Coffin Lowering Machine for Sale: In Depth Guide to Buying

Why Coffin Lowering Machines Are Essential for Modern Funeral Services

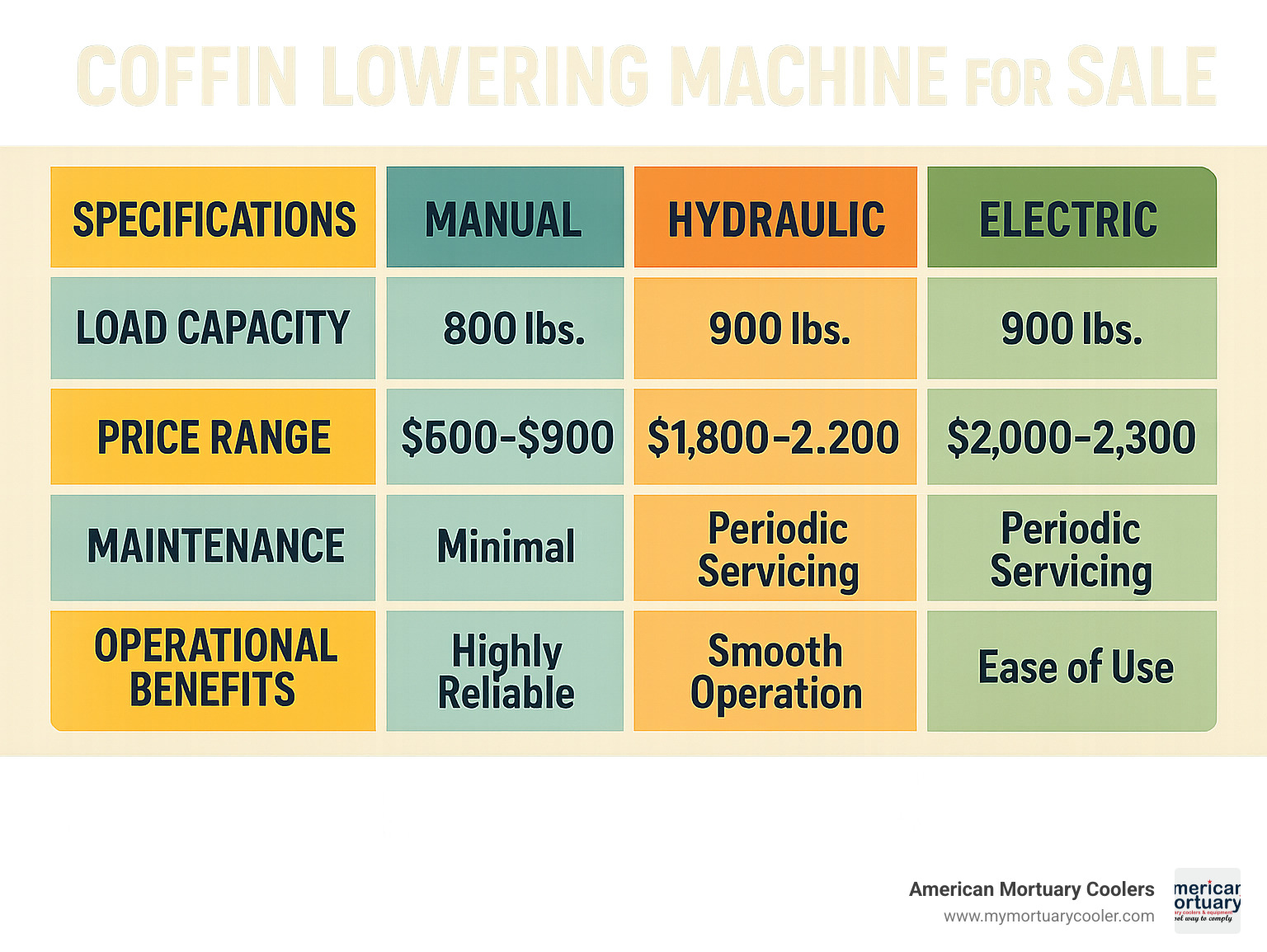

Coffin lowering machine for sale options range from $600 to $2,300, with devices rated for 800-900 pound loads and constructed from stainless steel or cast aluminum for maximum durability.

