How to Fix Commercial Fridge Problems and Save Money at the Same Time

Why Commercial Refrigeration Problems Cost More Than You Think

Fixing commercial fridge issues quickly can save thousands in spoiled inventory and emergency repair costs. Whether you're dealing with temperature fluctuations, water leaks, or unusual noises, most commercial refrigeration problems follow predictable patterns that you can diagnose and often fix yourself.

Quick fixes for common commercial fridge problems:

- Temperature issues: Check thermostat settings, clean condenser coils, test door seals

- Water leaks: Clear blocked drain lines, inspect door gaskets, level the unit

- Unusual noises: Tighten loose panels, check fan motors, add vibration pads

- Frost buildup: Test defrost timer, clear air vents, replace worn door seals

- Power problems: Check circuit breakers, test electrical connections, verify voltage

The commercial refrigeration market has grown to $39.31 billion as of 2022, yet most businesses still face the same basic problems that cause 35% higher energy costs when condenser coils get dirty. A malfunctioning commercial fridge can cost thousands in lost inventory and health code violations - but regular maintenance can extend equipment life by up to 50% and reduce emergency repairs by 30%.

When to call a professional vs. DIY:

- Simple fixes: gasket replacement, coil cleaning, thermostat calibration

- Professional help: refrigerant leaks, compressor failure, electrical faults

Fixing commercial fridge terms you need:

Fixing Commercial Fridge: Step-by-Step Troubleshooting

When your commercial refrigerator starts giving you trouble, don't panic. Most fixing commercial fridge problems follow patterns that experienced technicians see every day, and you can solve many of them yourself with the right approach.

Start with basic checks - is the unit plugged in securely? Has someone accidentally bumped the circuit breaker? These simple issues cause about 15% of all service calls.

Check your thermostat calibration by comparing the display temperature with an independent thermometer. Sometimes the fix is as simple as adjusting the setpoint that got accidentally changed during cleaning.

Condenser coil cleaning deserves special attention because dirty coils are silent killers. They force your compressor to work overtime, hiking energy costs by up to 35% while shortening equipment life. Look for dust, grease, or kitchen grime blocking airflow around the coils.

Don't forget your door gaskets during this initial inspection. These rubber seals work harder than you might think, and when they fail, your refrigerator runs constantly trying to keep up with warm air infiltration.

First Steps When Fixing Commercial Fridge

Before you start any inspection work, always unplug the unit or flip the dedicated circuit breaker. Commercial refrigeration carries serious electrical risks.

Your circuit breaker deserves a careful look because commercial units draw massive amperage during startup - sometimes 7 to 10 times their normal running current. If that breaker keeps tripping, you've got an electrical problem that needs professional attention.

Inventory relocation becomes your next priority. Move perishable items to backup refrigeration immediately because you're racing against food safety deadlines. The USDA guidelines are clear: dispose of perishable items that stay above safe temperatures for more than four hours.

Fixing Commercial Fridge Temperature Problems

Temperature problems frustrate restaurant owners more than almost any other refrigeration issue, but most causes are surprisingly straightforward to identify.

Sensor faults top the troubleshooting list because these thermistors control everything. They can drift out of calibration or fail completely, sending your control board bad information.

Refrigerant leaks create another common temperature headache. Look around fittings, coils, and connections for oily spots that might indicate refrigerant loss. Refrigerant work requires EPA certification.

Iced coils block airflow and kill cooling performance. This usually happens when defrost cycles fail or drain lines get blocked. You can manually defrost by unplugging for 24 hours, but you need to fix the root cause.

Airflow blockages deserve serious attention because good air circulation is everything in commercial refrigeration. Keep at least 6 inches of clearance around air intake and discharge areas.

For more detailed temperature control guidance, check out our article on Beginner Freezer Temperature Mistakes and How to Avoid Them.

Dealing With Water Leaks and Condensation

Water where it shouldn't be signals trouble, but most leaks come from just three sources: clogged drains, cracked pans, or door seal gaps.

