Everything You Need to Know About Walk-In Cooler Door Hardware

The Complete Guide to Walk-In Cooler Door Hardware

Walk in cooler door hardware is the critical component system that ensures your cold storage operates efficiently, maintains temperature integrity, and provides reliable access. For anyone maintaining or replacing parts on a walk-in cooler, understanding these components is essential.

Quick Reference Guide to Walk-In Cooler Door Hardware:

| Component | Function | Common Materials | Price Range |

|---|---|---|---|

| Latches & Handles | Secure door closure with inside safety release | Stainless steel, Chrome-plated | $84-$450 |

| Hinges | Support door weight and allow smooth operation | Cam-lift design with steel pins | $50-$200 |

| Closers | Ensure automatic door closure | Hydraulic mechanisms | $75-$250 |

| Gaskets | Create airtight seal | Magnetic PVC, Double-sweep | $40-$150 |

| Pressure Relief Ports | Prevent vacuum formation | Heated aluminum/plastic | $30-$100 |

| Safety Releases | Allow exit from inside when locked | OSHA-compliant mechanisms | Included with latches |

The right hardware makes all the difference between a walk-in cooler that maintains perfect temperature with minimal energy consumption and one that leaks cold air through poor seals or misaligned components.

I'm Mortuary Cooler, a national-level supplier specializing in walk-in cooler systems including the critical walk in cooler door hardware that ensures optimal performance in mortuary and food service applications.

Walk in cooler door hardware further reading:

Walk-In Cooler Door Hardware 101

Ever wonder what makes those massive walk-in cooler doors work so smoothly? Let me walk you through walk in cooler door hardware – the unsung heroes keeping your cold storage running efficiently.

Think of your walk-in cooler door as a carefully orchestrated system. It's typically a 4-inch thick insulated panel with impressive R-values between 28-32, surrounded by a frame housing various hardware components.

