Everything You Need to Know About Morgue Freezer 12

Why Morgue-Freezer-12 Units Are Essential for Modern Facilities

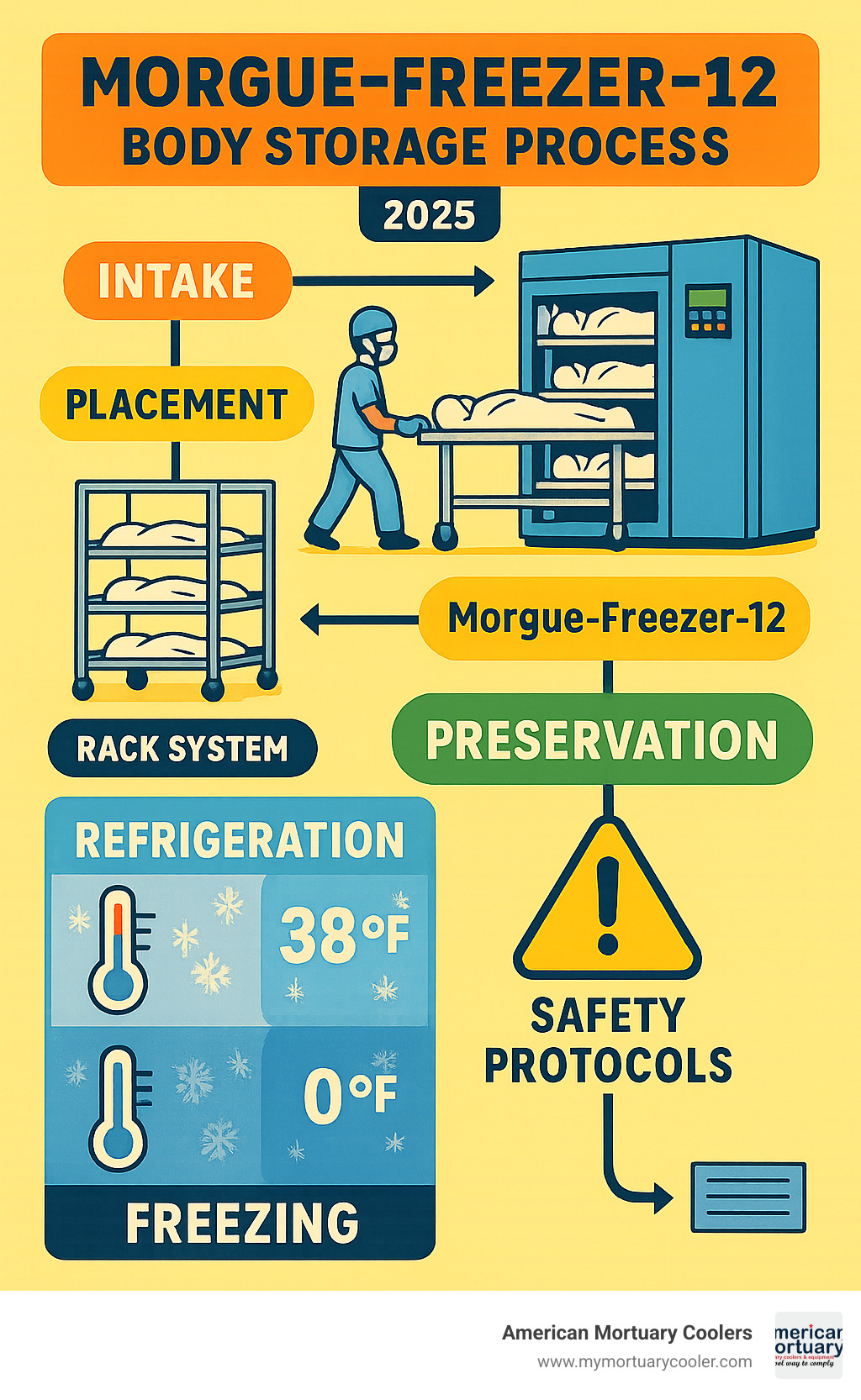

A morgue-freezer-12 is a specialized refrigeration unit designed to store up to 12 bodies in individual compartments, maintaining precise temperatures between 38°F for refrigeration or 0°F for freezing. These high-capacity units are essential for hospitals, funeral homes, forensic institutions, and disaster response facilities that need reliable, large-scale body storage.

