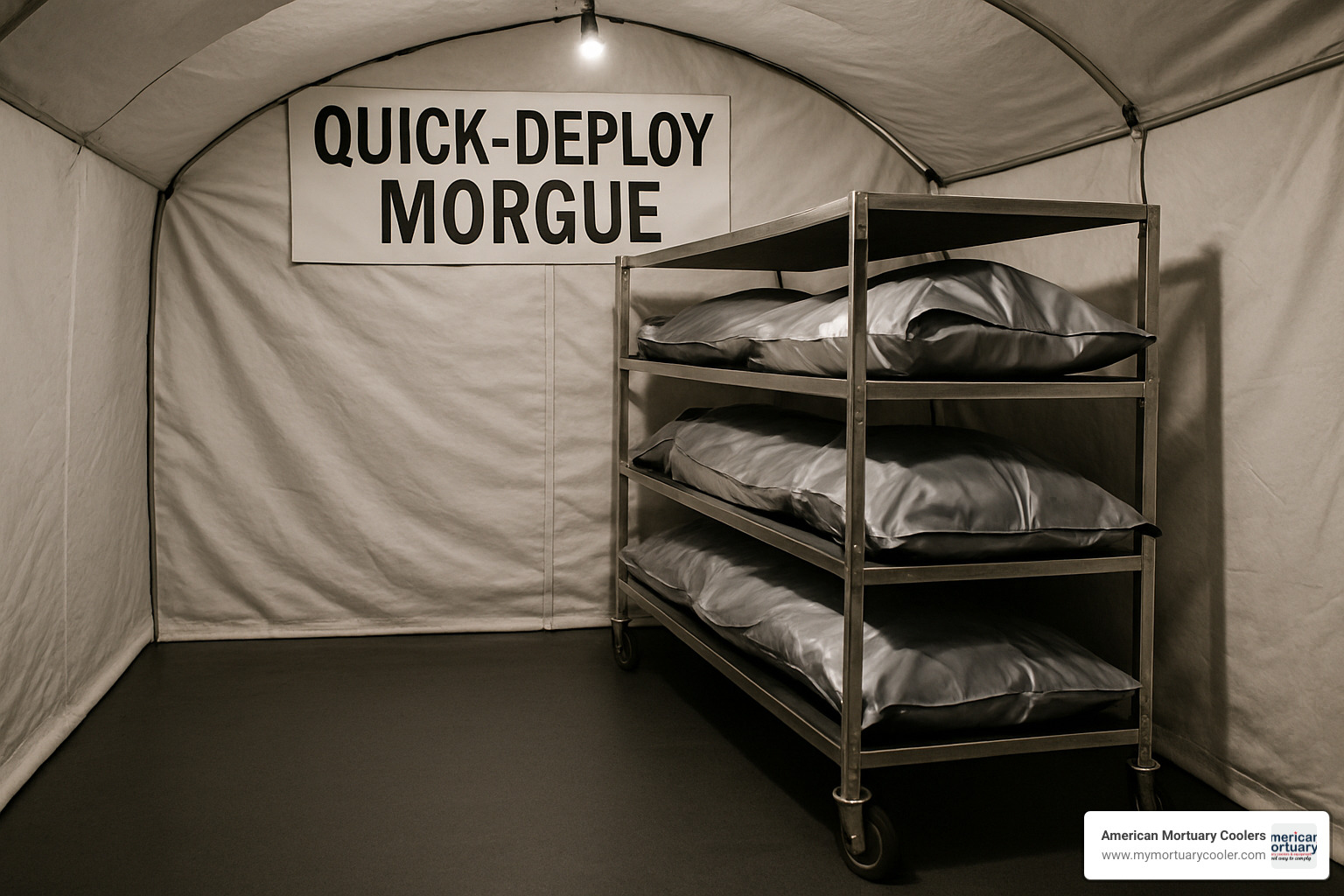

A quick-deploy morgue is a rapidly assembled temporary morgue facility that can be set up within hours to handle surge capacity during mass fatality events. These systems typically include:

- Collapsible storage racks that assemble with 8 bolts in under 15 minutes

- Refrigerated trailers holding 16-90 remains depending on size

- Pop-up shelter systems providing 650+ square feet of workspace

- Portable cooling units maintaining 36-39°F in any climate

Recent events have shown just how unprepared many facilities are for surge situations. As one hospital director noted during COVID-19, "There are countless lessons that can be learned from recent mass fatality events." New York and Los Angeles borrowed refrigerated food trucks during the pandemic, while rural areas struggled with second and third wave surges.

