Cheat Sheet to Finding Safe & Clean Paraffin Wax

Why Clean Paraffin Wax Quality Matters for Professional Operations

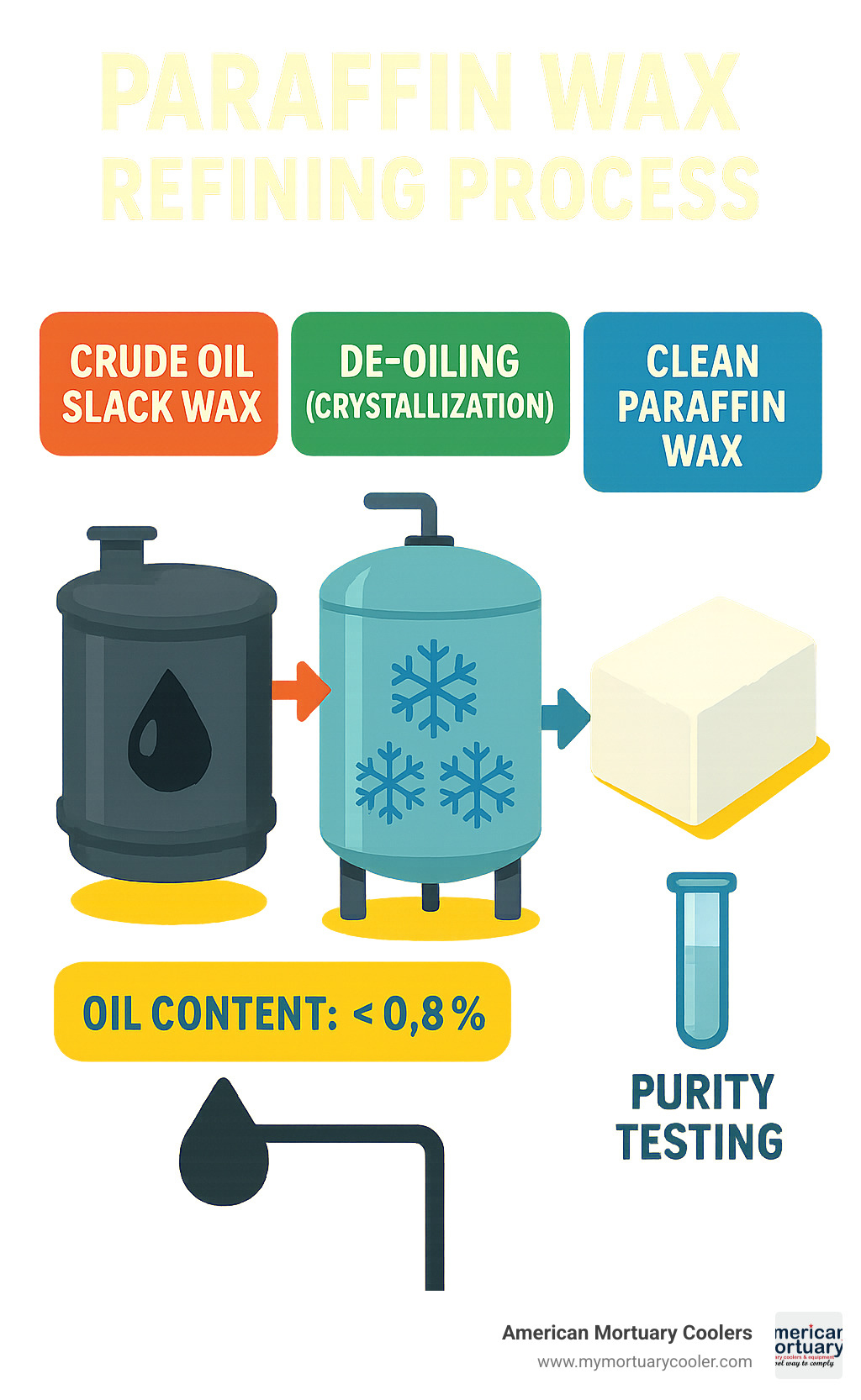

Clean paraffin wax is fully refined paraffin with maximum oil content of 0.5-0.8% by weight, making it highly pure and suitable for professional applications. Here's what defines clean paraffin wax:

