Everything You Need to Know About Refrigerated Trailers

Why Refrigerated Trailers Are Essential for Temperature-Controlled Transport

A refrigerated trailer is an insulated mobile unit equipped with a cooling system that maintains specific temperatures for transporting temperature-sensitive goods. These "reefers" can maintain temperatures ranging from -20°F to 55°F, making them crucial for preserving everything from food and pharmaceuticals to flowers and medical supplies.

Key Refrigerated Trailer Facts:

- Temperature Range: -20°F to 55°F (-29°C to 13°C)

- Common Sizes: 6'×8' to 53' lengths

- Power Options: Electric (110V), diesel, or generator

- Main Types: Single-temp, multi-temp, and specialized pharma units

- Applications: Food transport, events, emergency storage, healthcare

The cold chain industry relies heavily on these mobile refrigeration units. The key thing to remember is that refrigerated trailers are designed to maintain temperature, not rapidly cool products.

Whether you need temporary cold storage for an event, emergency backup during equipment failures, or regular transport of perishables, understanding how these systems work is essential. From small 6'×8' units perfect for catering to massive 53' semi-trailers for long-haul transport, there's a refrigerated trailer solution for every need.

I'm Mortuary Cooler, and I've spent years helping funeral homes and healthcare facilities across the nation find reliable refrigerated trailer solutions that meet their specific temperature control needs.

Refrigerated trailer further reading:

Refrigerated Trailer Basics: How a Reefer Works

Understanding How it Works – Refrigerated Trailers is key to making smart decisions about your cold storage needs.

