Everything You Need to Know About Pull Behind Freezer Trailers

Why Pull Behind Freezer Trailers Are Essential for Mobile Cold Storage

A pull behind freezer trailer is a towable refrigerated unit that provides portable cold storage ranging from -20°F to +50°F, powered by standard 110V household outlets or generators. These compact mobile freezers offer businesses and organizations flexible cold storage solutions without the high costs of refrigerated trucks or permanent walk-in coolers.

Quick Facts About Pull Behind Freezer Trailers:

- Size Range: 5'x10' to 7'x16' (148-600 cubic feet)

- Temperature: -20°F to +50°F (dual cooler/freezer modes)

- Power: 110V/15A standard household outlet

- Rental Cost: $130-$220 per day, $715-$1,190 per week

- Purchase Price: $25,000-$50,000 new

- Payload: Up to 9,990 lbs with dual 5,200 lb axles

- Uses: Restaurants, catering, events, emergency backup, farming

From catering companies and restaurants seeking a refrigerated trailer solution, to farmers that need to transport produce—the demand in North America for a commercial grade, yet affordable solution to refrigerated transport has not been addressed until now. These trailers fill the gap between expensive refrigerated trucks and stationary walk-in coolers.

Key advantages include:

- Easy towing with standard pickup trucks

- Seamless fiberglass construction with 4-inch insulation

- Digital temperature control switching between freezer and cooler modes

- No CDL required for operation

- 70% lower insurance costs than refrigerated trucks

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping businesses select the right pull behind freezer trailer for their specific needs. My background includes working with funeral homes, restaurants, and emergency services to deploy mobile cold storage solutions nationwide.

Basic pull behind freezer trailer terms:

Pull Behind Freezer Trailer Fundamentals

Getting to know pull behind freezer trailers means understanding what makes them tick from the ground up. These aren't just boxes on wheels with a cooling unit slapped on top. They're carefully engineered mobile cold storage systems that bring together smart construction, reliable refrigeration, and real-world practicality.

What is a pull behind freezer trailer?

A pull behind freezer trailer is essentially your cold storage solution that goes wherever you need it. Think of it as a walk-in cooler that decided to grow wheels and hit the road. The bumper-pull design means it hooks right up to your standard hitch—no special equipment or commercial license needed.

What really sets these units apart is the monoblock refrigeration system. Most quality trailers use something like the GOVI arktik 2000US unit, which is basically the workhorse of the portable refrigeration world. This all-in-one system keeps things simple while delivering serious cooling power.

The digital controller is where the magic happens. You can switch from deep freeze mode for storing ice cream to cooler mode for keeping produce fresh, all with the push of a button.

How does a pull behind freezer trailer work?

The science behind your pull behind freezer trailer is surprisingly straightforward. It uses the same vapor-compression cycle that keeps your home refrigerator humming, just scaled up for commercial needs.

Here's how it works: The compressor squeezes the refrigerant, making it hot and pressurized. This hot refrigerant flows through the condenser (usually mounted on top), where it cools down and turns into a liquid. Then it passes through an expansion valve, which drops the pressure and temperature dramatically.

This super-cold liquid refrigerant flows through evaporator coils inside your trailer, absorbing heat from the air and keeping your products cold. The beauty of modern units is their 110V/15A plug-in design. You literally just plug it into any standard household outlet with an extension cord. The hot-gas defrost system automatically prevents ice buildup.

Main uses & industries that benefit

Restaurants love these trailers for emergency backup when their main cooler goes down. Caterers practically live by these units for outdoor events. Florists use them to keep arrangements fresh during transport. Farmers maintain the cold chain from harvest to market. Disaster relief organizations deploy these for emergency food storage. Pharmaceutical companies use them for vaccine storage during transport. Hunting operations rely on portable freezer trailers for proper game processing.

Key features & construction materials

Quality pull behind freezer trailers start with seamless fiberglass construction. Unlike aluminum units that dent and corrode, fiberglass stays smooth and easy to clean for decades. The real insulation hero is 4-inch polyurethane foam in the walls, floor, and ceiling.