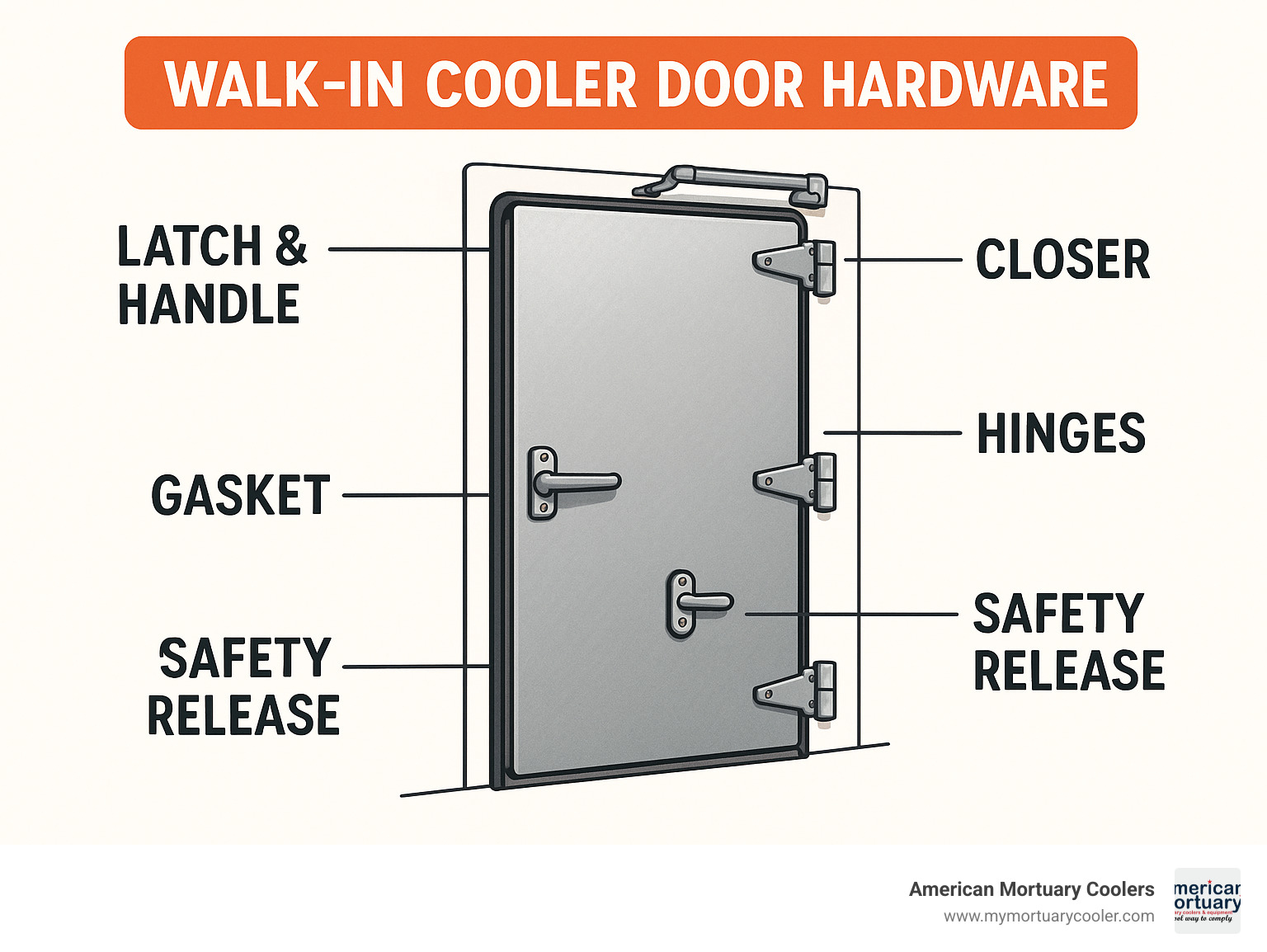

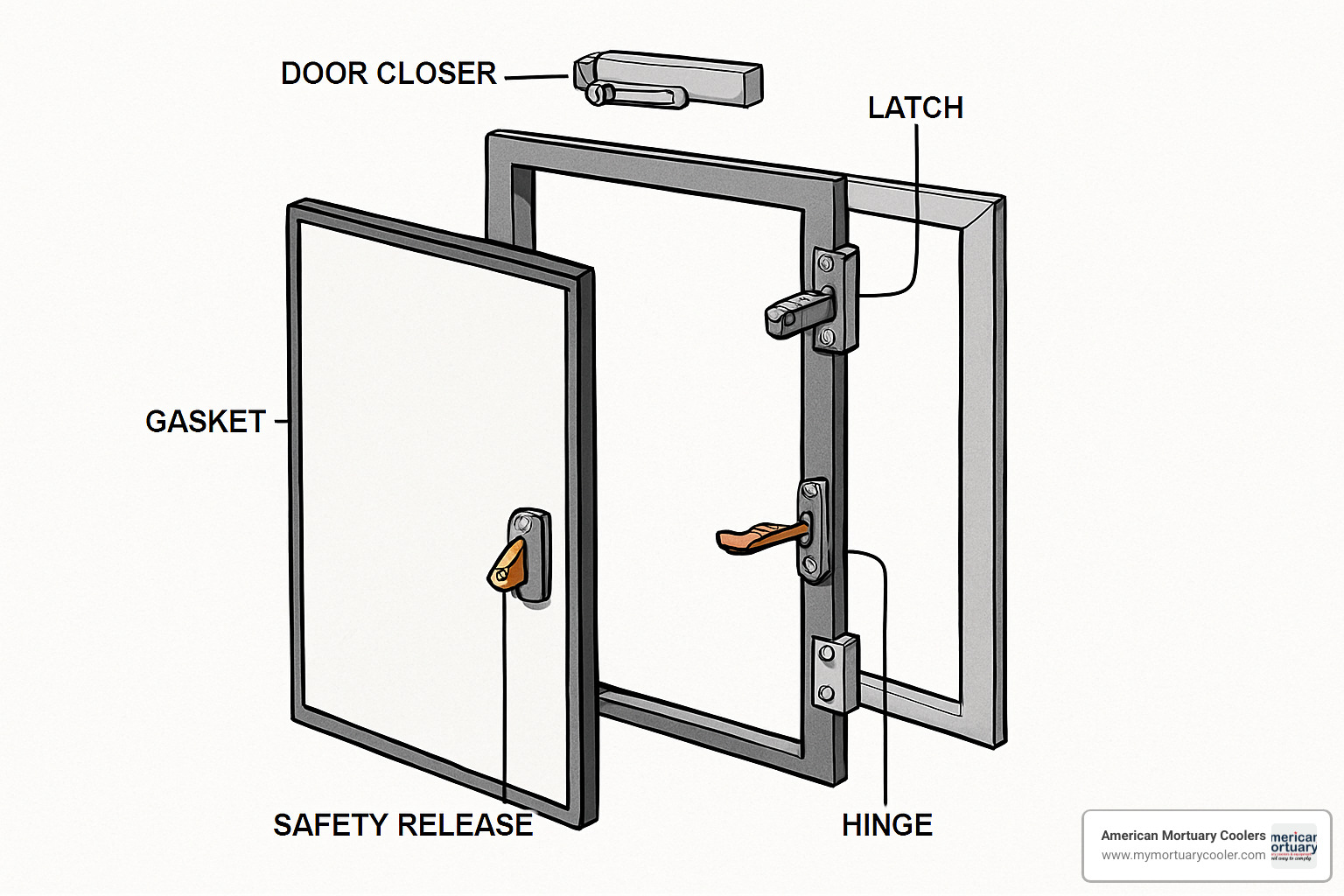

Main Types of Walk-In Cooler Door Hardware

Latches and handles are the heart of any door system. Modern options like the Kason 0056 or Keil W19 include OSHA-required safety release mechanisms and often come with locking capabilities. Basic models start around $84, while premium locking versions can run up to $443.

Hinges do the heavy lifting – literally. The industry standard cam-lift hinges slightly raise the door during opening, clearing floor sweeps and reducing gasket wear. Good hinges support twice the door's weight, ensuring years of smooth operation.

Door closers automatically pull the door shut, preventing those "oops, I left it open" moments that spike energy bills. Quality closers include tension adjustment features for fine-tuning closing speed.

Gaskets and sweeps are the heroes of energy efficiency. The magnetic gasket creates the primary seal around the door perimeter, while sweeps prevent cold air from escaping underneath.

View windows let you peek inside without opening the door, while pressure relief ports prevent vacuum formation when warm air inside the cooler cools and contracts. In freezers, these ports are typically heated to prevent icing.

Kick plates protect against bumps from carts and foot traffic, and safety releases allow anyone accidentally locked inside to exit.

Sliding vs. Swing vs. High-Speed Door Systems

Swing doors use cam-lift hinges, latches with safety releases, and hydraulic closers. They need less space alongside the door but require room for the swing arc.