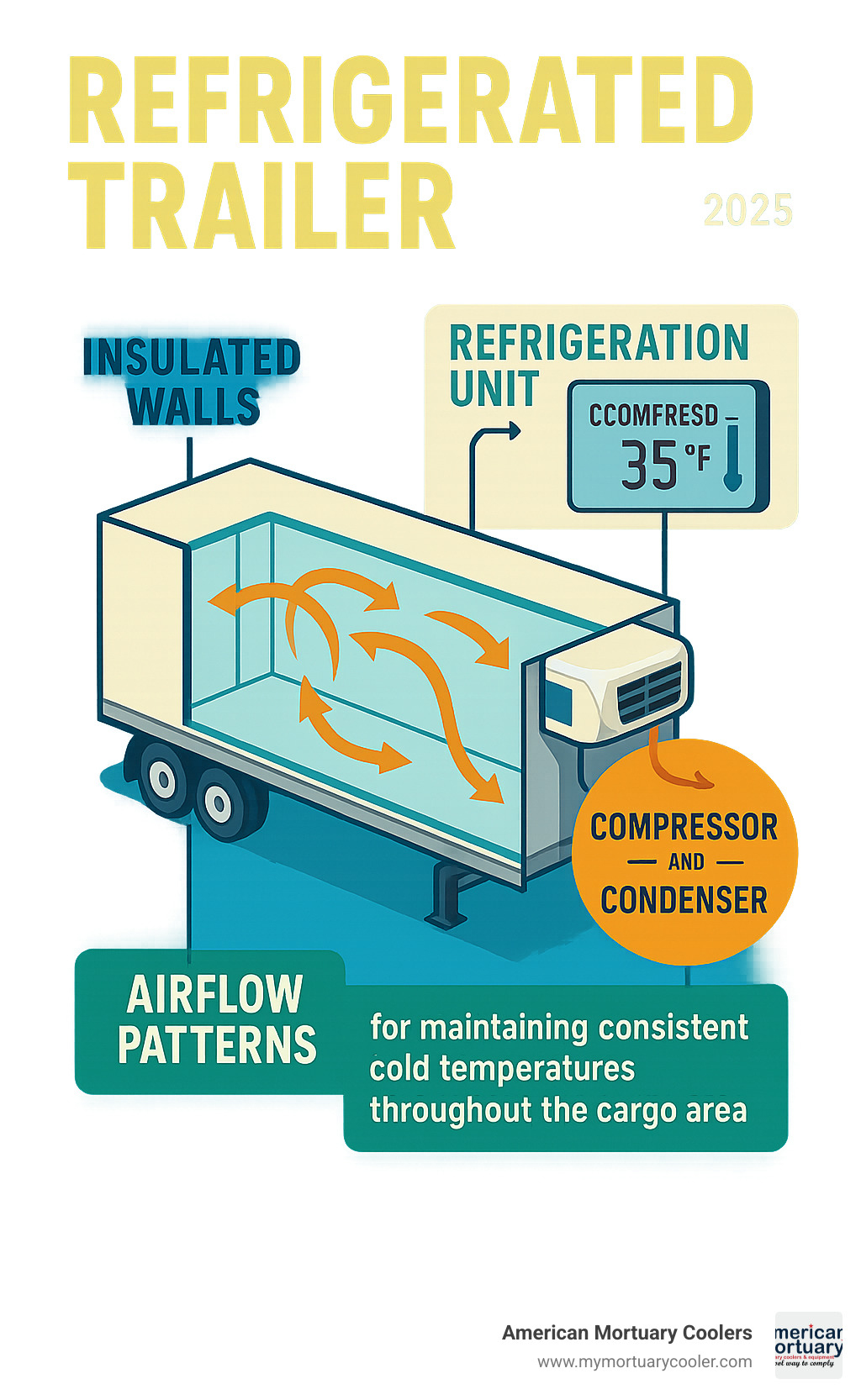

A refrigerated trailer works like your home refrigerator's big brother. The compressor squeezes refrigerant gas until it's hot and pressurized. This hot gas flows to the condenser where it releases heat and transforms into liquid. The liquid refrigerant passes through an expansion valve, dropping pressure and becoming super cold. Finally, this cold refrigerant enters the evaporator coils inside your trailer, absorbing heat from your cargo and turning back into gas.

With proper maintenance, a quality refrigeration unit can maintain temperatures from -20°F to 55°F for years of dependable service.

What is a Refrigerated Trailer (Reefer Trailer)?

A refrigerated trailer is a fortress against heat, designed to keep temperature-sensitive cargo exactly where it needs to be. Quality reefers feature seamless fiberglass construction with 4 inches of insulation wrapping the entire cargo area.

The real magic happens with airflow paths engineered throughout the trailer. Cold air circulates in carefully designed patterns to ensure every corner stays at the right temperature. It's a closed system that works continuously to maintain temperatures.

Remember: reefers are designed to maintain temperature, not cool down warm products. Load your goods pre-cooled, and your refrigerated trailer will keep them perfect.

Key Components & Power Sources

The compressor is the heart of the operation. Modern units come with microprocessor controls that make temperature management incredibly precise. The condenser sits on the exterior with metal fins for efficient heat transfer. Inside, evaporator coils do the actual cooling work with strategic placement for optimal airflow.

Diesel engine units are workhorses for long-haul transport, running independently without external power. Shore power units plug into standard electrical outlets for stationary use. Generator power provides flexibility when electrical hookups aren't available, while solar-assist systems offer environmental benefits and fuel savings.

Types, Sizes & Specifications

| Type | Temperature Zones | Typical Use | Size Range |

|---|---|---|---|

| Single-Temp | One uniform temperature | General food transport | 6'×8' to 53' |

| Multi-Temp | 2-3 separate zones | Mixed cargo loads | 28' to 53' |

| Specialized Pharma | Ultra-precise control | Vaccines, medicines | Various sizes |

When it comes to refrigerated trailers, one size definitely doesn't fit all. I've helped countless customers find the perfect match for their needs, and the variety available today is remarkable.

Single-temp units are the workhorses of the industry. They maintain one consistent temperature throughout the entire cargo area, making them perfect when you're transporting similar products. Whether you need to keep produce at 34°F or ice cream at -10°F, these units do one job exceptionally well.

Multi-temp trailers are the Swiss Army knives of cold transport. With bulkheads creating 2-3 separate temperature zones, you can haul frozen pizzas and fresh lettuce on the same trip. It's like having multiple trailers in one, which can be a real game-changer for efficiency.

