Everything You Need to Know About Embalmer Supply Companies

Why Embalmer Supply Companies Are Essential to Modern Funeral Service

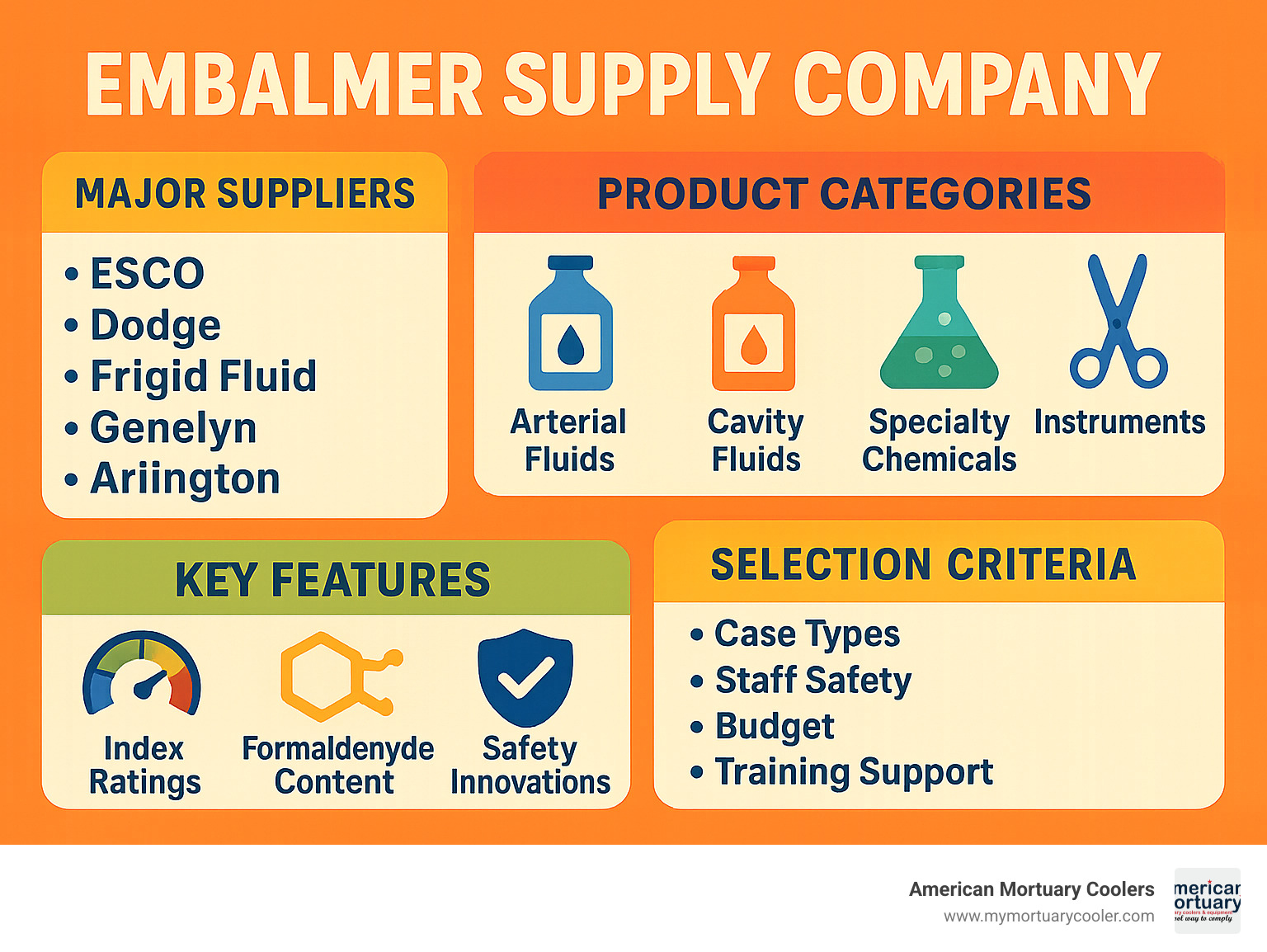

An embalmer supply company provides the specialized chemicals, instruments, and equipment that funeral homes need to preserve human remains and serve families with dignity. Here are the key players and what they offer:

Top Embalmer Supply Companies:

- ESCO (Embalmers' Supply Company) - Founded 1886, specializes in triple-base chemicals with Bacterin and Destrin