Sliding doors shine in tight spaces, using track systems with rollers and anti-derailment devices. Their specialized latches pull the door tight against seals for a secure closure.

High-speed doors feature motorized operation with sophisticated control systems and safety sensors. While more expensive, they quickly pay for themselves in energy savings for high-traffic applications.

| Door Type | Hardware Components | Best Application | Approximate Cost |

|---|---|---|---|

| Swing | Hinges, latches, closers, magnetic gaskets | Standard coolers, low-medium traffic | $1,000-$2,300 |

| Sliding | Tracks, rollers, anti-derail systems, pull-tight latches | Large openings, space constraints | $2,000-$5,000 |

| High-Speed | Motors, control systems, safety sensors, curtain or panel | Very high traffic, loading docks | $5,000-$15,000 |

How Walk-In Cooler Door Hardware Affects Energy Efficiency

Industry data shows that a properly sealed and maintained door can slash energy costs by 10-15% compared to one with worn or misaligned hardware.

Thermal breaks in quality door frames prevent cold transfer through metal components. Magnetic gaskets create that crucial airtight seal when properly aligned. (Pro tip: Worn gaskets are among the most common energy wasters.)

Auto-closers prevent costly mistakes. A door left ajar for just 20 minutes can raise internal temperature by 7-10°F, forcing your refrigeration system into overdrive.

Proper hinge alignment keeps the door perfectly aligned with gaskets for optimal sealing, while pressure relief ports prevent vacuum formation that can strain your gaskets and seals.