Specialized pharma units represent the gold standard of temperature control. These units don't just maintain temperature - they guard it with their lives. With ultra-precise sensors and backup systems, they're designed for cargo where even a few degrees can mean the difference between life-saving medication and expensive waste.

The size range is equally impressive. From compact 6'×8' units perfect for catering events to massive 53-foot semi-trailers that can haul entire grocery store orders, there's a size for every application. The cubic-foot capacities scale accordingly, with payload limits varying based on the specific model and configuration.

Modern units like the GOVI Arktik systems are designed for efficiency, running on standard 110V 15A power while providing reliable cooling. The 4-inch insulation standard across quality units ensures your temperature stays where you set it, even in challenging conditions.

Standard & Specialty Refrigerated Trailer Options

The Utility 3000R has earned its reputation as the #1 selling reefer in North America since 1994, according to In-Depth Guide to Reefer Trailers: Understanding the Basics (1). That's quite a track record, and it speaks to the reliability operators need in real-world conditions.

For smaller operations, Polar King Mobile trailers offer right-sized solutions. Their seamless fiberglass construction eliminates the weak points that can lead to temperature loss over time. I've seen these units perform beautifully for everything from farmers market vendors to small restaurant chains.

Slip-in boxes provide incredible flexibility for pickup trucks and smaller vehicles. They're perfect when you need refrigeration but don't want to commit to a dedicated trailer. Think of them as the convertible option in the refrigerated world.

At American Mortuary Coolers, we specialize in mortuary coolers - a very specific type of refrigerated unit designed for funeral homes and healthcare facilities. These aren't your typical food transport units. They're built with dignity and reliability in mind, providing the respectful, temperature-controlled environment that our industry demands.

Temperature Ranges & Control Technology

Here's where things get really impressive. Modern refrigerated trailers can achieve temperatures as low as -4°F for freezer applications and maintain comfortable 0°F to 50°F ranges for cooler needs. The most versatile units handle the full spectrum from -20°F to 55°F, giving you maximum flexibility for different cargo types.

The control technology has come a long way from simple thermostats. Dual-zone sensors monitor temperature at multiple points throughout the cargo area, ensuring no hot spots develop. Data loggers create detailed temperature records - essential for compliance in food service and pharmaceutical transport.

Remote monitoring systems are becoming standard on many units. Imagine getting an alert on your phone if the temperature drifts even a degree outside your set range. It's like having a dedicated technician watching your cargo 24/7, which provides incredible peace of mind when you're transporting valuable or critical items.

Applications and Real-World Use Cases

The true power of refrigerated trailers shines through their incredible versatility. The Science Behind a Reefer Trailer's Cool Temperatures reveals the fascinating engineering behind these workhorses.

Industries that Rely on Refrigerated Trailers

Foodservice operations depend on temperature control. Restaurant chains, catering companies, and food distributors know that one broken cold chain can mean thousands in lost inventory and health risks. Refrigerated trailers provide flexibility to transport everything from ice cream to fresh produce.

Agriculture has acceptd mobile refrigeration. Dairy farmers transport milk to processing facilities, while produce growers rely on them to get delicate berries to market before spoiling.

The pharmaceutical industry takes temperature control to another level. When dealing with vaccines or life-saving medications, specialized pharma trailers come with backup systems, continuous monitoring, and detailed documentation.

Retail operations use refrigerated trailers for emergencies. When a supermarket's refrigeration fails, a temporary trailer can save thousands in inventory.

Government agencies, from military operations to disaster relief, depend on mobile refrigeration for field kitchens, emergency medical supplies, and crisis storage.

Case Studies & Testimonials

A small catering company invested in their first refrigerated trailer for a large outdoor festival. The trailer not only helped them succeed at that event but opened up an entire new market. As the owner said, "Our entire experience was a stellar example of customer service and satisfaction."

Emergency response stories are dramatic. A busy supermarket lost power during Friday lunch rush. Their backup refrigerated trailer saved thousands in frozen and fresh foods while customers barely noticed the problem.