- The Dodge Company - World's largest supplier since 1893, offers formaldehyde-free options

- Frigid Fluid Company - Operating since 1892, known for silicone-improved fluids

- Genelyn - Focuses on low-fume, methanol-free formulations

- Arlington Chemical - Manufacturing since 1924, ships globally including Caribbean and West Africa

What They Supply:

- Arterial fluids (for circulation)

- Cavity fluids (for body cavities)

- Specialty chemicals (edema, jaundice, drainage)

- Embalming instruments and prep room equipment

- Training seminars and technical support

The embalming supply industry has evolved dramatically since the Civil War era. Early embalmers relied on basic formaldehyde solutions, but today's embalmer supply company options include low-fume alternatives, silicone-improved diffusion, and methanol-free formulations that protect staff health while delivering superior preservation results.

Modern funeral directors face complex decisions when choosing suppliers. Water hardness, case mix, staff safety concerns, and budget constraints all influence which embalmer supply company best serves their needs.

As American Mortuary Coolers, we've worked with funeral homes nationwide to optimize their prep room operations, including partnerships with leading embalmer supply companies to ensure seamless equipment integration.

Explore more about embalmer supply company:

From Civil War to Silicon Era: The History & Evolution of Embalming Chemicals

The story of modern embalming begins on Civil War battlefields, where families desperately needed ways to bring their loved ones home for burial. Those early preservation efforts were crude, but they sparked an entire industry built around dignity and care.

By the 1880s, smart entrepreneurs saw opportunity in this growing need. ESCO (Embalmers' Supply Company) broke ground in 1886, becoming one of the first dedicated embalmer supply company operations in North America. The Dodge Company joined in 1893, and Frigid Fluid Company rounded out the pioneering trio in 1892, creating the foundation of what we now call the modern funeral industry.

Those early formulas were basically formaldehyde and hope. The real breakthrough came when ESCO developed triple-base chemistry - combining formaldehyde with Bacterin and Destrin, plus lanolin for tissue conditioning. Suddenly, embalmers had chemicals that actually worked consistently.

Fast-forward to today, and the science is mind-blowing. Frigid Fluid's Silitech technology uses silicone additives to help chemicals penetrate deeper into tissue. The biggest game-changer might be methanol-free formulations from companies like Genelyn. Traditional fluids used methanol to stabilize formaldehyde, but it created rock-hard tissue and dangerous fumes.

Even sustainability has reached the prep room. Modern embalmer supply company options include biodegradable powders and reduced-toxicity formulations. Scientific research on formaldehyde exposure continues driving innovation toward safer alternatives that don't compromise preservation quality.

Milestone Innovations That Changed the Prep Room

Triple-base fluid technology revolutionized preservation chemistry. ESCO's formula combining formaldehyde, Bacterin, and Destrin meant embalmers needed fewer additives to achieve better results.

Silicone diffusion improvements solved getting chemicals to penetrate evenly throughout the body. Frigid Fluid's Silitech system allows deeper penetration into tiny capillaries for better, more consistent results.

Low-fume glutaraldehyde alternatives protect embalmer health without sacrificing quality. Companies like Genelyn developed formulations that drastically reduce toxic vapor exposure.

Mobile app integration brought the prep room into the digital age. The Dodge Company's Arterial Solution Calculator app lets embalmers calculate proper dilution ratios on their phones.

At American Mortuary Coolers, we've seen how these chemical innovations work hand-in-hand with proper refrigeration equipment.

What's in the Bottle? Key Categories of Embalming Fluids & When to Use Them

Walking into any prep room, you'll find shelves lined with bottles containing different types of embalming fluids. Each serves a specific purpose, and understanding when to use which type can make the difference between adequate preservation and exceptional results.

Arterial fluids do the heavy lifting in preservation. These are pumped through the circulatory system and contain the highest concentrations of preservatives. ESCO offers arterial fluids ranging from their gentler Keltone 15 for routine cases up to their powerful Kelspecial 35 for challenging preservation situations.

Cavity fluids handle what arterial fluids can't reach effectively - the internal organs and body cavities. After aspiration, these fluids go directly into the thoracic and abdominal cavities. They typically pack more preservative punch than arterial fluids.

Pre-injection and co-injection fluids are your prep work specialists. Pre-injection fluids prepare the vascular system before the main arterial treatment, while co-injection fluids work alongside arterial fluids to solve specific problems. ESCO's Keledema E-II specifically targets swelling issues.