Clogged drain lines cause the majority of water headaches. Clear these blockages with a plumber's snake or warm water flush. Some techs pour diluted bleach down the drain monthly to prevent algae growth.

Cracked pans under your unit create mysterious puddles. These plastic condensate pans get brittle with age and crack from constant temperature changes. Replacement pans usually cost under $50.

Door seal gaps let humid outside air sneak into your refrigerated space, creating condensation problems that get worse in hot, humid weather.

For critical food safety information during temperature problems, reference this Scientific research on safe food temps.

Silencing Unusual Noises

Commercial refrigeration systems naturally make some noise, but learning to distinguish normal sounds from problem noises helps you catch issues before they become expensive failures.

Fan motor problems announce themselves with rattling, squealing, or grinding sounds. Evaporator fans typically last 3 to 5 years and replacement is usually straightforward once you properly defrost the unit.

Loose panels create annoying rattles that are easy to fix. Check all access panels, fan guards, and trim pieces for secure mounting.

Compressor rumble varies depending on your unit's age and design. But loud banging, knocking, or grinding from the compressor compartment means serious internal damage that needs immediate professional attention.

Vibration pads under your unit reduce noise transmission through floors and walls. These pads compress over time and need replacement every few years.

Common Causes and DIY Fixes You Can Handle

Here's the truth about fixing commercial fridge problems: most issues aren't as complicated as they first appear. The same handful of problems show up again and again, and you can handle many of these repairs yourself with basic tools and patience.

Dirty condenser coils are the biggest troublemaker in commercial refrigeration. When dust, grease, and kitchen debris coat the coils, they can't release heat properly. Your compressor starts working overtime, energy bills climb, and eventually something breaks. In restaurant kitchens, clean these coils monthly.

Frost buildup tells a story about what's going wrong inside your unit. Maybe the defrost timer stopped working, or those door seals aren't sealing anymore. Thick frost acts like a blanket over your evaporator coils, blocking the airflow that keeps things cold.

Door gasket problems start small but get expensive fast. A tiny tear might not seem like much, but it lets warm, humid air sneak into your cooler all day long. Even gaskets that look fine can lose their grip over time.

Loose hinges might seem minor, but they throw off door alignment and mess up the seal. A commercial cooler door opens and closes thousands of times each year, so those hinge pins take a beating.

How to Replace Worn Door Gaskets

Replacing door gaskets might be the smartest money you'll spend on your commercial refrigeration. A new gasket costs $50-150 but can slash your energy bills and prevent thousands in spoiled inventory.

Start with the model number - this is crucial. You'll find it on a data plate inside your unit or on the back panel. Gaskets need to fit exactly right or they won't work.

Document everything before you start. Take photos of how the old gasket mounts and seals. This saves headaches later when you're installing the new one.

Most commercial gaskets have magnetic strips built into the rubber material. This magnetic seal keeps consistent pressure around the entire door. Don't cheap out on gaskets without magnetic strips.

A heat gun or hair dryer helps soften old gaskets for removal, but keep the heat low. Work slowly around the door, gradually loosening the gasket from its channel. Clean that mounting surface really well before the new gasket goes in.

Need more detailed help with gasket selection? Check out our comprehensive guide: A Practical Guide to Finding Replacement Gaskets for Walk-In Coolers.

How to Defrost an Iced Evaporator

When your evaporator coils look like an ice sculpture, cooling performance drops dramatically. Your automatic defrost system should prevent this, but sometimes components fail.

The fan delay relay is often the hidden culprit behind ice problems. This component controls when the evaporator fan runs during defrost cycles. When it fails, the fan keeps blowing cold air across the heating elements during defrost, preventing complete ice melting.

For manual defrosting, patience beats power tools every time. Unplug the unit and let nature take its course, or use a hair dryer on low heat. Never attack ice with scrapers - one slip can puncture those delicate evaporator coils.