The reality is stark: smaller trailers hold about 16 sets of remains, while full-size 53-foot trailers accommodate up to 90 remains. Quick-deploy systems like the Mopec Guardian Rack support up to 1,500 lbs per unit and are available in 3-, 4-, or 5-tier configurations. The BLU-MED Deployable Morgue provides 650 square feet with capacity for 24 victims, while the Flexmort AirCool system scales from 4 to 24 remains in multiples of four.

Whether you're facing a natural disaster, transportation accident, or infectious disease outbreak, having a tested deployment plan isn't optional—it's essential for maintaining dignified care when your community needs it most.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping facilities prepare for surge events through quick-deploy morgue solutions and custom cooling systems. Over the past decade, I've worked with funeral homes, hospitals, and emergency responders to design rapid-deployment strategies that work when minutes matter.

Terms related to quick-deploy-morgue:

Method 1: The Quick-Deploy-Morgue Rack & Trailer System

When disaster strikes, you need a solution that works fast and works right. The rack and trailer system has become the gold standard for emergency morgue deployment because it's been tested in real-world crisis situations - from pandemic surges to mass casualty events.

The Mopec Guardian system exemplifies why this approach works so well. Picture this: your facility gets the call that you need triple capacity in the next few hours. With just 8 bolts and 15 minutes, you can have a complete storage rack assembled and ready. Each rack handles up to 1,500 pounds and features lockable casters that let you position everything exactly where you need it.

What really sets this system apart is how simple it is to scale up. You might start with one refrigerated trailer, but as the situation develops, you can add more units. The all-stainless-steel construction means you're not compromising on hygiene standards, even in emergency conditions.

The beauty of this approach is that it works with existing infrastructure. Many facilities already have relationships with refrigerated truck companies, making it easy to secure trailer space when needed. Keep Calm and Refrigerate: Mobile Morgue Trailer Options walks through how to build these partnerships before you need them.

Quick-Deploy-Morgue Setup in 15 Minutes

I've watched teams go from zero to fully operational in under a quarter hour. The IR rack models - whether you choose the IR26301 (3-tier), IR26401 (4-tier), or IR26501 (5-tier) - all follow the same straightforward process.

The first five minutes are all about getting your space ready. You'll position your refrigerated trailer, double-check that power connections are solid, and make sure your temperature settings are dialed in. Clear the interior space and verify door clearances - you don't want any surprises when you're moving equipment.

Minutes six through ten focus on the actual assembly. Connect the base frame using the provided bolt pattern, install the tier supports in the manufacturer's sequence, and attach those roller guide rails for body tray compatibility. The whole time, you're checking structural integrity and weight distribution.

The final five minutes are about positioning everything perfectly. Use a JD450 forklift or equivalent to safely load the racks, position them with adequate clearance between units, and lock those heavy-duty casters so nothing shifts. Test your body tray insertion and removal to make sure everything moves smoothly.

Once your team gets comfortable with this process, you can add additional racks in under 10 minutes each. I've worked with facilities that can transform an empty trailer into a 15-body morgue in less than half an hour total.

Quick-Deploy-Morgue Capacity Planning

Getting your capacity planning right means thinking about both your day-to-day needs and those worst-case scenarios nobody wants to face. The tier system gives you real flexibility - 3-tier units fit perfectly in standard-height trailers, while 5-tier configurations let you maximize every inch of space in taller structures.