Specialty formulations are the problem solvers in your chemical arsenal. When standard fluids aren't enough, these targeted solutions step in. EDEMA PRO can eliminate swelling in specific body regions. ESCO's Keljaundice 4 tackles yellow discoloration that regular fluids can't touch.

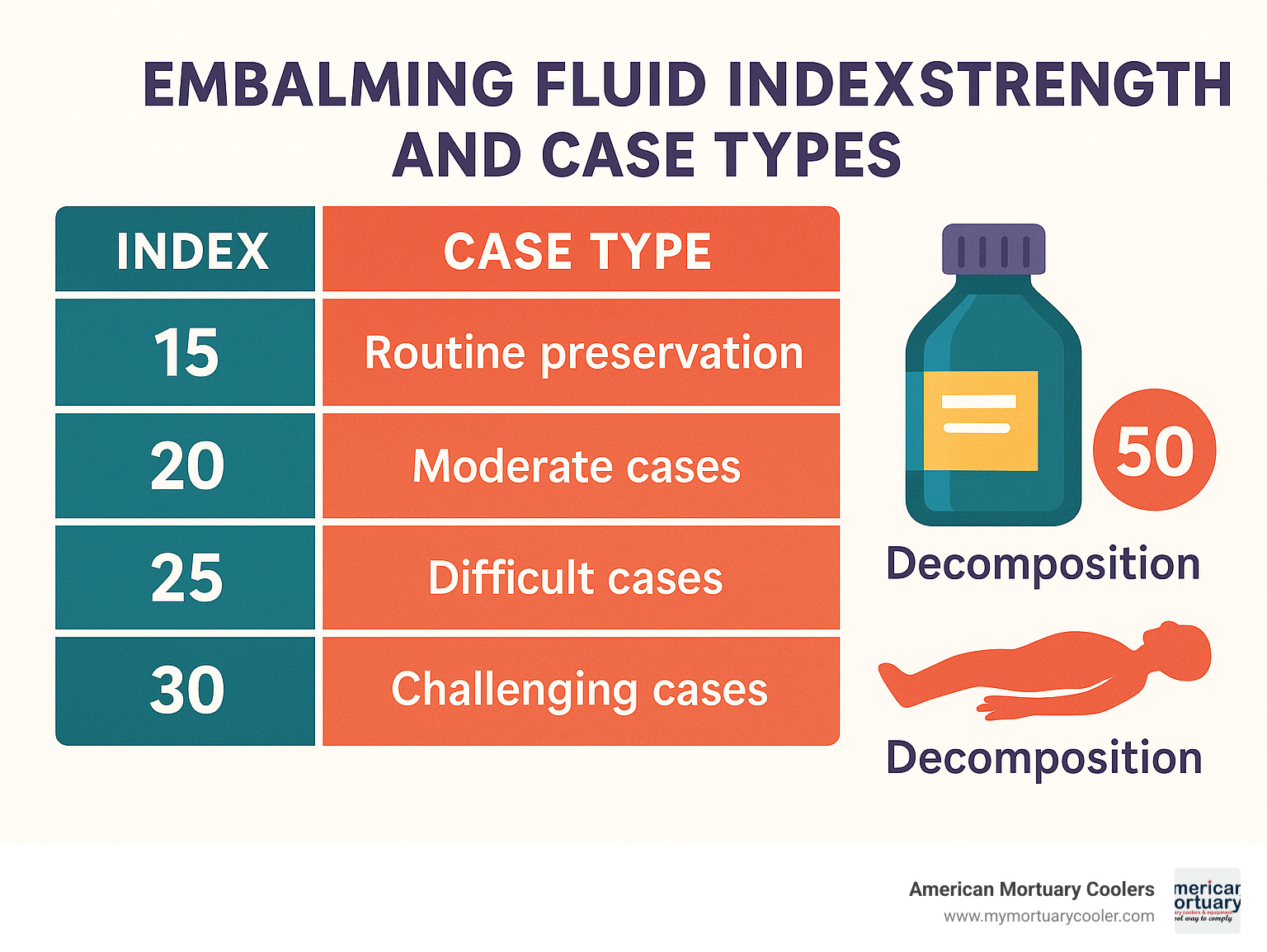

Understanding "Index" and Why It Matters

The index tells you the formaldehyde concentration, which directly affects how strong your preservation will be, how firm the tissues become, and how well color is retained.