Key Characteristics:

- Oil content: Less than 0.8% by weight

- Appearance: Colorless, odorless, translucent solid

- Melting point: 51.7°C to 73.3°C (125°F to 164°F)

- Purity: Meets FDA requirements (21 CFR 178.3710) for food contact

- Composition: Straight-chain hydrocarbons (C20-C40)

Common Applications:

- Candle making (superior scent throw, no smoking)

- Food packaging and coatings

- Cosmetic formulations

- Laboratory embedding medium

- Protective coatings and sealants

The difference between clean and standard paraffin comes down to the refining process. As Karl von Reichenbach finded in 1830, proper refinement creates a cleaner-burning alternative to traditional materials like tallow. Today's fully refined paraffin undergoes extensive de-oiling and purification to remove contaminants like sulfur compounds and aromatic hydrocarbons.

Clean paraffin wax has become essential in professional settings because of its consistent performance and safety profile. Industries from funeral services to food packaging rely on its purity standards and predictable properties.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in mortuary industry materials and equipment. Through years of working with funeral professionals, I've seen how clean paraffin wax quality directly impacts everything from embalming procedures to facility maintenance standards.

Quick clean paraffin wax definitions:

Why this guide matters

Paraffin wax has been a cornerstone material since the 1850s, when it revolutionized candle making by offering a cleaner burn than tallow. This petroleum-derived product consists of hydrocarbon molecules containing between 20 and 40 carbon atoms, with the general molecular formula CnH2n+2.

Today's consumer demand for high-quality, safe materials has pushed the industry toward increasingly refined grades. We're seeing funeral professionals, cosmetic manufacturers, and food packaging companies all requiring documentation of purity levels that would have been unimaginable decades ago.

Understanding Clean Paraffin Wax

Clean paraffin wax begins life as something much less glamorous—slack wax, a byproduct pulled from petroleum refining that looks nothing like the pristine white blocks we use in professional applications. Think of slack wax as the rough diamond that needs careful cutting and polishing to reveal its true potential.

The change happens through solvent crystallization, where that raw slack wax gets dissolved, carefully cooled, and filtered to strip away oils and impurities. Additional bleaching and odor removal steps create the translucent, colorless solid that meets professional standards. It's a bit like turning muddy water crystal clear—the process matters as much as the end result.

What makes clean paraffin wax truly "clean" comes down to oil content. Fully refined grades contain just 0.5-0.8% oil and appear water-white, perfect for candles, cosmetics, and food contact applications. Semi-refined versions hold 1.5-3.0% oil with a light yellow tint, suitable for industrial coatings. Unrefined paraffin carries 3.0-10% or more oil content, showing yellow to brown coloration that limits its use to matches, crayons, and basic industrial purposes.

The contaminants that refining removes include residual slack oil, sulfur compounds, and polycyclic aromatic hydrocarbons (PAHs). These troublemakers cause smoking, unpleasant odors, and potential health concerns—exactly what professional operations can't tolerate.

Here's something that might surprise you: paraffin wax is actually biodegradable under composting conditions according to ASTM D6400-12 standards. That makes it more environmentally friendly than many people assume.

What Does "Clean Paraffin Wax" Mean?

When we say "clean" paraffin wax, we're talking about specific purity standards that change depending on how you plan to use it. It's not just marketing speak—there are real benchmarks that matter.

For food-grade applications, wax must meet FDA requirement 21 CFR 178.3710 for materials that contact food. This ensures nothing harmful transfers from the wax to food products. Think of it as the difference between using a clean plate versus one that might have soap residue.

Cosmetic and fragrance applications demand even stricter standards. The wax needs to be virtually odorless and colorless, typically with oil content below 0.5%. Those straight-chain paraffin hydrocarbons provide excellent gloss and water-repellent properties without adding unwanted scents or colors to your final product.

Testing for Clean Paraffin Wax Purity

Professional testing separates truly clean paraffin wax from products that just claim purity without backing it up. The main testing methods each serve a specific purpose in quality verification.