Inside, you'll find antimicrobial gel coat surfaces that meet NSF food safety standards. The pallet-duty floor with aluminum base plates means you can roll heavy loads in and out with forklifts or pallet jacks. The reinforced 54-inch doors feature stainless steel frames and EPDM seals that maintain their grip for years.

GOVI refrigeration units with cold plate technology provide backup cooling even when power is temporarily interrupted.

| Feature | Pull Behind Freezer Trailer | Walk-in Cooler |

|---|---|---|

| Mobility | Fully portable, towable | Permanent installation |

| Power Requirements | 110V/15A standard outlet | 220V hardwired connection |

| Installation Time | Ready in 1 hour | 1-3 days professional install |

| Permits Required | None (under 10,000 lbs) | Building permits, inspections |

| Insurance Cost | 70% lower than reefer trucks | Property insurance rates |

| Temperature Range | -20°F to +50°F | Typically single-temp |

For more details about traditional cold storage costs, check out our guide on antimicrobial gel coating benefits for food service applications.

Sizing, Temperature & Power Options

Finding the right pull behind freezer trailer is like choosing the perfect tool for your job. Too small, and you'll be making multiple trips. Too large, and you're paying for space you don't need while dealing with a heavier trailer that's harder to tow.

Standard sizes & capacities of a pull behind freezer trailer

The 5'x10' compact units with 148 cubic feet are perfect for florists or small restaurants needing emergency backup storage. These single-axle trailers with 3,500 lb capacity tow easily behind most SUVs.

6'x8' models provide 336 cubic feet of storage—enough for a weekend farmers market or small catering event. The 5,200 lb single axle provides better stability while maintaining easy towing.

The 6'x12' mid-size trailers at 500 cubic feet hit the sweet spot for many caterers and farmers market vendors. With dual 3,500 lb torsion axles providing 7,000 lb GVWR, these units handle substantial loads while remaining manageable.

For serious commercial applications, 6'x16' large units offer 600 cubic feet of storage with dual 5,200 lb torsion axles supporting up to 9,990 lbs payload capacity. These are ideal for transporting heavy items like meat or dairy products.

The largest standard offerings are 7'x12' and 7'x16' commercial models, providing maximum cubic footage for high-volume applications.

Temperature ranges & refrigeration units

Pull behind freezer trailers provide impressive temperature flexibility. The GOVI arktik 2000US refrigeration system found in quality units provides an impressive range from -20°F to +50°F, all controlled by a simple digital display.

This multi-temp capability means your trailer can store frozen ice cream at -10°F for a summer festival one weekend, then switch to storing fresh produce at 35°F for a farmers market the next.

The cold plate technology offers another approach entirely. These systems store refrigeration energy during overnight charging, then maintain temperatures for 8-10 hours without external power.

Power sources & electrical specs

One of the biggest advantages of modern pull behind freezer trailers is their power flexibility. Standard units operate on 110V/15A household power—the same draw as your microwave. This means you can plug into any standard outlet using a heavy-duty extension cord.

When electrical service isn't available, generators provide reliable power. Most refrigeration units require only 1,800-2,000 watts. Solar-assisted systems combine battery banks with solar panels for environmentally conscious operations.

| Size | Cubic Feet | Standard Amps | BTU Output | Axle Configuration |

|---|---|---|---|---|

| 5'x10' | 148 | 15A @ 110V | 8,500 BTU | Single 3,500 lb |

| 6'x8' | 336 | 15A @ 110V | 10,200 BTU | Single 5,200 lb |

| 6'x12' | 500 | 15A @ 110V | 12,500 BTU | Dual 3,500 lb |

| 6'x16' | 600 | 15A @ 110V | 15,000 BTU | Dual 5,200 lb |

| 7'x16' | 672 | 20A @ 110V | 17,400 BTU | Dual 5,200 lb |

Buying, Renting & Operating Tips

Making the smart choice between buying and renting a pull behind freezer trailer comes down to understanding your real needs and crunching the numbers honestly.

