Beginner's Guide to Refrigerant R404A: Properties & Uses

What You Need to Know About Refrigerant R404A

Refrigerant R404A is a widely used hydrofluorocarbon (HFC) blend that has served as the industry standard for commercial refrigeration systems since the mid-1990s. This near-azeotropic refrigerant replaced ozone-depleting CFCs like R-502 and R-22, offering zero ozone-depletion potential while maintaining excellent cooling performance.

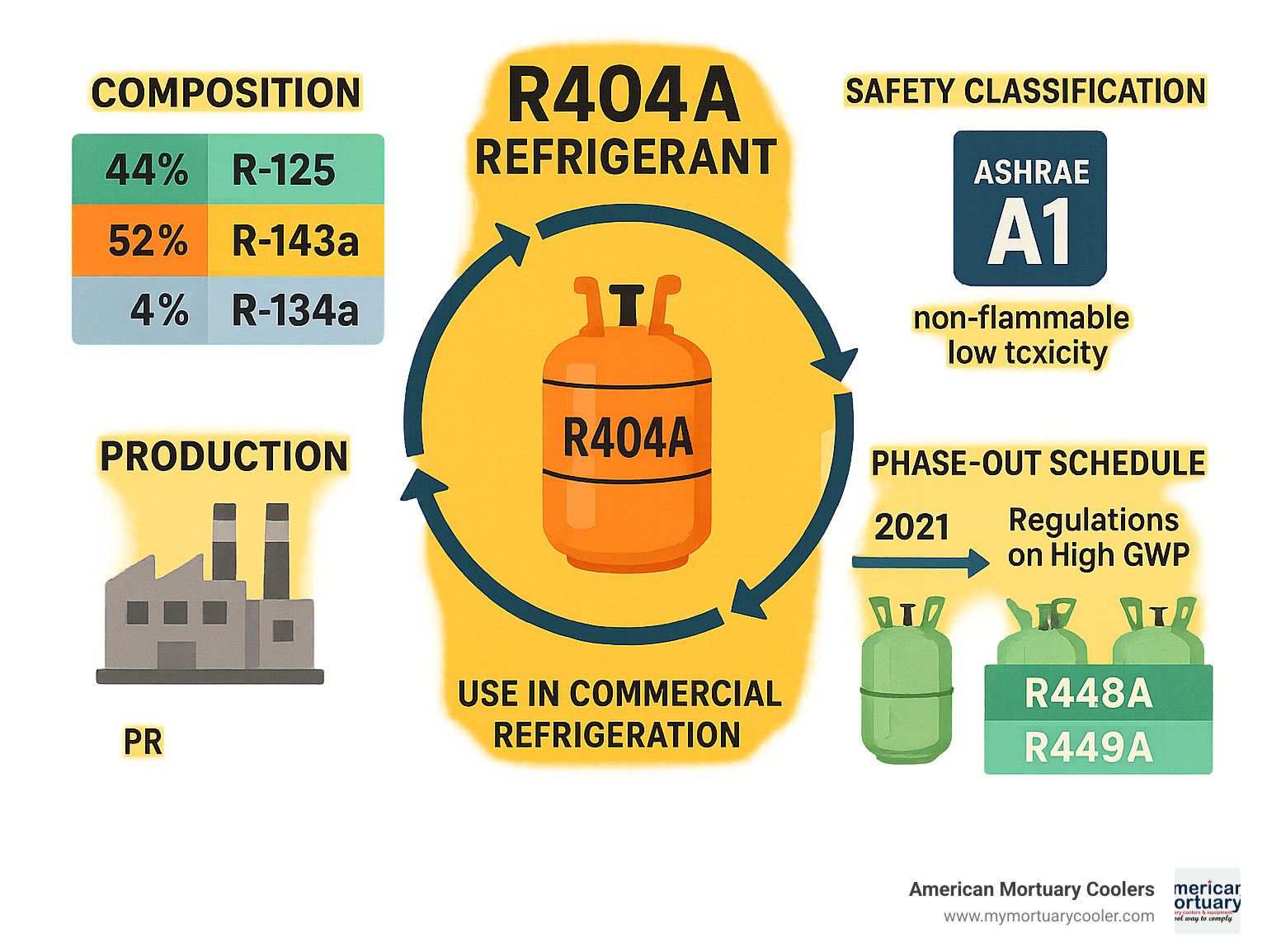

Key R404A Quick Facts:

- Composition: 44 % R-125, 52 % R-143a, 4 % R-134a

- Safety Classification: ASHRAE A1 (non-flammable, low toxicity)

- Boiling Point: ‑46.5 °C (-51.2 °F)

- Global Warming Potential (GWP): 3,922

- Primary Uses: Medium- and low-temperature commercial refrigeration

- Required Oil: Polyolester (POE) lubricant

- Regulatory Status: Being phased down due to high GWP

R404A became the go-to refrigerant for supermarket display cases, cold-storage warehouses, ice machines, and transport refrigeration. However, its high global warming potential has led to increasing regulatory restrictions, with the EU banning virgin R404A for service since 2021 and the US implementing gradual phase-downs under the AIM Act.

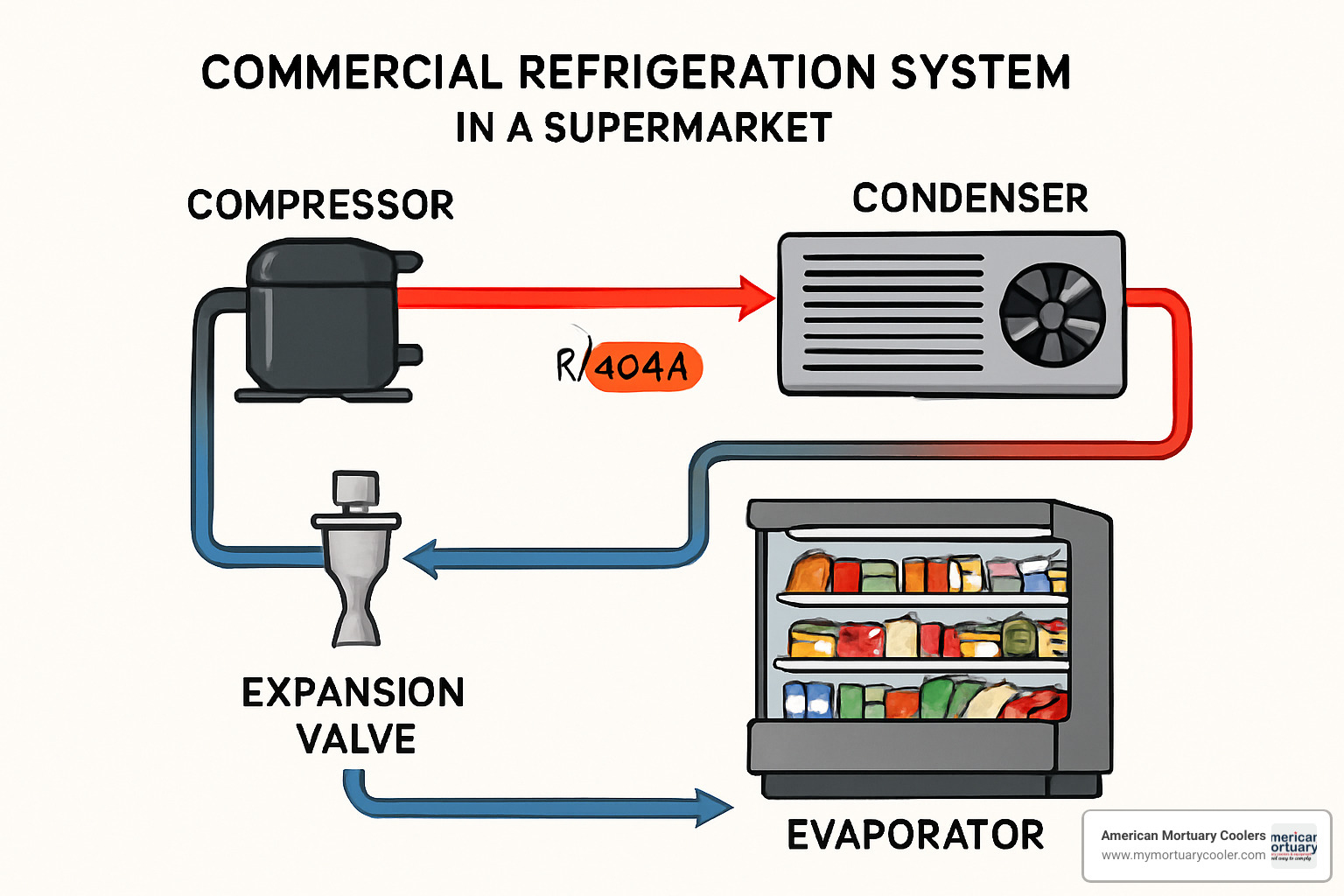

Understanding the refrigeration cycle is crucial when working with R404A. The refrigerant circulates through four main components: the compressor increases pressure and temperature, the condenser removes heat and converts vapor to liquid, the expansion valve drops pressure, and the evaporator absorbs heat while converting liquid back to vapor.

We're American Mortuary Coolers, a Tennessee-based manufacturer specializing in custom mortuary coolers for the funeral industry. Through years of crafting durable solutions for funeral homes across the contiguous 48 states, we've gained extensive experience with commercial refrigeration systems that rely on refrigerant R404A for reliable low-temperature performance.

Understanding Refrigerant R404A: Chemistry, Properties & Safety

Refrigerant R404A is a carefully engineered blend that revolutionized commercial refrigeration in the 1990s. This ternary blend combines three different refrigerants into one powerhouse mixture with an A1 safety classification, meaning it won't catch fire and has low toxicity.