Quick Buying Guide:

- Price Range: $600-$2,300 per unit

- Load Capacity: 800-900 pounds standard

- Materials: Stainless steel (premium) or cast aluminum (lightweight)

- Frame Size: Adjustable 62" x 25" to 94" x 38"

- Minimum Order: 1 unit (no bulk requirements)

- Certifications: Look for ISO and CE standards

- Strap Length: 20-21 feet typical

The funeral industry has relied on mechanical casket lowering for over a century - the first coffin lowering device was patented by A.C. Richardson on November 13, 1894. Today's devices use centrifugal brake mechanisms and precision gear systems to provide consistent lowering speed regardless of casket weight.

These machines eliminate the physical strain of manual lowering while adding dignity to burial ceremonies. Modern units feature weather-resistant stainless steel construction, telescoping frames that adjust to various grave sizes, and modular designs for easy transport and storage.

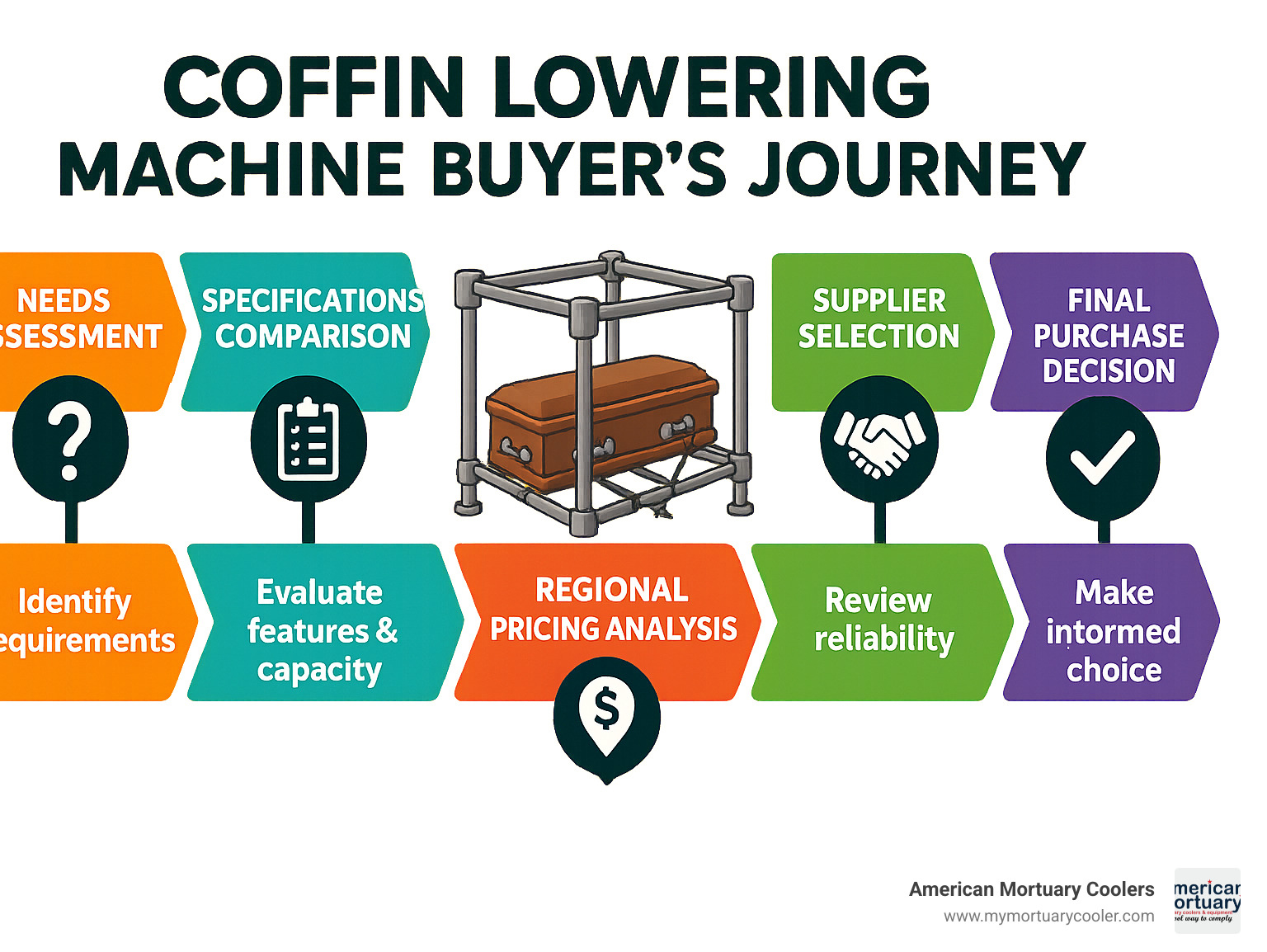

Whether you're upgrading from manual methods or replacing aging equipment, understanding the types, specifications, and regional pricing differences will help you make an informed purchase decision.

I'm Mortuary Cooler, a national-level mortuary equipment supplier with extensive experience helping funeral homes select the right coffin lowering machine for sale based on their specific operational needs and budget constraints. My background includes working directly with funeral directors across the US to source reliable, American-made mortuary equipment that improves service quality while meeting strict durability requirements.

Quick coffin lowering machine for sale terms:

How Coffin Lowering Machines Work & Benefits

The beauty of modern coffin lowering machines lies in their neat simplicity. These remarkable devices work without engines, batteries, or complex electronics – just mechanical gears, ratchet straps, and a reliable braking system that has been refined over more than a century.

At the heart of every quality coffin lowering machine for sale is a centrifugal brake system paired with precision gear assemblies. When you release the brake, gravity does the heavy lifting while the mechanical components provide smooth, controlled resistance. The result? A dignified lowering process that takes about one minute from start to finish.

The mechanical magic happens through carefully engineered components. Ratchet straps rated for 400 pounds each work alongside noiseless ball bearings for whisper-quiet operation. The gear systems, typically manufactured from durable steel and bronze, maintain constant speed regardless of whether you're lowering a lightweight casket or one at the full 900-pound capacity.

What's particularly impressive is how the 21-foot straps automatically adjust their resistance through the centrifugal mechanism. This means every lowering proceeds at the same dignified pace, providing consistency that families and funeral directors can count on.

What Is a Coffin Lowering Machine?