Interior clearances matter more than you might think. Each tier provides 15" height and 10" depth when collapsed, but once deployed, you need adequate spacing for safe body removal. Standard body trays are 26" wide and compatible with JD026 specifications. For bariatric situations, specialized racking can handle individuals up to 256 kg (40 stone).

Population-based planning typically breaks down like this: small communities under 10,000 need 8-12 body capacity minimum, medium cities between 10,000-100,000 should plan for 20-40 body surge capacity, and large metropolitan areas need 50+ bodies with modular expansion capability.

The Mopec MRS Collapsible Racks are brilliant for storage efficiency. They collapse down to compact dimensions for transport and storage, but when deployed, each tier still supports a full 300 pounds. This means you can stockpile equipment without dedicating your entire warehouse to emergency gear that hopefully never gets used.

Method 2: Pop-Up Mortuary Shelters & Tents

Sometimes you need more than just storage racks—you need a complete workspace that can appear anywhere, anytime. That's where pop-up mortuary shelters shine. Think of them as quick-deploy morgue facilities that pack down small but expand into full-featured temporary morgues.

The Flexmort AirCool and BLU-MED deployable morgue are the gold standard here. These aren't your typical camping tents. The AirCool system can maintain a steady 5°C internal temperature even when it's blazing 40°C outside—perfect for those summer emergencies when regular cooling systems would struggle.

What really impresses me about these systems is their scalability. The AirCool starts with 4-body capacity and grows to 24 remains in multiples of four. The BLU-MED offers 650 square feet of workspace for up to 24 victims. Both use modular panels that snap together like oversized building blocks.

Military units have been using custom AirCool systems for years (NATO number 9930-99-671-2467), proving their reliability in harsh conditions. For more background on portable cooling technology, check out The Ultimate Guide to Finding a Portable Walk-In Cooler.

| Feature | AirCool System | BLU-MED Deployable |

|---|---|---|

| Capacity | 4-24 remains (multiples of 4) | Up to 24 victims |

| Floor Space | Variable by model | 650 square feet |

| Assembly Time | 45-60 minutes | 60-90 minutes |

| Power Requirements | Standard electrical | Self-contained power/HVAC |

| Transport | Lightweight panels | Integrated shelter system |

| Climate Range | -5°C to +40°C ambient | Ground-level entry design |

Rapid Assembly Workflow

Setting up a pop-up shelter takes more hands than rack systems, but the payoff is huge. You get a complete morgue facility, not just storage space. I recommend a three-person team for smooth deployment.

The lightweight insulation panels are surprisingly easy to handle—much lighter than you'd expect for something that creates such effective cold storage. The rollered racking system slides into place once your framework is up, and those raised bottom rails make cleaning so much easier later.

Here's how a typical setup flows: Start with your foundation work and get the framework squared up. This takes about 20 minutes if your team knows what they're doing. Next comes connecting your cooling system and getting power sorted—another 15 minutes. Finally, install your interior racking and do your safety checks. Total time: 45-60 minutes from boxes to operational morgue.

The modular design means you can connect multiple units for larger events or create specialized zones. Some facilities set up one unit for initial processing and another for longer-term storage.

Extreme-Climate Operation

The AirCool Extreme is where this technology really shows off. I've seen these systems work flawlessly in desert heat over 45°C and arctic cold below -20°C. The secret is HVAC redundancy—if your primary cooling system hiccups, the backup kicks in automatically.

Generator readiness is built into the design because these systems know grid power isn't always reliable during emergencies. Most units need 240V service, though smaller models can run on standard 120V circuits. The key is understanding your power needs before deployment day arrives.

What I love about these shelter systems is how they transform challenging deployment sites into professional morgue facilities. Whether you're dealing with a remote accident scene or need surge capacity during a heat wave, these units deliver the controlled environment that dignified care requires.

Method 3: MERC Modular Liquid Cooling Units

When traditional refrigeration just won't cut it, the MERC (Modular Emergency Refrigeration Container) system steps in as the game-changer for quick-deploy morgue operations. This isn't your grandfather's cooling technology—we're talking about direct-contact liquid cooling that maintains precise temperatures through actual contact with remains rather than just cooling the air around them.

