Everything You Need to Know About Lysol Disinfectant Spray MSDS

Why Understanding Lysol Disinfectant Spray MSDS is Critical for Workplace Safety

Lysol disinfectant spray MSDS documents contain vital safety information that every funeral home director needs to understand before using these products in their facility. The Material Safety Data Sheet reveals that while Lysol kills 99.9% of viruses and bacteria - including SARS-CoV-2 in just 15 seconds - it also presents specific hazards that require proper handling protocols.

Quick MSDS Key Points:

- Active ingredient: Ethanol (30-60%) with quaternary ammonium compounds

- Primary hazards: Flammable aerosol, eye irritant, pressurized container

- Storage limit: Below 50°C (122°F) to prevent container bursting

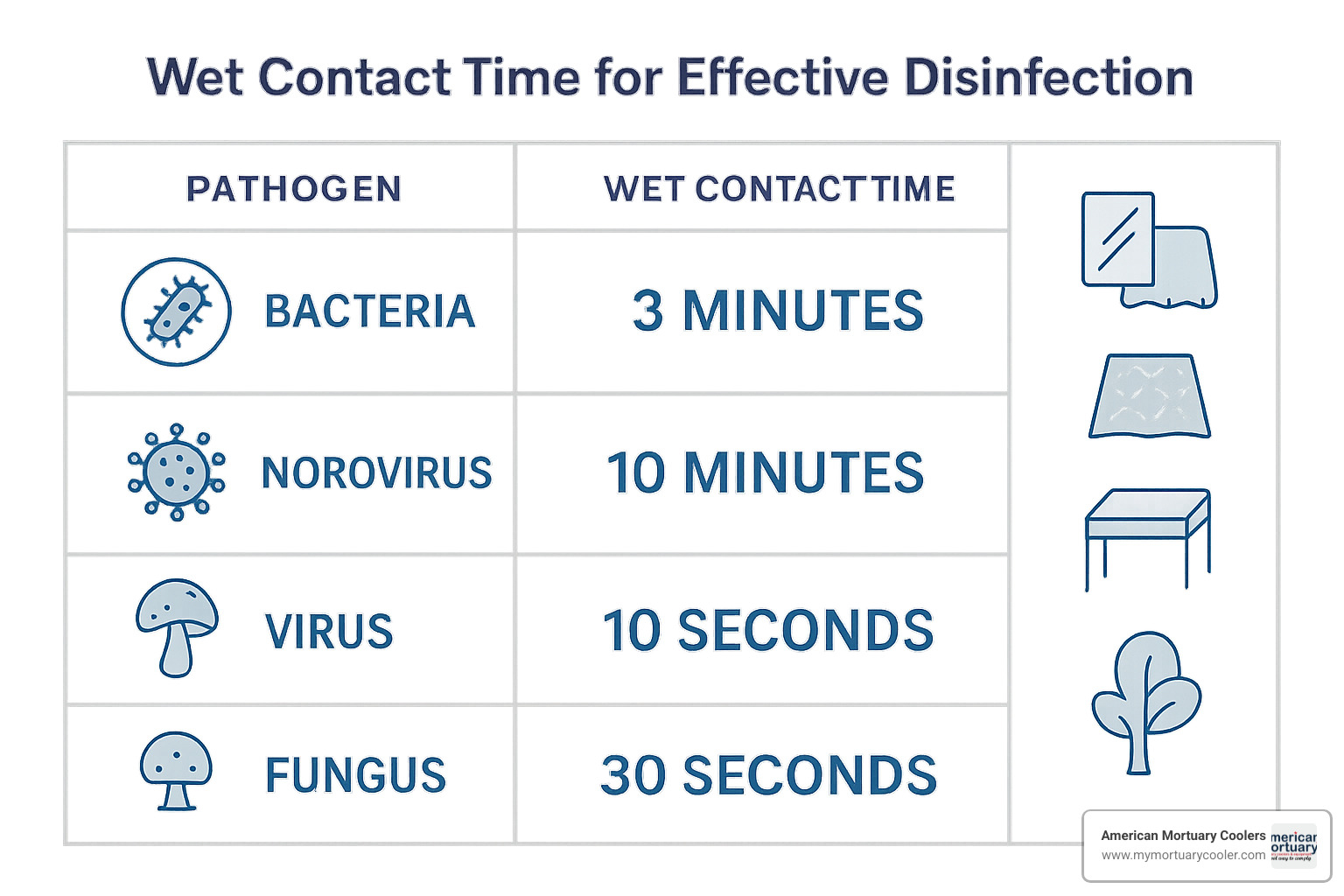

- Contact time: 3 minutes for disinfection, 10 minutes for norovirus

- PPE required: Chemical-resistant gloves, splash goggles, adequate ventilation

- EPA registration: 777-99 for surface antimicrobial use

The MSDS explicitly states: "This SDS is designed for workplace employees, emergency personnel and for conditions where there is potential for large-scale or prolonged exposure." This distinction matters because workplace use requires different safety protocols than typical consumer applications.