Plan for the water that's coming. Melting ice creates more water than you'd expect. Set up containers to catch drips and make sure your drain lines are clear.

Complete defrosting takes 12-24 hours depending on how thick the ice got. Don't rush it - a thorough defrost now prevents bigger problems later.

For advanced ice troubleshooting techniques, read our detailed guide: How to Fix an Iced Evaporator with These 5 Easy Changes.

Maintenance, Energy Savings & Cost Decisions

Fixing commercial fridge problems becomes much easier when you stay ahead of them. Smart maintenance decisions can stretch your equipment's lifespan from the typical 10-15 years to over 20 years while slashing operating costs. We've watched businesses cut their refrigeration energy bills by 25-40% through simple, systematic maintenance.

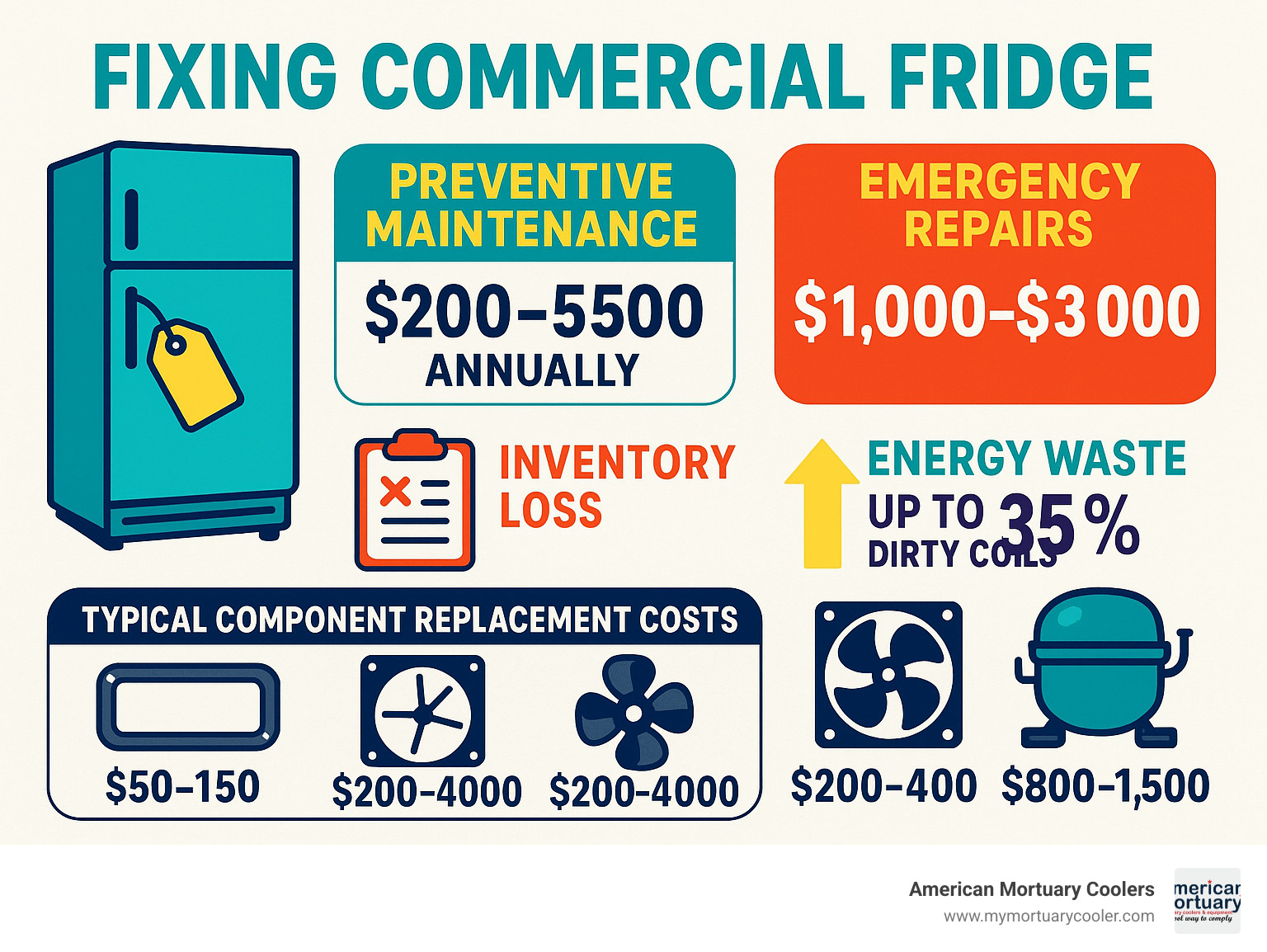

Here's the math that makes maintenance a no-brainer: preventive care costs $200-500 annually but prevents emergency repairs that average $1,000-3,000. Even better, planned maintenance lets you schedule repairs during slow periods instead of scrambling when your walk-in cooler dies during the dinner rush.

Your coil-cleaning schedule depends entirely on your environment. Restaurant kitchens need monthly cleaning, while cleaner environments might get by with quarterly attention. Those dirty coils can jack up your energy consumption by 35% and kill your compressor years early.

When major repairs loom, the numbers get interesting: compressor replacement typically runs $800-1,500, while new commercial units range from $2,000-10,000+ depending on size and features.

| Repair vs Replacement Cost Analysis |

|---|

| Preventive Maintenance: $200-500/year |

| Emergency Repairs: $1,000-3,000 average |

| Compressor Replacement: $800-1,500 |

| New Unit Cost: $2,000-10,000+ |

| Energy Savings: 25-40% with proper maintenance |

| Equipment Lifespan: 10-15 years typical, 20+ with care |

Regular Maintenance Checklist

Quarterly inspections catch problems while they're still small and cheap to fix. Keep a maintenance log to track your equipment's condition over time.

Temperature logging acts like a health monitor for your refrigeration system. Commercial units should hold steady within ±2°F of your setpoint. When you start seeing wider temperature swings, that's your early warning.