Think of it like the difference between standing in a cold room versus having a cooling pad directly on your skin. The MERC system delivers that level of precision and efficiency, which makes all the difference when you're dealing with surge capacity situations or challenging environments.

The beauty of these portable pods lies in their plug-and-play simplicity. You don't need to be an engineer to get them running. They integrate seamlessly with your existing PPE protocols and body lift equipment, which means your staff can focus on providing dignified care rather than wrestling with complicated technology.

During crisis situations like the Haiti earthquake fatality surge, liquid cooling technologies proved their worth in maintaining proper conditions when everything else was falling apart. If you want to dive deeper into the technical side, The Ultimate Guide to Body Freezers for Morgues covers the advanced cooling systems that make this possible.

The real advantage? Energy efficiency. These units use significantly less power than traditional refrigeration while providing better temperature uniformity. That's a win-win when you're dealing with emergency situations and potentially limited power resources.

MERC Deployment Scenarios

The MERC system really shines in three specific situations where regular refrigeration systems struggle or fail completely.

Pandemic overflow situations are where MERC units truly prove their worth. When your existing morgue is packed beyond capacity, you can deploy these units in virtually any available space. Got a conference room? Perfect. Large gymnasium? Even better. The liquid cooling technology doesn't need a dedicated refrigerated environment, so you can convert spaces that would be impossible to use with traditional systems.

Hazmat remains present unique challenges that most cooling systems simply can't handle safely. MERC units operate in negative pressure environments without compromising their cooling circuits. The sealed liquid cooling system prevents cross-contamination while maintaining the precise temperatures needed for safe handling of chemically, biologically, or radiologically contaminated remains.

Remote site deployments often face power reliability issues that make traditional refrigeration impractical. MERC units require significantly less energy than conventional systems, making them ideal for generator-powered operations. Whether you're responding to a disaster in a rural area or working in a developing region with unreliable infrastructure, these units keep running when others fail.

The modular design means you start small and scale up as needed. Deploy one unit initially, then add pods as the situation demands. This flexibility prevents over-deployment while ensuring you can handle whatever capacity requirements develop.

Integration with Existing Quick-Deploy-Morgue Assets

Here's where MERC technology gets really smart—it plays well with everything you probably already have. Rack compatibility means these units can supplement your existing collapsible rack systems by providing additional cooling capacity exactly when and where you need it most.

The liquid cooling circuits can be routed through standard morgue racks, giving you more precise temperature control than you'd get from ambient air cooling alone. It's like adding a turbo boost to your existing setup without starting from scratch.

Walk-in cooler integration is seamless, which means you can upgrade your current infrastructure gradually rather than replacing everything at once. MERC systems provide backup cooling during maintenance periods or boost capacity during surge events. Your existing investment stays protected while you gain improved capabilities.

Generator tie-ins are refreshingly straightforward thanks to MERC's lower power requirements. A standard 15kW generator can operate multiple MERC units, compared to the 25-30kW typically needed for equivalent refrigerated trailer capacity. When you're dealing with emergency situations and limited power resources, that efficiency difference can make or break your operation.

The system works particularly well with surge container rentals, allowing you to expand capacity quickly without major capital investments. You get the cooling technology when you need it, where you need it, without the long-term storage and maintenance commitments.

Operational & Safety Checklist

When you're deploying a quick-deploy-morgue system, having the right operational and safety protocols can mean the difference between a smooth response and a dangerous situation. I've worked with facilities across the country during their most challenging moments, and I've learned that preparation beats improvisation every time.

Transport logistics form the backbone of any successful deployment. You'll need to verify that your trailer dimensions and weight restrictions match your deployment routes—there's nothing worse than finding your equipment can't make it through a low bridge during an emergency. Make sure you've confirmed crane or forklift availability at your deployment site ahead of time, and don't forget to coordinate with local authorities for any road closures or special permits you might need.

The fuel supply chain deserves special attention. Your generators and refrigerated units will be running continuously, so establish reliable fuel delivery arrangements before you need them. During extended operations, fuel consumption can be substantial.