Gas Chromatography-Flame Ionization Detection (GC-FID) identifies the exact hydrocarbon composition and spots unwanted impurities hiding in the mix. Fourier Transform Infrared Spectroscopy (FTIR) confirms the molecular structure matches what you ordered and ensures no unwanted compounds snuck through processing.

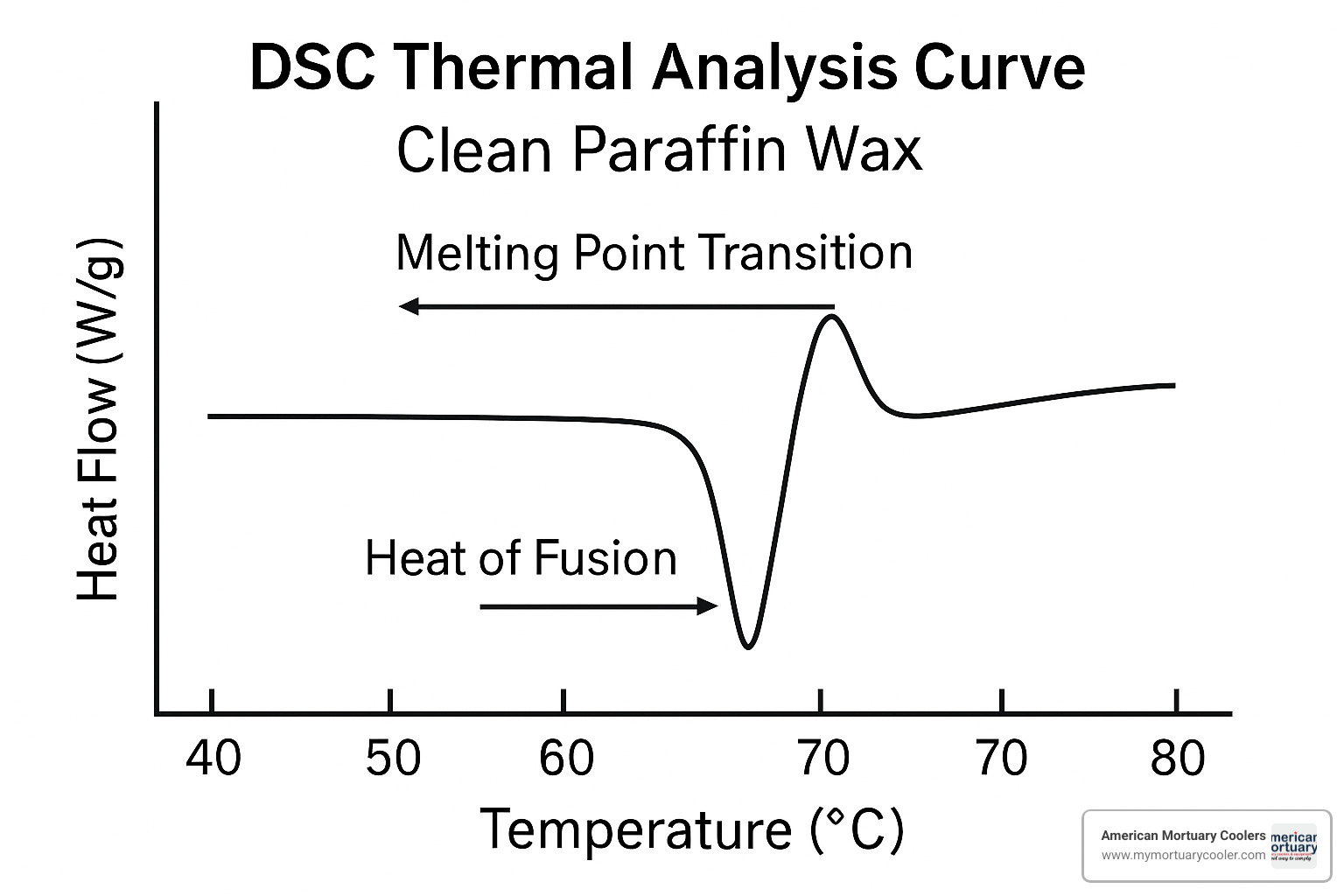

Penetrometer testing measures hardness and consistency—critical for applications where texture matters. Differential Scanning Calorimetry (DSC) determines precise melting points and thermal properties, while ash content and color index testing quantifies mineral impurities and visual quality.