Understanding these requirements is especially important in funeral home settings where staff may experience prolonged exposure during routine disinfection of preparation rooms, transport vehicles, and high-touch surfaces throughout the facility.

I'm Mortuary Cooler from American Mortuary Coolers, and I've spent years helping funeral directors steer safety compliance requirements, including proper lysol disinfectant spray MSDS implementation in mortuary environments. My experience with mortuary equipment safety standards has shown me how critical it is to understand these technical documents before they're needed in emergency situations.

Understanding Lysol Disinfectant Spray MSDS

When you pick up a can of Lysol Disinfectant Spray, you're holding a powerful tool that's been specifically engineered for one primary purpose: eliminating pathogens on hard, non-porous surfaces. The lysol disinfectant spray msds tells the complete story of what makes this product so effective - and why it demands respect.

The numbers speak for themselves: 99.9% efficacy against viruses and bacteria. But here's what really matters in funeral home settings - this spray can neutralize SARS-CoV-2 in just 15 seconds on hard surfaces. That's remarkably fast action when you're dealing with potentially infectious materials.

However, speed isn't everything. The MSDS makes it clear that proper contact times are essential for thorough disinfection. While that 15-second kill time sounds impressive, standard protocols require surfaces to stay wet for 3 minutes to ensure complete pathogen elimination. When you're dealing with particularly stubborn viruses like norovirus, you'll need to extend that contact time to a full 10 minutes.

The EPA registration number 777-99 isn't just bureaucratic paperwork - it's your assurance that this product has been rigorously tested and meets federal standards for professional antimicrobial use. This registration validates every efficacy claim and ensures the product meets the strict requirements needed for healthcare and mortuary applications.

What the Lysol Disinfectant Spray MSDS Reveals about Health Hazards

The lysol disinfectant spray msds doesn't sugarcoat the risks - and that's exactly what makes it so valuable for workplace safety. Eye irritation tops the hazard list, with the product classified as a Category 2B eye irritant under current safety standards.

What catches many funeral directors off guard are the inhalation effects. That high ethanol content (30-60%) can cause significant respiratory irritation, especially in the confined spaces of preparation rooms. The MSDS identifies several target organs that prolonged exposure can affect: your central nervous system, respiratory system, blood, liver, and heart.

The warning signs of overexposure read like a checklist you never want to complete: eye irritation and tearing, respiratory tract irritation, dizziness, headaches, and nausea. These symptoms can creep up gradually during extended disinfection sessions, which is why proper ventilation isn't optional - it's essential.

There's also a sobering warning about inhalation abuse in the MSDS. While this might seem irrelevant in professional settings, it underscores just how potent these vapors can be when concentrated. The document states plainly that deliberately concentrating and inhaling vapors can be harmful or fatal.

Using the Lysol Disinfectant Spray MSDS for Safe Workplace Practices

Here's where things get interesting: OSHA HazCom standards require that the lysol disinfectant spray msds be available to all workplace employees - and they need to actually understand what's in it. The document makes a crucial distinction between workplace versus consumer use that many facilities overlook.

Those simple label directions on the can? They're designed for occasional home use, not the intensive, repeated applications common in funeral homes. The workplace MSDS dives much deeper, covering occupational exposure limits, engineering controls, specific PPE requirements, and detailed emergency procedures.

In hospital settings and funeral homes, staff must follow the complete MSDS protocols rather than just glancing at the product label. This means ensuring adequate ventilation before you start spraying, wearing the right protective equipment, and knowing exactly what to do if something goes wrong.

The difference between consumer and professional use isn't just about liability - it's about creating a safe working environment where your staff can perform their duties without unnecessary health risks. When you're disinfecting multiple surfaces throughout the day, every day, those workplace protocols become your safety net.

Key Ingredients & Their Functions

When you look at the lysol disinfectant spray msds, you'll find a carefully balanced formula that explains why this product works so well - and why it requires proper safety precautions. Understanding these ingredients helps you make informed decisions about using it safely in your funeral home.

