Everything You Need to Know About Walk-In Refrigerator Dimensions

Why Getting Walk-In Refrigerator Dimensions Right Matters

Walk in refrigerator dimensions determine whether your cold storage solution will efficiently serve your business or become a costly mistake. Getting the size wrong means wasted energy, inadequate storage, or units that simply won't fit your space.

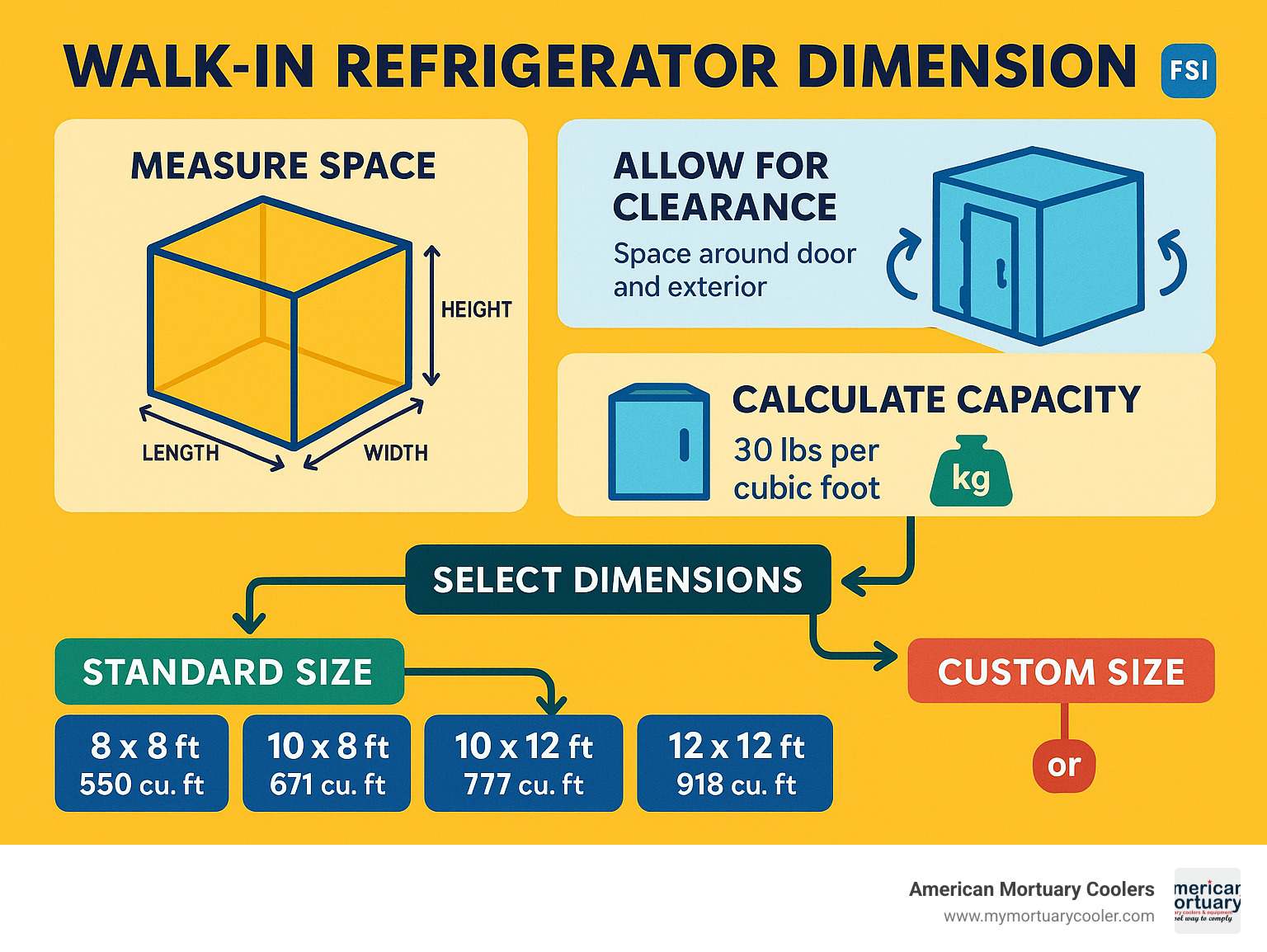

Quick Reference - Standard Walk-In Refrigerator Dimensions:

- 8' × 8' = 550 cubic feet (most common)

- 10' × 8' = 671 cubic feet

- 10' × 12' = 777 cubic feet

- 12' × 12' = 918 cubic feet

- Standard height: 8 feet

- Storage capacity: ~30 pounds per cubic foot

- Panel increments: 11½" for custom sizing

Walk-in refrigerators serve industries from restaurants to medical facilities, but the stakes are particularly high in mortuary operations where temperature control is critical. As one industry expert notes: "A walk-in cooler or freezer is essential across many industries, from foodservice to medical and industrial operations, both to meet federal regulations and ensure product longevity."

