How to Find Reliable Refrigeration Repair in 5 Simple Steps

Why Professional Refrigeration Repair Can Save Your Business Thousands

Refrigeration repair is critical for any business that relies on temperature-controlled storage - from restaurants to funeral homes. When your cooling system fails, you're facing potential product loss, safety hazards, and costly downtime that can shut down operations for days or weeks.

Common refrigeration repair needs include:

- Temperature fluctuations - Unit not maintaining proper cooling

- Strange noises - Compressor, fan, or motor issues

- Ice buildup - Evaporator coil freezing or defrost problems

- Water leaks - Drain clogs or seal failures

- High energy bills - Dirty coils or failing components

The stakes are high. A single freezer mishap can shut a business down for days, and commercial refrigeration breakdowns degrade operational efficiency while affecting employee productivity and sales.

Response time is everything. Most professional services offer same-day repairs, with companies like Tech24 providing 24/7 nationwide coverage and 90-day guarantees on parts and labor. The best technicians carry over 400 genuine parts on-site, allowing most repairs to be completed on the first visit.

As Mortuary Cooler with years of experience in commercial cooling systems, I've seen how the right refrigeration repair approach can mean the difference between minor maintenance costs and complete system replacement.

Refrigeration repair terms made easy:

Why Fast Action Matters

When refrigeration equipment fails, time isn't just money - it's everything. Food spoilage can happen within hours, and for businesses like ours at American Mortuary Coolers, maintaining proper temperatures is absolutely critical for safety and regulatory compliance.

The real costs of delayed repairs:

- Food spoilage - Restaurants can lose thousands in inventory overnight

- Business losses - Chain restaurants lose money every time their walk-in cooler or display cases fail

- Safety hazards - Temperature-sensitive products become unsafe, creating liability issues

- Compounding damage - What starts as a minor issue can escalate to complete system failure

Commercial freezer compressors typically last around 10 years, while walk-in cooler compressors average about 15 years. But when they fail unexpectedly, you're dealing with spoiled inventory, lost revenue, and emergency service fees that can cost 2-3 times more than planned repairs.

What You'll Learn

We've developed this 5-step guide based on our experience serving clients across Tennessee, Atlanta, Chicago, and nationwide. You'll find:

- Diagnosis techniques - How to spot problems before they become emergencies

- Technician credentials - What certifications actually matter (hint: EPA Section 608 is non-negotiable)

- Maintenance strategies - Why planned maintenance agreements can extend equipment life from 10 to 15 years

- Cost factors - When repair makes sense versus replacement, and how to avoid surprise fees