The powerhouse behind Lysol's effectiveness is ethanol at 30-60% concentration. This high alcohol content serves as both the primary disinfectant and solvent, breaking down the protective barriers of viruses and bacteria. It's the same reason hand sanitizers work - alcohol disrupts cellular membranes and denatures proteins that pathogens need to survive.

Working alongside ethanol are quaternary ammonium compounds, commonly called "quats." These specialized chemicals provide broad-spectrum antimicrobial activity, particularly against bacteria and enveloped viruses like SARS-CoV-2. In mortuary settings, this combination gives you reliable protection against the wide range of pathogens you might encounter.

The aerosol delivery system relies on butane (5-10%) and propane (1-5%) as propellants. While these gases enable even distribution across surfaces - which is exactly what you want when disinfecting preparation room equipment - they're also what makes the product flammable. This dual nature explains why proper storage and handling are so critical.

The formula includes several supporting ingredients that improve performance. Fragrance components help mask odors rather than just covering them up with chemicals. Corrosion inhibitors protect metal surfaces like your mortuary equipment from damage during repeated use. pH adjusters optimize the antimicrobial activity to ensure maximum effectiveness.

Here's something that might surprise you: despite being a powerful disinfectant, this product achieves 94% biobased content according to USDA Biopreferred certification. That makes it significantly more environmentally friendly than many synthetic alternatives - a consideration that's becoming increasingly important to families and regulatory agencies.

| Component Type | Examples | Function | Concentration |

|---|---|---|---|

| Active Ingredients | Ethanol, Quaternary ammonium compounds | Disinfection | 30-60% ethanol |

| Propellants | Butane, Propane | Aerosol delivery | 5-10% butane, 1-5% propane |

| Inactive Ingredients | Fragrance, pH adjusters, inhibitors | Performance improvement | Variable |

The balance between active and inactive ingredients creates a product that's both effective and practical for daily use. However, it's this same chemical complexity that makes understanding the lysol disinfectant spray msds so important - each ingredient contributes to both the benefits and the potential hazards you need to manage.

Major Hazards, First Aid & PPE

When you look at the lysol disinfectant spray msds, you'll notice some serious hazard classifications that might surprise you. This isn't just another cleaning product - it's classified as an extremely flammable aerosol under Category 1 standards, which is the highest flammability rating possible.

The combination of ethanol and propellant gases creates a perfect storm of fire risk. Those innocent-looking cans contain gases under pressure that can turn dangerous quickly if mishandled. Heat that container above 122°F, and you're looking at a potential explosion hazard that could seriously injure someone.

Eye irritation ranks as another major concern. The MSDS classifies Lysol spray as a Category 2B eye irritant, meaning it can cause significant discomfort and potential damage to your vision if it gets in your eyes during application.

When Things Go Wrong: First Aid That Actually Works

If someone gets Lysol spray in their eyes, time matters. Rinse cautiously with water for several minutes - and I mean really rinse, not just a quick splash. Remove contact lenses if they're easy to get out, then keep rinsing. The MSDS is clear: seek medical attention if irritation persists.

Skin contact usually isn't as serious, but it still needs proper attention. Wash the affected area with plenty of water for at least 10 minutes and remove any contaminated clothing. Most skin incidents resolve quickly, but prolonged contact can cause irritation that lingers.

Inhalation problems require immediate action. Move the person to fresh air and keep them comfortable - sitting upright often helps with breathing. If someone's having trouble breathing after inhaling the spray, don't wait around hoping it gets better. Get medical help right away.

Ingestion is less common but more serious. Give small amounts of water if the person is conscious and able to swallow. Never try to make someone vomit unless medical personnel specifically tell you to - it can make things worse.

Symptoms of overexposure can sneak up on you during long disinfection sessions. Watch for eye irritation, respiratory tract irritation, dizziness, headaches, or nausea. In severe cases, the MSDS warns about effects on your liver, blood, and cardiovascular system.

Protective Gear That Actually Protects You

The lysol disinfectant spray msds doesn't mess around when it comes to protective equipment recommendations. Chemical-resistant nitrile gloves top the list because they won't break down when exposed to ethanol and other solvents.

Splash-proof safety goggles or a face shield become essential when you're doing extensive disinfection work. Regular safety glasses won't cut it - you need protection that seals around your eyes to prevent spray from getting in during application.

Respiratory protection becomes necessary if your ventilation isn't adequate. In smaller preparation rooms or enclosed spaces, a proper respirator can prevent the headaches and dizziness that come from inhaling too much product.

