How Does Order Processing Work? A Step-by-Step Guide

Understanding the Order Process in Today's Business World

What is the order process? It's the complete workflow that handles customer orders from initial placement through delivery, including verification, payment processing, picking, packing, and shipping. This systematic approach ensures products move efficiently from warehouse to customer.

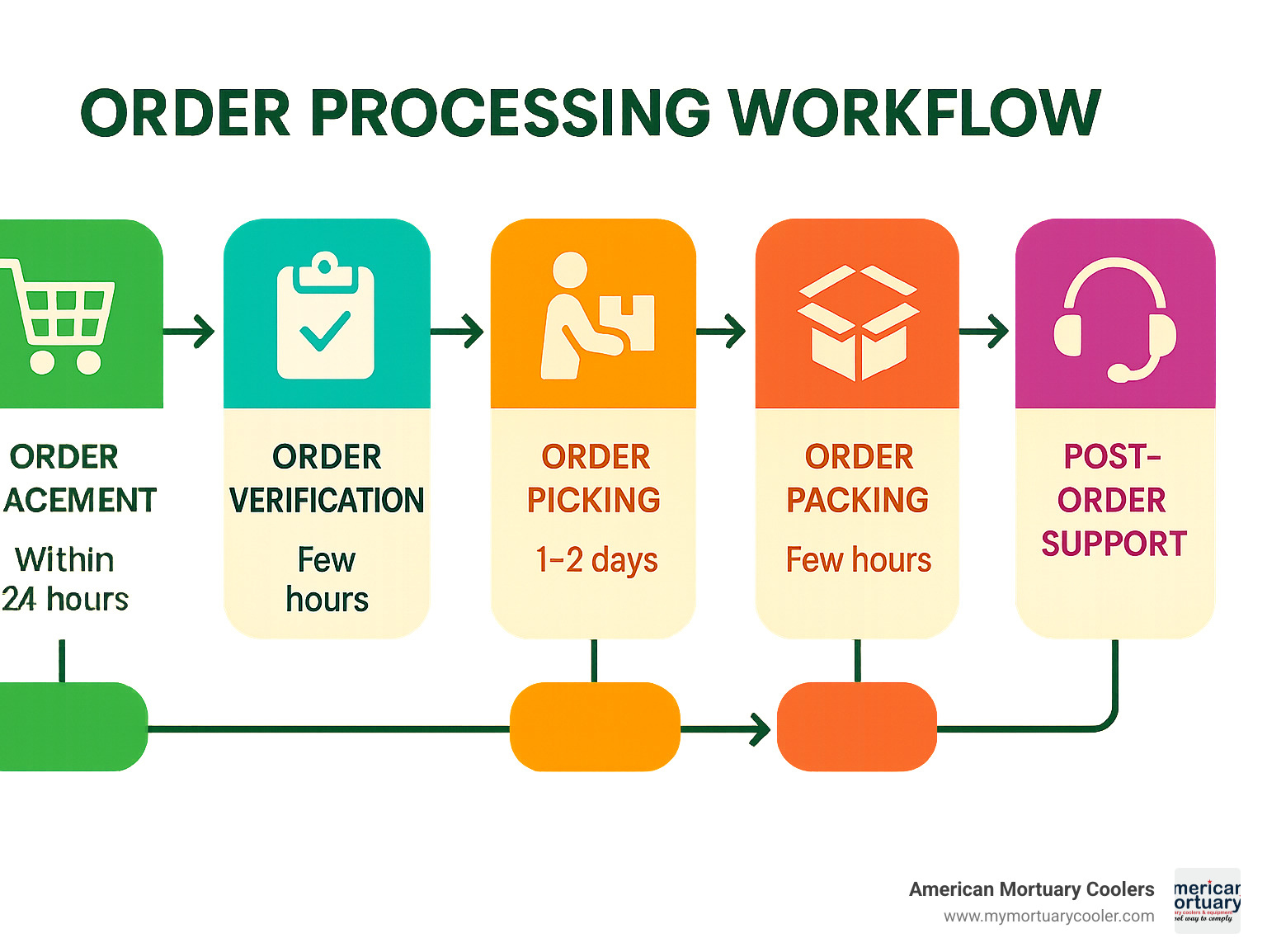

The order process typically follows these key steps:

- Order Placement - Customer submits an order through website, phone, or in-person

- Order Verification - System confirms payment and inventory availability

- Order Picking - Warehouse staff locate and retrieve products from inventory

- Order Packing - Items are packaged appropriately for shipping

- Order Shipping - Products are handed to carriers and delivered to customers

- Post-Order Support - Handling tracking, customer questions, and potential returns

In today's market, efficient order processing gives businesses a competitive advantage. With 65% of customers unlikely to return after just one bad experience, getting this process right isn't just about operational efficiency—it's about customer retention.

