Embalming Table 101: What It Is and How It's Used

Why Every Funeral Home Director Needs to Understand Embalming Tables

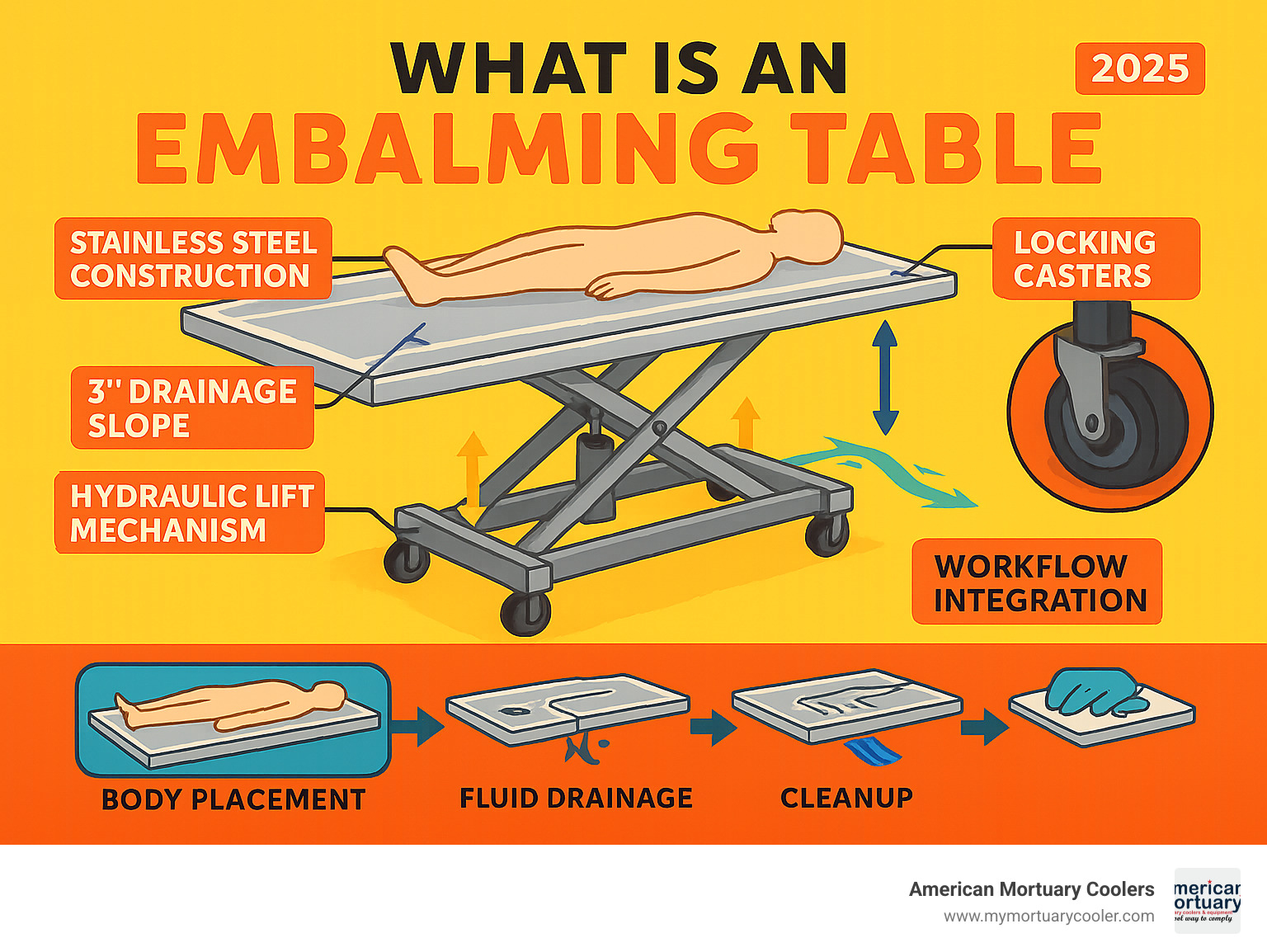

What is an embalming table is a question that goes beyond simple equipment selection - it's about understanding the foundation of your entire preparation process. An embalming table is a specialized stainless steel work surface designed to support, position, and facilitate the safe preparation of human remains during the embalming process.