The most common mistake businesses make is choosing dimensions based on current needs alone, without considering future growth or proper workflow clearances. A unit that's too small forces costly upgrades within a few years, while oversizing wastes energy and valuable floor space.

About the Author: I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes steer walk in refrigerator dimensions and space planning challenges. My background in commercial refrigeration has taught me that proper sizing is the foundation of any successful cold storage installation.

Walk in refrigerator dimensions terminology:

Standard Walk-In Refrigerator Dimensions

When you're shopping for a walk-in refrigerator, you'll quickly find that certain sizes have become the go-to choices for businesses across industries. The 8' x 8' unit, offering 550 cubic feet of storage, sits at the top of the popularity list for good reason – it fits most spaces while providing serious storage capacity.

The next step up brings us to the 10' x 8' configuration with 671 cubic feet, followed by the 10' x 12' at 777 cubic feet, and the spacious 12' x 12' unit delivering 918 cubic feet of cold storage. These dimensions have earned their status as industry standards because they strike that sweet spot between storage needs and practical installation requirements.

But here's where it gets interesting – you're not stuck with just these options. Modern walk-in construction uses a clever modular panel system where each panel is built in 11½-inch increments. This means if you need something between an 8' x 8' and 10' x 8', a 9' x 8' unit is completely doable.

Standard ceiling heights give you flexibility too, ranging from 6'10" all the way up to 10 feet, with the most common being 8 feet. The 4-inch thick wall panels aren't just for show – they pack serious insulation power with R-29 values for coolers, keeping your temperatures steady while your energy bills stay reasonable.

Here's a handy rule of thumb that'll serve you well: one cubic foot of walk-in space holds roughly 30 pounds of product when properly organized. So that popular 8' x 8' unit? It can handle approximately 16,500 pounds of materials – that's some serious storage capacity.

Common Floor Sizes & Cubic Footage

Let's break down how these popular walk in refrigerator dimensions translate into real-world storage capacity. The 8' x 8' x 8' unit delivers 550 cubic feet, which means about 16,500 pounds of storage capacity when you follow the 30-pound rule.

Step up to the 10' x 8' x 8' and you're looking at 671 cubic feet – that's 20,130 pounds of capacity. The 10' x 12' x 8' configuration bumps you up to 777 cubic feet and 23,310 pounds, while the roomy 12' x 12' x 8' gives you 918 cubic feet and 27,540 pounds of storage potential.

The beauty of that 11½-inch panel increment system means you're not boxed into these exact measurements. Need something a bit smaller or larger? The modular construction makes custom sizing straightforward without the headaches of completely custom fabrication.

Walk-in floors are built tough too – they're engineered to handle uniformly distributed loads up to 700 pounds per square foot. This robust construction proves especially important in mortuary applications where durability and reliability aren't just nice-to-haves, they're absolute necessities.

Walk-In Refrigerator Dimensions Sizing Chart

Understanding the relationship between floor space and cubic capacity makes choosing your walk in refrigerator dimensions much more straightforward. The decision between standard and custom sizes often boils down to whether your space constraints and storage needs align with these common configurations.

Those modular panels connect using cam-lock fasteners, which sounds technical but actually makes life easier. This system allows for future expansion or reconfiguration when your business grows or needs change – and let's face it, business needs always seem to change.

The standard versus custom choice doesn't have to be overwhelming. Most businesses find that standard sizes work perfectly, but when they don't, the modular system makes customization surprisingly manageable.

For more detailed guidance on selecting the right size for your specific situation, our comprehensive sizing charts guide walks you through the entire process step by step.