Some applications might require anti-static protective clothing, especially if you're working around other flammable materials or in environments where static electricity could create ignition sources.

The bottom line? This stuff works incredibly well at killing pathogens, but it demands respect. Treat it like the industrial-strength disinfectant it is, not like household spray cleaner.

Safe Handling, Storage & Spill Response

Think of lysol disinfectant spray msds safety protocols as your insurance policy against workplace accidents. The most critical rule? Keep this product away from any heat source, spark, open flame, or hot surface. That includes the obvious culprits like cigarettes, but also less obvious ones like static electricity from synthetic clothing or even a hot light bulb.

The no smoking rule extends to the entire work area where you're using or storing the product. I've seen funeral directors step outside for a quick smoke break and forget they still had residual product on their gloves - that's exactly the kind of oversight that can lead to serious accidents.

Storage requirements are surprisingly specific because we're dealing with a pressurized container that can become dangerous when mishandled. The magic number to remember is 50°C or 122°F - never let your storage area exceed this temperature.

Your storage area should have adequate ventilation and stay protected from direct sunlight. Those metal storage cabinets that sit in direct sun all afternoon? Not ideal for aerosol disinfectants. And here's something many people don't realize: never puncture or incinerate the containers, even when they seem empty. The residual propellant can still cause the container to explode.