Quick Morgue-Freezer-12 Overview:

- Capacity: 12 individual body compartments with telescopic racks

- Temperature Range: 38°F (refrigeration) to 0°F (freezing)

- Power: 208-230V single-phase or 115V plug-in options

- Construction: 4" urethane insulation, stainless steel trays, magnetic gaskets

- Installation: Ships knocked-down for on-site assembly

The mortuary industry has seen continuous improvements in refrigeration technology, with manufacturers emphasizing "modern technology, economic efficiency and German preciseness, with continuous improvements for improved performance and reduced energy consumption." Today's morgue-freezer-12 units feature digital temperature controllers, antimicrobial finishes, and energy-efficient compressors that significantly reduce operating costs compared to older models.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral facilities select the right morgue-freezer-12 solutions for their specific needs. My background in US cooler supply has shown me how proper capacity planning and equipment selection can transform facility operations and service quality.

Simple guide to morgue-freezer-12:

Morgue-Freezer-12 Essentials

When you're looking at morgue-freezer-12 units, you're really looking at the backbone of professional mortuary facilities. These aren't just big refrigerators - they're carefully engineered systems that handle one of the most important aspects of funeral service and forensic work.

Let me break down what makes these units so essential. A morgue-freezer-12 is basically a specialized refrigeration system that stores up to 12 bodies in separate compartments. Each compartment maintains precise temperatures, whether you need 38°F for refrigeration or 0°F for freezing. Think of it as having 12 individual climate-controlled spaces, each doing its job perfectly.

The beauty of the 12-body capacity is that it hits that sweet spot. You're not scrambling with a tiny 2-body unit when things get busy, but you're also not dealing with a massive walk-in system that might be overkill for your needs. Hospitals use these for temporary storage before transferring patients to funeral homes. Forensic labs rely on them for evidence preservation during investigations. Funeral homes love having 12 separate compartments because they can handle different preservation needs at the same time.

Disaster response is where these units really shine. During mass casualty events or public health emergencies, you need storage capacity fast. The knocked-down shipping design means these units can squeeze through standard doorways and get assembled right where you need them. It's like having emergency surge capacity that actually works when you need it most.

You'll find both upright and walk-in configurations available, depending on your space and workflow needs. The upright models work great for most facilities, while walk-in versions offer easier access for facilities with high throughput requirements.