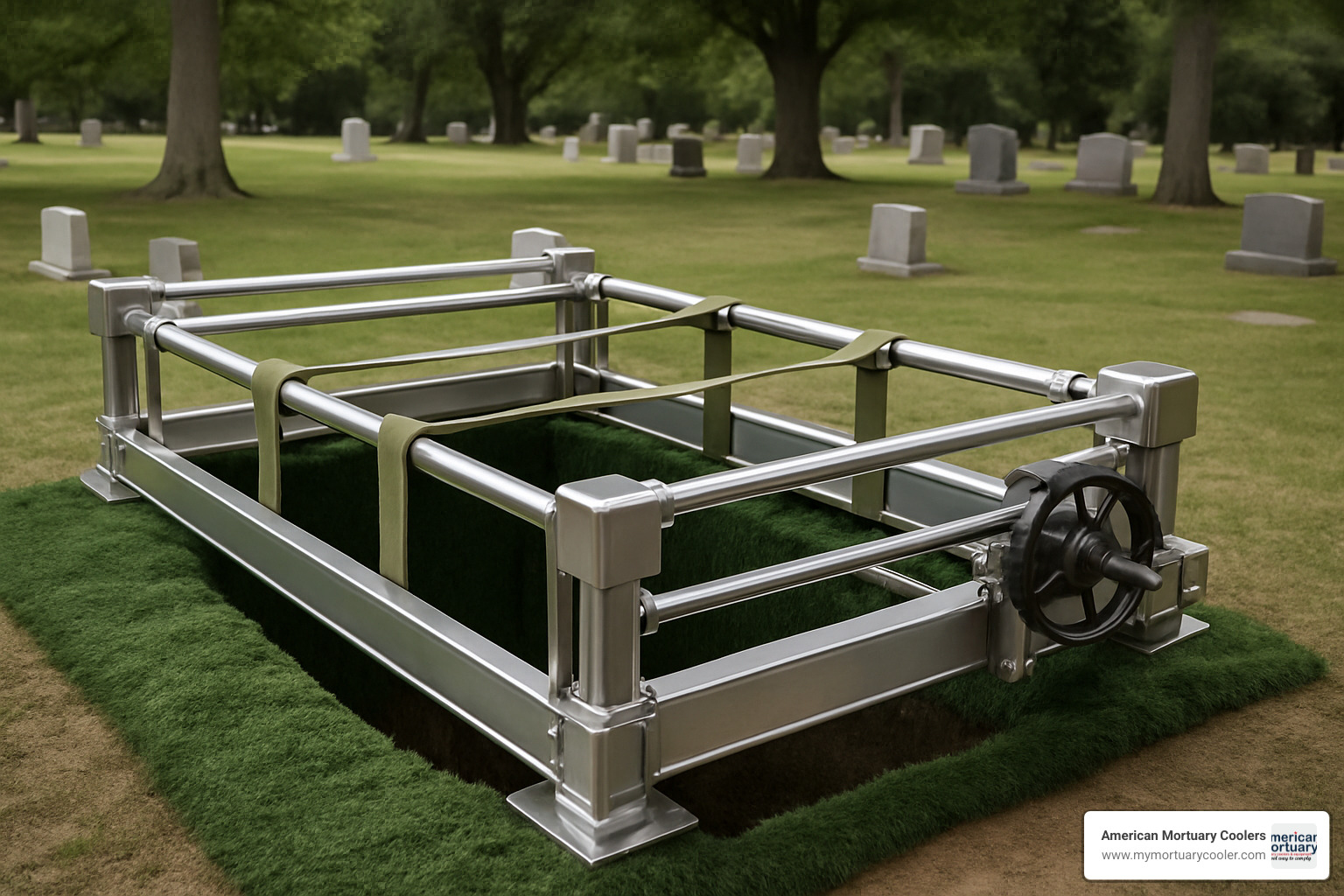

Think of a coffin lowering machine as a mechanical assistant that replaces the traditional need for multiple pallbearers during burial. These devices use a gravity brake system combined with a telescoping frame that expands from roughly 62" x 25" to 94" x 38" – adapting to virtually any grave size you'll encounter.

The typical setup includes two head units (often crafted from 50mm cast aluminum), two adjustable pipes, two heavy-duty belts, and a crank handle. It's modular by design, which means you can assemble it quickly at the graveside and pack it away just as easily when the service concludes.

Modern innovations have made these devices incredibly practical. Take the Philitech P4000, for example – it completely collapses to fit in a standard car trunk, weighs just 42 kg, yet confidently supports loads up to 350 kg. That's the kind of engineering that makes funeral directors' lives easier while maintaining the solemnity these occasions demand.

Key Advantages During Funerals

The most profound benefit isn't mechanical – it's emotional. When family comfort is your priority, these devices deliver something invaluable: peace of mind during an already difficult time. Families can focus on saying their final goodbyes instead of worrying about the logistics of the burial process.

Weather-resistant setup means ceremonies proceed smoothly whether it's a sunny spring morning or a cold, rainy afternoon. The stainless steel construction laughs off corrosion, while the mechanical operation stays consistent regardless of temperature or humidity. Unlike electronic alternatives that might fail when you need them most, these mechanical workhorses just keep going.

Perhaps the most practical advantage is reduced manpower requirements. Where manual lowering typically demands 6-8 pallbearers working in careful coordination, a single trained operator can handle the entire process with a coffin lowering machine. This eliminates physical strain on funeral staff and dramatically reduces the risk of accidents during the ceremony's most solemn moments.