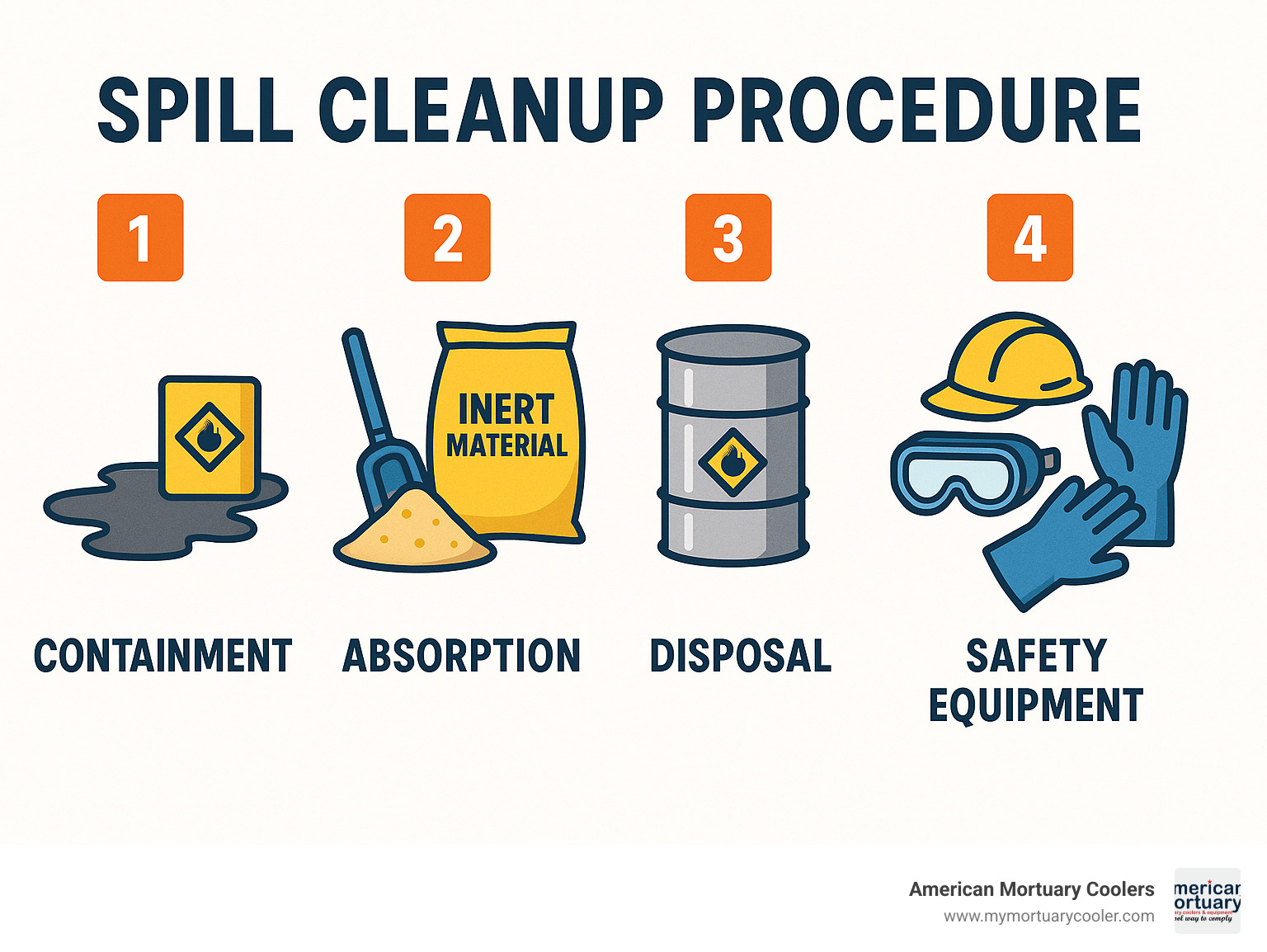

When spills happen - and they will - your response depends on the size. Small spills are manageable if you follow the right steps. First, eliminate all ignition sources in the area. Then contain the spill and absorb it with inert materials like sand or vermiculite. Regular paper towels or cloth rags can create static electricity, so stick with inert absorbents.

Large spills require a more serious response. You'll need to evacuate the area, ensure adequate ventilation, and use spark-proof tools and explosion-proof equipment for cleanup. The contaminated materials must go into appropriate waste containers and get disposed of through a licensed hazardous waste contractor.

Firefighting presents its own challenges with aerosol products. The recommended extinguishing agents are CO₂, dry chemical, or foam. Water spray can be used to cool fire-exposed containers and prevent them from rupturing, but it won't effectively extinguish the fire itself. Anyone fighting fires involving these products needs self-contained breathing apparatus and full protective gear.

The key to safe handling is treating the product with the respect its flammability demands while not letting safety concerns prevent you from using this effective disinfectant properly.

Regulatory, Environmental & Disposal Considerations

When you're managing a funeral home, understanding the regulatory landscape around disinfectants isn't just about compliance - it's about protecting your staff and your business. The lysol disinfectant spray msds reveals a complex web of regulations that govern everything from how you store the product to how you dispose of empty containers.

EPA registration number 777-99 gives you confidence that this product actually works as advertised. Unlike some cleaning products that make vague claims, this registration means the EPA has reviewed the science and confirmed the antimicrobial effectiveness. That's particularly important when families trust you to maintain the highest standards of cleanliness and safety.

The GHS Flammable Aerosol Category 2 classification affects how the product gets shipped to your facility and where you can store it. This same classification creates the DOT UN1950 designation for transportation, which is why you might notice special handling requirements when orders arrive.

Here's something that might surprise you: this disinfectant spray carries USDA Biopreferred certification at 94% biobased content. In an industry where environmental responsibility increasingly matters to families, that's a significant advantage. You're getting powerful disinfection while supporting more sustainable practices.

SARA 313 reporting requirements may apply to your facility depending on usage volumes, and various state right-to-know listings mean you'll need to include this product in workplace chemical inventories. Your state regulations might require additional documentation, so check with your local authorities.

From an environmental perspective, the news is mostly good. While you absolutely don't want this product entering waterways, the aquatic toxicity data shows low bioaccumulation potential. The primary components - ethanol, butane, and propane - break down readily in the environment rather than building up in ecosystems.

Disposal gets a bit tricky with aerosol products. Empty containers should never be punctured or thrown into incinerators, even when they seem completely empty. Residual product and propellant can create serious hazards. Any leftover product needs disposal via licensed contractor who understands hazardous waste regulations.

The good news is that aerosol cans may be recyclable in areas where specialized facilities exist. Check with your waste management provider about options in your area. Some funeral homes find it cost-effective to coordinate with other local businesses to share licensed hazardous waste pickup services.

Because funeral homes often use significant volumes of disinfectants, establishing relationships with licensed hazardous waste contractors who understand mortuary industry requirements makes sense. They can help you stay compliant while managing costs effectively.

For the latest research on EPA SARS-CoV-2 efficacy, visit the EPA coronavirus information page. Additional guidance on PPE selection is available in our comprehensive PPE guide.

Frequently Asked Questions about Lysol Disinfectant Spray MSDS

What surfaces can be safely treated?

When you're working with lysol disinfectant spray msds guidelines, understanding which surfaces are safe makes all the difference in your daily operations. The good news is that most surfaces in funeral homes are perfectly compatible with this disinfectant.