Standard Dimensions for morgue-freezer-12

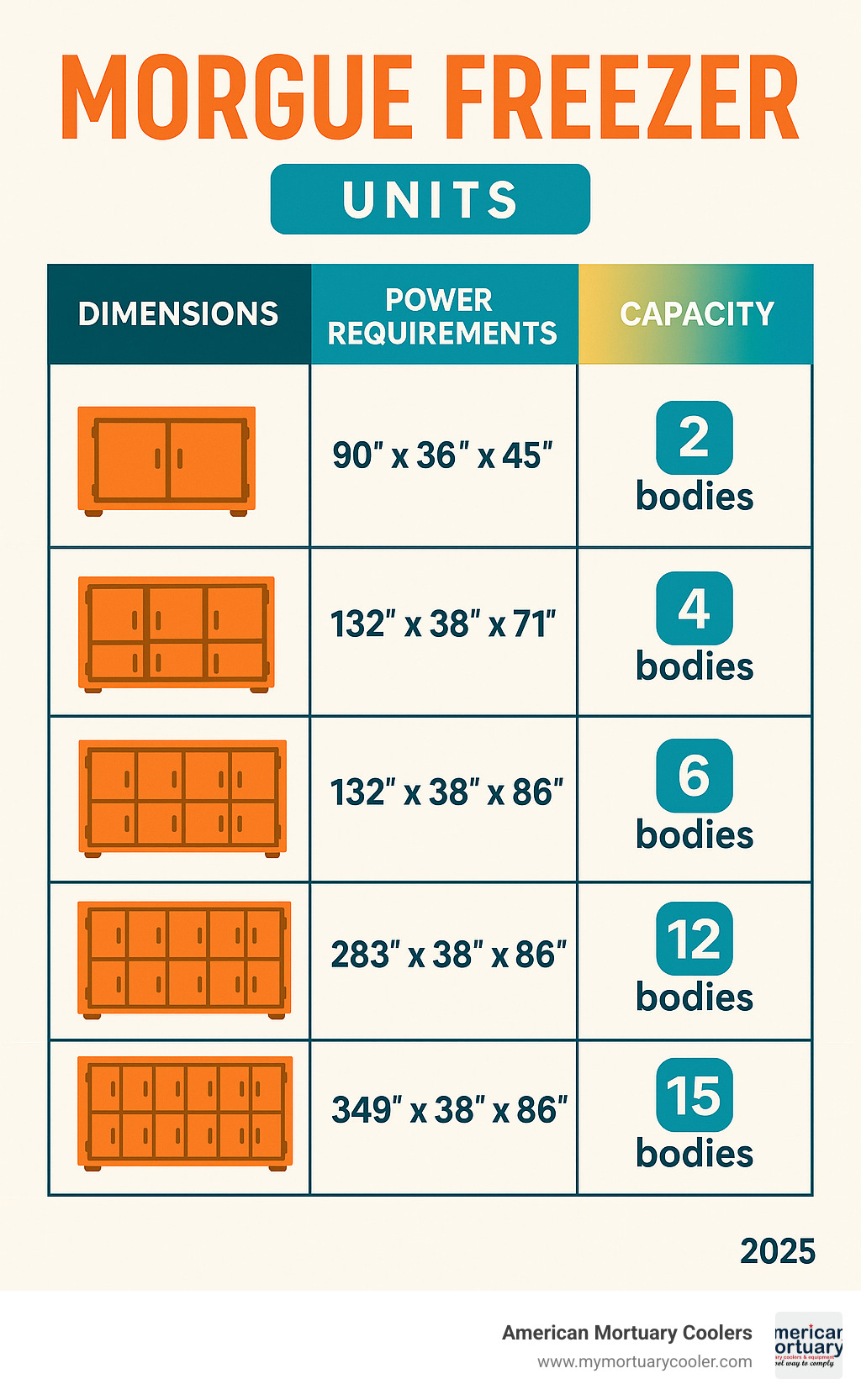

Here's where the engineering really matters. A standard morgue-freezer-12 measures 153 inches wide, 97 inches deep, and 109.5 inches high. Those aren't random numbers - they're carefully calculated to give you maximum storage in a manageable footprint.

Each of the 12 doors measures 27 inches by 22 inches. That might not sound huge, but it's exactly the right size for comfortable access with mortuary cots and equipment. Trust me, facilities that try to save money with smaller door openings regret it every single day when staff are struggling to maneuver during body placement.

The rack spacing inside follows industry standards, with each compartment handling bodies up to 6'6" in length. For facilities serving larger populations, bariatric options are available with wider compartments and reinforced systems that can safely support up to 1,000 pounds per compartment.

Planning your space is crucial. You'll want at least 36 inches of clearance on all sides for maintenance access and proper airflow around the condensing units. The height clearance becomes especially important if you're installing in a basement or lower-level facility - measure twice, install once.

Capacity & Rack Configurations

The rack system is where practical meets brilliant. Most morgue-freezer-12 units come with either 3-tier or 4-tier configurations, depending on your facility's needs and local regulations about body stacking.

Telescopic racks are the real game-changer here. These three-piece extruded aluminum racks with nylon rollers extend about 75%, giving you safe and easy access for transfers. When you're using mechanical lifts or need precise positioning, that smooth operation isn't just convenient - it's essential for safety.

The removable trays are built from 18-gauge Type 304 stainless steel with a No. 4 finish. They're designed to resist corrosion and clean easily, with seamless construction that eliminates those hard-to-clean cracks where bacteria love to hide.