Low index fluids in the 15-20 range are your go-to for routine cases where maintaining a natural appearance is crucial. Medium index fluids between 25-30 handle the bulk of challenging situations. High index fluids from 35-50 are your heavy artillery for tough cases - advanced decomposition, severe edema, or situations where maximum preservation is absolutely necessary.

The trick is matching your index to your case needs. Use too high an index and you'll create unnecessarily firm tissues. Go too low and you risk inadequate preservation.

Specialty Formulas Tackling Difficult Cases

Edema cases require specialized chemistry. Products like Keledema E-II work as pre-injection treatments to break down swollen tissue before your main arterial injection.

Discoloration problems need specialized chemistry. ESCO's Drug & Stain Remover tackles postmortem discolorations that standard fluids can't touch.

Penetration issues get solved with advanced chemistry. Frigid Fluid's Silitech line uses silicone technology to improve how fluids distribute throughout the body.

Hard water problems can sabotage even the best embalming technique. ESCO's drainage chemicals sequester calcium at 50% higher levels than competitors.

Comparing Leading Embalmer Supply Companies

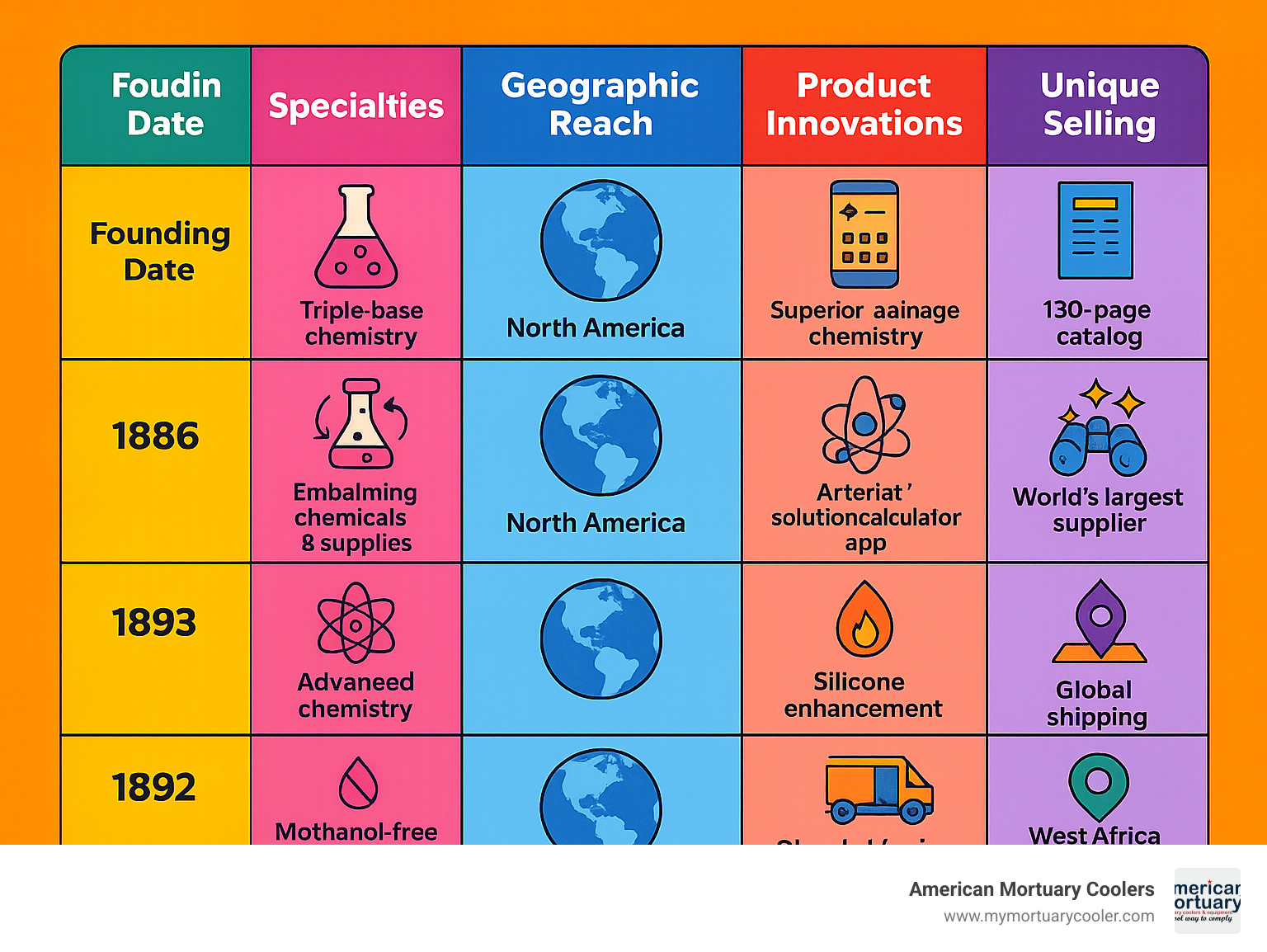

The embalmer supply company world is filled with companies that have shaped funeral service for over a century. Each major player brings something unique to the table.

ESCO (Embalmers' Supply Company) is the granddaddy of them all, starting in 1886. Their claim to fame is triple-base chemistry combining formaldehyde, Bacterin, and Destrin. What really sets ESCO apart is their drainage chemistry, which outperforms competitors by 50% when it comes to calcium sequestration.

The Dodge Company started in 1893 and has grown into what they call the world's largest embalming chemical supplier. Dodge doesn't just sell chemicals - they offer everything from instruments to urns to aftercare products. Their latest innovation is a mobile app that calculates arterial solution ratios.