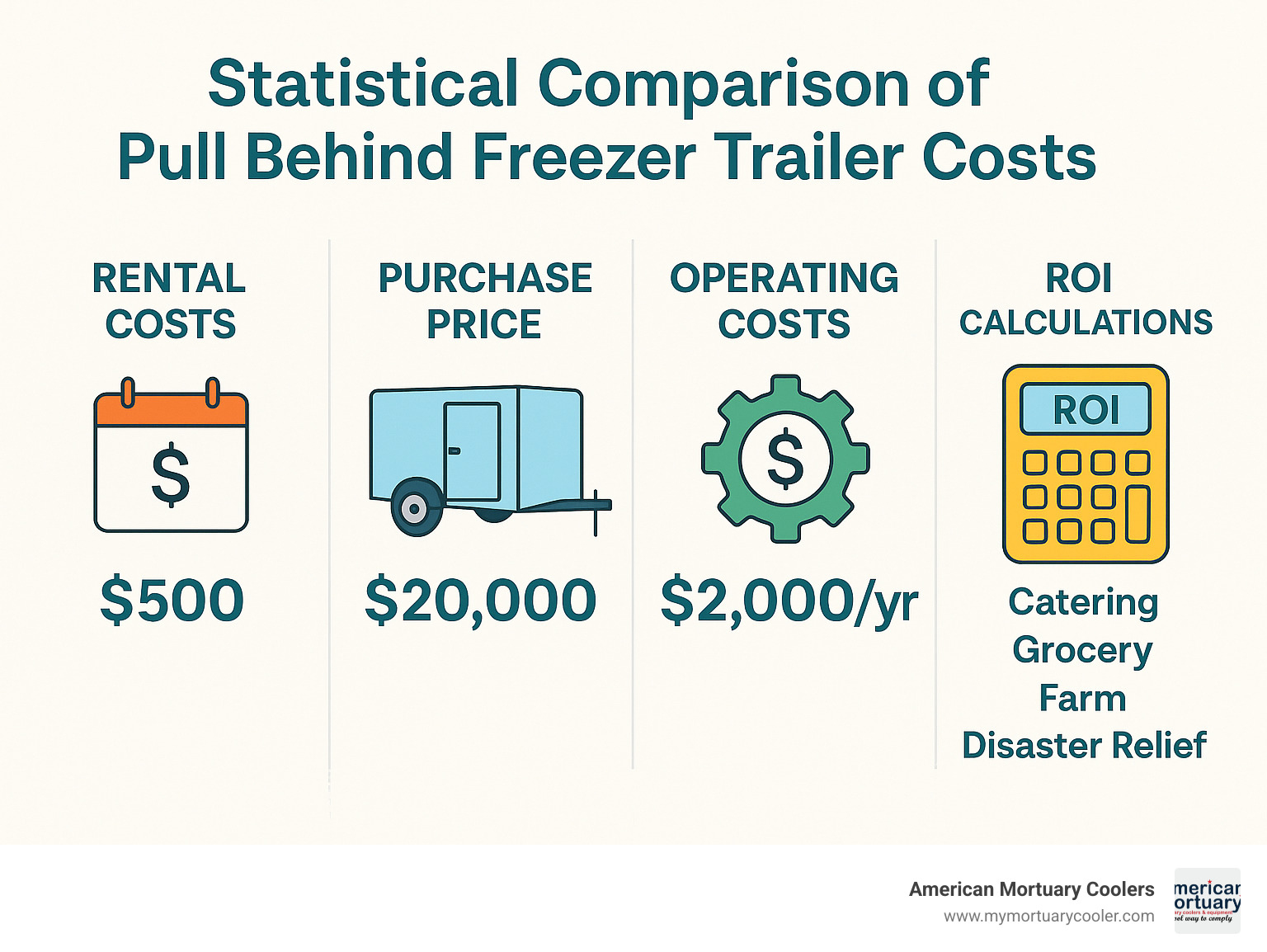

Purchase vs rental: costs & ROI

Pull behind freezer trailer rentals currently run $130-$220 per day, $715-$1,190 per week, and $2,505-$3,750 per month. Those rates typically include delivery and pickup within 30 miles.

New pull behind freezer trailers start around $25,000 for a basic 5'x10' unit and can reach $50,000+ for fully-loaded 7'x16' models. Used units offer 30-50% savings, but inspect that refrigeration system carefully.

Here's the magic number: if you're using a trailer more than 60 days per year, buying usually makes sense. The resale value story gets even better. Quality manufacturers back up their claims about holding value, and some customers rent their trailers to other businesses during slow periods, earning $500-$1,000 monthly.