With a boiling point of -46.5°C (-51.2°F), R404A excels at keeping things really cold. However, its GWP of 3,922 means it packs a serious environmental punch if it escapes into the atmosphere. The good news? Its ODP is zero, so it won't harm the ozone layer.

One thing that catches many people off guard is the polyolester oil requirement. You can't just use any lubricant with R404A—it needs POE oil to keep everything running smoothly. Understanding pressure-temperature relationships becomes crucial when working with this refrigerant.

What is Refrigerant R404A Made Of?

Refrigerant R404A is actually three refrigerants working together in perfect harmony. The recipe breaks down like this: R125 makes up 44% of the blend, R143a contributes 52%, and R134a rounds out the remaining 4%. This precise mixture creates what we call a near-azeotropic blend.

The glide of just 0.7 K means the refrigerant maintains consistent properties throughout your system. Unlike some blends that can separate over time, R404A stays stable and reliable. Each component brings something special: R125 handles cooling capacity, R143a manages pressure characteristics, and R134a fine-tunes everything else.

Refrigerant R404A vs R-502 & R-22: Key Specs

When refrigerant R404A hit the market, it had to prove it could replace both R-502 and R-22. The results were impressive. Compared to R-502, R404A delivers similar pressures and capacity while offering better environmental credentials. Discharge temperatures run about 9°C cooler than R-502, reducing compressor stress.

| Property | R404A | R-502 | R-22 |

|---|---|---|---|

| GWP | 3,922 | 4,657 | 1,810 |

| ODP | 0 | 0.33 | 0.055 |

| Boiling Point (°C) | -46.5 | -45.6 | -40.8 |

| Safety Class | A1 | A1 | A1 |

| Oil Type | POE | Mineral/AB | Mineral/POE |

For low-temperature work, R404A proved superior to R-22, which is why it became the go-to choice for applications like mortuary coolers where consistent low temperatures are critical.