The ripple effects extend beyond safety and labor-saving benefits. Funeral homes find their staff can focus on comforting families rather than coordinating complex manual procedures. The dignity of the service increases when everything proceeds smoothly and predictably, creating the respectful atmosphere that families deserve during their time of grief.

Types, Materials, and Specifications

When you're shopping for a coffin lowering machine for sale, you'll encounter three main types that each serve different needs and budgets. Manual devices lead the pack in popularity, and for good reason - they're reliable workhorses that keep operating year after year with minimal fuss. Hydraulic and electric options offer more convenience, especially if you're running a busy funeral home with multiple services daily.

The beauty of modern collapsible models lies in their clever engineering. Take the innovative color-coded assembly rods that eliminate the guesswork during setup - no more squinting at instruction manuals during stressful moments. These portable units solve a real headache for funeral directors who need to transport equipment to remote cemeteries or squeeze storage into tight spaces.

Your material choice will determine how long your investment lasts and how much you'll spend upfront. Stainless steel represents the gold standard for durability, while cast aluminum strikes a smart balance between strength and portability. Both materials can meet ISO and CE certification standards when manufactured properly, giving you peace of mind about quality and safety.

For a deeper dive into selecting reliable suppliers, our comprehensive guide to funeral equipment suppliers covers everything you need to know about vetting manufacturers and distributors.

Manual vs Hydraulic vs Electric

Manual devices dominate the market for solid reasons. They're the dependable choice that funeral directors trust day after day. The Revolution Lowering Device perfectly demonstrates why - built from heavy-wall stainless steel, it safely handles up to 900 pounds while weighing only 90 pounds itself. You simply turn the crank to engage the centrifugal brake system, and gravity does the rest.

The simplicity means fewer things can go wrong. No hydraulic leaks, no dead batteries, no electrical failures during critical moments. Just reliable mechanical operation that works the same way every time.

Hydraulic lifters step up the convenience factor significantly. These units typically allow true one-person operation, which becomes invaluable when you're short-staffed or handling multiple services. The hydraulic mechanism delivers smooth, controlled lowering with precise speed adjustment that manual cranking can't match.

The trade-off comes in maintenance complexity. You'll need to monitor hydraulic fluid levels and replace seals periodically. They also carry higher upfront costs than manual alternatives, but many funeral homes find the operational benefits worth the investment.

Electric lifters represent the premium end of the market. Many feature wireless remote controls and programmable lowering speeds that add a professional touch to services. Some models use 12V DC battery systems that can operate for extended periods without external power, perfect for remote cemetery locations.

However, electric units bring the most complexity. More components mean more potential failure points, and repairs typically require specialized technicians. The convenience comes at the cost of the bulletproof reliability that manual devices provide.

Portability varies dramatically between types. Manual devices often break down into manageable pieces for transport, while hydraulic and electric units usually need specialized handling or permanent installation.

Material Spotlight: Stainless Steel vs Aluminium

Stainless steel construction delivers best durability and corrosion resistance. This material choice becomes critical when your equipment faces constant outdoor exposure to moisture, salt air, and temperature swings. Quality stainless steel units maintain their appearance and structural integrity for decades - some manufacturers report devices operating maintenance-free for over 30 years.

Yes, stainless steel adds weight, but it also provides superior load-bearing capacity. Heavy-wall stainless steel frames safely handle maximum 900-pound loads while maintaining structural integrity through thousands of cycles. The material's non-reactive properties also make it ideal for funeral applications where cleanliness and professional appearance matter most.

Cast aluminum offers compelling weight advantages, especially for portable applications. The Philitech P4000 showcases this benefit perfectly - at just 42 kg total weight, it remains easily transportable while supporting 350 kg loads. Aluminum's natural corrosion resistance makes it suitable for outdoor use, though it requires more careful handling to prevent dents and scratches.