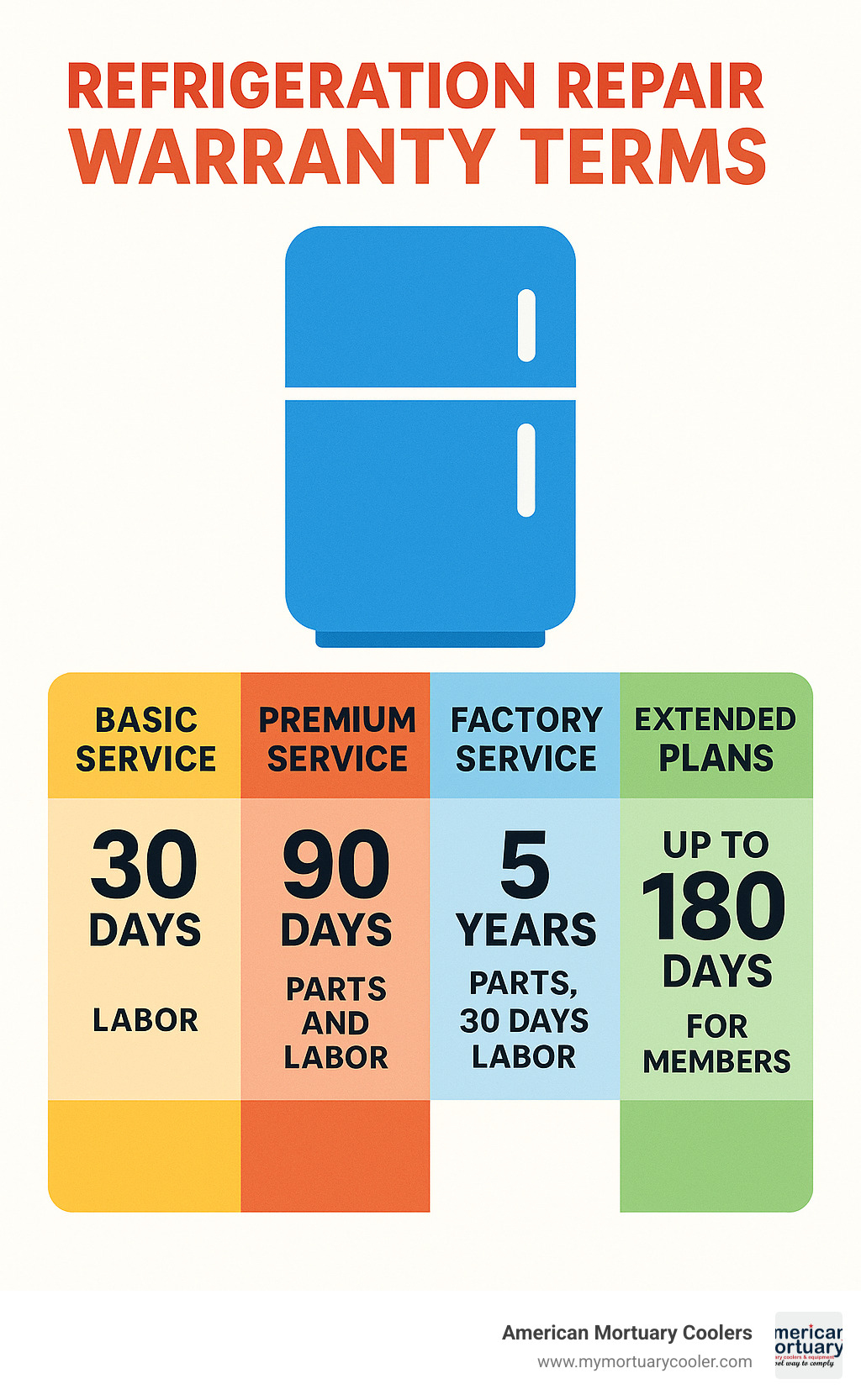

- Service guarantees - What 60-day, 90-day, and even 5-year warranties really mean

Step 1 – Spot the Warning Signs Early

Your refrigeration system is trying to tell you something - the question is, are you listening? Most refrigeration repair emergencies don't happen overnight. Instead, they give you plenty of warning signs.

Temperature troubles are usually the first red flag. When your unit starts struggling to maintain set temperatures or begins cycling on and off more frequently than usual, it's crying for help. You might notice warm spots in your coolers or soft spots in freezers. Food spoiling faster than normal is another dead giveaway that something's not right.