What to look for when choosing a trailer

Not all pull behind freezer trailers are built the same. Axle rating matters more than most people realize. If you're hauling meat, you need dual 5,200 lb axles. Frame construction separates the pros from the wannabes. Look for galvanized steel or heavy tubular steel frames.

The insulation quality should be four-inch polyurethane as standard. Refrigeration units need to be purpose-built for mobile applications. The GOVI arktik 2000US series represents the gold standard.

Modern security features like GPS tracking are becoming essential. Door hardware might seem like a small detail, but cheap hinges and seals lead to temperature problems. Stainless steel frames and commercial-grade locks are worth every penny.

For more guidance on selecting commercial refrigeration equipment, check out our complete guide to commercial walk-in freezer cost.

Customization & accessories

The beauty of modern pull behind freezer trailers lies in their flexibility. Adjustable shelving systems with E-track mounting let you reconfigure storage on the fly. Freezer/cooler bulkheads create dual-temperature zones in one trailer.

Generator packages open up off-grid possibilities. Don't forget the basics: spare tires, tire pressure monitoring, and emergency repair kits. Loading aids like ramps and lift gates might seem like luxury items until you're loading 200 cases of frozen food by hand.

Operating, towing & maintenance

Successfully operating a pull behind freezer trailer starts with proper towing setup. You'll need a Class III hitch rated for 5,000+ pounds and an electric brake controller. Half-ton pickups handle smaller units fine, but 6'x16' and larger trailers often require 3/4-ton vehicles.

Tongue weight should be 10-15% of total trailer weight. Annual refrigeration service prevents emergency calls. Monthly defrost cycle inspections ensure proper ice removal. For food applications, NSF cleaning requirements mean regular sanitization with approved cleaners.

Safety, Compliance & Real-World Performance

Operating a pull behind freezer trailer involves various safety and regulatory considerations that ensure both legal compliance and operational safety.

Certifications & regulations to know

NATM Compliance: The National Association of Trailer Manufacturers (NATM) Compliance Verification Program ensures trailers meet Federal Motor Vehicle Safety Standards.

DOT Requirements: While pull behind freezer trailers under 10,000 lbs GVWR don't require commercial licensing, they must still comply with basic DOT safety standards including proper lighting, braking systems, and safety chains.

NSF and UL Certifications: Food service applications require NSF approval for interior surfaces and UL certification for electrical components.

Food-Grade Liners: Interior surfaces must use FDA-approved materials for direct food contact. Quality manufacturers include antimicrobial gel coatings that prevent bacterial growth.

Emergency & backup scenarios

Pull behind freezer trailers excel in emergency situations where traditional cold storage fails or isn't available:

Power Outage Response: When facility power fails, these trailers provide immediate backup cold storage. Restaurant owners particularly value this capability.

Hospital Overflow: During pandemic peaks, hospitals used refrigerated trailers for temporary morgue capacity and medical supply storage.

Storm Relief Operations: Emergency management agencies deploy pull behind freezer trailers for disaster relief food distribution in areas where infrastructure is damaged.

Mobile Morgue Applications: Funeral homes and coroner's offices use these trailers for temporary body storage during mass casualty events. For more information on this application, see our guide on freezer trucks as morgues.

User testimonials & case studies

Real-world performance data demonstrates the reliability and versatility of quality pull behind freezer trailers:

Catering Success Story: A Montreal rental business owner shared: "We purchase cold wall units annually for event rentals. The durability and minimal repair needs make them an excellent investment."

Farmer Market Application: A fifth-generation farmer reported: "Using our refrigerated trailer to transport certified naturally grown produce in hot weather has been game-changing. The temperature control keeps everything fresh from field to customer."

Long-Term Reliability: Quality units demonstrate exceptional longevity. While poor-quality trailers may fail in 5 years, properly maintained high-quality pull behind freezer trailers regularly provide 10-20 years of reliable service.

Frequently Asked Questions about Pull Behind Freezer Trailers

Let's tackle the most common questions we hear from customers considering their first pull behind freezer trailer. After helping businesses nationwide with mobile cold storage solutions, these are the questions that come up again and again.