How to Calculate the Right Size for Your Business

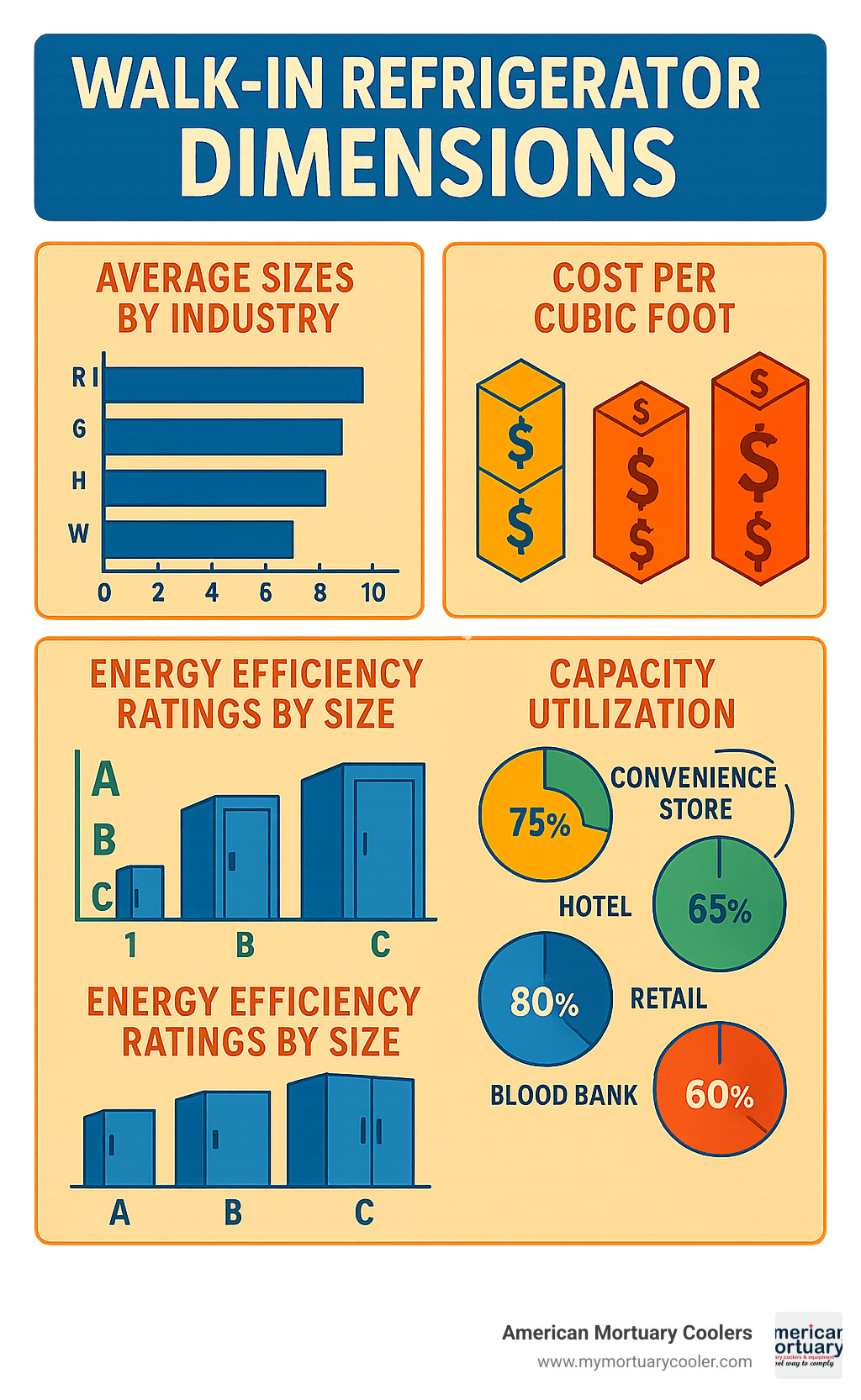

Determining the correct walk-in size requires more than measuring available floor space. We recommend using the storage weight calculation: 1 cubic foot equals approximately 30 pounds of storage capacity. This rule of thumb works well across most applications, from food service to mortuary operations.

For food service operations, multiply meals served per day by 1-1.5 cubic feet to estimate minimum storage needs. A facility serving 300 meals daily would need 300-450 cubic feet of walk-in storage. However, this baseline should be adjusted for your specific workflow patterns and product types.