You can choose between side-load and end-load configurations based on your workflow. Side-load works great in narrow spaces where staff approach from the side, while end-load is perfect when you have plenty of front access space. It really comes down to your facility's layout and how your team prefers to work.

For facilities serving bariatric populations, specialized bariatric bays feature 31.5-inch wide openings and heavy-duty trays designed to handle the additional weight safely. It's not just about capacity - it's about maintaining dignity and safety for everyone involved.

Core Features, Components & Technology

When you're investing in a morgue-freezer-12, you're getting some seriously impressive engineering. Think of it as the luxury car of mortuary equipment – everything is designed to work together perfectly, and the details really matter.

The foundation starts with 4-inch foamed-in-place urethane insulation. This isn't your typical cooler foam. With an R-value of 8.49 per inch, this insulation creates a thermal barrier that keeps temperatures rock-steady while keeping your energy bills reasonable. It's like wrapping your entire unit in a super-efficient winter coat.

The construction materials tell a story of smart engineering choices. The front panels feature stainless steel with No. 4 finish – that's the stuff that stays looking professional even after years of daily use. For the top, sides, back, and interior, most units use stucco embossed galvanized steel. This gives you excellent corrosion resistance without the premium price tag of full stainless steel construction throughout.

Those magnetic gaskets around each door might look simple, but they're doing heavy lifting. They create airtight seals that prevent temperature fluctuations and stop cross-contamination between compartments. Quality gaskets maintain their grip even after thousands of door cycles – because nobody wants to deal with a gasket that's given up on life.

Digital controls have completely changed the game for morgue operations. Modern morgue-freezer-12 units come with microprocessor-based controllers that show temperature readings down to 0.1°C. These smart systems include programmable alarms for temperature variations, door-open alerts, and power failure notifications. It's like having a dedicated technician watching your unit 24/7.

You'll need to choose between split and self-contained refrigeration systems. Self-contained units are the plug-and-play option – everything's built right in, making installation straightforward. Split systems give you more flexibility in where you put the condenser and often run more efficiently in challenging environments.

Redundancy features are your insurance policy against disasters. Double cooling systems with automatic switchover mean that if one system decides to take a break, the backup kicks in seamlessly. This is especially crucial for forensic facilities where evidence preservation can't be compromised.

Antimicrobial finishes add an extra layer of protection beyond your regular cleaning routine. These specialized coatings actively fight bacterial growth on interior surfaces. Some manufacturers also offer seamless fiberglass interior options that eliminate virtually every crack and crevice where unwanted guests might try to set up shop.

The vapor-proof lighting ensures you can see what you're doing while meeting safety standards for potentially hazardous environments.

Latest research on refrigeration controls shows continued improvements in energy efficiency and control precision.

For more detailed information about mortuary freezer technology, check out our Freeze Your Essential Guide to Mortuary Freezers.

Refrigeration System & Temperature Ranges

The heart of any morgue-freezer-12 is its refrigeration system, and modern units are engineering marvels. Standard refrigeration mode maintains 38°F, which is perfect for short-term body preservation and most forensic work. When you need freezer mode at 0°F, the system transitions smoothly for long-term storage requirements.

Today's systems use CFC-free refrigerants like R134a, R404a, or R507. These aren't just environmentally friendly – they actually provide better cooling performance than older refrigerants. Your energy bills will thank you, and so will the planet.

Hot-gas defrost systems handle frost buildup automatically. Instead of letting ice accumulate until someone notices, these smart systems use heated refrigerant gas to melt frost as needed. The microprocessor controls monitor actual conditions rather than just running on a timer, so the system only defrosts when necessary.

The microprocessor-controlled alarm systems are like having a vigilant assistant who never sleeps. Visual and audible alarms alert you to temperature deviations, power failures, door-open situations, and system malfunctions. Many modern units offer remote monitoring capabilities, so you can check system status from anywhere with an internet connection.

Condenser design makes a bigger difference than most people realize. Air-cooled condensers work great in most situations, but facilities in hot climates or tight spaces might benefit from water-cooled or remote condenser setups.

morgue-freezer-12 Maintenance Checklist

Keeping your morgue-freezer-12 running smoothly isn't complicated, but consistency matters. Daily sanitation should include cleaning all interior surfaces with approved disinfectants and checking those temperature displays for any unusual readings.