Superheat measurements between 30-45°F at the compressor tell you whether your refrigerant charge and expansion valve are working properly. Numbers outside this range usually mean professional help is needed.

Your quarterly routine should cover cleaning condenser and evaporator coils, inspecting door gaskets, checking drain lines for blockages, and verifying temperature accuracy with a calibrated thermometer.

For a deeper understanding of how these systems work together, check out our guide: Refrigeration System 101: Understanding the Basics.

When to Repair, Replace, or Buy Refurbished

Age becomes your biggest decision factor in the repair-versus-replace game. Units under 5 years old usually make sense to repair unless major components like compressors fail completely. Equipment that's 10+ years old requires serious number-crunching.

Part availability hits older equipment hard. Most manufacturers support parts for 10-15 years after they stop making a model. You might find obsolete components through salvage suppliers, but their reliability becomes questionable.

Refurbished units offer a smart middle path for budget-conscious businesses. Quality refurbished equipment delivers 70-80% of new equipment life at 50-60% of the cost.

Optimizing Energy Efficiency

Energy efficiency improvements often pay for themselves within 2-3 years through lower utility bills. Modern commercial refrigeration technology offers huge advantages over equipment built even 5-10 years ago.

ECM fans use 50-70% less energy than old-school motors while giving you better speed control and quieter operation. They cost more upfront but save hundreds annually in electricity costs.

LED lighting generates way less heat than fluorescent bulbs, which reduces your cooling load. LED retrofits typically pay for themselves within 6-12 months.

Smart monitoring systems give you real-time alerts for temperature problems, door openings, and equipment malfunctions. These systems prevent spoilage losses and let you schedule maintenance based on actual operating conditions.

Safety Precautions and When to Call a Professional

Fixing commercial fridge systems safely requires understanding the real hazards involved. Between high-voltage electricity, pressurized refrigerants, and heavy mechanical components, commercial refrigeration work can be dangerous.