These aren't just fancy lab procedures—they're your insurance policy that the wax will perform as expected in your specific application.

Differences Between Fully, Semi & Unrefined Grades

The crystal structure tells the real story of paraffin quality. Fully refined clean paraffin wax forms superior crystals that create a harder, more stable structure. This crystallinity affects everything from how evenly a candle burns to how smooth a cosmetic feels on skin.

Semi-refined grades retain more oil, making them softer and giving them that yellowish tint that limits where you can use them. They're perfectly fine for industrial applications but won't meet the standards for consumer products.

Unrefined paraffin often carries a waxy odor and brown coloration from leftover impurities. While it works for waterproofing and basic industrial uses, it's completely inappropriate for professional applications requiring purity.

The price tiers reflect this quality hierarchy directly. Fully refined grades cost more because of the additional processing steps, but that premium pays for superior performance characteristics that matter in professional settings.

Essential Properties & Performance Metrics

Understanding the technical specs of clean paraffin wax makes all the difference when you're selecting materials for professional use. Think of these properties as your roadmap to consistent results—whether you're making candles or preparing materials for mortuary applications.

The melting point range of 51-73°C gives you plenty of options to match your specific needs. If you're working with container candles, those lower-melt grades around 125-135°F work beautifully. Need something for pillar candles or industrial coatings? The higher-melt varieties at 151-164°F provide the structure you're looking for.

Density sits at approximately 900 kg/m³ at room temperature, which means this material is lighter than water but substantial enough to hold its shape well. The heat of fusion ranges from 200-220 J/g—that's the energy needed to melt it completely. This consistent energy requirement helps predict heating costs and processing times.

Here's something interesting: clean paraffin wax acts as an excellent electrical insulator with resistivity between 10¹³-10¹⁷ Ω·m. While that might not matter for candle making, it's crucial for certain industrial applications.

The solubility characteristics tell an important story too. Clean paraffin wax won't dissolve in water (which is why it's great for protective coatings), but it dissolves readily in warm alcohol, chloroform, and petroleum ether. This selective behavior lets you use it where you need water resistance while still being able to clean it up with the right solvents.

Physical Stats Every Formulator Should Know

Safety starts with understanding that clean paraffin wax has a flash point between 200-240°C. That's relatively safe for handling, though you'll still want proper ventilation in your workspace. Nobody wants to work in a stuffy room with any melting wax.

Here's something that catches people off guard: this material expands significantly when it melts. That expansion property actually gets used in thermostatic elements and actuators, but for most applications, you just need to account for it in your containers and molds.

The smoke point directly relates to oil content—and this is where quality really shows. Fully refined grades with oil content below 0.8% produce almost no smoke during burning. Semi-refined varieties with higher oil content? They'll smoke noticeably, which defeats the purpose if you're aiming for clean performance.

Clean Paraffin Wax in Candle Performance

When it comes to candles, clean paraffin wax really shines in the scent throw department. The high purity means fragrance molecules can do their job without interference from residual oils or impurities. You get the full fragrance experience you're paying for.

Color compatibility is another win. The straight-chain hydrocarbon structure plays nicely with commercial dyes, giving you those bold, stable colors that won't fade or bleed over time. There's nothing worse than a candle that looks great initially but develops weird color patterns after a few months.

Burn rate consistency comes from that uniform composition we talked about earlier. Each molecule behaves predictably during combustion, so you get reliable performance from batch to batch. The glossy finish that makes quality paraffin candles look so appealing? That comes from proper crystal formation during cooling—something you can only achieve with fully refined grades.

For comprehensive safety information, check out this Scientific research on paraffin safety which covers occupational exposure limits and handling guidelines.