Quick Answer:

- Purpose: Supports bodies during embalming with built-in fluid drainage

- Materials: Typically 14-gauge 304 stainless steel construction

- Key Features: 3-inch permanent slope, drainage system, locking casters

- Standard Size: 32"×80" (up to 35"×85" for bariatric models)

- Weight Capacity: 600-1,000 lbs depending on model type

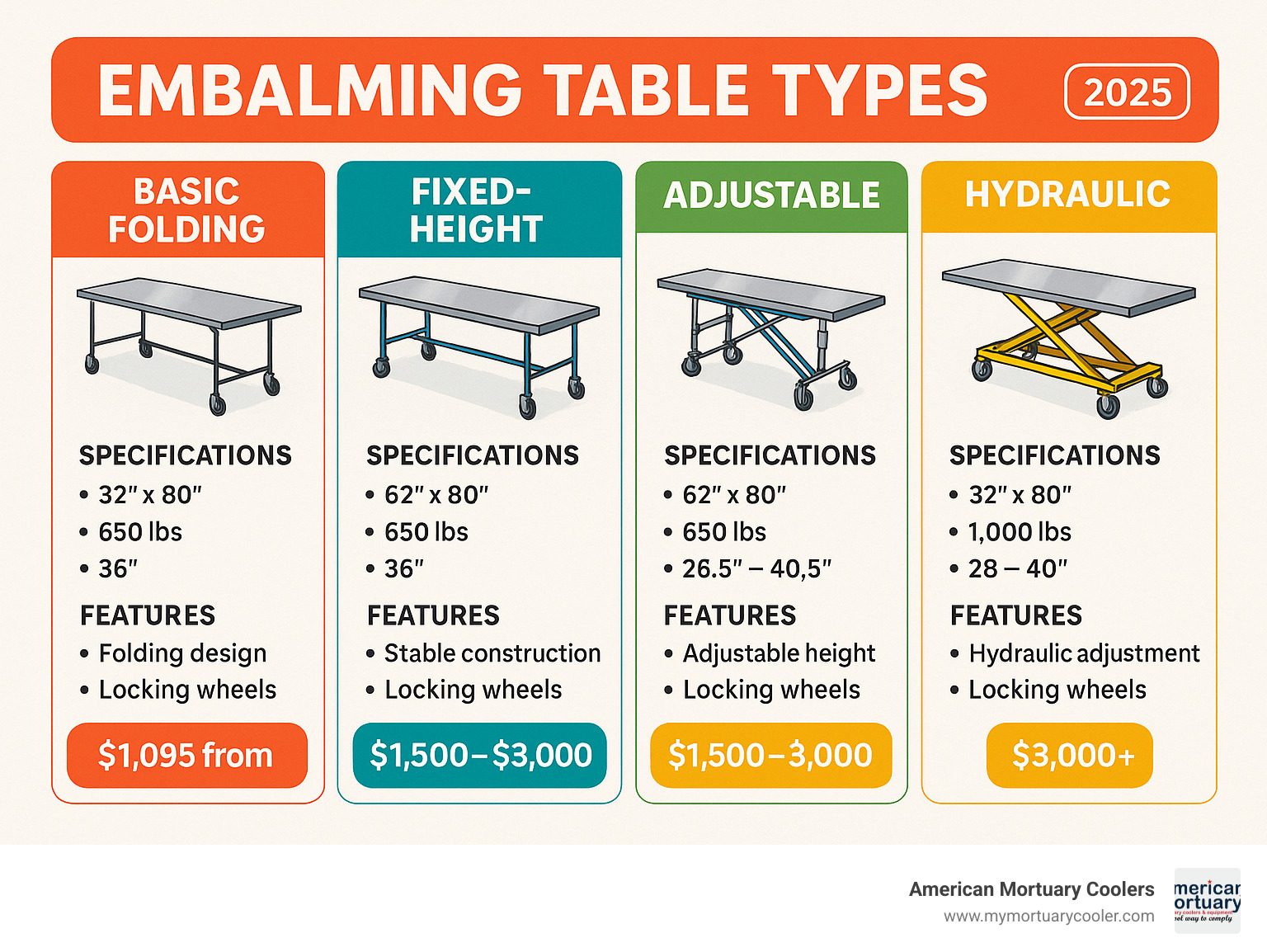

- Price Range: $1,095 for basic folding models to $5,000+ for hydraulic systems

As one Pittsburgh funeral director put it: "Investing in a hydraulic table was the best decision we made for our prep room." The right table doesn't just hold bodies - it improves workflow, reduces staff injury, and ensures proper sanitation through intelligent drainage design.

Modern embalming tables feature convex tops with permanent slopes that direct fluids to central drains, eliminating pooling and contamination risks. Whether you're dealing with standard cases or need bariatric capacity up to 1,000 lbs, the table becomes your most critical piece of preparation equipment.

I'm Mortuary Cooler from American Mortuary Coolers, and I've helped funeral directors nationwide understand what is an embalming table and how to select the right model for their specific needs. My experience spans everything from space-constrained facilities needing folding tables to high-volume operations requiring hydraulic systems with ventilation integration.

Key terms for what is an embalming table:

What is an Embalming Table?

When you walk into any professional preparation room, the centerpiece is always the same: a gleaming stainless steel surface that represents decades of innovation in mortuary science. What is an embalming table isn't just about defining a piece of equipment - it's about understanding the sophisticated workstation that makes safe, dignified preparation possible.

An embalming table serves as both a support surface and a fluid management system rolled into one essential piece of equipment. Think of it as the command center where science meets compassion, where every design element has been carefully considered to protect both the deceased and the professionals who serve them.

The journey from past to present tells a remarkable story of innovation. Early practitioners worked with simple wooden boards or marble slabs that featured basic drainage channels carved around the edges. These primitive surfaces offered little protection against contamination and made thorough cleaning nearly impossible.