Lift equipment requirements are non-negotiable for safe operations. A JD450 forklift or equivalent handles rack positioning efficiently, while portable body lifts rated for 375-1000 lb capacity ensure dignified handling. Electric stair climbing systems become essential for multi-level access situations, and always maintain backup manual lifting equipment in case of power failure.

Bio-containment protocols protect both your staff and the community. Heavy-duty body bags prevent tearing and leakage during transport and storage. For infectious remains, double-bagging procedures provide an extra layer of protection. Leak-proof transport containers with secure closures are essential, along with adequate decontamination supplies for thorough equipment cleaning between uses.

Your disinfection and maintenance routine keeps operations running smoothly. EPA-approved disinfectants work effectively on 304 stainless steel surfaces without causing corrosion. Steam cleaning equipment provides deep sanitization when needed, while temperature monitoring with redundant sensors ensures you catch any cooling system issues before they become critical problems.

Essential PPE creates a safe working environment for your team:

- MAXAIR CAPR® powered air-purifying respirators for respiratory protection

- Full-face shields with anti-fog coating for clear vision during procedures

- Chemical-resistant gloves (nitrile or neoprene) for direct contact protection

- Disposable coveralls with integrated boot covers for full-body protection

- Infrared thermometers for non-contact temperature monitoring

- Disinfecting wipes for quick equipment cleaning between tasks

The Complete Guide to the Temperature of Morgue Coolers provides detailed guidance on maintaining proper temperatures throughout your deployment.

Temperature monitoring requires constant vigilance. Your systems should maintain 36-39°F (2-4°C) for standard remains storage, with forensic freezers operating below 32°F (0°C) when required. Backup monitoring systems should trigger alarms if temperatures drift outside acceptable ranges—you don't want to find cooling problems after they've already compromised your operation.

Regular maintenance schedules for cooling systems prevent unexpected failures during critical periods. Simple daily checks can identify potential issues before they become major problems, keeping your quick-deploy-morgue system running when your community needs it most.