For funeral homes and mortuary services, reliable order processing means receiving critical equipment when promised, maintaining dignity in service, and avoiding unnecessary stress during sensitive times.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience streamlining what is the order process for funeral industry professionals. My expertise ensures your mortuary equipment arrives on time and meets your exact specifications.

What is the order process terminology:

What Is the Order Process?

Ever wonder what happens after you click "buy now"? The order process is the heartbeat of any product-based business. It's everything that happens from the moment a customer decides to purchase until they're happily using their new item—and sometimes beyond. Think of it as a carefully choreographed dance between administrative tasks (like processing payments) and physical activities (like picking products from shelves).

Let's clear up some commonly confused terms:

Order Processing focuses mainly on the paperwork side—capturing the order details, verifying payments, and updating your inventory records. It's the "brain work" behind each sale.

Order Fulfillment is where things get physical—picking the actual products, packing them safely, and shipping them to your doorstep. It's the "hands-on" part of getting orders to customers.

Order Management is the big picture that brings everything together, including processing, fulfillment, plus handling returns and keeping customers informed along the way.

Here at American Mortuary Coolers, we know that each step matters tremendously. When you're ordering specialized equipment like a mortuary cooler, you need confidence that every detail will be handled with care and precision.

What is the order process in retail?

Retail order processing kicks off the moment a customer completes their checkout. In today's multi-channel world, this might happen:

On your website while they're in pajamas at midnight Through your mobile app during their lunch break At your physical store's register Over the phone with your sales team Via third-party marketplaces like Amazon

The real challenge? Keeping everything synchronized. If you sell the last unit of a product in-store, your website needs to know immediately to prevent disappointment. Modern retail businesses need real-time inventory systems that talk to each other across all sales channels.

SKU tracking becomes your best friend in this environment. Each product variant needs its unique identifier—so that navy blue medium shirt doesn't get confused with the black large one. This becomes especially critical when you're managing thousands of products.

Smart retailers also keep an eye on their Inventory turnover ratio, which shows how efficiently they're selling and replacing stock. A healthy ratio usually signals that your order process is humming along nicely.

What is the order process for B2B manufacturing?

B2B manufacturing marches to a different drummer. Instead of individual shoppers making spontaneous purchases, you're dealing with formal purchase orders (POs) that spell out exactly what the buyer wants—quantities, specifications, pricing, and delivery terms.

The gold standard in B2B order processing is the three-way match. This careful verification compares the purchase order against what was actually delivered and the supplier's invoice. It's like triple-checking your work before turning it in—and it prevents paying for items you never received.

Unlike retail's immediate payment, B2B often works on credit terms. At American Mortuary Coolers, we offer qualified businesses NET 30 payment terms after their first order (which is pre-paid or COD). This approach builds trust while managing cash flow for both parties.

B2B shipping looks different too. Instead of sending out individual packages, you're often dealing with pallets or even full truckloads. This requires specialized handling, different documentation, and careful coordination—especially when delivering sensitive equipment like mortuary coolers across state lines.

The 5-Step Order Processing Workflow

Ever wonder how your order actually makes it from a click on your screen to your doorstep? Let's walk through the journey together. While every business has its own unique twist, these five core steps form the backbone of most order processing systems – whether you're ordering a book online or, in our case, a custom mortuary cooler.

What is the order process step-by-step?

The magic begins the moment a customer decides to make a purchase. This "cart to cash" journey has several important milestones:

When you place an order with us at American Mortuary Coolers, we immediately generate a unique order number and record all your specifications in our system. You'll get a friendly confirmation letting you know we've received your request for that custom cooler your funeral home needs.