Hard, non-porous surfaces are your best bet - think of all that stainless steel mortuary equipment, sealed countertops, and medical equipment surfaces that define most preparation rooms. These surfaces handle the alcohol content beautifully and give you the full disinfecting power you need.

For soft surfaces, you can spot-sanitize when needed, but don't go overboard with saturation. The key is treating these areas gently while still getting effective sanitization.

Your safe zone includes stainless steel mortuary equipment, sealed granite or quartz countertops, ceramic and porcelain fixtures, glass surfaces, and most painted surfaces (though testing a small area first never hurts). Vinyl and sealed leather also handle the treatment well.

However, you'll want to avoid polished wood furniture, rayon fabrics, acrylic plastics, unsealed natural stone, and delicate electronic equipment. The alcohol content can damage these materials, and nobody wants to explain why the beautiful wooden reception desk now has white spots.

Why must the can stay below 122°F?

Here's where things get serious - that 50°C (122°F) temperature limit isn't just a suggestion, it's a safety requirement that could prevent a dangerous situation in your facility.

The lysol disinfectant spray msds is crystal clear about this because the product contains pressurized propellants like butane and propane. When these get too hot, pressure builds up fast, and that can mean container rupture or even explosion.

This becomes especially important during summer months when you might store products in vehicles for transport calls, or if you have storage areas near heating equipment. Summer storage in vehicles can easily exceed this temperature, turning a helpful disinfectant into a serious safety hazard.

The burst risk isn't just about property damage - it creates both physical injury potential and fire hazards because of those flammable contents. Nobody wants to deal with that kind of emergency when you're already managing the demands of serving families.

How long should surfaces remain wet to disinfect?

Getting the contact time right is where the science meets practical application. The lysol disinfectant spray msds specifies different wet contact times depending on what you're trying to eliminate.

For standard disinfection, you need 3 minutes of visible wetness on the surface. This covers most of your daily cleaning needs and handles the majority of pathogens you'll encounter.

Norovirus requires 10 minutes - this stubborn virus needs that extra time to be effectively eliminated. It's longer than you might expect, but it's worth the wait for complete protection.

If you're doing quick sanitization between tasks, 10 seconds of wet contact time will handle basic sanitizing needs. For soft surface spot sanitization, 30 seconds gives you effective treatment without oversaturating delicate materials.

The critical point is that surfaces must remain visibly wet for the entire contact period. If the surface dries out before the time is up, you haven't achieved the claimed kill rates. On porous or absorbent surfaces, this might mean applying the product multiple times to maintain that wet contact throughout the required period.

Conclusion

Understanding the lysol disinfectant spray msds isn't just about checking a compliance box - it's about creating a genuinely safe workplace where your team can focus on serving families during their most difficult times. At American Mortuary Coolers, we've seen how proper safety protocols make all the difference in funeral home operations across our service area from Tennessee to California.

The beauty of mastering these safety requirements is that they become second nature with practice. Your staff will automatically reach for chemical-resistant gloves and splash goggles, check ventilation systems, and verify storage temperatures stay below 122°F. These habits protect everyone while ensuring your disinfection efforts actually work.

Proper disposal practices matter more than many funeral directors realize. Working with licensed hazardous waste contractors might seem like an extra expense, but it's far less costly than dealing with regulatory violations. Never puncture or incinerate those empty containers - the pressurized contents can create serious hazards even when the can feels empty.

Staying compliant with OSHA HazCom requirements means making sure every team member can access and understand the lysol disinfectant spray msds contents. This isn't about overwhelming people with technical details - it's about giving them the knowledge they need to work safely and confidently.

Whether you're maintaining mortuary coolers in your prep room, disinfecting transport vehicles after difficult removals, or sanitizing high-touch surfaces throughout your facility, these MSDS guidelines keep your operations running smoothly. The combination of proper training, appropriate PPE, and consistent adherence to contact times creates that safe working environment where accidents simply don't happen.

From our Tennessee headquarters to our delivery routes reaching every corner of the contiguous 48 states, we've watched funeral homes transform their safety cultures by taking MSDS requirements seriously. The facilities that invest time in understanding these documents before emergencies arise are the ones that avoid preventable incidents entirely.

Take a few minutes today to review your current disinfection protocols. Make sure your team knows where to find the MSDS documents, understands the contact times for different pathogens, and has easy access to proper PPE. These small steps create the foundation for years of safe, effective operations.

For more comprehensive guidance on maintaining safe funeral home environments, check out our essential guide to funeral home equipment. Because when safety becomes routine, you can focus on what matters most - caring for the families who trust you with their loved ones.