Cost, Procurement & FAQs

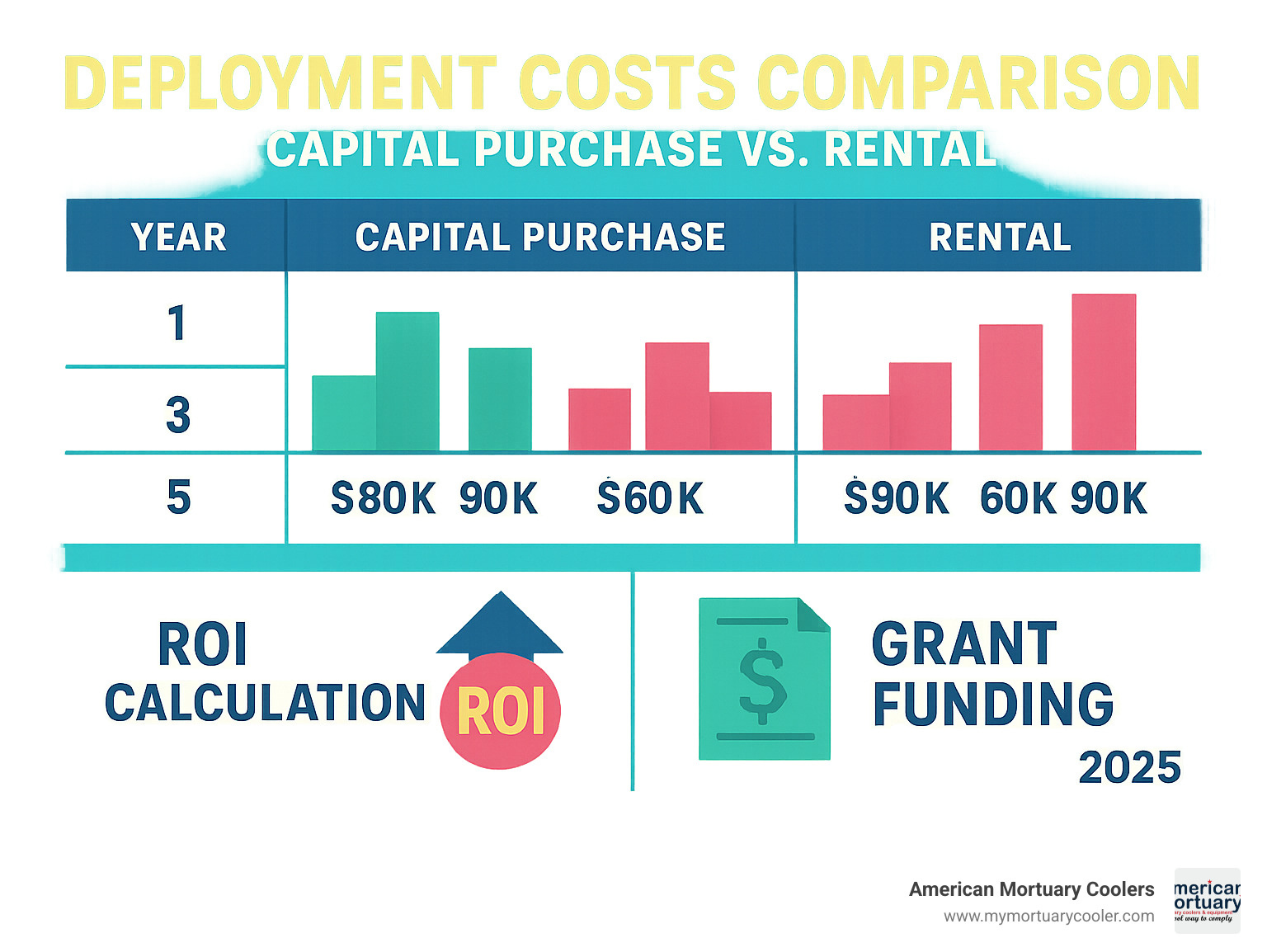

Let's talk money – because nobody wants sticker shock during an emergency. The financial side of quick-deploy morgue systems can seem overwhelming at first, but understanding your options helps you make smart decisions that protect both your budget and your community.

The big question most facilities face is whether to buy or rent. Capital purchases make the most sense if you're a larger facility or serve as a regional emergency hub. A complete system with racks, trailers, and shelter components typically runs $75,000 to $200,000 depending on what you need. That sounds like a lot, but the cost per deployment drops fast when you use it multiple times.

Rental options give you flexibility without the big upfront cost. Refrigerated trailers rent for $800 to $2,500 monthly, while pop-up shelter systems run $1,500 to $4,000 per month. MERC units typically lease for $2,000 to $5,000 monthly. The math works well if you only need surge capacity occasionally.

Here's some good news: grant funding is available. FEMA, state emergency management agencies, and public health preparedness programs all offer funding opportunities. Many facilities have successfully obtained grants by showing how they fit into regional emergency response plans. The key is demonstrating your role in community preparedness.

We've helped hundreds of facilities steer procurement challenges, especially during crisis periods. Best Readiness: American Mortuary Coolers Led the Way During COVID-19 and Continues to Be the Top Cold Storage Producer shows how we kept facilities running when they needed us most.

Warranty terms matter more than you might think. Look for comprehensive coverage that includes both equipment and refrigeration components. Quick-ship inventory becomes critical during emergencies – you can't wait weeks for delivery when you need capacity now.

FAQ #1 – How much storage do I really need?

This is the question that keeps emergency planners up at night. The honest answer is: it depends on your situation, but we can give you some solid guidelines to work with.

Start with the basics. Look at your facility's normal daily volume and multiply by how long you expect a surge to last. Population multipliers give you a reality check on community needs. Emergency management experts recommend rural areas plan for 0.1 to 0.2% of population capacity, while urban areas need 0.05 to 0.1%. If you're in a high-risk region (think hurricane zones or earthquake areas), bump that up to 0.2 to 0.5%.