Load factor calculations become critical when sizing refrigeration systems. The Heatcraft BTUH Load Calculation Chart provides ballpark requirements - for example, a 6x6 cooler at 35°F requires approximately 4,986 BTUH for typical loads or 6,540 BTUH for heavy-load applications with glass doors or frequent traffic.

Budget impacts extend beyond the initial purchase. Oversized units consume more energy, while undersized units may require costly upgrades. We've found that planning for 10-15 year growth projections often justifies selecting a slightly larger unit initially.

Workflow clearance requirements affect usable space significantly. Allow 40" aisles for cart access and two feet of clearance above packaged refrigeration units for service access. These clearances reduce effective storage but ensure operational efficiency.

Capacity Formula & Load Calculations

Proper refrigeration sizing requires gathering comprehensive data across five categories:

- Room Information: Length, width, height, holding temperature, relative humidity, and design ambient temperature

- Insulation Details: Type, thickness (typically 4" urethane R-25), and external temperatures on all surfaces

- Infiltration Loads: Entering air temperature/humidity, door usage frequency, and door types

- Product Loads: Product type, weight, entering temperature, loading time, pull-down requirements, and respiration loads for organic materials

- Miscellaneous Loads: Personnel count, lighting wattage, and motor horsepower

Using these factors with established BTUH charts ensures proper refrigeration capacity. For a 10x10 cooler at 35°F, typical loads require 9,072 BTUH while heavy loads need 10,790 BTUH. Undersized refrigeration leads to constant running and eventual system failure.

Avoiding Oversizing & Undersizing Walk-Ins

The energy cost penalty for oversizing can be substantial. A unit 20% larger than needed typically consumes 15-20% more energy continuously. Over a 15-year lifespan, this excess consumption often exceeds the cost difference between properly sized alternatives.

Undersizing creates more immediate problems - inadequate storage leads to spoilage risk, operational inefficiencies, and the need for costly premature replacement. We've seen funeral homes forced to rent temporary cold storage because their initial walk-in was too small for actual needs.

Future expansion considerations matter tremendously. A modular system allows adding sections later, but this costs more than building the right size initially. Consider your business trajectory - will you need 25% more capacity in five years? Plan for it now.

Resale value favors properly sized units. Standard dimensions like 8x8 or 10x12 have broader market appeal than unusual custom sizes, making them easier to relocate or resell if business needs change.

Design Factors That Affect Walk-In Refrigerator Dimensions

When planning your walk in refrigerator dimensions, the basic measurements are just the starting point. Several design factors can dramatically impact how your walk-in fits and functions in your space.

Ceiling height often becomes the deciding factor in your installation. Most facilities can accommodate the standard 8-foot height, but if you're dealing with low ceilings or overhead obstacles, you might need to consider shorter options or make building modifications.

The choice between floor panels or floorless installation affects your total height requirements significantly. Units with floor panels add 4-6 inches to the overall height but provide better insulation and much easier cleaning - especially important in mortuary applications where sanitation is critical. Floorless installations save that precious height but require proper floor preparation and drainage systems.

Door swing clearances can eat up more space than you'd expect. That standard 36" x 72" hinged door needs about 40" of clearance when it's fully open. In tight spaces, this can make the difference between a functional layout and a cramped mess. Sliding doors eliminate the swing problem entirely, though they do cost more upfront.

Here's something that catches many people off guard: wall thickness impacts your interior space more than you might think. Those standard 4" insulation panels reduce your interior dimensions by 8" in each direction compared to the exterior measurements. So your 10' x 10' exterior footprint becomes roughly 9'4" x 9'4" on the inside.

Insulation requirements vary depending on your application. Cooler applications typically use 4" panels with R-29 insulation values, while freezer applications may need 6" panels with R-32 ratings for optimal efficiency. Thicker panels mean better temperature control but less interior space for the same exterior footprint.

Don't forget about ventilation clearance - your refrigeration system needs room to breathe. Indoor units require 2" clearance on the sides and back, plus a full 12" above for proper heat dissipation. Strip curtains can help maintain temperature while reducing the impact of frequent door openings.

Ceiling Heights & Floor Panels

The standard height options of 6'10", 7'11", 8'5", 9½', and 10' cover most installation scenarios. The popular 8'5" height strikes a nice balance - you get good storage volume without needing special handling equipment or dealing with most ceiling constraints.

Floor panels do more than just add insulation. They're engineered to handle 700 pounds per square foot of uniformly distributed weight, making them perfect for heavy equipment or dense storage situations. In mortuary applications, this structural integrity is often essential.