Lockout/tagout procedures aren't just good practice, they're lifesavers. Turn off the main disconnect switch and physically lock it in the off position before touching anything electrical. Test that the unit won't start before you begin any work.

Personal protective equipment makes the difference between a routine repair and a trip to the emergency room. Safety glasses protect your eyes from refrigerant spray. Insulated gloves prevent electrical shock, while non-slip shoes keep you stable on wet floors.

EPA regulations around refrigerant handling are serious business. The government doesn't mess around with environmental violations - fines start at thousands of dollars and can reach $37,500 per day. Unless you have proper certification and equipment, refrigerant work belongs in professional hands.

Warranty considerations often make the decision for you. Most manufacturers void warranties if unauthorized people work on their equipment. That seemingly simple repair could cost you thousands in future warranty coverage.

Handling Refrigerant Safely

Refrigerant work requires EPA Section 608 certification - this isn't optional. The certification exists because refrigerants can cause frostbite, asphyxiation, and serious environmental damage when handled improperly.

Electronic leak detectors help professionals pinpoint tiny leaks that might be invisible to the naked eye. These specialized tools cost $200-500 but can detect refrigerant concentrations as low as a few parts per million.

Recovery machines capture refrigerant during repairs or equipment disposal. The EPA requires proper refrigerant recovery - you can't just vent it into the atmosphere. Keep detailed records of all refrigerant transactions for EPA compliance.

Signs You Need Professional Help Beyond DIY

Temperature problems that persist despite basic troubleshooting usually indicate complex issues beyond typical DIY scope. Refrigerant leaks, compressor internal damage, or sophisticated control system failures require specialized diagnostic equipment.

Repeated circuit breaker trips create genuine fire hazards that demand immediate professional attention. Commercial refrigeration systems draw heavy electrical loads, and persistent electrical faults can damage expensive components or start fires.

Silent compressors often signal catastrophic internal failure or complete electrical breakdown. Compressor replacement runs $800-1,500 plus labor costs, making accurate professional diagnosis essential.

Refrigerant leaks require professional attention because of EPA regulations and specialized equipment needs. Even if you could legally handle refrigerants, the leak detection and repair process requires tools and experience that most businesses don't have.

Control system malfunctions in modern commercial units involve complex electronic components that require specialized knowledge to diagnose and repair.

For help connecting with qualified local professionals, check out our guide: How to Find Walk-In Cooler Repair Fast by Using Local Experts.

Frequently Asked Questions About Fixing Commercial Fridge Problems

When your commercial refrigerator starts acting up, you probably have the same questions we hear every day. After years of helping businesses troubleshoot their cooling systems, we've noticed these three issues come up most often.

Fixing commercial fridge problems doesn't have to be overwhelming. Most temperature issues, frost buildup, and compressor failures follow predictable patterns that you can understand and often prevent with the right knowledge.

What causes inconsistent temperatures in a commercial fridge?

Temperature swings in your commercial unit usually point to one of four culprits, and you can check most of them yourself before calling for expensive service.

Blocked airflow tops our list of temperature troublemakers. When you pack shelves too tightly or stack boxes against air vents, cold air can't circulate properly. Keep at least 6 inches of clearance around all air intakes and outlets.

Faulty thermostats send mixed signals to your refrigeration system. Grab an independent thermometer and place it in the center of your storage area. If it reads more than 3-4°F different from your unit's display, your thermostat needs attention.

Worn door seals let warm, humid air sneak into your cooler constantly. The paper test works perfectly here - close the door on a piece of paper and try to pull it out. If it slides out easily anywhere around the door, you've found your problem.

Refrigerant leaks develop slowly but create increasingly noticeable temperature problems over time. Look for oily spots around pipe connections that might indicate refrigerant loss. This repair requires professional help since refrigerant work needs EPA certification.