For more detailed information about cooler features that work alongside your hardware, check out our complete guide to walk-in cooler features and prices.

Selecting the Right Hardware for Your Application

Choosing the right walk in cooler door hardware can feel overwhelming. Whether you're replacing worn-out parts or selecting components for a new installation, the decisions you make now will impact performance for years to come.

Key Features to Compare Before Buying

Your cooler environment should guide hardware decisions. Working in a humid coastal area? That 304 stainless steel hardware isn't just a luxury—it's practically a necessity to avoid rust issues. For truly harsh environments with heavy cleaning chemicals, 316 stainless offers the ultimate protection.

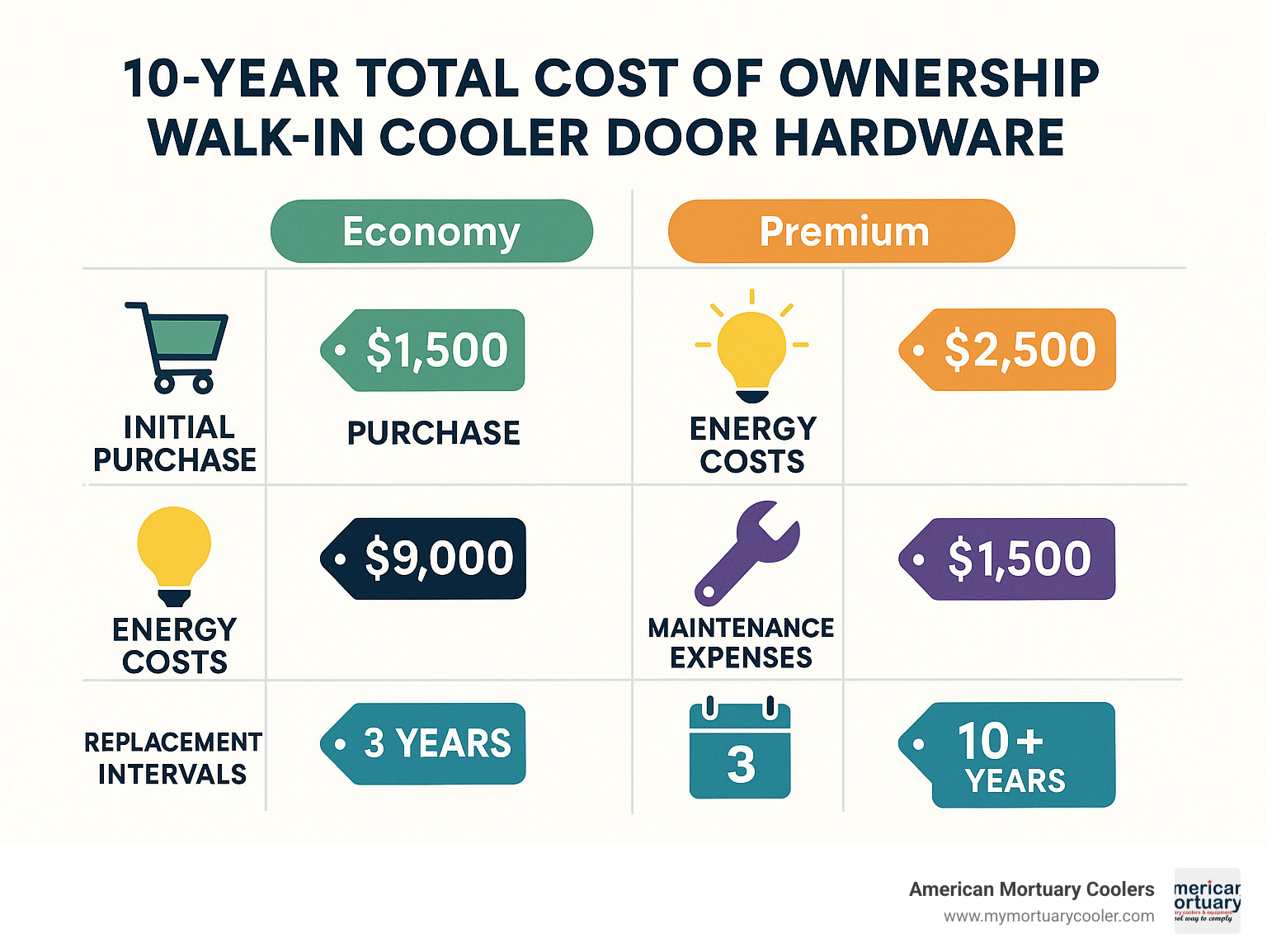

Durability matters, especially in busy facilities. Economy-grade hardware can fail within months in high-traffic settings, while premium components soldier on for years. Anodized aluminum offers a middle ground—lightweight but still resistant to most environmental challenges.

Always check for proper certifications and compliance. NSF approval ensures food safety, while UL certification confirms electrical components meet safety standards. OSHA compliance for inside release mechanisms is non-negotiable.

Temperature rating is critical. Standard cooler hardware designed for 32°F to 41°F will fail prematurely in freezer applications. For mortuary applications, components rated for standard cooler temperatures typically suffice.

Price tiers generally reflect quality and longevity. Economy hardware ($84-$150) might make sense for temporary installations. Most commercial facilities are better served by mid-range options ($150-$300). For critical applications where downtime isn't acceptable, premium hardware ($300-$450) offers peace of mind.

KIT Form vs. Pre-Assembled Doors

KIT form doors reduce freight expenses by up to 50% compared to bulky pre-assembled doors. Components arrive in manageable packages that can be easily transported through narrow hallways—a real advantage in older buildings with limited access.

Kits offer flexibility for on-site customization and allow replacement of individual components rather than entire assemblies. With industry-wide delays affecting custom units, standard KIT components might be available immediately from stock.

Pre-assembled doors eliminate potential errors during installation, reducing on-site work by 60-75%. Factory testing ensures each door is checked for proper operation before shipping, and some manufacturers offer more comprehensive warranties on pre-assembled units.

Retrofitting & Replacement Checklist

When replacing hardware on existing walk-in cooler doors, accurate measurements make all the difference.