Healthcare facilities face unique challenges. During major renovation, one hospital used multiple refrigerated trailers to maintain food service and medication storage, allowing normal operations during system upgrades.

At American Mortuary Coolers, we've seen how reliable temperature control transforms operations across all these industries.

Choosing, Renting or Buying the Right Refrigerated Trailer

Choosing between renting and buying a refrigerated trailer comes down to understanding your specific needs and usage frequency.

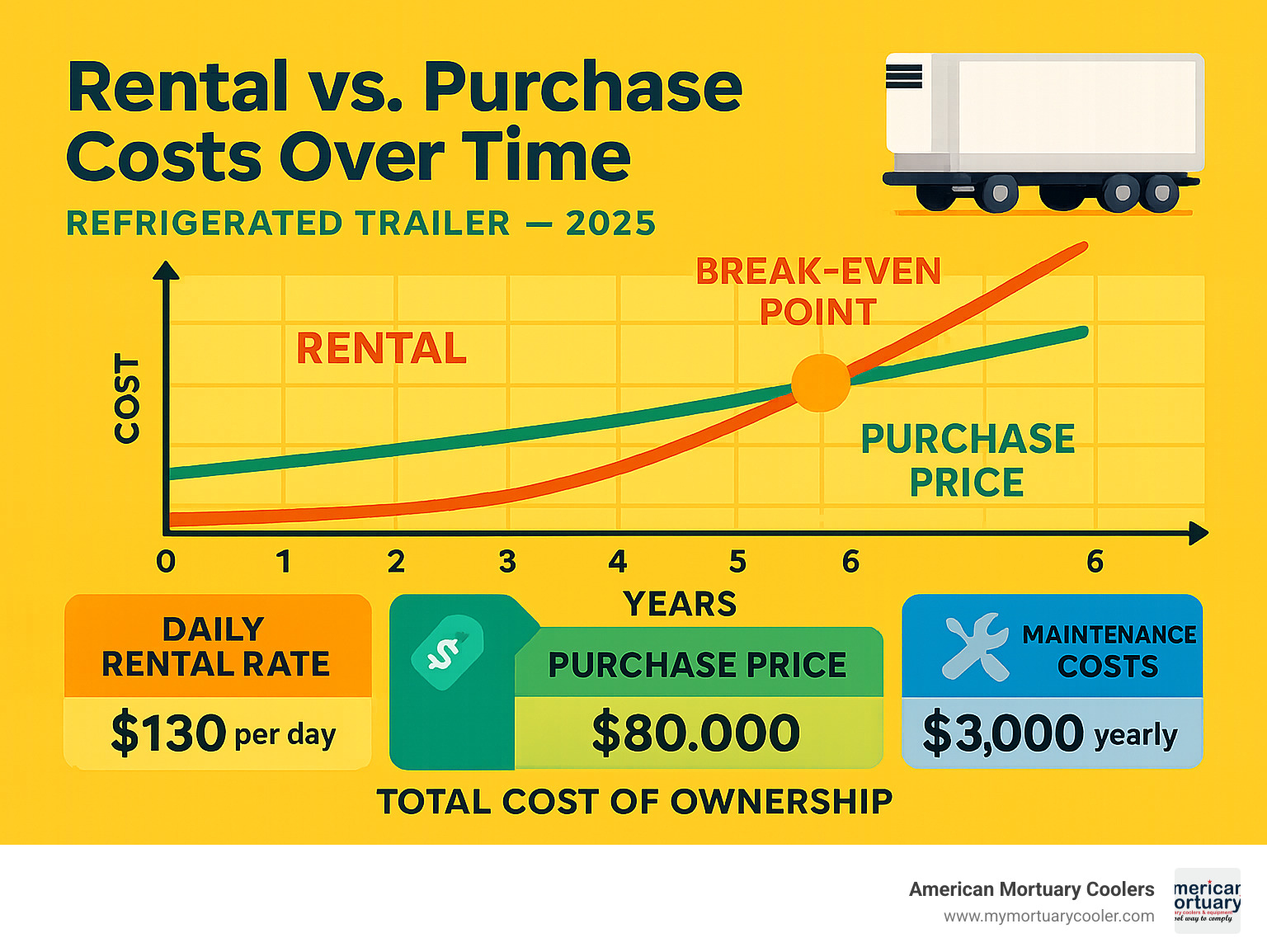

If you only need cold storage occasionally - for special events or seasonal peaks - rental makes sense. Costs range from $130 per day to $1,340 per week for smaller units. Renting means someone else handles maintenance, and you're not stuck with a depreciating asset.