How do I stop frost or ice buildup quickly?

Excessive frost makes your commercial fridge work harder and reduces storage space, but you can usually trace the problem to a few common causes.

Defrost system failures cause the most dramatic ice buildup. Your unit should automatically defrost every 6-12 hours depending on usage. If ice keeps accumulating despite automatic defrost cycles, the defrost timer or heating elements might have failed.

Door seal problems let humid outside air rush in every time someone opens the door, and that moisture immediately freezes on your cold evaporator coils. Even tiny gaps in door gaskets can cause major frost issues over time.

Manual defrosting gives you immediate relief but won't solve the underlying problem. Unplug your unit and let it defrost completely - this usually takes 12-24 hours depending on how much ice has built up. Never try to chip away ice with tools since you could puncture the delicate evaporator coils.

Humidity control becomes critical in hot, humid climates or high-traffic areas. Installing vinyl strip curtains can dramatically reduce the amount of humid air that enters when doors open frequently.

What does it cost to replace a commercial fridge compressor?

Compressor replacement represents one of the biggest fixing commercial fridge decisions you'll face. The total cost typically ranges from $1,100 to $2,100 when you factor in parts, labor, and related components.

Parts costs for the compressor itself run $800-1,500 depending on your unit's size and brand. Larger walk-in cooler compressors cost more than reach-in units, and certain brands command premium prices.

Labor expenses add another $300-600 to your bill, but this varies dramatically based on accessibility. Compressors in tight spaces or awkward positions take longer to replace.

Hidden costs often catch business owners off guard. Your technician should replace the refrigerant, filter drier, and expansion valve at the same time to prevent future problems. These additional parts and labor can add $200-400 to your final bill.

Age considerations really matter when facing compressor replacement. If your unit is over 10 years old, you might want to compare replacement costs against buying new equipment. A $1,500 compressor repair on a 12-year-old unit rarely makes financial sense.

Timing factors can double your costs if the compressor fails during peak business hours or weekends. Emergency service calls typically cost 2-3 times normal rates.

Conclusion

When your fixing commercial fridge challenges feel overwhelming, most problems have straightforward solutions. You don't need to be a certified technician to handle basic maintenance and troubleshooting that keeps your equipment running smoothly and your inventory safe.

We've walked through the most common refrigeration problems together - from temperature fluctuations and water leaks to unusual noises and frost buildup. These issues follow predictable patterns that you can diagnose systematically. Start with the basics like checking power connections and thermostat settings, then move on to cleaning coils and inspecting door seals.

The 70% of service calls that stem from simple maintenance oversights can be prevented with regular attention. Clean those condenser coils monthly in dusty environments, replace worn door gaskets before they waste energy, and keep drain lines clear to prevent water damage.

At American Mortuary Coolers, we've seen how proper refrigeration care transforms business operations. While we specialize in custom mortuary coolers for funeral homes across the contiguous 48 states, the maintenance principles apply whether you're storing flowers, food, or pharmaceuticals. Reliable refrigeration protects your investment and keeps you compliant with health codes.

Know your limits though. Handle routine cleaning, gasket replacement, and basic troubleshooting yourself, but respect the complexity of refrigerant work and electrical systems. EPA regulations exist for good reasons, and warranty coverage protects your investment when you use authorized service providers for complex repairs.

The math works in your favor when you take maintenance seriously. Regular care extends equipment life by up to 50% and can reduce energy costs by 25-40%. With commercial units typically lasting 10-15 years, proper maintenance can add 5-10 years of reliable service while slashing your utility bills.

Your commercial refrigeration system works hard around the clock to protect your business. Return the favor with consistent care, systematic troubleshooting, and smart repair decisions. The time you invest in understanding your equipment pays dividends in reduced downtime, lower operating costs, and peace of mind.

For businesses needing specialized refrigeration solutions, explore our custom cooler solutions to find how proper equipment design and maintenance can solve your unique challenges while building competitive advantages that last for decades.