Safe Handling & Storage Basics

Working with refrigerant R404A safely requires proper PPE—safety glasses, insulated gloves, and appropriate clothing are non-negotiable. Cylinder labeling tells you everything you need to know at a glance. The AEL of 1000 ppm means you need good ventilation, especially in enclosed spaces.

Always use liquid charging with R404A to prevent blend separation. Your leak detection equipment needs to be HFC-compatible. Storage and transport follow standard practices, but keep cylinders upright and away from heat sources. The frostbite risk from liquid contact is real—proper caution protects both you and the environment.

Applications & Purchasing Essentials for Low- and Medium-Temperature Cooling

Refrigerant R404A found widespread adoption across commercial refrigeration due to its excellent low-temperature performance. Supermarkets rely on it for frozen food display cases, while cold storage warehouses use it for maintaining consistent temperatures. Transport refrigeration, ice-making equipment, and food service applications also commonly specify R404A.

At American Mortuary Coolers, R404A has proven valuable in mortuary applications where precise temperature control is critical. Our custom cooling systems across Tennessee, Georgia, Illinois, and other states have relied on R404A's dependable performance.

Cylinder sizes include 24 lb for smaller systems, 100 lb for medium applications, and larger 800 lb and 1,300 lb cylinders for industrial use. EPA Section 608 certification is required for purchasing, along with proper record-keeping for environmental compliance.

Legacy & Current Uses of Refrigerant R404A

R404A became the standard choice for display cases in supermarkets and convenience stores, representing the largest application segment during retrofits from R-502 throughout the late 1990s and 2000s. Marine refrigeration adopted R404A for ship-board cooling systems, while morgue and mortuary freezers benefited from its reliable low-temperature performance.

Current applications continue in many sectors, though new restrictions are driving changes. Existing systems can still be serviced with reclaimed refrigerant in many jurisdictions, while new installations increasingly specify lower-GWP alternatives.

Packaging, Documentation & Purchase Rules

Common cylinder sizes for R404A include:

- 24 lb cylinders for small commercial systems

- 100 lb returnable cylinders for medium applications

- 800 lb returnable cylinders for larger installations

- 1,300 lb cylinders for industrial and bulk applications

EPA forms and documentation requirements have become more stringent. Purchasers must complete EPA Certification Proof and Resale Forms, providing either EPA Section 608 certification or wholesaler resale status. Some states have additional requirements—Florida customers must contact suppliers directly rather than ordering online.

California and New York have implemented reclaimed refrigerant mandates for servicing existing equipment, effective January 1, 2025. DOT shipping regulations govern transport, with specific requirements for cylinder preparation, labeling, and documentation.

Compatible Oils & Retrofit Pointers

POE (polyolester) oil is the only compatible lubricant for R404A systems. When retrofitting from R-502 or R-22 systems using mineral oil, a complete oil change is essential. The retrofit process requires flushing the system to remove at least 95% of the original mineral oil before adding POE lubricant.

Filter-drier replacement is mandatory during retrofits. Molecular sieve types XH9 and XH7 are recommended for HFC systems. Liquid-only charging prevents fractionation of the R404A blend. Superheat adjustment typically requires fine-tuning after retrofit, and pressure controls require resetting for R404A's operating characteristics.