The manufacturing precision possible with cast aluminum allows for tighter tolerances and smoother operation. CNC-machined aluminum components achieve the precision necessary for noiseless ball bearing systems and smooth telescoping action that families notice during services.

Specifications Checklist

Load capacity represents your most critical specification. Standard units handle 800-900 pound loads, accommodating virtually all casket types including oversized models. The Revolution Lowering Device's 900-pound rating provides comfortable safety margins for standard caskets, which typically weigh 200-400 pounds when occupied.

Strap length typically ranges from 20-21 feet, allowing for lowering depths suitable for standard grave excavations. The straps themselves are rated for 400 pounds each, providing redundant safety even if one strap fails unexpectedly.

Frame dimensions vary from compact 61" x 25" closed positions to extended 96" x 37" configurations. The telescoping capability ensures compatibility with various grave sizes while maintaining structural integrity across the entire adjustment range.

Warranty terms vary significantly between manufacturers, so read the fine print carefully. Quality units typically include 12-month warranties on repaired or replaced parts, with some manufacturers offering extended coverage for premium models. Always verify warranty coverage includes both parts and labor, particularly for complex hydraulic or electric systems that require specialized service.

Coffin Lowering Machine for Sale: Price & Regional Insights

Shopping for a coffin lowering machine for sale means navigating a complex pricing landscape that varies dramatically by region. We've found prices ranging from $600 for basic manual units to $2,300 for premium hydraulic systems with complete accessory packages.

The real challenge comes when you factor in the hidden costs. That $1,200 unit from China might look appealing until you add import duties, shipping, and handling fees - suddenly your total jumps to $1,800. Meanwhile, domestic manufacturers often provide better overall value despite higher sticker prices because you're getting local support and faster delivery.

Exchange rates add another layer of complexity. The recent dollar strength has made American equipment pricier for international buyers, but it's potentially good news if you're buying imported equipment from overseas suppliers.

Here's what we're seeing across different regions:

| Region | Average Price | Lead Time | Notes |

|---|---|---|---|

| USA | $1,500-$2,300 | 4-6 weeks | Premium materials, full warranties |

| China | $600-$1,200 | 6-8 weeks | Lower costs, variable quality |

| South Africa | $800-$1,500 | 8-12 weeks | Local manufacturing, good value |

| Nigeria | $1,000-$1,800 | 10-16 weeks | Import dependent, higher logistics costs |

For international options, you can browse Lowering Device Cheap Products from various suppliers, though quality can be inconsistent.

Budget-Friendly Coffin Lowering Machine for Sale Options

Don't overlook the used equipment market - it's where smart buyers find real value. Many devices keep working for decades, especially those built with stainless steel construction. You'll typically pay $400-$800 for a manual unit in good condition.

Refurbished equipment offers another smart path. Specialized restoration companies can bring aging devices back to "brilliant condition" with 12-month warranties on all repaired parts. Expect to pay 40-60% of new prices while getting near-new performance.

Here's something many people don't realize: wholesale doesn't require huge orders. Most suppliers accept minimum orders of just one unit. But if you're buying for multiple locations, quantity discounts kick in at 5+ units with typical savings of 10-15%.

Smart buyers focus on manual units over hydraulic or electric for better reliability and lower maintenance costs. They buy directly from manufacturers to skip distributor markups and time purchases during off-peak seasons (late fall and early winter) when demand drops. Always calculate the total delivered cost including shipping and duties, and factor in warranty coverage and local service availability before making your final decision.

Premium Coffin Lowering Machine for Sale Packages

Premium packages transform basic equipment into comprehensive ceremony solutions. The Frigid Streamliner Device Combo at $11,585.61 exemplifies this approach with its complete mobile setup including cart, stands, and curtains.

Professional stands and curtains add tremendous value to burial ceremonies. Quality stands feature adjustable legs for level operation on uneven cemetery ground, while weather-resistant curtains provide visual privacy and improved dignity during the lowering process. These aren't just accessories - they're ceremony improvers.