Monthly gasket inspection prevents expensive problems down the road. Door gaskets need checking for tears, warping, or loss of magnetic seal. Even tiny gasket issues can waste energy and mess with temperature stability – it's amazing how much trouble a small piece of rubber can cause.

Annual condenser service is non-negotiable for maintaining cooling efficiency. Dirty condensers force compressors to work overtime, driving up energy costs and shortening equipment life. Professional cleaning should include checking refrigerant levels, electrical connections, and control system calibration.

Warranty terms vary between manufacturers, but quality units typically offer 10-15 year coverage on panels and doors, with 1-5 year coverage on mechanical components. Some manufacturers provide extended warranty options for additional peace of mind.

Remote monitoring systems are becoming the smart choice for proactive maintenance. These systems can alert maintenance staff to developing issues before they cause failures, reducing downtime and repair costs. It's like having an early warning system for your equipment.

Installation, Power Requirements & Safety Compliance

Setting up your morgue-freezer-12 is like putting together a really important puzzle – one that needs to work perfectly every time. The good news is that manufacturers have made this process much easier than it used to be. These units ship in pieces (what we call "knocked-down" shipping) so they can actually fit through your regular doorways during delivery.

The tricky part isn't getting it in the door – it's making sure you have enough room to put it all together. You'll need adequate assembly space at the final location, plus those crucial 36 inches of clearance on all sides. This isn't just for show – your maintenance team will thank you later when they can actually reach everything they need to service.

Don't forget about ceiling height either. With the unit standing 109.5 inches tall, you'll need extra space above for the assembly process. We've seen too many installations where someone forgot to measure the ceiling and had to scramble for solutions.

Modern units use cam-lock fastener systems that make assembly much simpler than the old bolt-together designs. You won't need a toolbox full of specialized equipment, but you will need 2-3 experienced technicians and a solid 4-8 hours to get everything properly assembled and tested.

The electrical requirements are straightforward but critical. Most morgue-freezer-12 units need 208-230V single-phase power with dedicated breakers sized for your specific compressor setup. Some smaller self-contained models offer 115V plug-in options, which can be a real convenience if your facility's electrical setup is limited.

Here's something many people overlook: floor insulation. It might not seem important, but insulated floors prevent heat transfer from your building's foundation. This is especially crucial in basement installations or facilities built on concrete slabs. The energy savings add up quickly, and your cooling system won't have to work as hard.

Safety compliance covers several important standards. NSF approval ensures your unit meets sanitation requirements, UL listing verifies electrical safety, and ISO certifications confirm quality management standards. These aren't just bureaucratic checkboxes – they protect your facility and staff.

Every compartment must have safety release handles inside – it's required by building codes and provides critical protection if someone accidentally gets trapped. These handles glow in the dark and operate the door mechanism from inside the compartment.

Door-open alarms are another essential safety feature. They activate after 60-90 seconds if a compartment door is left open, preventing temperature loss and alerting staff to potential problems.

Electrical & HVAC Planning

Getting the electrical planning right for your morgue-freezer-12 is crucial for reliable operation. The load calculations need to account for more than just the compressors – you've got interior lighting, control systems, and alarm circuits all drawing power. We always recommend oversizing electrical circuits by 20-25% to handle startup current surges and any future modifications you might need.

Dedicated breakers are absolutely essential. Sharing circuits with other equipment creates voltage fluctuations that can affect cooling performance and potentially damage those sensitive control electronics. Each major component should have its own appropriately sized overcurrent protection.

Remote condenser installations can be a game-changer for many facilities. You can locate the condenser outside the building or in a separate mechanical room, which reduces heat load in your morgue area and makes maintenance much easier. Just remember that refrigerant line length has limitations that need to be considered during the design phase.

If your condenser will be exposed to outdoor temperatures below 65°F, you'll need low-ambient kits. These include head pressure controls and other components that keep your refrigeration system working properly even in cold weather.