Frigid Fluid Company has been around since 1892, and they're the chemistry specialists. Their Silitech technology uses silicone to help embalming fluid penetrate deeper into tissues for better preservation all around.

Genelyn represents the new generation of thinking in embalming chemistry. They've tackled the methanol problem head-on, creating formulations that drastically reduce toxic fumes while maintaining preservation quality. Their non-flammable formulations also make storage and shipping much simpler.

Arlington Chemical rounds out the major players with global reach. While most suppliers focus on the domestic market, Arlington ships to the Caribbean and West Coast of Africa.

How Each Embalmer Supply Company Supports Education & Safety

Dodge Company has been the education leader since the mid-1950s, hosting technical seminars that draw embalmers from across the country. They publish a quarterly magazine and maintain licensed-embalmer sales representatives who provide hands-on field training.

Frigid Fluid Company takes a more personal approach, building relationships through webinars and one-on-one consultations.

Genelyn focuses on creating products that inherently improve workplace safety. Their methanol-free formulations and low-fume chemistry directly address health concerns.

ESCO provides comprehensive technical support through their extensive documentation and detailed usage instructions.

The Usage Instructions Safety Data Sheets that responsible suppliers provide are lifelines for safe operation.

The "embalmer supply company" Showdown: Who Excels Where?

Drainage Chemistry belongs to ESCO with their calcium sequestration technology that outperforms competitors by 50%.

Low-Toxicity Innovation is Genelyn's domain with their methanol-free chemistry and low-fume alternatives.

Comprehensive Service goes to Dodge, who've built an empire around the idea that funeral homes need more than just chemicals.

Advanced Chemistry belongs to Frigid Fluid and their Silitech technology.

Global Reach is Arlington Chemical's specialty, serving markets that other suppliers don't reach.

At American Mortuary Coolers, we've worked with funeral homes that use products from all these suppliers. The best prep room setups often involve partnerships with multiple companies.