Next comes the verification stage – we'll make sure your payment goes through smoothly, whether that's processing your credit card or validating your purchase order. Our system then checks if we have all the necessary components to build your mortuary cooler to your exact specifications. Since our coolers are custom-built, we'll confirm we have the right materials on hand to create your perfect solution.

Once verified, your order moves to our production floor where our skilled team begins the picking process. They'll gather all the components needed for your specific cooler model, carefully checking each item against your order details. For standard products, this might involve retrieving items from warehouse shelves, but for our custom coolers, it means assembling the precise parts needed for your build.

The packing stage is where we take extra care – mortuary equipment requires special attention. We select appropriate packaging materials that will protect your cooler during its journey across the country. Every cooler gets a final quality inspection before being secured for shipping, and we include all documentation you'll need for installation.

Finally, we coordinate with our shipping partners for the delivery of your cooler. We'll select the best carrier based on your location and timeline needs, generate tracking information, and send you confirmation with all the details you need to prepare for arrival. For funeral homes expecting a mortuary cooler, knowing exactly when it will arrive is crucial for planning.

Throughout this entire process, we keep you updated with clear, timely communications. No mysterious gaps where you're left wondering what's happening with your order!

Inventory management's role in what is the order process

Behind every smooth order process is a robust inventory management system keeping everything on track. Think of it as the brain of the operation – constantly tracking what's available and what's needed.

At American Mortuary Coolers, our inventory system does much more than count products. It serves as our system of record, providing real-time visibility into component availability for building your custom cooler. When materials run low, our system triggers automatic alerts so we can restock before it affects your order timeline.

We also rely on demand forecasting to anticipate busy periods in the funeral industry. By analyzing historical data and seasonal trends, we can prepare for increased order volumes during certain times of the year. This proactive approach helps us maintain consistent delivery times even during peak periods.

Our implementation of Pick to box procedures streamlines how we assemble orders. Rather than gathering components and then figuring out packaging, we determine the appropriate shipping container from the start. This reduces handling time and decreases the chance of damage during the fulfillment process.

For custom products like our mortuary coolers, inventory management becomes particularly complex. We're not just tracking finished goods sitting on shelves – we're balancing raw materials with production capacity and your specific requirements. When you need a cooler with custom capacity for your funeral home, our inventory system ensures we have the right components on hand to build exactly what you need, when you need it.

This careful orchestration behind the scenes is what allows us to deliver reliable service to funeral professionals across all 48 contiguous states, ensuring your mortuary equipment arrives on time and built to your exact specifications.

Methods, Systems & Common Challenges

Let's talk about how businesses actually handle their orders. Whether you're running a small shop or a large warehouse, the what is the order process question has different answers depending on your system and approach.

Types of Order Processing Systems

The world of order processing spans from old-school paper methods to cutting-edge automation. Most businesses fall somewhere on this spectrum:

Manual Systems still have their place in very small operations. Picture handwritten orders, staff calling across the room to check inventory, and physical picking lists. While charming in their simplicity, these systems quickly become overwhelming as a business grows.

Electronic Systems represent the middle ground many businesses occupy. These digital workflows use computers for tracking and documentation, but still rely on humans to execute most tasks. It's like having a digital co-pilot – the technology guides you, but you're still doing the work.

Automated Systems take things to the next level with minimal human intervention. Barcode scanners beep throughout the warehouse, conveyor belts whisk packages along, and software makes real-time decisions. For high-volume operations, this investment pays off quickly.

The difference in performance is striking:

| System Type | Average Error Rate | Cost Per Error | Processing Time |

|---|---|---|---|

| Manual | 1-3% | $50-$100 | 15-30 minutes |

| Automated | 0.1-0.5% | $10-$50 | 2-5 minutes |

Those numbers tell a powerful story – automation not only reduces mistakes but makes each mistake less costly and dramatically speeds up the entire process.

4 key order processing methods

Beyond systems, there are different methodological approaches to handling orders:

Order-to-Cash Processing takes the broadest view, following the customer journey from initial order through payment collection. This approach shines in B2B environments where financial tracking is paramount. It's like following the money through every step of your business.

Sales Order Processing focuses more narrowly on fulfilling customer expectations after they've placed an order. The emphasis here is on getting things right for the customer – confirmation, accurate picking, careful packing, and timely delivery.