Environmental Impact & Evolving Regulations

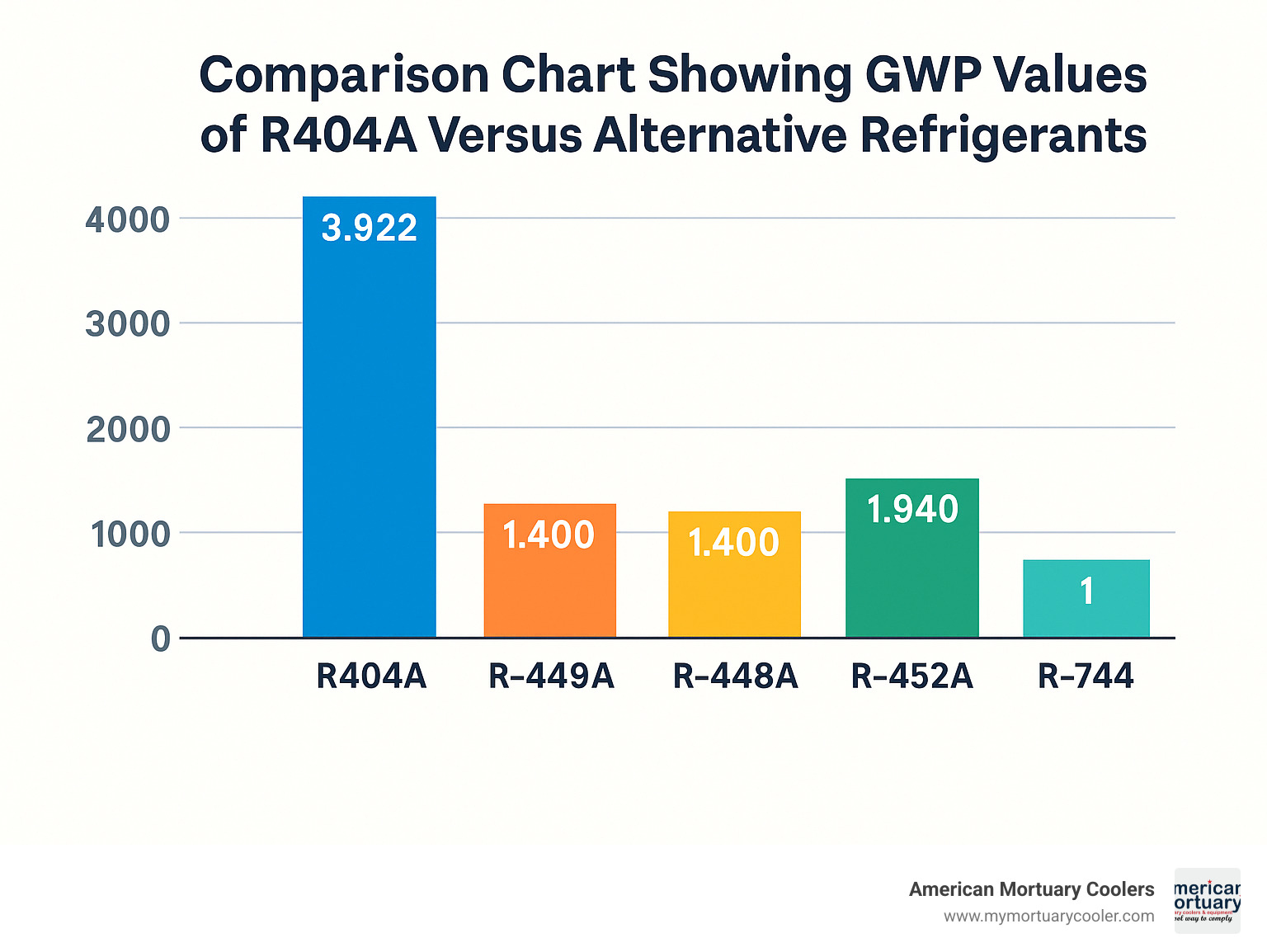

Refrigerant R404A has a staggering global warming potential of 3,922, meaning it traps nearly 4,000 times more heat than CO₂ over a century. This massive climate impact sparked the Kigali Amendment to the Montreal Protocol, pushing countries worldwide to phase down HFCs. In the US, the AIM Act now sets strict production quotas, while the EU banned virgin R404A for service work in 2021.