Applications, Benefits & Alternatives

Clean paraffin wax shows up in more places than you might expect. Walk into any cosmetics lab, and you'll find it creating the smooth texture in cold creams and lip balms. Its moisture-barrier properties make it perfect for protecting skin while feeling pleasant to apply.

The food industry has relied on paraffin for decades. Those waxy coatings on paper milk cartons and cheese wheels? That's clean paraffin wax doing its job. Its FDA approval means it can safely touch food without transferring harmful chemicals. Many home canners still use it to seal their homemade jellies and preserves.

In funeral homes and medical facilities, paraffin serves a completely different purpose. Histology labs use it to embed tissue samples—the wax infiltrates the tissue, then hardens to allow precise, thin slicing for microscope examination. This application demands the purest grades available since any impurities could interfere with diagnosis.

Here's something interesting: clean paraffin wax is finding new life in energy storage. Its ability to melt and solidify at predictable temperatures makes it useful for passive cooling systems. When temperatures rise, the wax melts and absorbs heat. When it cools down, it releases that stored energy back.

The lubrication industry uses paraffin in specialty applications where its chemical inertness matters more than high performance. It won't react with sensitive equipment or degrade rubber seals over time.

| Property | Clean Paraffin | Soy Wax | Beeswax |

|---|---|---|---|

| Burn Time | 45-50 hours/lb | 50-60 hours/lb | 60-70 hours/lb |

| Cost per lb | $2-4 | $3-6 | $8-15 |

| Fragrance Load | Up to 12% | 6-10% | 4-8% |

| Environmental Score | Moderate | High | High |

Why Industries Prefer Clean Paraffin Wax

When you're running a business, consistency matters more than almost anything else. Clean paraffin wax delivers the same performance batch after batch because its purity eliminates variables. That oil content below 0.8% means no surprise smoking, no unexpected odors, and no color variations that could ruin a product run.

FDA compliance opens doors that other materials can't. Food packaging companies need that certification to legally use any wax near consumables. Without it, they'd have to source more expensive alternatives or redesign their entire process.

The shelf life advantage is huge for inventory management. While natural waxes can go rancid or develop off-odors after a year, properly stored clean paraffin wax stays fresh for three years or more. That translates to less waste, fewer emergency reorders, and better cash flow.

Comparing Clean Paraffin Wax to Natural Waxes

The renewable versus petroleum debate gets heated in some circles. Soy wax comes from soybeans, palm wax from palm trees, and beeswax from busy honeybees. These natural origins appeal to environmentally conscious consumers who prefer agricultural products over petroleum derivatives.

But here's where clean paraffin wax shines: fragrance load capacity. It can hold up to 12% fragrance oil without affecting burn quality. Soy wax typically maxes out around 10%, while beeswax struggles with anything over 8%. For candle makers who want strong scent throw, this difference matters enormously.

Color stability is another paraffin advantage. Natural waxes can fade or shift colors over time, especially when exposed to light. Paraffin holds its color indefinitely, which is why commercial candle manufacturers still prefer it for vibrant, long-lasting products.

The biodegradability question isn't as simple as it seems. While natural waxes break down faster in normal conditions, clean paraffin wax does biodegrade under composting conditions according to ASTM D5339 testing. It just takes longer than plant-based alternatives.

Microcrystalline wax, paraffin's petroleum cousin, offers different properties with smaller crystal structure and higher melting points. It's often blended with paraffin to modify texture and flexibility in applications like protective coatings and adhesives.

For detailed technical specifications on industrial applications, the External guide on fully refined grades provides comprehensive information from major manufacturers.

Safety, Environmental Impact & Handling Best Practices

When working with clean paraffin wax, safety comes first. NIOSH sets the exposure limit for paraffin wax fumes at 2 mg/m³ over an 8-hour workday. The good news? Clean paraffin produces much fewer fumes than lower-grade waxes because of its low oil content.

Still, you'll want proper ventilation whenever you're melting wax. Think of it like cooking—even the cleanest ingredients benefit from a good exhaust fan. Heat-resistant gloves and safety goggles are must-haves when handling molten material. Nobody wants a surprise splash of 180°F wax.