Today's embalming tables represent a complete change from those early days. Where our predecessors struggled with crude surfaces that absorbed fluids and harbored bacteria, modern tables integrate advanced drainage systems, ergonomic adjustments, and materials specifically engineered to resist both chemicals and pathogens.

What is an Embalming Table in Modern Funeral Practice?

In today's funeral homes, an embalming table functions as a non-porous support surface that's been engineered specifically for cadaver handling. Every aspect of its design addresses three critical needs that define professional preparation work.

The non-porous design makes all the difference in maintaining a sanitary environment. Quality embalming tables use 304 stainless steel with a grained finish that actively resists microbial growth while remaining incredibly easy to disinfect between cases. This isn't just a work surface - it's a preservation workbench that becomes the foundation for every safe, efficient preparation procedure.

Modern tables eliminate the guesswork from contamination control. Unlike traditional surfaces that can harbor bacteria in microscopic cracks and absorb fluids over time, today's stainless steel construction provides a barrier that protects both your staff and your facility's reputation.

What is an Embalming Table's Primary Purpose?

The heart of what is an embalming table lies in three core functions that work together seamlessly: proper body positioning during procedures, efficient fluid drainage to prevent pooling and contamination, and safe manipulation of human remains throughout the entire preparation process.

Body positioning isn't just about comfort - it's about ensuring thorough, professional results. The table's convex surface and adjustable height (ranging from 28.5" to 40.5" on hydraulic models) allow embalmers to work at optimal angles while ensuring complete fluid distribution throughout the body's vascular system.

The safe manipulation aspect extends far beyond simply holding the body in place. Quality tables incorporate features like roller loading systems that can cut body transfer time in half while dramatically reducing the risk of staff injuries. The permanent 3-inch slope ensures continuous fluid drainage toward the central drain, eliminating the biological hazards that come with fluid pooling.

Anatomy of the Table: Key Features, Components & Materials

When you really look at what is an embalming table, you're seeing decades of thoughtful engineering packed into what might appear to be a simple stainless steel surface. Every curve, slope, and component has been refined to solve real problems that embalmers face every day.