The impact on overall height from floor panels is typically 4-6 inches, depending on the panel construction. This might seem minor, but it can be the difference between fitting under that low beam or needing costly building modifications.

Custom heights are available when standard options don't work with your space, but they increase both costs and lead times. We often find it's more economical to make minor building adjustments rather than ordering unusual walk-in heights.

Doors, Aisles & Workflow Around Walk-Ins

Standard 36" x 72" doors handle most commercial needs perfectly, but larger operations might benefit from 48" wide doors for easier cart access. The trade-off is more cold air loss each time the door opens and higher initial costs.

The sliding vs. hinged door decision comes down to space and budget. Hinged doors need that swing clearance but cost less initially. Sliding doors save valuable floor space but require overhead track systems and more complex installation.

40" aisles represent the sweet spot for most operations - wide enough for comfortable cart maneuvering without wasting cubic footage. Go narrower and you create operational bottlenecks. Go wider and you're giving up storage space unnecessarily.

For detailed guidance on maximizing your storage efficiency with proper shelving layouts, check out our More info about shelving.

Walk-In Refrigerator Dimensions & Ventilation Needs

Getting the ventilation right is crucial for your walk in refrigerator dimensions planning. Inadequate airflow around the condensing unit leads to poor performance, sky-high energy bills, and equipment that fails way too early.

Ambient heat buildup is the enemy of refrigeration efficiency. That 12" top clearance allows proper heat dissipation from air-cooled condensers, while 2" side and back clearances ensure adequate airflow without wasting too much space.

Outdoor vs. indoor installations each have their ventilation quirks. Outdoor units benefit from natural airflow but need weatherproofing and low-ambient controls for cold climates. Indoor units require mechanical ventilation but stay protected from weather extremes - often the better choice for mortuary applications where consistent performance is non-negotiable.

Modular Panels, Custom Builds & Future Expansion

The 11½" panel increment system revolutionizes walk-in flexibility. This modular approach means you can specify virtually any dimension while maintaining structural integrity and thermal performance. Panels connect using cam-lock fasteners that create vapor-tight seals without requiring skilled labor.

CSA and ULC fire-rated panels meet stringent safety standards, particularly important in mortuary applications where building codes may be more restrictive. These certifications ensure compliance with Canadian and U.S. safety requirements.

Retrofits and add-on sections become feasible with modular construction. Need to expand your 8x8 to a 10x8? Simply remove one wall panel and add a new section. This flexibility proves invaluable as businesses grow or needs change.

The cam-lock spacing specification of no more than 48" on center ensures airtight seals throughout the structure. Proper installation involves turning the hex wrench clockwise three-quarters turn until the cam-lock is secure.

For detailed panel specifications and certifications, visit the government database for Walk-in freezer and walk-in cooler panels.

Specifying a Custom Walk-In

Custom walk-in specifications require precise height, width, and length codes to ensure proper manufacturing and installation. Professional drawings help visualize the final installation and identify potential issues before construction begins.

Lead times for custom units typically extend 2-4 weeks beyond standard sizes, depending on complexity and current demand. Planning ahead prevents project delays and ensures installation schedules remain on track.

Cost variables for custom builds include non-standard panel sizes, special door configurations, unusual heights, and unique refrigeration requirements. However, the cost premium often justifies itself through improved operational efficiency and perfect space utilization.

For comprehensive guidance on available customization options, review our More info about options.