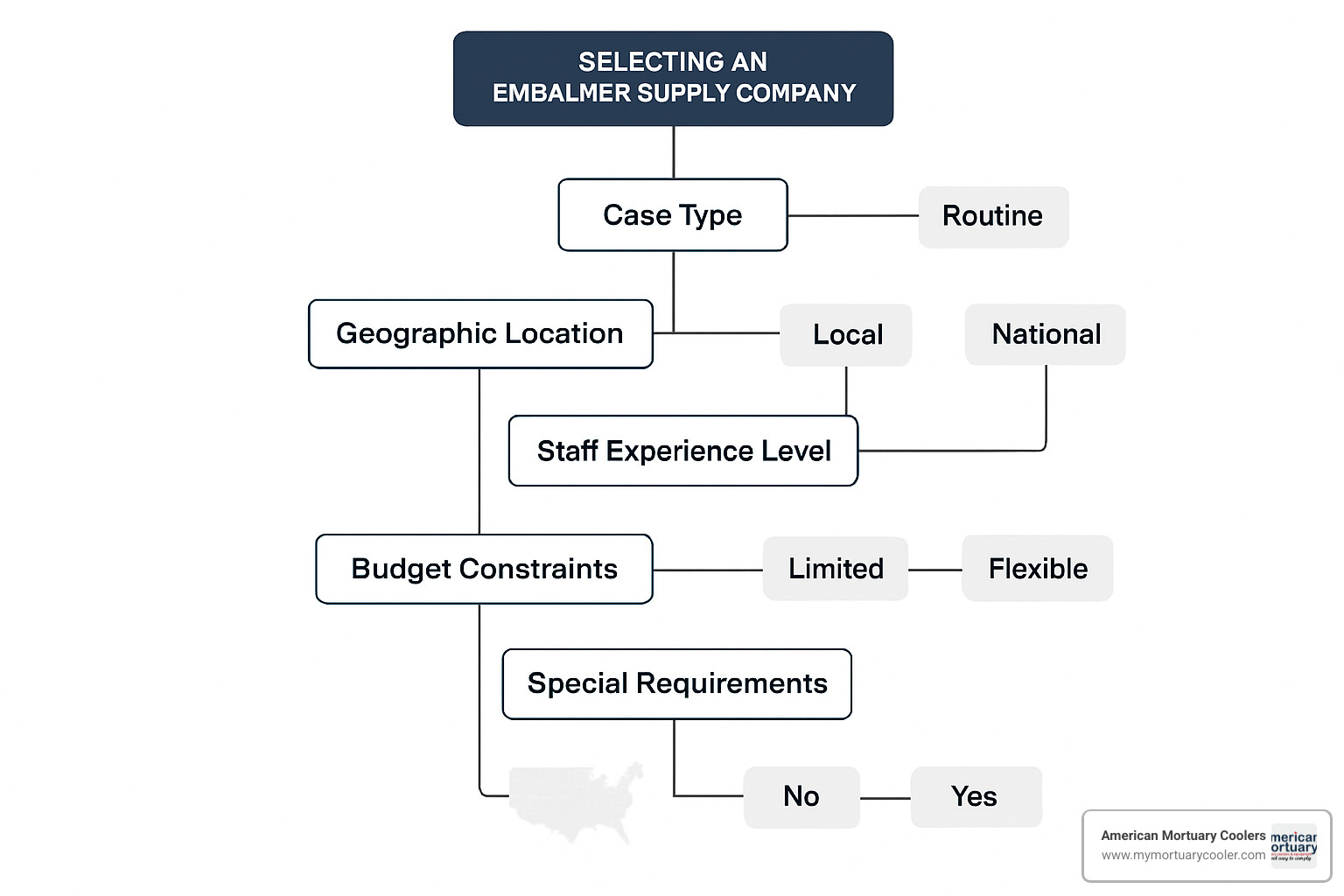

Choosing the Right Embalmer Supply Company for Your Funeral Home

Finding the perfect embalmer supply company for your funeral home isn't just about price - it's about finding a partner who understands your unique needs and challenges.

Your case mix tells the story of what you really need from a supplier. If you're handling mostly peaceful, natural deaths, you'll want a company that excels in natural-looking results with lower-index fluids. But if you handle difficult cases - trauma, decomposition, or challenging transport situations - you need an embalmer supply company with serious high-index specialty formulations.

Water quality matters more than most people realize. If you're dealing with hard water, ESCO's superior calcium sequestration technology could save you significant frustration. Their drainage chemicals outperform competitors by 50% in challenging water conditions.

Staff health should never be an afterthought. If you have team members with respiratory sensitivities, companies like Genelyn with their low-fume, methanol-free formulations become incredibly valuable. One customer with asthma reported eliminating workplace attacks entirely after switching to their products.

Budget considerations are always real, but they're more nuanced than just looking at per-bottle prices. Some suppliers offer bulk discounts for high-volume operations. Others focus on premium products that cost more upfront but might require less product usage.

Technical support needs vary dramatically depending on your staff experience and case complexity. New embalmers benefit enormously from suppliers offering extensive training. Dodge's seminars and field representatives provide hands-on education that can transform your operation.

10-Step Checklist When Vetting an "embalmer supply company"

Start with sample packs - most reputable suppliers offer them, and ESCO's 24-pack Arterial Fluid Sample Case lets you test their range before committing.

Safety Data Sheets aren't exciting reading, but they're crucial. Pay special attention to formaldehyde content, vapor hazards, and required PPE.

Non-flammable options like Genelyn's formulations simplify storage and reduce regulatory headaches.

Training access varies wildly between suppliers. Match the support level to your team's needs and experience.