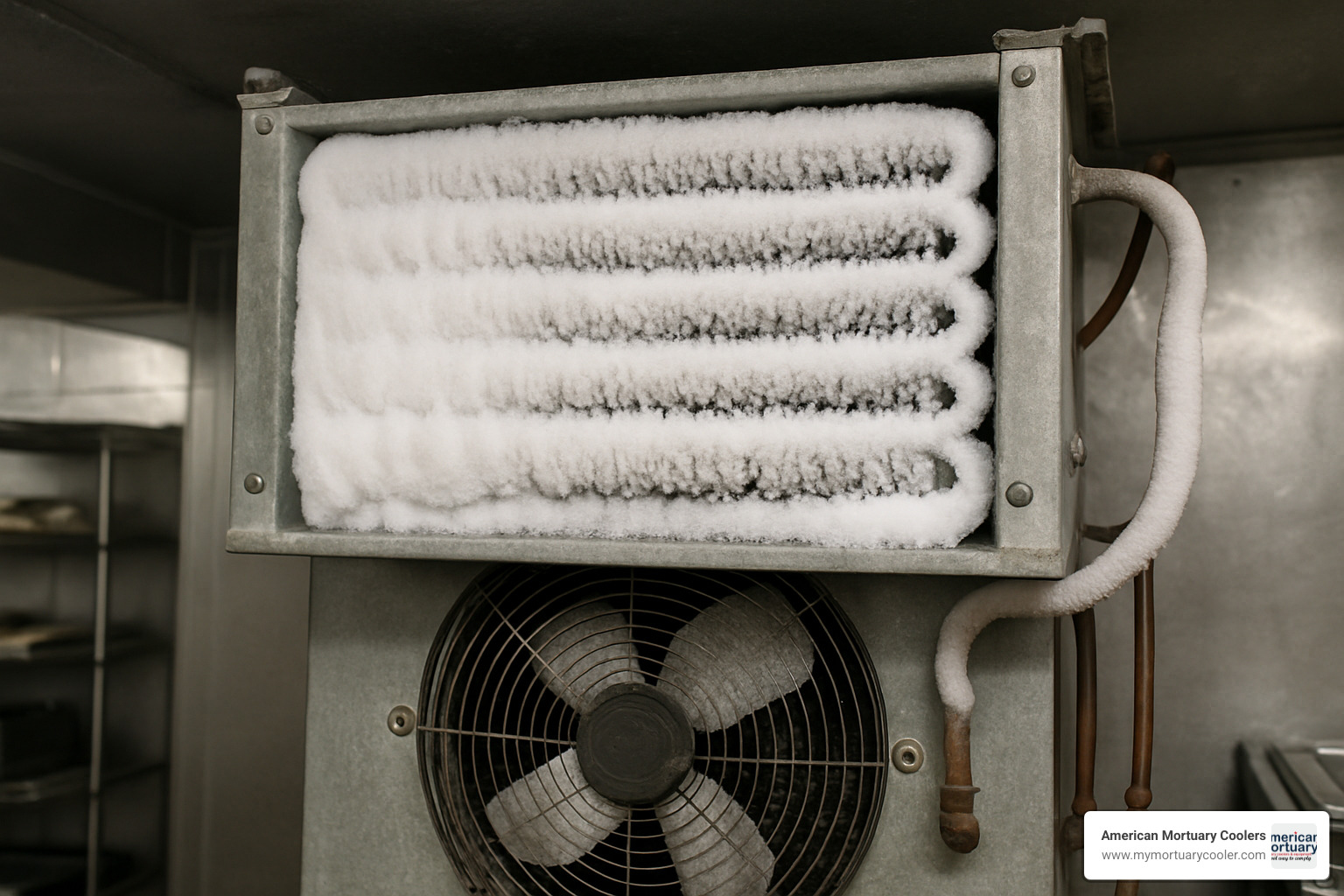

Ice and moisture problems can turn your refrigeration system into an unwanted ice sculpture exhibit. When you see excessive frost building up on evaporator coils (like in the image above), that's your system working overtime to compensate for underlying issues.

Ice stalactites forming inside your unit might look impressive, but they're actually a clear sign of structural damage that needs immediate attention. Water pooling inside or around the unit, along with condensation on exterior surfaces, means moisture is getting where it shouldn't be.

Strange noises from your refrigeration equipment are like hearing your car make weird sounds - they're never a good sign. Unusual sounds from the compressor, fans, or motors, along with vibrations or rattling, suggest mechanical components are struggling.