Purchase Order Processing flips the script, addressing how your business orders from suppliers. This method involves requisitions, approvals, and invoice matching – critical for manufacturing businesses like ours at American Mortuary Coolers, where we need the right materials to build custom coolers.

Order Fulfillment zooms in on the physical handling of products. This is the warehouse dance – the picking strategies, packaging decisions, and shipping arrangements that get products out the door efficiently.

At American Mortuary Coolers, we blend sales order processing with fulfillment methods, adapted for the unique needs of mortuary equipment. When a funeral home orders a custom cooler, we're not just pulling a standard product off the shelf – we're starting a manufacturing process custom to their specifications.

Top challenges businesses face

Every business struggles with order processing challenges. Here are the problems we see most often:

Inventory Discrepancies cause headaches across industries. There's nothing worse than telling a customer "yes, we have that" only to find your physical inventory doesn't match your system. Regular cycle counting helps, but this remains a persistent challenge.

Data Silos and System Integration Issues slow everything down. When your ordering system can't talk to your inventory system, which can't communicate with shipping, you end up with a digital version of the telephone game. Information gets lost or distorted, leading to mistakes and delays.

Shipping and Delivery Complications are often beyond your control but still your responsibility in the customer's eyes. From weather delays to address errors to international customs headaches, the last mile of delivery presents countless challenges.

Returns and Exchange Management adds another layer of complexity. Processing returns efficiently, determining whether items can be resold, and issuing refunds promptly all require careful attention – especially for specialized equipment.

Seasonal Demand Fluctuations test even the most robust systems. Staffing appropriately for peak periods while maintaining service levels requires careful planning and flexible resources.

In our business at American Mortuary Coolers, we face unique challenges related to customization and the time-sensitive nature of the funeral industry. Our customers often need equipment quickly during difficult circumstances, which means we must maintain flexible manufacturing capacity without compromising quality. When a funeral home calls needing a cooler after an unexpected event, we understand that "soon" usually means "yesterday" – and we've built our entire order process around that reality.

Optimizing & Automating Order Processing

Improving your order process doesn't have to be complicated, but it can make a world of difference for your business and customers alike. When you streamline these workflows, you're not just saving money—you're creating happier customers who keep coming back.

How to improve what is the order process in your business

Start by taking a good look at how orders flow through your business today. Grab a pen and paper and map out each step—from the moment a customer clicks "buy" until they receive their package. Where are things getting stuck? Which steps take the longest? This simple exercise often reveals bottlenecks you might not have noticed before.

Automation doesn't have to mean a complete system overhaul. Begin with those repetitive tasks that eat up your team's time. Before investing in new technology, do the math on your potential return on investment (ROI). Many businesses find that cloud-based solutions offer the flexibility they need without massive upfront costs.

Success needs measurement, so establish clear key performance indicators (KPIs) that matter to your business. Order accuracy, processing time, and cost per order give you meaningful insights into how well your process is working. Create simple dashboards so your team can see progress in real-time—there's nothing more motivating than watching those numbers improve!

Smart shipping choices make a huge difference in both cost and customer satisfaction. Instead of defaulting to one carrier, develop rules that select the best shipping option based on package size, destination, and delivery timeline. We've found that regional carriers sometimes offer better rates and service for certain routes—a win-win for everyone.

Today's customers care about sustainability, and your packaging choices matter. Right-sized boxes not only reduce waste but can significantly lower shipping costs. At American Mortuary Coolers, we've redesigned our packaging to use fewer materials while actually improving protection for our products during transit. Our customers appreciate this commitment to environmental responsibility, especially those in California and other eco-conscious regions.

Post-order processes: returns, exchanges & feedback

The journey doesn't end when the package arrives. What happens after delivery can make or break customer loyalty.

A clear, simple returns process reassures customers they won't be stuck with something that doesn't meet their needs. Document your RMA (Return Merchandise Authorization) process in plain language, and make sure your team follows it consistently. When returns do happen, inspect items promptly and process refunds quickly—nobody likes waiting for their money back.

For specialized equipment like ours, we've developed a detailed assessment process for any returned items. Each cooler undergoes thorough cleaning, repair if needed, and comprehensive testing before we consider making it available again. This maintains our quality standards while reducing waste.