Test regional delivery before you need it urgently. Check shipping times, costs, and reliability for your specific location.

Index ranges should match your typical case mix - there's no point in a supplier who excels at routine cases if you handle mostly challenging preservation situations.

Specialty products matter when you need them. Review availability of edema control, jaundice treatment, and other specialized formulations.

Technical support should include licensed embalmers or qualified technical representatives available for consultation.

Calculate total cost of ownership beyond just product prices - include shipping costs, minimum orders, and potential waste from unused products.

More info about embalming supplies provides additional guidance on supply selection and management.

At American Mortuary Coolers, we've worked with funeral homes nationwide to optimize their prep room operations. The best partnerships feel less like vendor relationships and more like having knowledgeable colleagues who understand your challenges.

Safety, Health & Environmental Considerations

The embalming profession has come a long way from the days when embalmers worked with crude formaldehyde solutions in poorly ventilated rooms. Today's safety-conscious funeral homes need an embalmer supply company that prioritizes worker health and environmental responsibility alongside preservation quality.

Personal protective equipment requirements have evolved dramatically as we've learned more about chemical exposure risks. Modern suppliers are designing products with PPE considerations built in from the start. Low-fume formulations mean less reliance on respiratory protection, while non-flammable chemicals eliminate storage safety concerns.

Ventilation standards set by OSHA require specific air exchange rates in prep rooms. Companies like Genelyn have developed formulations that produce significantly fewer vapors, which can actually reduce your ventilation requirements and cut energy costs.

The formaldehyde exposure limits mandated by OSHA are no joke. Traditional embalming fluids can easily push you over these limits, creating compliance headaches and health risks. Newer formulations from progressive suppliers dramatically reduce vapor production. One embalmer with asthma told us they completely eliminated workplace attacks after switching to low-fume products.

Environmental consciousness has finally reached our industry. ESCO's BTU hardening compound offers superior absorption capacity while being environmentally friendly for cremation cases. Other suppliers are developing biodegradable powders and reduced-impact formulations.

Waste disposal considerations vary significantly depending on which formulations you choose. Non-flammable products simplify waste handling procedures, while biodegradable options reduce long-term environmental impact.

Scientific research on chemical toxicity continues to drive innovation toward safer alternatives.

Reducing Fumes & Protecting Staff in Modern Prep Rooms

The evolution toward safer embalming chemicals represents one of the most important developments in modern funeral service. Your staff's health shouldn't be compromised by outdated chemistry when better options exist.

High-preservation, low-fume technology represents a genuine breakthrough in embalming chemistry. Companies like Genelyn have solved what seemed like an impossible puzzle - maintaining excellent preservation results while dramatically reducing vapor production. Their methanol-free formulations eliminate one of the primary sources of toxic fumes.

Glutaraldehyde alternatives have gained attention as potential formaldehyde replacements, but Genelyn's research suggests glutaraldehyde may present its own health risks. Their approach focuses on improving formaldehyde chemistry rather than replacing it entirely.

Formaldehyde scavengers built into advanced formulations work like chemical janitors, neutralizing formaldehyde vapors after the preservation process is complete. This reduces ongoing exposure in the prep room.

Air exchange optimization becomes much more manageable when you're working with low-fume products. Reduced vapor production means you can optimize your ventilation systems for both safety and energy efficiency.

The investment in safer chemistry pays real dividends in staff retention, reduced workers' compensation claims, and improved working conditions that help attract quality employees to our profession.

Frequently Asked Questions about Embalmer Supply Companies

How have embalming chemicals become less toxic over time?

The journey toward safer embalming chemicals tells a fascinating story of innovation driven by genuine concern for embalmer health. In the early days, embalmer supply company formulations were essentially crude formaldehyde solutions with methanol added as a stabilizer. While this worked for preservation, it created serious problems - toxic vapors that made embalmers sick and tissue over-firming that made cosmetic work nearly impossible.

The breakthrough came when companies like Genelyn developed proprietary chemistry that completely eliminates methanol dependency. Their scientists figured out how to maintain high preservation efficacy while dramatically reducing the toxic fumes that plague traditional formulations. One embalmer with asthma reported that switching to these low-fume products eliminated his workplace attacks entirely.

Modern formulations also incorporate sophisticated stabilizers and carriers that reduce vapor production without compromising preservation quality. Frigid Fluid's Silitech technology represents another approach - using silicone improvement to improve fluid distribution so effectively that lower chemical concentrations can achieve the same preservation results.