Here's something important: paraffin wax is classified as a Class B fire material. That means water won't put out a paraffin fire—it'll actually make things worse. Keep foam or dry chemical extinguishers nearby instead.

From our years at American Mortuary Coolers, serving facilities from Tennessee to California, we've seen what happens when places cut corners on wax quality. Inferior grades create ventilation nightmares and safety headaches. Investing in clean paraffin wax eliminates most of these problems before they start.

The environmental picture has gotten clearer over the years. Clean paraffin wax does biodegrade under composting conditions, meeting ASTM D5339 standards. It's not as fast as plant-based waxes, but it's far from the "never breaks down" myth some people believe. VOC emissions stay minimal with fully refined grades, making them safe for indoor use.

For mortuary professionals dealing with complex odor management, our guide at More info about odor management in prep rooms covers strategies that work alongside proper wax handling.

Clean Paraffin Wax Handling Checklist

Smart handling starts with adequate ventilation during any melting operation. Your workspace should have good air exchange—not just a tiny fan in the corner. Thermostatically-controlled melters prevent the overheating that causes most problems. They're worth every penny.

Keep spill kits ready with absorbent materials and the right solvents. Murphy's Law applies to wax handling—spills happen when you're least prepared. Store your clean paraffin wax between 10-27°C in dry conditions. Hot storage areas can cause quality problems, while cold storage makes handling difficult.

Waste segregation matters more than people realize. Don't mix contaminated wax with clean material—it ruins the whole batch. Install appropriate fire suppression for Class B materials. Your insurance company will thank you.

Temperature monitoring keeps everything running smoothly. Simple digital thermometers prevent most overheating issues that create fumes and degrade wax quality.

Frequently Asked Questions about Clean Paraffin Wax

What temperature should I melt clean paraffin wax at safely?

Melt clean paraffin wax about 10-15°F above its melting point. For most grades, that means 140-180°F. Going over 200°F degrades the wax and creates unnecessary fumes—there's no benefit to superhot wax.

Double-boiler methods work great for small batches. For larger operations, thermostatically-controlled melters give you consistent results without babysitting. Think slow and steady rather than hot and fast.

Is clean paraffin wax biodegradable or eco-friendly?

Clean paraffin wax does break down naturally under composting conditions. It meets ASTM D6400-12 and D5339-11 standards for biodegradability. The process takes longer than plant-based waxes, but it's not permanent pollution.

The eco-friendly question depends on your priorities. It's petroleum-derived, which some people avoid. But it also lasts longer than natural alternatives, potentially using fewer resources over time. Soy wax and other plant-based options offer faster biodegradation and renewable sourcing if that's important to your operation.

How do I test a shipment for "clean" certification?

Start with the paperwork. Request certificates of analysis showing oil content below 0.8%, color index values, and melting point ranges. Reputable suppliers provide this documentation without hesitation.

Do a simple burn test on a small sample. Clean paraffin should burn without smoking or producing odors. Any yellowing, cloudiness, or waxy smell indicates lower-grade material. Visual inspection reveals a lot—quality wax looks colorless and translucent, like clear ice.

Trust your nose and eyes. If something seems off, it probably is. We've helped too many facilities deal with substandard wax that caused problems down the line.

Buying, Storing & Cleaning Up Spills

Shopping for clean paraffin wax feels a bit like buying equipment for your facility—you want quality that won't let you down when it matters most. The market offers everything from convenient 1-pound blocks perfect for small operations to hefty 110-pound bulk slabs that make sense for high-volume users.

Pastille forms look like tiny white pellets and melt faster than solid blocks. They're easier to measure and handle, though you'll pay a premium for the convenience—typically $0.50 to $1.00 more per pound. Bulk slabs offer the best value, with prices ranging from $1-3 per pound depending on the grade and your order size.

When evaluating suppliers, dig into their refining processes and quality control procedures. Any reputable supplier should provide certificates of analysis showing oil content specifications. If you're shopping online and can't find oil content clearly listed, that's your cue to keep looking.