For regular operations requiring consistent cold storage, purchasing becomes smarter financially. Upfront costs range from $25,000 to $150,000+, but long-term savings add up with regular use.

Leasing offers a middle ground with predictable monthly payments and often includes service packages.

| Option | Best For | Typical Costs | Advantages |

|---|---|---|---|

| Rental | Occasional use, events | $130-$1,340/week | No maintenance, lower upfront cost |

| Purchase | Regular use, business operations | $25,000-$150,000+ | Long-term savings, customization |

| Lease | Predictable usage, tax benefits | Monthly payments | Newer equipment, service included |

For more guidance, see A Practical Guide to Reefer Refrigerated Trailer Options.

Evaluating a Refrigerated Trailer for Your Operation

Whether buying new or used, thorough inspection saves thousands later. Check door seals carefully - they're often first to fail. Feel along insulation for soft spots or damage. Verify floor rating can handle your typical loads.

The refrigeration unit deserves special attention. Look for refrigerant leaks, listen for unusual noises, and verify all connections are clean. Run the unit through a full cooling cycle to confirm it reaches required temperatures.

Modern refrigerated trailers include telematics and monitoring systems that prevent costly product losses. Documentation tells the real story - maintenance records and service history give insight into what you're buying and affect resale value.

Costs, Financing & Customization

The purchase price is just the beginning. Maintenance is your biggest ongoing expense - plan for oil changes every 1,500 hours, regular inspections, and occasional major repairs.

Customization can pay off. Generators enable off-grid operations. Loading ramps help with heavy cargo. Partition systems can transform single-temp units into multi-temperature powerhouses. Monitoring systems provide real-time temperature tracking that can literally save your business.

Financing options include traditional loans for ownership, leasing with maintenance packages, or rent-to-own programs. Match your financing to your business model - leasing might provide flexibility for growing operations.

Operating & Maintaining a Refrigerated Trailer Safely

Proper maintenance isn't just about avoiding repairs - it ensures cargo safety and smooth operations. The golden rule is maintenance every 1,500 operating hours.

Your routine should cover: oil and filter changes at 1,500-hour intervals, regular belt and hose inspections, thorough cleaning of air passages and floor channels, and calibration of temperature sensors.

Airflow verification is critical but often overlooked. If air can't circulate properly, you'll have hot spots that ruin cargo.

Compliance requirements include FSMA regulations, NATM guidelines, and HACCP logging. Keep detailed records - they're your best defense if questions arise.

Refrigerated Trailer Loading, Stacking & Airflow Tips

Proper loading makes the difference between consistent temperatures and product loss. Pallet patterns matter - leave space between pallets and walls for air circulation. Pack too tightly, and you'll create dead zones where temperatures spike.

Keep floor channels clear - they're essential for air circulation. Even small debris can disrupt airflow patterns.

For multi-temp units, bulkheads separate temperature zones. Strip curtains dramatically reduce temperature loss when opening doors.

Follow proper door-open protocol by turning off refrigeration before opening doors. This prevents the system from working overtime cooling incoming warm air.

Compliance, Documentation & Common Misconceptions

The biggest misconception: refrigerated trailers are designed to maintain temperature, not cool products down. Load products at correct pre-chilled temperature, and your trailer will keep them there reliably.

Temperature records with continuous monitoring prove you maintained the cold chain. Calibration certificates show sensor accuracy. Maintenance logs demonstrate proper equipment care.

Driver training is essential - the best equipment won't help if operators don't understand procedures. Modern units are quieter and more environmentally friendly than older models.