How cold can a pull behind freezer trailer get?

Modern pull behind freezer trailers can reach impressive temperatures between -10°F to -20°F in sub-zero mode. This makes them perfect for everything from ice cream storage to long-term frozen food preservation.

Most standard units running on 110V power can reliably hit 0°F, which handles the majority of freezing applications. If you need those deeper temperatures for ice cream or specialty frozen products, 220V systems can push down to -20°F without breaking a sweat.

The GOVI arktik 2000US refrigeration system found in quality units provides rock-solid temperature control even when Mother Nature isn't cooperating. We've seen units maintain -10°F during scorching summer days in places like Daytona Beach—that's some serious cooling power.

What vehicle do I need to tow one?

The good news is you probably already have what you need. Most pull behind freezer trailers work great with a standard half-ton pickup truck equipped with a Class III hitch (5,000+ lb capacity).

Here's the breakdown: Smaller units like 5'x10' and 6'x8' trailers can be towed by most SUVs and pickup trucks without any issues. Mid-size trailers (6'x12' and 6'x16') need at least a half-ton pickup for safe operation. The largest units (7'x12' and 7'x16') might require a 3/4-ton vehicle, especially when fully loaded.

Don't forget about the electric brake controller—it's required for safe stopping and honestly makes towing much more comfortable. Always check that your vehicle's towing capacity covers both the trailer weight and whatever you plan to haul inside.

Can the same trailer switch between cooler and freezer?

Absolutely, and this is one of the best features of modern pull behind freezer trailers. The dual-mode digital controllers let you switch between cooler and freezer temperatures with just a few button presses.

Picture this: Monday you're storing ice cream at -10°F for a wedding reception. Wednesday you flip the switch and you're keeping fresh produce at 35°F for a farmers market. Same trailer, completely different applications.

The GOVI arktik systems handle the full temperature range from -10°F to +50°F, making these trailers incredibly versatile. This flexibility means you don't need separate freezer and cooler units—one trailer can handle whatever your business throws at it.

Conclusion

When your restaurant's walk-in cooler dies at 5 PM on a Friday, or when you need to keep wedding flowers fresh at an outdoor venue, a pull behind freezer trailer becomes more than just equipment—it becomes your business lifeline. These versatile units have proven themselves across countless real-world scenarios, from emergency disaster relief to high-end catering events.

The beauty of a quality pull behind freezer trailer lies in its simplicity and reliability. You don't need a commercial driver's license, expensive insurance, or complex maintenance schedules. Just hook it up to your pickup truck, plug it into any standard outlet, and you have professional-grade cold storage wherever you need it.

The investment pays for itself quickly. Restaurant owners save thousands in spoiled inventory during power outages. Caterers expand their service radius and take on larger events. Farmers maintain the cold chain from field to farmers market. Emergency responders deploy critical cold storage within hours of a disaster.

Quality matters tremendously in this industry. While cheaper units might seem tempting, they often fail within five years. Premium pull behind freezer trailers with proper insulation, reliable GOVI refrigeration systems, and seamless fiberglass construction regularly provide 10-20 years of dependable service.

At American Mortuary Coolers, we've seen how the right mobile cold storage solution transforms businesses. Our experience across Tennessee and throughout all regions of the United States has taught us that every operation has unique needs. Whether you're a funeral home needing temporary morgue capacity, a restaurant requiring emergency backup, or a caterer serving outdoor events, we understand the critical role reliable refrigeration plays in your success.

We don't just sell equipment—we solve problems. Our custom approach means you get exactly the features, size, and capacity that match your specific requirements. From compact 5'x10' units perfect for florists to large 7'x16' commercial models for major catering operations, we deliver solutions that work.

The nationwide delivery across all 48 contiguous states means you're never too far from the mobile cold storage solution you need. Our Tennessee-based team combines decades of refrigeration expertise with the flexibility to customize units for specialized applications.

For businesses still weighing their cold storage options, our complete guide to choosing a walk-in freezer provides additional insights into permanent versus mobile solutions.

Ready to find how a pull behind freezer trailer can revolutionize your cold storage capabilities? Contact our team today for personalized recommendations. We'll help you choose the right size, features, and configuration to meet your specific operational needs and budget requirements.