Backup generator connections are becoming more important, especially for critical applications. Your emergency power system needs to handle the full electrical load of the morgue-freezer-12 plus other essential facility systems. Automatic transfer switches ensure smooth transition to backup power when the lights go out.

Hygiene & Safety Features

Modern morgue-freezer-12 units go way beyond basic refrigeration when it comes to hygiene and safety. The anti-microbial interior finishes actively fight bacterial growth on all interior surfaces, giving you an extra layer of protection that works alongside your regular cleaning protocols.

Seamless fiberglass interior options are available for facilities with the strictest hygiene requirements. These smooth surfaces eliminate virtually all joints and crevices where contaminants could hide, making cleaning and sanitizing much more effective.

Drain-free self-contained units simplify installation by eliminating the need for floor drains and plumbing connections. The condensation management happens through interior evaporation or dedicated collection systems, reducing both installation complexity and potential contamination pathways.

Planning PPE zones around your mortuary equipment helps maintain proper safety protocols. Having clearly marked areas with adequate space for putting on and taking off personal protective equipment ensures your staff stays safe during body handling procedures.

Customization, Mobility & Sustainability

When you're investing in a morgue-freezer-12, you want equipment that fits your facility like a glove. That's where customization really shines. Modern units offer color-matched exteriors that blend seamlessly with your facility's existing design. Whether you need to match hospital whites, funeral home earth tones, or forensic lab grays, PMS color matching is often available at no extra charge. It's one of those details that makes a big difference in how professional your facility looks.

LED lighting systems have revolutionized interior illumination in these units. Not only do they provide crystal-clear visibility when you need it most, but they also consume far less energy than old fluorescent systems. The best part? These lights last 10-15 times longer and generate minimal heat that could interfere with your cooling performance. It's a win-win for both your electric bill and equipment efficiency.

For facilities using wheeled mortuary cots or gurneys, insulated ramps make loading and unloading much smoother. These can be designed as removable units for easy cleaning or permanent installations depending on how your facility operates. The insulation prevents thermal bridging that could affect temperature control.

Sometimes flexibility matters more than permanence. Heavy-duty locking castors can transform your stationary morgue-freezer-12 into a mobile unit. These aren't your average furniture wheels – they're engineered to support the full weight of a loaded unit while rolling smoothly when you need to reposition equipment. The locking mechanism ensures the unit stays put during normal operations.

The modular panel construction of modern units offers incredible long-term value. If your facility needs change, or if you're in a leased space and need to relocate, these units can be disassembled and moved to a new location. It's like having portable infrastructure that moves with your business needs.

Trailer-mounted units represent the ultimate in mobility and disaster preparedness. These self-contained systems can be rapidly deployed wherever surge capacity is needed. They include their own power generation and climate control, making them invaluable for emergency response teams, temporary facilities, or organizations serving multiple locations.

Sustainability isn't just good for the planet – it's good for your bottom line. Solar assist systems are gaining popularity as facilities look to reduce energy costs and environmental impact. While solar alone typically can't handle the full cooling load of a morgue-freezer-12, hybrid systems can significantly cut your grid power consumption during peak sunlight hours.

Energy-efficient compressors in today's units consume 20-30% less power than older designs while actually providing better temperature control. Variable-speed compressors are particularly smart – they adjust cooling output to match actual demand rather than running at full blast all the time. Your utility company will thank you.

The refrigerant industry continues evolving toward more eco-friendly options that often perform better than the chemicals they replace. These newer refrigerants not only meet strict environmental regulations but frequently provide superior energy efficiency compared to older types. Manufacturers are constantly evaluating new options that balance cooling performance, energy efficiency, and environmental responsibility.

In-Depth Guide to American Mortuary Coolers 12-Body Morgue Cooler Options

Frequently Asked Questions about morgue-freezer-12

When you're considering a morgue-freezer-12 for your facility, you probably have some practical questions about how these units actually work in real-world situations. We've been helping funeral homes, hospitals, and forensic facilities across the country for years, and these are the questions that come up most often.

How long does a morgue-freezer-12 take to reach operating temperature?