Placer arms represent a significant operational upgrade, particularly for busy funeral homes. Stainless steel placer arm systems (around $4,290.95) provide precise casket positioning while eliminating risky manual handling. They improve both safety and ceremony flow.

Custom finishes let funeral homes match equipment to their facility's aesthetic. Options include brushed stainless steel, powder-coated colors, and custom engraving for professional branding.

Extended warranties on premium models provide real peace of mind. Some manufacturers offer 3-5 year coverage including annual maintenance visits and priority parts availability - valuable benefits when you're investing in top-tier equipment.

Buying, Operating & Maintaining Your Device

Choosing the right coffin lowering machine for sale feels overwhelming at first, but breaking it down into manageable steps makes the process much clearer. You're making a decision that will serve your funeral home for decades, so taking time to evaluate your specific needs pays off in the long run.

Certification requirements matter more than many buyers realize. Most regions require ISO and CE standards for safety compliance, while facilities handling medical examiner cases might need FDA certification too. A quick call to your local authorities can save headaches later - nobody wants to find certification issues after the equipment arrives.

Online suppliers offer great pricing and selection, but they're not all created equal. Established platforms provide buyer protection and supplier verification, which gives you some peace of mind when spending thousands of dollars. Direct manufacturer websites often cost a bit more upfront, but their technical support and warranty service usually make up the difference.

Local distributors charge higher prices, but there's real value in being able to see the equipment in person. When something breaks at 2 PM on a Friday, having local parts availability and service support becomes priceless. The relationship aspect matters too - a good local distributor becomes a trusted partner for all your equipment needs.

For detailed guidance on making this important decision, our Essential Guide to Buying a Funeral Lowering Device walks through every consideration step by step.

How to Choose the Right Model

Grave size compatibility should be your first consideration. Take actual measurements at your local cemeteries - don't guess or rely on "standard" dimensions. Most devices adjust from 62" x 25" to 94" x 38", which covers nearly every situation you'll encounter. But measuring first prevents that sinking feeling when your new equipment doesn't fit.

Service volume determines whether manual operation makes sense or if you need powered assistance. Funeral homes handling fewer than 100 services annually do perfectly fine with manual devices. The reliability and lower maintenance costs often outweigh the convenience factor. Higher-volume operations benefit from hydraulic or electric assistance, especially when the same staff member operates the device multiple times per week.

Budget planning gets tricky because the lowest purchase price doesn't always mean the best deal. A reliable $2,000 manual unit might cost less over ten years than a $1,200 hydraulic model when you factor in maintenance visits, hydraulic fluid changes, and potential repairs. Think total cost of ownership, not just the initial check you write.

Other factors deserve attention too: available storage space for when the device isn't in use, transportation requirements if you serve multiple locations, staff training needs for different device types, and local service availability when things go wrong.

Step-by-Step Operation Guide

Assembly becomes routine once you've done it a few times, but the first setup can feel intimidating. Start by laying out all components in an organized way - this isn't the time to wing it. Color-coded systems like those on the Philitech P4000 eliminate guesswork, which reduces setup time and prevents mistakes during emotional moments.

Connect the telescoping frame sections first, making sure everything aligns properly and locks securely. Crank operation requires understanding how the centrifugal brake system works - it's actually quite clever. Engage the brake before positioning the casket, then release gradually to begin lowering.

Lowering speed control happens through brake adjustment, not how fast you turn the crank. The centrifugal mechanism automatically maintains consistent speed regardless of the casket weight. Most devices complete the lowering in about one minute, which provides appropriate ceremony pacing without making families feel rushed.

Personal protective equipment keeps everyone safe during what's already a difficult time. Work gloves protect hands from metal edges and strap friction. Safety glasses prevent eye injuries from tensioned mechanisms. Steel-toed boots protect feet during setup, and high-visibility clothing helps in cemetery environments where vehicle traffic might be present.

Always inspect strap condition before each use - frayed or damaged straps create dangerous situations that no funeral home wants to experience.

Routine Maintenance & Repair Services

Strap inspection takes thirty seconds but prevents disasters. Check for fraying, cuts, or excessive wear before every single use. Each strap handles 400 pounds, but that safety margin disappears quickly with worn components. Replace damaged straps immediately - this isn't something to put off until next week.