Energy spikes often show up on your electricity bill before you notice performance issues. If your refrigeration system suddenly starts running constantly without reaching proper temperatures, or if cool-down times after door openings get longer, your equipment is working harder but accomplishing less.

Here's something we've learned from years of working with cooling systems: warm, humid air entering a cooler creates a domino effect. The moisture condenses and freezes into ice, especially in hot kitchen environments. Even leaving a door open for just 5-10 minutes can trigger excessive compressor run-time and serious ice build-up. More info about freeze-up causes

DIY vs Professional Refrigeration Repair?

Let's be honest - there's a fine line between being handy and being dangerous when it comes to refrigeration repair. While your DIY spirit might be admirable, refrigeration systems aren't exactly like fixing a leaky faucet.

You can safely handle basic detective work like checking your power supply and circuit breakers. Inspecting door seals and gaskets for damage is also within the safe zone, as is clearing visible debris from condenser coils. Making sure vents aren't blocked by inventory and ensuring proper airflow around your unit falls into the "anyone can do this" category.

But here's where you need to pump the brakes and call in the professionals: anything involving refrigerants requires EPA certification for a reason. These chemicals aren't just regulated - they can be dangerous in the wrong hands. Electrical issues beyond checking breakers, compressor problems, unusual noises, temperature control malfunctions, and suspected refrigerant leaks all need professional attention.

As one industry expert puts it, "Appliance repair is best left to professionals with specialized tools and training to avoid hazards and warranty voids." DIY repairs might seem cost-effective until you void your warranty or create a safety hazard.

The refrigeration circuit is a sealed system that works with refrigerants like R134A, R600, R290, and R404A. Working with these requires specialized tools like electronic leak detectors, vacuum pumps, and refrigerant manifolds - not exactly items you'll find in your average toolbox.

Step 2 – Verify Technician Qualifications & Certifications

Here's the truth: not all refrigeration repair technicians are the same. I've seen what happens when businesses hire the wrong person - recurring problems, voided warranties, and repairs that cost more than they should.

EPA Section 608 certification is absolutely non-negotiable. This isn't optional - it's required by federal law for anyone handling refrigerants. Without it, the technician can't legally work on your system. Ask to see their certification card and make sure it covers the type of equipment you have. There are different levels: Type I for small appliances, Type II for high-pressure systems, Type III for low-pressure, and Universal for all types.

NATE certification goes beyond the basics. The North American Technician Excellence program shows a technician has advanced knowledge and keeps up with continuing education.

Your state's HVAC/R license matters too. Most states require this for commercial work, and it usually means the technician carries proper insurance.

Factory authorization can make a huge difference in your repair experience. These technicians get manufacturer-specific training and have access to genuine parts and technical support. Companies like Bodewell (GE's service arm) and Frigidaire factory service train their people extensively. Scientific research on technician training shows that factory-trained technicians complete most repairs on the first visit because they know the equipment inside and out.

Look for other quality signs too. Does the company run background checks on technicians? Do they carry professional liability insurance? Are they members of trade organizations like the Institute of Refrigeration?

Questions to Ask Before Hiring

Before you hand over your keys to any refrigeration repair service, have a real conversation with them. Here's what you need to know:

Start with insurance questions. Ask if they carry general liability and professional liability coverage, and don't be shy about requesting proof. Find out what happens if something goes wrong during the repair.

Warranty support tells you a lot about confidence in their work. Do they honor manufacturer warranties? What warranty do they provide on their own work? Look for at least 60-90 days. Ask whether they use genuine manufacturer parts or cheaper aftermarket alternatives - this affects both performance and warranty coverage.

Parts availability can make or break your repair timeline. Find out if they stock common parts on their service vehicles and how quickly they can get specialized components. Ask about their first-visit completion rate. The best companies, like Frigidaire factory service, carry over 400 genuine parts on-site.