The industry has also acceptd non-flammable formulations that eliminate fire and explosion hazards during storage and transport. Companies now offer biodegradable additives that reduce environmental impact.

What factors influence fluid selection for edema or jaundice cases?

Choosing the right products for challenging cases requires understanding both the underlying condition and the specialized chemistry needed to address it. Edema cases present unique circulation challenges because accumulated fluids disrupt normal blood flow patterns and prevent standard arterial fluids from reaching tissues effectively.

For edema, embalmers need specialized pre-injection or co-injection fluids that break down the accumulated fluids first. ESCO's Keledema E-II specifically targets edematous conditions by restoring circulation pathways before the main arterial injection. Products like EDEMA PRO allow embalmers to eliminate swelling in specific body regions without affecting areas that don't need treatment.

Jaundice cases require a completely different strategy because the challenge isn't circulation - it's pigmentation. The intense yellow discoloration that characterizes jaundice simply cannot be overcome by standard embalming fluids. These cases demand specialty formulations like ESCO's Keljaundice 4 that are specifically designed to counteract yellow pigmentation.

How can embalmers access bulk pricing and rapid delivery?

Getting the best pricing and fastest delivery from your embalmer supply company requires understanding how the industry structures its distribution and pricing models. Most major suppliers offer bulk pricing tiers that kick in based on either individual order volume or annual purchase commitments. The savings can be substantial - sometimes 20% or more off standard pricing for larger orders.

Geographic location plays a huge role in delivery speed. Dodge Company's nationwide distribution network and ESCO's established warehouse system typically provide faster service than smaller regional suppliers.

Most suppliers now offer online ordering systems that streamline the process. Dodge requires registration for their web store but provides access to complete catalogs, current price lists, and special promotional offerings.

For true emergencies, most suppliers offer expedited delivery options, though these typically carry premium pricing. Smart funeral directors establish relationships with multiple suppliers to provide backup options when their primary embalmer supply company faces supply chain disruptions.

Conclusion

The journey from Civil War battlefield preservation to today's sophisticated embalmer supply company offerings tells a remarkable story of innovation and care. What began with basic formaldehyde solutions has blossomed into an industry where companies like ESCO, Dodge, Frigid Fluid, Genelyn, and Arlington Chemical don't just manufacture chemicals—they create partnerships that transform how funeral homes serve families.

The modern embalmer supply company landscape offers genuine choice backed by real expertise. Whether you need ESCO's time-tested triple-base chemistry, Genelyn's groundbreaking low-fume formulations, or Frigid Fluid's advanced Silitech diffusion technology, today's suppliers understand that every funeral home faces unique challenges.

Finding your ideal supplier isn't about picking the biggest name or the lowest price—it's about finding which company truly understands your daily reality. Do you handle challenging edema cases that require specialized pre-injection fluids? Are you concerned about staff health and looking for methanol-free alternatives? Do you need a supplier who can deliver quickly to your location?

At American Mortuary Coolers, we've watched this industry evolve from our base in Tennessee while serving funeral homes across all 48 contiguous states. Our experience crafting custom mortuary coolers has taught us something important: the best prep room operations happen when excellent equipment works seamlessly with quality chemicals. We've seen how the right embalmer supply company relationship can transform a funeral home's entire operation.

The suppliers we've worked with don't just drop off products and disappear. They offer education through seminars and training programs. They provide technical support when unusual cases arise. They innovate constantly, developing safer formulations that protect your staff while delivering superior preservation results.

What excites us most about the future is how innovation continues accelerating. Companies are developing biodegradable options for environmentally conscious families. Non-flammable formulations are simplifying storage and safety compliance. Low-fume chemistry is creating healthier workplaces that attract quality staff to our profession.

Your choice of embalmer supply company partner will shape your funeral home's success for years to come. Take time to test sample products, evaluate technical support, and consider how each supplier's strengths align with your specific needs. The right partnership will improve not just your preservation results, but your entire operation's efficiency and sustainability.

From our facilities across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania, we've seen how thoughtful supplier relationships create lasting value. When funeral homes invest in both quality equipment and chemistry partnerships, they build operations that truly serve families with dignity while protecting the dedicated professionals who make it all possible.

The Complete Guide to Buying Embalming Equipment provides additional insights on creating comprehensive prep room solutions that integrate seamlessly with your chosen embalmer supply company products.