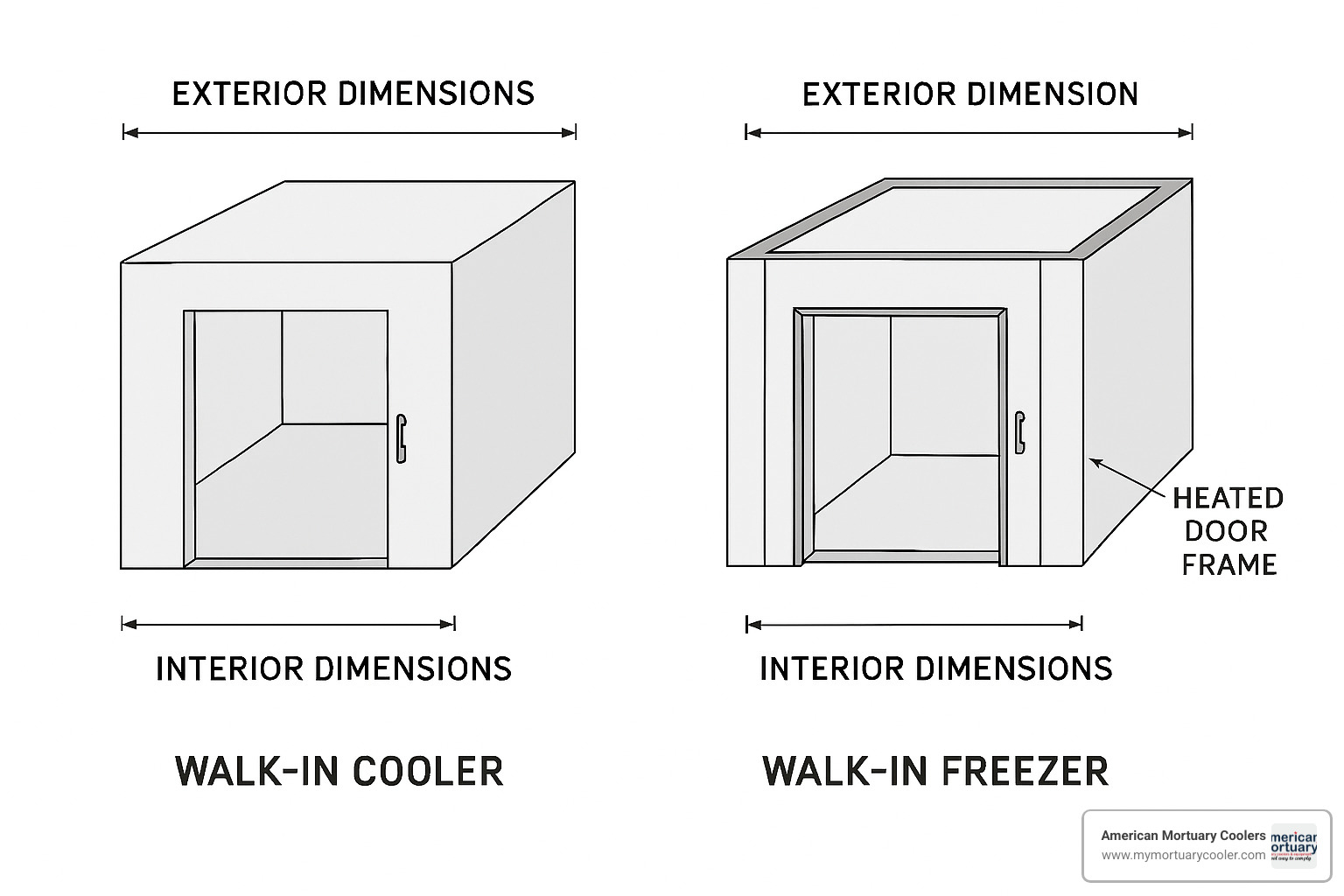

Walk-In Refrigerator vs. Walk-In Freezer Dimensions

When you're deciding between a walk-in cooler and freezer, the dimensional differences might surprise you. Walk in refrigerator dimensions change significantly when you move from cooler to freezer applications, and understanding these differences helps you plan your space properly.

The biggest difference comes down to panel thickness. Walk-in coolers typically use 4" thick panels, while freezers need 6" or even 8" thick panels to maintain those ultra-low temperatures. This might not sound like much, but it adds up quickly - those extra-thick panels reduce your interior space by 4-8" in each direction.

Think about it this way: a 10' x 10' exterior freezer with 6" panels gives you roughly 18" less interior space in each direction compared to a cooler with 4" panels. That's a significant chunk of storage capacity you're losing to insulation.

Thresholds and heated jambs add another layer of complexity to freezer installations. These heated door frames prevent ice buildup - trust me, you don't want to deal with a frozen-shut freezer door during a busy day. But these essential features require electrical connections and make the door frame thicker than standard cooler doors.

The temperature difference between -10°F for freezers and 35°F for coolers demands completely different insulation strategies. That extra insulation needed for freezers reduces your cubic-feet efficiency compared to cooler applications of the same exterior size. You're essentially trading storage space for temperature performance.

Combination units offer an interesting solution - both cooler and freezer sections in a single footprint. These units maximize versatility in smaller spaces, but they require careful planning to ensure you get adequate capacity for both temperature zones.