The regulatory landscape changes rapidly. California CARB and New York Part 494 regulations add state-level restrictions, creating a complex web of rules that vary by location. At American Mortuary Coolers, we've helped funeral homes across Tennessee and beyond steer these transitions.

Global Warming Potential & Climate Metrics

Every kilogram of refrigerant R404A that leaks equals roughly 4 tonnes of CO₂ in warming potential. A small system leak losing just 2 pounds creates the same climate impact as burning about 900 gallons of gasoline. A transport unit losing 10 kg during its lifetime equals nearly 40 tonnes of CO₂ equivalent.

R404A maintains its zero ozone depletion potential, successfully helping heal the ozone hole while we now address climate concerns.

Current Rules in the US & EU

The EPA uses SNAP listings to determine acceptable refrigerants. For R404A, restrictions have been rolling out since 2016, hitting different applications at different times. The EU took a harder line with their F-Gas Regulation—since January 1, 2021, you can't use virgin R404A with GWP above 2,500 for service work.

Service ban dates vary by application. New retail food refrigeration equipment couldn't use R404A starting in 2017, but existing systems can still be serviced with reclaimed refrigerant. State-level rules add complexity—California now requires reclaimed refrigerant for servicing existing R404A systems, while New York has similar mandates.

Future Outlook for Refrigerant R404A

The AIM Act production quotas show R404A's future clearly. By 2036, HFC allowances will drop to just 15% of historic baseline levels—an 85% reduction that will drive prices up significantly and force most applications to find alternatives.

Recycled and reclaimed R404A will become increasingly valuable as production quotas tighten. End-of-life planning isn't optional anymore—it's a business necessity. Technician training on A2L mildly flammable refrigerants, CO₂ systems, and advanced leak detection is essential for staying in business.

R404A served us well for over two decades, but its days are numbered. Planning ahead and working with knowledgeable suppliers will make the transition smoother.

Alternatives to R404A & Retrofit Best Practices

The phase-out of refrigerant R404A has sparked an industry-wide search for practical alternatives. R-449A (XP40), R-448A (N40), and R-452A (XP44) lead as drop-in alternatives, each offering global warming potential around 1,400—a 65% reduction compared to R404A's 3,922 GWP. These blends maintain the familiar A1 safety classification.

For bigger changes, CO₂ (R-744) and propane (R-290) offer even lower environmental impact but require significant system modifications. Many replacement blends actually outperform R404A in efficiency, potentially reducing operating costs. However, some newer alternatives fall into A2L safety classes (mildly flammable), requiring additional safety equipment.

At American Mortuary Coolers, we've been watching these developments as they affect our custom cooling systems, ensuring our funeral home clients maintain the precise temperature control that's critical in their operations.

Scientific research on low-GWP blends

Lower-GWP Drop-In Blends

R-449A and R-448A have emerged as the most practical immediate replacements for refrigerant R404A. These blends deliver capacity matching within 5% of R404A while slashing GWP by approximately 65%.

The oil compatibility story is encouraging—these alternatives work with existing POE lubricants, simplifying retrofits. Discharge temperature improvements provide bonus benefits, with R-449A typically reducing compressor discharge temperatures compared to R404A, extending equipment life and improving efficiency.

The GWP reduction to approximately 1,400 meets immediate compliance requirements while providing reasonable transition timelines for eventual moves to even lower-GWP solutions.

Step-by-Step Retrofit Checklist

Converting from refrigerant R404A to alternative blends requires systematic planning and careful execution.

Baseline data collection starts the process. Record existing operating pressures, temperatures, refrigerant charge weight, and performance metrics. Refrigerant recovery requires appropriate equipment rated for R404A pressures with careful documentation.

Deep vacuum is critical—achieve and maintain vacuum levels at or below 400 microns for minimum 4 hours. Charge adjustment typically involves using 105% of the original R404A charge for most alternatives, or 95% when converting from R-22 systems.