Let's start with that convex top design - it's not there to look fancy. This gentle outward curve works hand-in-hand with the permanent 3-inch slope to create a gravity-powered drainage system that never fails. Fluids naturally flow away from the body and toward the edges, preventing the pooling that can create unsanitary conditions and make your job harder.

The drainage trough that runs around the entire perimeter isn't just a gutter - it's an engineered collection system. This extra-deep channel captures every drop and funnels it toward the central drain connection. No spillage, no mess, no cleanup headaches that eat into your time.

Those locking casters underneath might seem basic, but they're your safety net. Quality tables come with heavy-duty 6" or 8" swivel wheels that lock with a single foot pedal. When all four wheels lock simultaneously, your table becomes rock-solid stable - essential when you're working with remains that can weigh several hundred pounds.

Hydraulic pedals on advanced models are game-changers for workflow efficiency. Height adjustments from 28.5" to 40.5" inches, plus tilt capabilities, all controlled by foot so your hands stay free for the procedure. No stopping, no manual cranking, just smooth adjustments that adapt to your needs.

The heart of any quality table is 14-gauge 304 stainless steel construction. This isn't just any steel - it's the same grade used in medical and food processing equipment because it resists corrosion, chemicals, and bacterial growth. The square tubing framework (typically 1.5" with .12" wall thickness) provides the structural integrity to handle up to 1,000 pounds safely.

Weld integrity separates quality tables from cheap alternatives. Professional manufacturers use matching stainless steel welds that create smooth, continuous surfaces. Poor welds create crevices where contaminants hide and cleaning becomes nearly impossible.

Modern tables often include roller loading systems - a feature that can cut body transfer time in half while protecting your staff from injury. These integrated rollers let you smoothly transfer remains from gurneys without the lifting and maneuvering that causes back problems.

| Surface Material | Pros | Cons | Best For |

|---|---|---|---|

| Stainless Steel | Chemical resistant, easy cleaning, durable | Higher initial cost | Daily use, high volume |

| Porcelain | Smooth surface, traditional | Can chip, harder to repair | Light use, budget conscious |

For detailed care instructions that'll keep your table performing like new for decades, check out our comprehensive maintenance tips for stainless steel tables.

Understanding these components helps you see why a quality embalming table is an investment in your facility's efficiency, safety, and professional standards. Every feature works together to support the dignified, thorough preparation that families deserve.

Types of Embalming Tables & Specialized Models

When you're wondering what is an embalming table that's right for your facility, the answer depends heavily on your specific needs. The funeral industry has evolved to offer everything from basic folding units to sophisticated hydraulic systems, each designed to serve different operational requirements and budgets.

Hydraulic lift tables represent the gold standard for busy preparation rooms. These premium units typically cost between $3,000 to $5,000+, but there's a reason they're considered the best investment many funeral directors make. The smooth height adjustment ranges from approximately 28.5" to 40.5", letting embalmers work at their optimal ergonomic position without back strain.

What makes hydraulic tables special is their foot pedal control system. You can adjust height and positioning without taking your hands off your work - a game-changer during delicate procedures. As one funeral director told me, "I wish I'd bought hydraulic tables years earlier. My back thanks me every day."

Folding and multi-height tables solve the space puzzle that many funeral homes face. These clever designs fold flat for storage - some models compress to just 6" thick - while still delivering professional-grade features when you need them. Multi-height models let you adjust each end independently, perfect when you have embalmers of different heights or need specific positioning for complex cases.

The reality of modern funeral service means bariatric tables have become essential equipment rather than optional accessories. These oversized units measure 35"×85" compared to standard 32"×80" dimensions, with weight capacities reaching 1,000 lbs. About 20% of funeral homes in the Midwest now include at least one bariatric-capable table - a number that's growing every year.

Ventilated autopsy tables take safety to the next level by integrating downdraft ventilation connections. These specialized units feature perforated surfaces that actively draw fumes and airborne contaminants away from your work area. If your facility handles medical examiner cases or performs frequent autopsies, proper ventilation isn't just nice to have - it's essential for staff health.