Door measurements form the foundation of your replacement project. Most walk-in cooler doors are 4" thick, but they can range from 3.5" to 6", so don't assume—measure!

Strike offset requirements often cause confusion. This is the distance between the door edge and frame, and it varies widely. Selecting latches with compatible strike plates for your specific offset ensures proper sealing.

Your gasket profile must match your door channel dimensions exactly. If you're still using older compression gaskets, consider upgrading to magnetic versions for better sealing.

Frame type compatibility matters tremendously. Flush mount plug doors with frames require different hardware than overlap doors with face case frames.

For freezer doors, verify electrical requirements for heater wires to prevent frost buildup that could impair operation.

Finally, check for adequate space for the door swing or slide path to avoid clearance issues.

For more detailed guidance on specific components like thresholds, check out our A Practical Guide to Finding the Right Walk-In Cooler Threshold.

Installation, Maintenance & Safety Standards

Let's explore the practical side of walk in cooler door hardware. Getting these components installed correctly and maintaining them properly isn't just about efficiency—it's about safety, compliance, and protecting your investment.

Step-by-Step Hardware Installation Basics

Proper installation begins with careful preparation. Before picking up a single tool, read through all manufacturer instructions and verify that all components arrived intact.

Ensure your door frame is perfectly square and level, using shims where needed. Keep your torque wrench handy, as proper fastener tension is critical for long-term performance.

When installing hinges (typically three per standard door), position them precisely according to manufacturer's specifications. Use only the recommended stainless steel fasteners and tighten them to the specified torque values—usually between 10-15 ft-lbs.

For latches and handles, positioning at the correct height (typically 36"-42" from the floor) ensures comfortable operation. The strike plate must align perfectly with the latch mechanism. Before finalizing the installation, verify that the inside safety release operates smoothly.

Door closers require careful adjustment to achieve the ideal closing speed—typically 5-7 seconds. After installation, test repeatedly to ensure the door closes fully and latches automatically every time.

Preventive Maintenance & Common Repairs

A simple monthly inspection routine can catch small issues before they become major problems:

- Examine gaskets for tears or compression set

- Test the inside safety release mechanism

- Check that the door closes completely on its own

Quarterly, lubricate hinges with food-grade lubricant and check all fasteners for tightness. For freezer doors, test heater wires to prevent ice buildup.