At American Mortuary Coolers, we've learned that material quality directly impacts equipment performance. Just like we demand precision in our custom mortuary coolers delivered across the contiguous 48 states, our customers need reliable specifications for their operations. Poor-quality wax can create ventilation issues and maintenance headaches that nobody wants to deal with.

Storage couldn't be simpler, but getting it wrong causes problems. Keep your clean paraffin wax in a cool, dry place between 50-80°F. A basement or climate-controlled warehouse works perfectly. Hot storage areas can cause the wax to soften and potentially leak from packaging.

First-in-first-out rotation makes sense even though properly stored wax lasts practically forever. Label everything with received dates and use older stock first. This prevents any chance of contamination and keeps your inventory fresh.

For funeral professionals looking at the bigger picture of procurement, our More info about mortuary equipment sourcing guide covers strategies that apply across your entire supply chain.

How to Identify Clean Paraffin Wax in the Market

Reading labels becomes second nature once you know what to look for. "Fully refined" should appear prominently, along with oil content specifications below 0.8%. If these details are buried in fine print or missing entirely, consider it a warning sign.

Safety Data Sheets tell the real story about what you're buying. These documents reveal detailed composition information and handling requirements that marketing materials often gloss over. Take five minutes to review the SDS before placing large orders—it can save you from costly mistakes.

The burn test never lies. In a well-ventilated area, melt a small sample of clean paraffin wax. It should melt without smoking, produce no petroleum odor, and burn with an almost invisible blue flame. Any yellowing, smoking, or strong smells indicate you're dealing with lower-grade material.

Visual inspection gives immediate feedback about quality. Clean grades look water-white when melted and crystal-clear when solid. Cloudiness, yellow tinting, or visible particles mean the refining process wasn't thorough enough for professional applications.

Cleaning Spills & Stains the Pro Way

Wax spills happen to everyone eventually, and knowing the right cleanup techniques saves time and prevents damage. The approach depends on your surface, but the basic principles remain consistent across situations.

For hard surfaces like floors and countertops, the freeze-and-scrape method works like magic. Grab some ice cubes, put them in plastic bags, and place them on the spill for 5-10 minutes. The wax becomes brittle and scrapes off easily with a plastic putty knife or credit card. Avoid metal scrapers that can scratch surfaces.

Fabric and carpet cleanup requires the paper towel and iron technique that many people learned from their grandmothers. Place several layers of paper towels over the wax, then apply a warm iron—not hot enough to damage the material underneath. The heat melts the wax into the paper towels. Keep rotating fresh towels as they absorb the wax.

Stubborn residues need solvent treatment. CT1 Multisolve and similar aliphatic solvents dissolve clean paraffin wax without damaging most surfaces. Always test solvents in hidden areas first and provide plenty of ventilation during cleanup.

Different surfaces need specific approaches. Wood surfaces respond well to mineral spirits followed by buffing with a soft cloth. Stone and marble require quick action to prevent absorption—commercial stone cleaners work best here. Carpets might need professional dry-cleaning solvents for complete residue removal after the iron treatment.

The key to successful cleanup is acting quickly before the wax has time to penetrate porous surfaces or harden completely. Keep cleanup supplies handy in areas where you regularly work with wax—it makes the whole process much less stressful when accidents happen.

Conclusion

American Mortuary Coolers' customers demand materials that are as reliable as our custom morgue equipment—use this guide to source, store, and handle only the safest, clean paraffin wax. Whether you're operating from our Southeast Region coverage area or anywhere across our service territories, the principles remain constant: verify purity specifications, maintain proper storage conditions, and implement safe handling protocols.

The investment in clean paraffin wax pays dividends through consistent performance, reduced maintenance issues, and compliance with safety regulations. Just as we've built our reputation on delivering durable, custom mortuary solutions, choosing properly refined paraffin ensures your operations meet the highest professional standards.

From our facilities serving Atlanta GA, Chicago IL, Dallas TX, and throughout our regional coverage areas, we've seen how attention to material quality translates to operational excellence. Don't compromise on purity when clean paraffin wax is readily available from qualified suppliers.

Explore our full mortuary solutions for your facility's next upgrade, and remember that every component—from major equipment to consumable materials—contributes to your professional reputation and service quality.