Portable combo units serve multiple masters, functioning as embalming tables, dressing stations, and transport surfaces. They're perfect for smaller facilities or mobile services where versatility matters more than specialization. Quick-connect fittings and removable components make setup and breakdown surprisingly fast.

Religious and cultural considerations have driven innovation in specialized designs. Ghusl tables for Muslim preparation and tahara tables for Jewish customs incorporate specific drainage patterns and positioning features required by religious protocols. These tables respect cultural needs while maintaining the sanitation standards modern funeral service demands.

The most popular models break down by facility type: High-volume operations gravitate toward hydraulic tables with ventilation integration, while space-constrained facilities choose folding tables with storage capability. Rural and mobile services prefer portable combination units, and facilities serving larger populations invest in bariatric tables with 1,000 lb capacity. Medical examiner offices typically specify ventilated autopsy tables with perforated surfaces.

For detailed comparisons of hydraulic systems and their specific advantages, our comprehensive analysis in The Ins and Outs of Hydraulic Embalming Tables: A Comparison Guide covers everything you need to know about making the right choice for your facility.

Usage, Safety & Maintenance Protocols

Getting the most from your embalming table starts with proper setup. Position the unit on a level surface, lock all casters, and confirm that the drainage hose is clear and connected.

For body transfer, use the roller loading system whenever possible; it protects staff and shortens transfer time. Without rollers, lift with adequate help and center the body to prevent tipping.

The 3-inch permanent slope works with gravity, so fluids move naturally to the central drain and on to the municipal sewer—standard, legal practice.

Follow OSHA PPE guidelines: fluid-resistant gown, gloves, eye protection and, when chemicals are aerosolized, a suitable respirator. Height-adjustable tables should be set so the work surface is at (or slightly below) elbow height; facilities that follow this rule report an 80 % drop in back-strain complaints.

Cleaning routine

Daily

- Rinse with water.

- Wash with mild germicidal detergent.

- Dry all surfaces, paying special attention to drainage channels.

Weekly

- Inspect welds, casters, locks and hydraulics.

- Flush the drainage system.

Quarterly

- Lubricate moving parts.

- Replace worn components before failure.

Always test the caster locks—if the table moves, repair or replace the faulty wheel immediately. For more detail, consult OSHA’s death-care industry manual.

Sizing, Capacity, Accessories & Buying Guide

Standard 32"×80" tables handle roughly 85 % of cases, while bariatric 35"×85" models rated to 1,000 lb add essential capacity for larger remains and extra structural strength.

Height matters: fixed 36" surfaces suit uniform-height staff, but adjustable 28.5"–40.5" ranges protect operators of all sizes. Multi-height ends help with complex positioning.

Key accessories

- Head blocks for accurate facial work

- Side extensions for extra instrument space

- Add-on roller decks that can cut transfer time in half

Pricing overview

- Folding models: $1,095

- Mid-range fixed or multi-height: $1,500–$3,000

- Premium hydraulic or ventilated units: $3,000–$5,000+

Popular brands serve different priorities: Ferno (ergonomics), Mopec (autopsy focus) and Mortech (value-oriented). Measure doorways and workflow clearances before ordering, and weigh total cost of ownership—durability and fewer workers’-comp claims often offset higher purchase prices.

For a deeper comparison, see The Essential Guide to Choosing the Right Embalming Table for Your Mortuary.

Frequently Asked Questions about Embalming Tables

When funeral directors call our Tennessee facility, they often have the same questions about what is an embalming table and how these critical pieces of equipment actually work in daily practice. Let me address the most common concerns we hear.

How does the drainage system on an embalming table work?

The drainage system is surprisingly neat in its simplicity - it's all about gravity and smart engineering. Every quality embalming table features a permanent 3-inch slope that's built right into the structure, not something you adjust or change.

This slope works with the table's convex design to continuously move fluids away from the body and toward the perimeter drainage channel. Think of it like a very shallow funnel that's 32 inches wide and 80 inches long. The convex surface prevents any pooling around the body, while the extra-deep drainage trough around the edges captures everything and funnels it to the central drain.