Response time matters when your business is losing money every hour. Do they offer same-day service? What are their emergency hours? How do they handle after-hours calls? Companies like Tech24 provide 24/7 service with GPS-equipped vans, so you know exactly when help is arriving.

The right technician will welcome these questions. If someone seems evasive or annoyed, that's your signal to keep looking.

Step 3 – Compare Refrigeration Repair Cost, Warranty & Service Guarantees

When your cooler breaks down, you're already stressed. The last thing you need is a surprise repair bill that could've been avoided with better planning. Understanding refrigeration repair costs upfront helps you make smart decisions and avoid those heart-stopping moments when the invoice arrives.

Most repair companies use different pricing approaches, and knowing what to expect can save you hundreds. Some charge a flat diagnostic fee of around $120, then credit it toward your repair if you move forward. Others, like Frigidaire, offer "Fixed Price Repair" starting at $190 - you know exactly what you'll pay before any work begins.

The breakdown typically includes both parts and labor costs. Labor rates vary depending on your location and how complex the repair is. Emergency calls during nights or weekends usually cost 1.5 to 2 times the normal rate - another reason why catching problems early matters so much.

Genuine manufacturer parts cost more than aftermarket alternatives, but they're usually worth it. We've seen too many businesses get burned by cheap parts that fail within months, requiring another service call and more downtime.

Service guarantees vary widely between companies, and this is where you really need to pay attention. Basic services might offer 30 to 60 days on labor only, while premium providers like Tech24 and 98 Refrigeration offer 90-day guarantees on both parts and labor.

The best warranties we've seen include 5-year parts coverage from companies like Bodewell (GE's service division), though labor warranties are typically shorter at around 30 days. Some companies extend coverage to 180 days if you're part of their service plan.

What does warranty coverage actually mean for you? If the same problem happens again within the warranty period, they'll fix it at no charge. This includes return visits, replacement of any defective parts they installed, and the labor to make it right. Just watch out for exclusions - normal wear items and damage from misuse usually aren't covered.

Are Repairs Covered Under Your Plan?

Before you reach for your wallet, take a moment to check what coverage you might already have. You could save yourself a significant expense.

Your manufacturer warranty might still be active. Most commercial refrigeration equipment comes with at least a one-year limited warranty covering defects in materials and workmanship. The catch is that you usually need to use factory-authorized service to keep the warranty valid.

Extended protection plans can be lifesavers if you purchased one. These third-party warranties kick in after your manufacturer coverage expires and often include both parts and labor for major components. Some even throw in preventive maintenance visits.

Service contracts offer the most comprehensive coverage in our experience. You get priority scheduling, reduced service fees, planned maintenance to prevent breakdowns, and sometimes even emergency after-hours coverage. For businesses that can't afford downtime, these plans often pay for themselves with just one major repair.

When Is Refrigeration Repair Cheaper Than Replacement?

This is the million-dollar question, and we get asked about it constantly. The answer depends on several factors, but we've developed some practical guidelines over the years.

Repair usually makes financial sense when your equipment is less than 10 years old and the repair cost is less than half what you'd pay for replacement. If the unit has been well-maintained and parts are readily available, fixing it is often the smart move.

Start thinking about replacement when repair costs exceed 60% of a new unit's price, especially if you've had multiple breakdowns recently. Compressor failures on units over 10 years old are often the tipping point.

Here's a real example: A commercial freezer compressor replacement might run $2,000 to $3,000, while a new unit costs $5,000 to $7,000. If your freezer is 8 years old and otherwise in good shape, repair makes sense. But if it's 12 years old with other issues developing, replacement often provides better long-term value.

Don't forget about energy efficiency. Older units that are constantly running up your electric bill might cost more to keep than replace, even if the repair itself seems reasonable. Sometimes the most expensive repair is the one that keeps an inefficient unit limping along.