The tier math is pretty straightforward once you get the hang of it. 3-tier systems handle 6 to 9 bodies per rack, 4-tier systems accommodate 8 to 12 bodies, and 5-tier configurations can hold 10 to 15 bodies depending on body size and tray specifications.

Don't forget about bariatric needs in your planning. Standard racks work fine for bodies up to 300 lbs per tier, but you'll need specialized bariatric systems for individuals over 500 lbs. It's better to plan for this now than scramble later.

FAQ #2 – What power sources are required on site?

Power planning might not be glamorous, but getting it wrong can shut down your entire operation. Let's break down what you actually need for different systems.

Refrigerated trailers need 240V service with 30 to 50 amp capacity. Pop-up shelters can run on 120V or 240V depending on size – check your specific model. MERC systems are more efficient, typically needing just 120V with 15 to 20 amp circuits. Rack systems don't need power themselves since they rely on the trailer or shelter for cooling.

Generator planning becomes critical when grid power fails. Diesel generators provide the most reliable backup power, but size them for 125% of your maximum electrical load to avoid overloading. Plan for 72-hour fuel autonomy minimum – you never know how long utility restoration will take.

Here's what many people miss: fuel planning. A 25kW diesel generator burns about 2.5 gallons per hour under full load. For a 72-hour deployment, you need 200+ gallons of fuel storage with arrangements for resupply. Don't forget about noise restrictions in residential areas – some generators are louder than others.

FAQ #3 – How do I handle infectious remains safely?

Infectious remains require stepping up your game significantly beyond standard quick-deploy morgue procedures. The three key principles are containment, protection, and decontamination – and you need to nail all three.

PPE protocols for infectious remains are more intensive. You'll need powered air-purifying respirators (no fit testing required, which is helpful), full-body coveralls with integrated hood and boot covers, double-gloving with puncture-resistant outer gloves, face shields in addition to respirator protection, and disposable outer garments that get changed between cases.

Negative pressure environments can be created using portable ventilation systems that exhaust air through HEPA filters. This prevents contaminated air from escaping your work area. The BLU-MED system includes integrated HVAC that can maintain negative pressure when you configure it properly.

Decontamination requires dedicated stations with pre-cleaning wash areas for gross contamination, disinfectant solutions appropriate for specific pathogens, clean water rinse stations for final decontamination, and waste collection systems for contaminated materials. It sounds complicated, but having the right setup makes the process much safer and more efficient.

Conclusion

When disaster strikes, the difference between chaos and compassionate response comes down to one thing: being ready before you need to be. Quick-deploy morgue systems aren't just equipment purchases—they're investments in your community's dignity during its darkest hours.

Throughout this guide, we've walked through three battle-tested approaches that deliver results when seconds count. Rack and trailer systems give you maximum flexibility and proven reliability. Pop-up shelters provide complete self-contained operations anywhere you need them. MERC liquid cooling brings cutting-edge technology to the most challenging situations.

The beauty of these systems lies in their scalability. You might start with a single collapsible rack system and grow into a comprehensive multi-method approach as your needs evolve. There's no one-size-fits-all solution, and that's exactly why we customize every system we build.

At American Mortuary Coolers, we've spent over a decade helping facilities across the country prepare for the unthinkable. Based here in Tennessee, we deliver our durable, custom solutions anywhere in the lower 48 states. We've seen how proper preparation transforms panic into purposeful action.

The time to plan is now, not when the emergency vehicles are already on scene. Start with an honest assessment of your current capabilities. Walk through potential surge scenarios with your team. Build relationships with suppliers who understand that in this business, reliability isn't negotiable—it's everything.

Your community trusts you to provide dignified care regardless of circumstances. Whether you need a simple quick-deploy morgue rack system or a comprehensive emergency response capability, we're here to help you honor that trust.

Step Inside: Top Morgue Walk-In Coolers Reviewed offers additional insights into permanent infrastructure that works alongside your quick-deploy systems.

Don't wait for crisis to test your readiness. Contact us today to discuss your specific needs and develop a response plan that works when your community needs it most. Because when that call comes, you'll be grateful you prepared.