Here's the honest answer: your morgue-freezer-12 will reach its target temperature within 4-6 hours of startup, but don't rush to use it right away. We always tell our customers to wait a full 24 hours before placing any bodies inside.

Think of it like a new house settling in. The thick urethane insulation, stainless steel trays, and all that thermal mass need time to reach complete equilibrium. If you start using the unit too early, you might see temperature swings that could affect preservation quality.

The weather makes a difference too. Units installed during Tennessee summers or in hot climates might take an extra hour or two to stabilize. High humidity can slow things down as well. And please - resist the temptation to keep opening doors to check on progress. Every time you open a door, you're letting warm air in and making the system work harder.

Can a morgue-freezer-12 be converted from cool to freeze mode?

This is where things get a bit technical, but we'll keep it simple. Most morgue-freezer-12 units can switch between refrigeration mode (38°F) and freezing mode (0°F), but it's not as easy as flipping a switch.

The conversion requires a trained technician to modify the evaporator setup, adjust how the refrigerant flows, and reprogram the digital controls. It's basically like giving your unit a mini-makeover that takes 2-4 hours and requires emptying all the compartments.

Some newer units come with dual-mode capability built right in. These can switch modes through the control panel, though the entire unit operates in one mode at a time. You can't have half your compartments cooling while the other half are freezing - it's all or nothing.

We recommend planning any conversions during your regular maintenance windows. Nobody wants to be without storage capacity during a busy period, and the unit needs to be completely empty during the work.

What certifications should my morgue-freezer-12 meet?

Getting the right certifications isn't just about checking boxes - it's about protecting your facility and ensuring you can serve families without worrying about compliance issues.

NSF approval is your foundation. This certification means your unit meets the same sanitation standards that apply to commercial food service equipment. It might seem odd, but the hygiene requirements are very similar, and NSF approval shows inspectors that your equipment can maintain proper sanitary conditions.

UL listing covers electrical safety. This certification means the unit's electrical components meet national safety standards. Most insurance companies require UL-listed equipment, and some local codes won't allow installation without it.

ISO certifications, particularly ISO 9001, tell you something important about the manufacturer. These certifications show that the company follows consistent quality management systems in their production process. It's like a guarantee that your unit was built to the same standards as every other unit they make.

If your facility handles infectious remains, you might need additional certifications that meet CDC guidelines for infectious material containment. Some states have their own specific requirements too, so check with your local health department.

Energy efficiency certifications are becoming more important as utility costs keep climbing. While not always required, ENERGY STAR ratings or similar efficiency certifications can help you predict and budget for long-term operating costs.

Conclusion

Choosing the right morgue-freezer-12 isn't just about buying equipment – it's about investing in your facility's future. These units hit that sweet spot between having enough capacity to handle busy periods while remaining manageable for daily operations.

At American Mortuary Coolers, we've been helping facilities across the country find their perfect storage solution for years. Our custom 12-body units combine rugged construction that stands up to constant use with flexible installation options that work in almost any space. Whether you're in Tennessee, Atlanta, Chicago, Columbia, Dallas, Los Angeles, New York, or Pittsburgh, we deliver nationwide across all 48 contiguous states.

Here's what we've learned from working with hundreds of facilities: proper capacity planning makes all the difference. Too little storage and you're scrambling during busy times. Too much and you're paying for space you don't need. The 12-body capacity gives you room to grow without the complexity of massive walk-in systems.

The energy savings alone can justify the investment. Modern morgue-freezer-12 units typically slash operating costs by 25-40% compared to older equipment. Better insulation, smarter compressors, and advanced controls mean your utility bills drop while your temperature control gets more precise.

But here's what really matters: our after-sales support. Buying the equipment is just the beginning. We're here for installation questions, maintenance guidance, and any issues that come up down the road. Your facility's success is our success.

The mortuary industry keeps evolving, and equipment keeps getting better. When you choose a quality morgue-freezer-12 from American Mortuary Coolers, you're getting equipment built to serve your facility reliably for decades to come.

Ready to explore your options? More info about modular mortuary coolers – we'd love to help you find the perfect solution for your facility's needs.