Customer feedback is pure gold for improving your business. Ask for it directly after purchase with simple surveys that respect your customers' time. When we implemented post-installation check-ins, we finded small adjustments that made a big difference in customer satisfaction. One funeral director in Chicago mentioned that additional temperature calibration guidance would be helpful—now it's standard in all our delivery packages.

The real magic happens when you close the loop with this information. We review return patterns monthly, looking for product improvements we can make. When multiple customers from Texas mentioned difficulty with a particular component, we redesigned it completely. This continuous improvement cycle keeps your order process getting better and better.

Best practices for special or high-value orders

Some orders simply deserve extra attention. Whether it's a long-time customer, a particularly large order, or specialized equipment, these VIP orders benefit from white-glove treatment.

Make these special orders stand out in your system with priority flags that everyone can see. At American Mortuary Coolers, our team gets automatic alerts for orders from repeat customers or for multi-unit purchases. This ensures these valuable relationships get the attention they deserve, whether the funeral home is in Miami or Seattle.

Communication becomes even more critical with high-value orders. We assign a dedicated point of contact who personally reaches out at each milestone. There's something reassuring about hearing a friendly voice confirm that your $15,000 equipment order is on schedule—especially when you're preparing to serve families during difficult times.

White-glove shipping takes delivery to another level. For mortuary coolers, this means not just dropping a box at the door but bringing it inside, positioning it exactly where needed, removing all packaging, and ensuring everything works perfectly before leaving. This service is particularly appreciated by smaller funeral homes that may not have staff available to move heavy equipment.

Maintaining detailed records protects both you and your customers. Document each handling step with care, especially for valuable items. We photograph each cooler before shipping and require signatures at multiple points in the delivery process. This comprehensive audit trail has proven invaluable on the rare occasions when shipping damage occurs.

Don't forget to show appreciation for your best customers. Something as simple as a handwritten thank-you note from your team can strengthen relationships. For customers who place large orders, we include milestone appreciation gifts that recognize their loyalty. One funeral director in Philadelphia was genuinely touched by the personalized maintenance kit we included with his third cooler purchase.

At American Mortuary Coolers, we understand that ordering mortuary equipment represents a significant investment for funeral homes. That's why we've built our entire order process around ensuring confidence and satisfaction at every step. From initial measurement consultation to final temperature verification, we handle each order with the care and respect it deserves.

For more information about specialized order processing for mortuary equipment, check out our resource on Order Picking: Methods and Equipment or learn about how to determine the proper mortuary cooler capacity for your specific needs.

Conclusion

What is the order process? As we've explored throughout this guide, it's the heartbeat of your business—changing customer wishes into delivered products. Each step in this journey matters, from the moment an order is placed through picking, packing, and shipping, all the way to that final follow-up after delivery.

The way you handle orders doesn't just affect your operations—it shapes your entire customer relationship:

- It builds (or breaks) customer loyalty, with 65% of customers likely to walk away after just one disappointing experience

- It directly impacts your profitability through inventory costs, staff efficiency, and shipping expenses

- It determines how smoothly you can grow when business picks up

- It shapes how people talk about your business, whether they're singing your praises or warning others away

Here at American Mortuary Coolers, we've spent years fine-tuning our order process specifically for funeral professionals. From our Tennessee manufacturing facilities, we craft custom mortuary coolers that meet the unique needs of funeral homes nationwide. When you're serving families during their most difficult moments, you can't afford equipment delays or quality issues—and we understand that deeply.

Whether your funeral home is in a busy city like New York or Los Angeles, or serving a smaller community in Johnson City or Columbia, we know that ordering mortuary equipment isn't just another business transaction. It's an essential part of providing dignified, respectful service to families during their time of need.

A smooth, reliable order process isn't just about efficiency on paper—it's about peace of mind when it matters most. By implementing even a few of the strategies we've shared in this guide, you can create a more dependable experience for your customers, no matter what industry you're in.

For funeral professionals looking to upgrade their facilities, we've made ordering simple and stress-free. Our approach eliminates the guesswork and ensures you get exactly what your preparation room needs. To explore our complete range of mortuary equipment and experience our streamlined ordering process firsthand, check out our guide to mortuary cooler solutions.

At its heart, what is the order process really about? It's a promise to your customers—a promise that you'll deliver exactly what they need, when they need it, just as they expected. When you consistently keep that promise, you don't just process orders—you build relationships that last.