Key Dimension Differences

The cubic capacity loss from thicker freezer panels can catch you off guard if you're not prepared. That 10' x 10' exterior freezer we mentioned earlier? With 6" panels, you're looking at roughly 8'6" x 8'6" of interior space instead of the 9'4" x 9'4" you'd get with a 4" panel cooler.

Door construction changes dramatically between coolers and freezers too. Freezer doors typically measure 6-8" thick compared to just 4" for cooler doors. This affects your door swing clearances and frame requirements - you'll need more space around the door for proper operation.

Door heaters and pressure relief vents add their own dimensional considerations. Those heated frames extend beyond standard door profiles, so you'll need to account for that extra space in your planning. Pressure relief vents require specific placement to function properly without compromising the structural integrity of your unit.

The bottom line? Freezers require more space to achieve the same interior capacity as coolers. When planning your installation, factor in these dimensional differences early in the process. It's much easier to plan for the right size from the start than to find space constraints during installation.

Frequently Asked Questions about Walk-In Refrigerator Dimensions

What clearance do I need around the unit?

Ventilation clearances are critical for proper operation. We recommend minimum 2" clearance on sides and back, with 12" above the unit for heat dissipation. These clearances ensure adequate airflow for efficient refrigeration system operation.

Service access requirements may exceed ventilation needs. Refrigeration components need periodic maintenance, so plan for technician access to electrical panels, refrigeration connections, and control systems. Cramped installations increase service costs and reduce system reliability.

How do door type and placement impact usable space?

Hinged doors require swing clearance equal to the door width plus operating space. A 36" door needs approximately 40" of clearance for comfortable operation. This clearance reduces effective aisle width and may impact workflow efficiency.

Sliding doors eliminate swing requirements but need overhead track space and cost more initially. The space savings often justify the additional expense in tight installations where every square foot matters.

Traffic flow patterns affect door placement significantly. Doors should open toward the most common approach direction to minimize interference with normal operations. Poor door placement creates bottlenecks that reduce operational efficiency.

Can I expand my walk-in later?

Modular add-ons are possible with proper initial planning. The key is ensuring adequate space for expansion and access for panel installation. Removing and reinstalling panels requires some skill but doesn't need specialized equipment.

Panel swaps allow reconfiguration without complete replacement. Need to move a door location? Simply swap door panels with wall panels. This flexibility makes modular systems highly adaptable to changing needs.

Structural considerations may limit expansion options. Ensure adequate floor support for larger footprints and verify that building systems (electrical, HVAC) can accommodate increased loads from expanded units.

Conclusion

Choosing the right walk in refrigerator dimensions feels overwhelming at first, but it really comes down to understanding your needs today while planning for tomorrow. The best installations happen when you take time to consider everything – your current storage requirements, future growth plans, workflow patterns, and yes, your budget too.

We've walked through the standard sizes (that trusty 8' x 8' remains popular for good reason), capacity calculations using the 30-pound rule, and all those design factors that can make or break your installation. Modular panel construction gives you flexibility down the road – you're not locked into your initial decision forever.

At American Mortuary Coolers, we understand that funeral homes have unique requirements that go far beyond typical food service applications. Temperature control isn't just about efficiency in our industry – it's about dignity, respect, and meeting families' expectations during their most difficult moments.

Our Tennessee-based operation has been crafting custom mortuary coolers specifically for funeral professionals across all 48 contiguous states. We're not just another refrigeration company trying to adapt food service equipment. We design every unit with mortuary operations in mind, from the extra-sturdy construction to the precise temperature control that your profession demands.

Whether you need a standard configuration or something completely custom for that awkward space in your prep room, we deliver durable, custom solutions directly to your door. No middlemen, no confusion about who's responsible if something goes wrong – just straightforward service from people who understand your business.

The modular approach we use means your investment grows with you. Start with what you need now, then expand when business picks up or you add new services. It's much smarter than guessing wrong and paying twice.

Getting your dimensions right the first time saves headaches, money, and ensures your families receive the care they deserve. Take time to measure carefully, plan for growth, and don't hesitate to call us with questions. We've probably solved whatever challenge you're facing before.

For detailed pricing information that'll help you budget properly and compare options, check out our comprehensive guide: More info about walk-in cooler pricing.

Your walk-in refrigerator will serve families for decades when sized and built correctly. Let's make sure we get it right together.