Frequently Asked Questions about Refrigerated Trailers

Let me answer the most common questions I hear from customers looking for refrigerated trailer solutions. These are the real concerns that keep people up at night when they're trying to make the right choice for their business.

How cold can a refrigerated trailer get?

Here's something that surprises many people: most refrigerated trailers can get surprisingly cold - down to -20°F (-29°C) in the best units. That's colder than most home freezers!

For everyday use, freezer applications typically run at -4°F (-20°C), which is perfect for frozen foods, ice cream, and other products that need to stay rock solid. The exact temperature your unit can achieve depends on two main factors: the power of the refrigeration system and the quality of insulation.

High-end units with superior insulation and powerful refrigeration systems can maintain these ultra-low temperatures even when it's blazing hot outside. I've seen units keep products frozen solid in 100°F+ weather - it's pretty impressive technology when you think about it.

What size refrigerated trailer do I need?

This is where I see people make the biggest mistakes - either going too small and regretting it later, or buying way more capacity than they'll ever use.

Small trailers (6'×8' to 6'×16') are perfect for catering companies, small restaurants, or if you only need cold storage occasionally. These compact units are easy to tow and don't require special licensing.

Medium units (20' to 28') work great for regional distribution, farmers markets, or businesses that need regular but not massive cold storage. They hit that sweet spot between capacity and maneuverability.

Large semi-trailers (48' to 53') are the workhorses of major distribution routes. If you're moving serious volume or need long-term storage, these giants can handle thousands of cubic feet of cargo.

My advice? Consider both your current needs and where you'll be in two years. It's better to have a little extra space than to outgrow your unit quickly. But don't go crazy - you'll pay for unused capacity every month.

Should I rent or buy a refrigerated trailer?

This question keeps me busy! The answer depends on your specific situation, but I can give you the framework to decide.

Rent if you need occasional use - like seasonal businesses, special events, or emergency backup. Renting makes sense when you want someone else handling maintenance headaches and you don't want a big upfront investment.

Buy if you have regular, predictable usage that justifies the investment. Our research shows the break-even point typically hits around 2-3 years of regular use, depending on rental rates versus purchase price.

Here's the real-world math: if you're renting more than a few weeks per year, buying probably makes financial sense. Plus, when you own it, you can customize it exactly how you want and you're building equity instead of just paying rent.

The sweet spot? If you're using a refrigerated trailer more than 60 days per year, buying usually wins. Less than that, and renting keeps your options open without the commitment.

Conclusion

Finding the right refrigerated trailer doesn't have to be overwhelming. Whether you need a compact 6'×8' unit for catering or a massive 53' semi-trailer for distribution, the perfect solution exists for your needs.

Refrigerated trailers are designed to maintain temperature, not rapidly cool products. Load products at the right temperature, follow proper airflow guidelines, and your reefer will serve you reliably for years.

At American Mortuary Coolers, we've built our reputation on understanding that reliability is absolutely critical. When families are counting on us during difficult moments, there's no room for equipment failure. That's why we've spent years perfecting custom solutions and building relationships with clients across all 48 contiguous states.

Our experience in funeral and healthcare industries has taught us that every application is unique. A mortuary cooler in humid Tennessee faces different challenges than one in the desert Southwest. We don't believe in one-size-fits-all solutions. Instead, we work with each client to understand their specific needs and deliver equipment that performs flawlessly.

The refrigerated trailer industry continues evolving with better insulation, more efficient refrigeration, and smarter monitoring technology. Solar-assist options are becoming popular for environmental benefits and cost savings. Remote monitoring systems provide peace of mind by alerting operators to temperature deviations before problems occur.

Whether you're exploring refrigerated transport options or looking to upgrade existing equipment, choose a partner who understands your industry and stands behind their equipment. From our Tennessee base, we've delivered custom solutions from Johnson City to Los Angeles.

For those considering broader options, The Ultimate Guide to Refrigerated Truck Options offers additional insights.

The cold chain depends on reliable equipment and knowledgeable operators. With the right refrigerated trailer and proper maintenance, you'll have confidence that your temperature-sensitive cargo will arrive in perfect condition, every single time.