Step 4 – Prioritize Speed: Response Time & Emergency Coverage

Time is your enemy when refrigeration systems fail. I've watched businesses lose thousands of dollars in spoiled inventory simply because they couldn't get a technician out fast enough. That's why refrigeration repair response time should be at the top of your priority list.

The reality is harsh: same-day service can mean the difference between a minor inconvenience and a business catastrophe. Companies like 98 Refrigeration understand this urgency, often getting technicians to your location "as early as today once you book." But not all service providers operate with this level of urgency.

True 24/7 emergency coverage isn't just about having someone answer the phone. Tech24 provides genuine round-the-clock nationwide service because they understand that refrigeration emergencies don't wait for business hours. Yes, emergency rates cost more, but they're a bargain compared to losing an entire cooler full of inventory overnight.

Modern service companies use GPS-tracked vehicles to minimize your waiting time. Instead of wondering when help will arrive, you get real-time updates on your technician's location. This technology helps companies like Tech24 optimize their routing and get to you faster than traditional dispatch methods.

The power of a nationwide network becomes obvious during peak seasons or local emergencies. When your local technician is swamped, companies with broad coverage can dispatch help from nearby areas.

Here's what realistic response times look like: Emergency service should reach you within 2-4 hours during business hours, while standard same-day service typically arrives within 8 hours of your call. Next-day service is fine for minor issues, but anything affecting temperature control needs faster attention.

More info about commercial repair near you

How Businesses Minimize Downtime During Refrigeration Repair

Smart business owners don't just cross their fingers and hope for the best. They build systems that protect them when equipment inevitably fails.

Planned maintenance agreements are your first line of defense. These aren't just fancy service contracts - they're strategic partnerships that schedule inspections during your slow periods. Maintenance customers typically get priority service when emergencies do happen, and regular check-ups catch problems before they become disasters.

Having backup systems ready isn't paranoia - it's good business sense. This might mean knowing which equipment rental company can deliver temporary refrigeration units quickly, or having relationships with nearby businesses who might help store critical inventory during repairs. The key is arranging these relationships before you need them.

Remote monitoring technology has become a game-changer for preventing emergency situations. Temperature monitoring systems with alert capabilities give you early warning when something's going wrong. Instead of finding a problem when you find spoiled food, you get alerts that let you call for service before complete failure occurs.

At American Mortuary Coolers, we've helped clients across Tennessee and beyond develop contingency plans that work. The businesses that handle equipment failures best are those who plan for them while everything's running smoothly.

Step 5 – Maintain & Extend Equipment Life After Repair (Plus Final Checklist)

Getting your refrigeration repair completed is only half the battle. The real value comes from making sure your equipment stays running strong for years to come. At American Mortuary Coolers, we've seen well-maintained systems operate reliably for 15+ years, while neglected units fail in half that time.

Coil cleaning should be your top priority every six months. Clean evaporator and condenser coils are essential for efficient operation. When coils get dirty, your system works harder and costs more to run. Use only approved cleaners - never acid-based products that can damage the coils. Always rinse thoroughly until there's no cleaning residue left behind.

Door gasket care prevents costly air leaks that force your system to work overtime. Inspect those rubber seals monthly and clean them regularly to maintain a proper seal. Even small gaps let humid air sneak in, which creates ice buildup and higher energy costs. Replace damaged seals immediately.

Temperature monitoring helps you catch problems before they become emergencies. Log temperatures daily and watch for unusual patterns. Your walk-in coolers should stay around 35°F, while freezers perform best at -10°F. If you notice the system cycling on and off more frequently than usual, or struggling to maintain temperature, it's time to investigate.

Don't overlook your drainage system maintenance. Clear condensate drains regularly and check for clogs that cause water backup. Make sure the drainage slope is correct and address any drain issues before they cause flooding.

Vinyl strip curtains are a simple upgrade that makes a big difference, especially in hot kitchen environments. They reduce humid air infiltration when doors open frequently, which means less work for your cooling system and fewer ice buildup problems.