System labeling isn't just good practice—it's an EPA requirement. Update all refrigerant and oil identification labels. Leak testing at operating pressures using HFC-compatible detection equipment ensures system integrity.

Performance verification closes the loop by comparing post-retrofit performance against baseline data. Use manufacturer's pressure-temperature chart references to confirm proper operation.

Frequently Asked Questions about Refrigerant R404A

Do I need EPA Section 608 certification to buy R404A?

Yes, you absolutely need EPA Section 608 certification to purchase refrigerant R404A. This requirement took effect January 1, 2018, and applies to all CFC, HFC, and HFO refrigerants. You'll need to provide your certification number and complete EPA forms when purchasing.

Wholesalers can check the resale box on EPA forms instead of providing individual certification, but must maintain proper documentation. Some states add complications—Florida residents can't buy R404A online and must contact suppliers directly. California and New York require reclaimed refrigerant for servicing existing equipment starting January 1, 2025.

Get your EPA 608 certification if you don't have it already. Without it, you'll need to call certified technicians every time you need refrigerant.

What lubricants work with Refrigerant R404A systems?

Polyolester (POE) oil is the only lubricant that works properly with refrigerant R404A systems. Don't use mineral oil or alkylbenzene lubricants from older systems—they won't work and will cause problems.

When retrofitting from R-502 or R-22 systems, you need to remove at least 95% of the original oil before adding POE lubricant. This requires multiple oil changes and thorough system flushing. You'll also need to replace filter-driers with types designed for HFC/POE systems.

POE oil is hygroscopic, meaning it absorbs moisture from air. Keep containers sealed tight, minimize air exposure, and properly evacuate the system to remove absorbed moisture.

Is R404A being completely banned soon?

Refrigerant R404A isn't disappearing overnight, but it's definitely being phased out through restrictions and production reductions. The timeline varies by location and application.

The EU banned virgin R404A for service in 2021, though reclaimed refrigerant can be used until 2029. In the US, the AIM Act uses gradual production quotas reducing availability through 2036. New equipment restrictions started between 2016-2020, but existing systems can typically keep running with proper recovery procedures.

California and New York require reclaimed refrigerant for existing system service starting January 1, 2025. The practical reality is you have time to plan, but shouldn't wait too long. Equipment owners need to consider retrofits or replacements based on their situations and local regulations.

Conclusion

The journey of refrigerant R404A tells a fascinating story about how the refrigeration industry adapts to environmental challenges. For over twenty-five years, this reliable workhorse has kept our food fresh, medicines cold, and helped funeral homes maintain proper preservation temperatures.

When R404A first appeared in the mid-1990s, it was the hero that saved the ozone layer, providing a drop-in replacement for ozone-depleting R-502. But environmental science doesn't stand still. Refrigerant R404A's high global warming potential of 3,922 now presents new climate challenges.

The phase-down isn't happening overnight, giving us time to plan smart transitions. Existing systems can continue operating with proper maintenance and recovered refrigerant in most areas. Safe handling practices matter more than ever as refrigerant becomes more valuable and regulated.

Retrofit planning doesn't have to be overwhelming. Lower-GWP alternatives like R-449A and R-448A offer straightforward transitions for most systems, maintaining the A1 safety classification while cutting climate impact by two-thirds.

Here at American Mortuary Coolers, we've watched this transition across hundreds of installations from Tennessee to California, Illinois, and Georgia. The funeral homes that plan ahead always fare better than those who wait until refrigerant becomes unavailable or equipment fails unexpectedly.

The refrigeration industry's environmental journey continues. Today's lower-GWP alternatives will likely give way to even better solutions. What remains constant is the need for reliable cooling in critical applications like food preservation and mortuary services.

Whether you're maintaining an existing refrigerant R404A system or planning your next equipment purchase, the key is working with suppliers who understand both technical requirements and regulatory landscapes. The transition period offers opportunities for improved efficiency and compliance—if you plan thoughtfully and act deliberately.