Bearing grease needs attention annually for devices with ball bearing systems. Marine-grade grease works best for outdoor applications, providing complete coverage of all moving parts. Proper lubrication extends bearing life dramatically and keeps operation smooth and quiet.

On-site service is available from specialized companies with decades of industry experience. These veteran-owned operations understand that funeral homes can't wait for repairs - they provide rain-or-shine reliability when critical equipment fails. Many offer same-day service within their coverage areas.

National repair networks cover major brands comprehensively. Companies like Wilbert provide 12-month warranties on all repaired or replaced parts, with turnaround times that won't leave you scrambling for alternatives during busy periods.

Accessories & Parts Included

Standard components vary between manufacturers, but typically include the lowering device itself, straps, crank handle, and basic assembly hardware. Premium packages add stands, curtains, and placer arms that significantly improve functionality and ceremony appearance.

Belts and straps are consumable items requiring periodic replacement based on usage volume. Quality units include 20-foot straps rated for 400 pounds each, often with color-coding to prevent installation errors during setup.

Placer arms make precise casket positioning much easier while reducing manual handling requirements. Stainless steel construction ensures these accessories last as long as the main device, while adjustable designs accommodate various casket dimensions.

Elevation stands provide stable, level operation on uneven cemetery ground. Adjustable-leg designs adapt to varying terrain conditions, which becomes especially important during wet weather when ground conditions change.

Transport carts enable easy movement of assembled devices between locations. This becomes particularly valuable for funeral homes serving multiple cemetery locations or providing graveside services at remote sites.

Conclusion & Where to Buy

After exploring the comprehensive world of coffin lowering machine for sale options, it's clear that these devices represent one of the most valuable investments a funeral home can make. The technology has evolved tremendously since that first 1894 patent, yet the core mission remains unchanged - providing dignity and safety during life's most solemn moments.

Your choice ultimately comes down to understanding your specific needs. Budget-conscious funeral homes will find excellent value in manual stainless steel units starting around $600, while high-volume operations might justify the $2,300 investment in premium hydraulic systems with full accessory packages. The sweet spot for most facilities falls around $1,500 for a quality manual device that will serve faithfully for decades.

Stainless steel construction consistently proves its worth over time, even with the higher upfront cost. We've seen manual devices from the 1990s still operating flawlessly today, requiring nothing more than occasional strap replacement and annual lubrication. That's the kind of reliability that makes funeral directors sleep better at night.

The load capacity of 800-900 pounds in modern devices eliminates any concerns about accommodating different casket types, while modular designs mean your team can set up and break down equipment efficiently - even when working in challenging cemetery conditions.

Here at American Mortuary Coolers, we've spent years helping funeral homes across the country steer these equipment decisions. Based in Tennessee with our network spanning from Johnson City to Los Angeles, we understand that every funeral home faces unique challenges. Some serve rural communities where portability matters most, while others handle high-volume urban operations requiring maximum efficiency.

Our approach is refreshingly straightforward - we listen to your specific operational needs, then recommend solutions that actually make sense for your facility and budget. No high-pressure sales tactics, no cookie-cutter recommendations. Just honest advice from people who understand the funeral industry's unique demands.

What sets us apart is our commitment to custom solutions with direct delivery across all 48 contiguous states. Whether you're in Columbia SC, Chicago IL, Dallas TX, or anywhere in between, we ensure your equipment arrives when promised and ready to serve your families with dignity.

The funeral industry deserves equipment suppliers who understand that this isn't just about machinery - it's about helping families through their most difficult moments. Every coffin lowering machine for sale represents countless families who will find comfort in knowing their loved one's final journey was handled with the utmost care and respect.

Ready to find the perfect solution for your funeral home? Our Funeral Supply Store offers comprehensive equipment options, and our experienced team is standing by to provide personalized consultation. Because when it comes to serving families in their time of need, you deserve equipment that never lets you down.