Planned maintenance agreements with qualified technicians give you peace of mind and priority service. These typically include quarterly, semi-annual, and annual inspections that catch small problems before they turn into expensive repairs.

The energy savings from proper maintenance are substantial. Clean coils and well-maintained systems can reduce energy consumption by 15-25%. That's real money back in your pocket.

The Ultimate Refrigeration Repair Checklist

Here's your complete maintenance roadmap, broken down by frequency:

Monthly: Visually inspect all components and check evaporator coils for cleanliness. Examine door seals and gaskets for damage. Verify proper temperatures and normal cycling patterns. Clear debris from the condenser area and check that electrical connections are tight.

Quarterly: Deep clean condenser coils and lubricate fan motors and bearings. Test defrost timers and controls, then inspect wiring for wear or damage. Check refrigeration cycle pressures and verify thermostat calibration.

Semi-annually: Schedule professional inspection by a certified technician for comprehensive cleaning of all coils and components. Check superheat levels (target 30°F-45°F range) and inspect all safety controls. Review maintenance logs for trends and plan any needed repairs or upgrades.

Annually: Submit compressor oil samples for laboratory analysis and replace oil and filter driers if needed. Conduct comprehensive electrical system inspection and review energy usage trends. Update maintenance agreements and plan capital improvements or replacements.

Predictive maintenance tools like digital thermometers with data logging, vibration monitors, and remote monitoring systems help you stay ahead of problems. These tools can send smartphone alerts when something's not right, giving you time to address issues during business hours instead of facing emergency repairs.

Watch for warning signs like unusual noises or vibrations, temperature fluctuations, increased energy consumption, frost buildup, or water leaks. Catching these early can save you thousands in emergency repair costs and lost inventory.

Every dollar spent on preventive maintenance typically saves three to five dollars in emergency repairs. It's not just smart business - it's essential for protecting your investment and keeping your operations running smoothly.

Conclusion & Next Steps

You've got the roadmap - now it's time to put it into action. Refrigeration repair doesn't have to catch you off guard when you're prepared with the right knowledge and relationships.

Think of it this way: every minute you spend preparing now saves you hours of stress later. We've seen too many businesses scramble when their cooling systems fail, frantically calling random repair companies and paying premium rates for subpar service.

Start with the basics. Train your team to recognize those early warning signs we covered - the strange noises, temperature fluctuations, and ice buildup that signal trouble ahead. Once you know what to look for, you'll catch problems while they're still manageable.

Build your service network before you need it. Research local technicians now, while you have time to verify their EPA certifications and check their insurance coverage. Ask about their response times and warranty policies. The middle of an emergency is no time to find your "technician" isn't properly licensed.

Understand your numbers. Know what your equipment is worth, what repairs typically cost, and when replacement makes more sense than fixing. Commercial freezer compressors usually last about 10 years, while walk-in coolers can go 15 years with proper care.

At American Mortuary Coolers, we've built our reputation on reliability because we understand what's at stake. Whether you're managing a restaurant kitchen or maintaining critical temperature control for sensitive products, equipment failure isn't just inconvenient - it can be devastating.

The smart money is on prevention. Those quarterly maintenance visits might seem like an unnecessary expense, but they're actually insurance against much bigger problems. Clean coils, proper refrigerant levels, and well-maintained seals can extend your equipment's life by years and slash your energy bills.

Your peace of mind is worth the investment. When you know you have qualified technicians on speed dial, comprehensive warranties protecting your repairs, and a maintenance plan keeping everything running smoothly, you can focus on what really matters - running your business.

Don't wait for the next breakdown to test your preparedness. The time to act is now, while your systems are running and you can make thoughtful decisions instead of desperate ones.

More info about maintenance collections

Ready to take the next step? We're here to help you implement these strategies and keep your operations running smoothly. After all, reliable refrigeration isn't just about keeping things cold - it's about keeping your business moving forward.