The beauty of this gravity-fed system is that it never stops working and requires no external power. From the central drain, a simple hose connection directs fluids to your facility's drainage system. The permanent slope ensures consistent performance regardless of how the table is positioned or which staff member is working.

Can one table be used for dressing or autopsy as well?

Absolutely - and many funeral homes do exactly that to maximize their equipment investment. Modern multi-use table designs can handle embalming, dressing, and even autopsy procedures when you follow proper protocols.

The key is thorough sanitization between different uses. After embalming, the table needs a complete cleaning with water, followed by germicidal detergent, and proper disinfection before switching to dressing work. This isn't just good practice - it's essential for preventing cross-contamination.

For facilities that regularly handle autopsy cases, we often recommend tables with perforated surfaces and ventilation connections. These specialized features help manage the additional challenges of medicolegal work. However, many smaller operations successfully use combination tables for all their preparation needs while maintaining professional standards.

Some funeral homes prefer dedicated tables for each function to streamline workflow, but that's often a luxury rather than a necessity. With proper cleaning protocols, one quality table can serve multiple purposes effectively.

How often should the table and drainage system be cleaned?

This is where many funeral homes either go overboard or don't do enough - the right approach is systematic and based on actual contamination risk. After every single case, the table must be rinsed with water and cleaned with germicidal detergent to remove all visible contamination.

Daily disinfection is non-negotiable, even on days when the table wasn't used. Airborne contaminants and dust settle on surfaces, and research shows that pathogens can survive for days on stainless steel. Use EPA-approved disinfectants designed for mortuary applications, and pay special attention to those drainage channels and connection points where organic matter can accumulate.

Weekly deep cleaning goes beyond the daily routine. This involves inspecting and clearing drain stems, checking all moving parts for proper operation, and thoroughly disinfecting areas that might not get attention during daily cleaning. It's also when you should test your caster locks and hydraulic systems if you have them.

Quarterly maintenance is your insurance policy against expensive repairs and safety issues. This includes structural inspections, lubrication of moving parts, and verification that all safety systems work properly. Many facilities schedule this with their regular equipment maintenance to keep everything on track.

The cleaning schedule might seem intensive, but it's actually straightforward once it becomes routine. And considering that quality tables can last decades with proper care, this maintenance schedule protects a significant investment while ensuring staff safety.

Conclusion

Understanding what is an embalming table goes far beyond recognizing it as a simple work surface. These sophisticated pieces of equipment represent the intersection of engineering, ergonomics, and public health safety in modern funeral service.

The journey from basic wooden boards to today's sophisticated stainless steel systems tells the story of our industry's evolution. Modern tables with hydraulic adjustments, integrated drainage, and specialized features reflect the funeral industry's commitment to professionalism and safety while addressing chemical, biological, and musculoskeletal hazards.

Your investment in the right table pays dividends every single day. Whether you choose a basic folding model at $1,095 for occasional use or a premium hydraulic system exceeding $5,000 for high-volume operations, the decision should align with your facility's specific needs, case volume, and operational requirements.

The benefits extend beyond the immediate work surface. Quality tables improve workflow efficiency, reduce staff injuries by up to 80%, and improve safety protocols throughout your preparation process. They become an extension of your professional capabilities, supporting your commitment to excellence while protecting your team's health and safety.

At American Mortuary Coolers, we've seen how the right table transforms preparation rooms across our service areas. From Tennessee to Georgia, Illinois to coast-to-coast deliveries, we provide durable, custom-built solutions designed to boost prep-room efficiency and safety for facilities just like yours.

Every funeral home has unique requirements, and that's exactly why we focus on custom solutions. Your table choice becomes the foundation of your preparation process and a critical component in providing families with the respectful, professional service they deserve during difficult times.

An embalming table is more than equipment - it's your daily partner in maintaining the dignity and efficiency that families expect from your services. When you choose wisely and maintain properly, your table will serve your facility and the families you serve for decades to come.

For deeper insights into maximizing your investment in quality preparation equipment, explore our comprehensive guide on Investing in Excellence: Why a High-Quality Embalming Table Matters.

The right embalming table doesn't just hold bodies - it holds up your reputation for professional excellence every single day.