Warning signs that components need replacement include visible corrosion, doors that won't close completely without help, gaskets that remain compressed after the door opens, or ice buildup despite proper defrost cycles.

Compliance & Safety Must-Haves

OSHA regulations require that all walk-in cooler doors include an inside safety release mechanism. This critical feature prevents anyone from being accidentally trapped inside.

For sliding doors, anti-derail systems prevent dangerous situations where doors could jump their tracks. Self-closing devices aren't just about convenience; many health departments require them to ensure temperature control and food safety.

Freezer doors have additional requirements, including heated components to prevent ice formation that could impair operation.

The regulatory landscape includes several important standards:

- OSHA 29 CFR 1910.36 covering exit route requirements

- NSF/ANSI Standard 7 for commercial refrigeration equipment

- UL 471 standards for commercial refrigerators and freezers

- Local health department regulations (which vary by jurisdiction)

At American Mortuary Coolers, we understand that proper installation and maintenance of walk in cooler door hardware is especially critical in mortuary applications. For more information on specific components, check out our guide to finding the right walk-in cooler threshold.

Brands, Costs & Modular Solutions You Should Know

When it comes to walk in cooler door hardware, not all brands are created equal. The right hardware can make the difference between a door that works flawlessly for a decade and one that causes headaches after just a few months.

Leading Models & Their Distinguishing Features

Kason Industries stands out with their premium 0056 Series latches ($249-$443). These aren't just latches – they're workhorses designed to operate smoothly even after years of heavy use. Their padlock hasps and cylinder locks provide security, while the mandatory inside safety releases ensure no one gets accidentally trapped.

For tighter budgets, Kason's 0027C offers a solid middle-ground at around $204. Their brushed chrome finish hides fingerprints and food splatter beautifully.

Component Hardware/Keil offers more economical options without sacrificing essential functionality. Their W19 Series starts at just $84 and includes various strike options to accommodate different door offsets.

If you're dealing with sliding doors, MIV/BMP Group deserves your attention. Their track systems and rollers glide smoothly even when frost tries to gum up the works.

U.S. Cooler takes a more integrated approach, offering complete door assemblies where all components are designed to work together harmoniously.

Other well-known manufacturers in the walk-in refrigeration space include Kolpak, Bally Refrigerated Boxes, Norlake, Imperial-Brown, Amerikooler, and Arctic Walk-Ins. While these companies primarily focus on entire walk-in boxes rather than hardware alone, their doors can usually be upgraded or retrofitted with the modular hardware options discussed here.

Economy hardware ($84-$150) works fine for light-duty situations, mid-range options ($150-$300) hit the sweet spot for most standard commercial applications, while premium hardware ($300-$450) proves its worth in harsh environments.

Benefits of Modular & Customizable Hardware

Modular hardware systems shine when downtime isn't an option. Instead of replacing an entire door assembly when a latch fails, you simply swap out the broken component and get back to business.

The cost savings are substantial – replacing a $200 latch beats installing a $2,000 door any day. For growing businesses, modular systems offer flexibility to reconfigure or expand as needs change.

The customization possibilities are particularly valuable. You might start with standard latches now but upgrade to locking models later as security needs evolve.

At American Mortuary Coolers, we've found that our funeral industry clients particularly value this modularity. When a family is waiting to view their loved one, there's simply no room for equipment failure. The ability to quickly replace a single component ensures continuous, respectful service during sensitive times.

For facilities planning future expansion, modular hardware offers another advantage: you can start with basic components and upgrade specific elements as your budget allows.

Frequently Asked Questions about Walk-In Cooler Door Hardware

We regularly receive questions about walk in cooler door hardware from customers across various industries. Here are answers to the most common inquiries:

What hardware lasts longest in corrosive kitchens?

In environments with high humidity, frequent cleaning with chemical agents, or exposure to salt, 304 or 316 stainless steel hardware offers the best longevity. While more expensive initially, stainless steel components typically last 2-3 times longer than chrome-plated or galvanized alternatives.

For moderate environments, brushed chrome finishes provide a good balance of corrosion resistance and value. If budget constraints are significant, look for hardware with protective coatings or anodized aluminum components.

How do I know my gasket needs replacing?

Gaskets typically require replacement when you observe:

- Visible damage: Tears, cracks, or chunks missing

- Compression set: The gasket remains compressed when the door opens

- Hardening: The gasket feels stiff rather than pliable

- Mold growth: Black spots or discoloration that cannot be cleaned

- Frost or condensation: Moisture or ice forming around the door perimeter

- Light visibility: When inside the closed cooler with lights off, you can see light around the edges

Most commercial walk-in cooler gaskets should be replaced every 1-2 years depending on usage patterns.

Are KIT doors DIY-friendly?

KIT-form walk-in cooler doors can be installed by experienced maintenance personnel with proper tools, but consider these factors:

DIY-Friendly Aspects:

- KIT doors come with detailed instructions and all necessary hardware

- Components are designed for logical assembly

- Individual components are lighter and easier to handle than pre-assembled doors

Potential Challenges:

- Precise alignment is critical for proper sealing and operation

- Some components require specific torque settings

- Electrical connections for heater wires require basic electrical knowledge

- Two-person installation is typically required for safety and proper alignment

For basic swing door installations in existing frames, DIY installation is reasonable for those with good mechanical skills. For sliding doors, high-speed doors, or new frame installations, professional installation is recommended.

What causes a walk-in door to stop sealing tightly?

Several factors can cause sealing failures:

- Hinge Issues: Worn or improperly adjusted hinges allow the door to sag

- Gasket Deterioration: Over time, gaskets harden, compress permanently, or tear

- Frame Damage: Impacts from carts or equipment can bend door frames

- Closer Malfunction: When door closers fail to pull the door completely shut

- Floor Settlement: Building settlement can cause frames to shift out of square

The solution depends on the specific cause but often involves adjusting or replacing hinges, realigning the frame, replacing gaskets, or servicing door closers and latches.

How often should door closers be adjusted?

Door closers typically require adjustment:

- Quarterly in high-traffic environments (20+ door operations per hour)

- Semi-annually in moderate-use facilities (5-20 door operations per hour)

- Annually in light-use applications (fewer than 5 door operations per hour)

The ideal closing time from 90 degrees open to fully closed is typically 5-7 seconds.

Conclusion

After exploring the ins and outs of walk in cooler door hardware, one thing becomes crystal clear – these components aren't just parts, they're the guardians of your cold storage investment. Even the most powerful refrigeration system can't overcome a poorly sealed door that leaks cold air.

The quality of your hardware directly impacts your bottom line. Premium components might cost more upfront, but they'll reward you with years of reliable service, lower energy bills, and fewer emergency calls.

Your environment should guide your material choices. Working in a steamy kitchen with harsh cleaning chemicals? Stainless steel components will serve you faithfully. Operating in a drier, less demanding space? Chrome-plated options might offer the perfect balance of performance and value.

Safety isn't something to compromise on – ever. Those inside safety releases might seem like a minor detail until someone finds themselves accidentally locked in a walk-in. OSHA requirements aren't just bureaucratic red tape; they protect people and prevent potentially tragic situations.

A simple maintenance schedule can prevent costly failures. A quick monthly check of gaskets, quarterly lubrication of hinges, and annual inspection of all components can extend hardware life by years.

The flexibility of modular systems has been a game-changer for many customers. When a component fails, being able to replace just that part rather than ordering an entire door assembly means the difference between a minor inconvenience and a major disruption.

At American Mortuary Coolers, we understand that reliable cold storage isn't just important – it's essential. Our Tennessee-based team has spent years perfecting custom mortuary coolers with hardware systems that stand the test of time. We're proud to deliver our solutions directly to customers across the lower 48 states, bringing quality cold storage to funeral homes nationwide.

The journey through walk in cooler door hardware might seem technical, but at its heart, it's about reliability. It's about the peace of mind that comes from knowing your cooler will maintain perfect temperature day after day.

For more specialized information about mortuary cooling solutions, check out our detailed guide on mortuary coolers.