Beginner's Guide to Reefer: Meaning and Types Explained

Understanding REEFER: Your Essential Cold Storage Guide

REEFER refers to refrigerated containers, trailers, ships, or storage units designed to transport and store temperature-sensitive goods at controlled temperatures. Here's what you need to know:

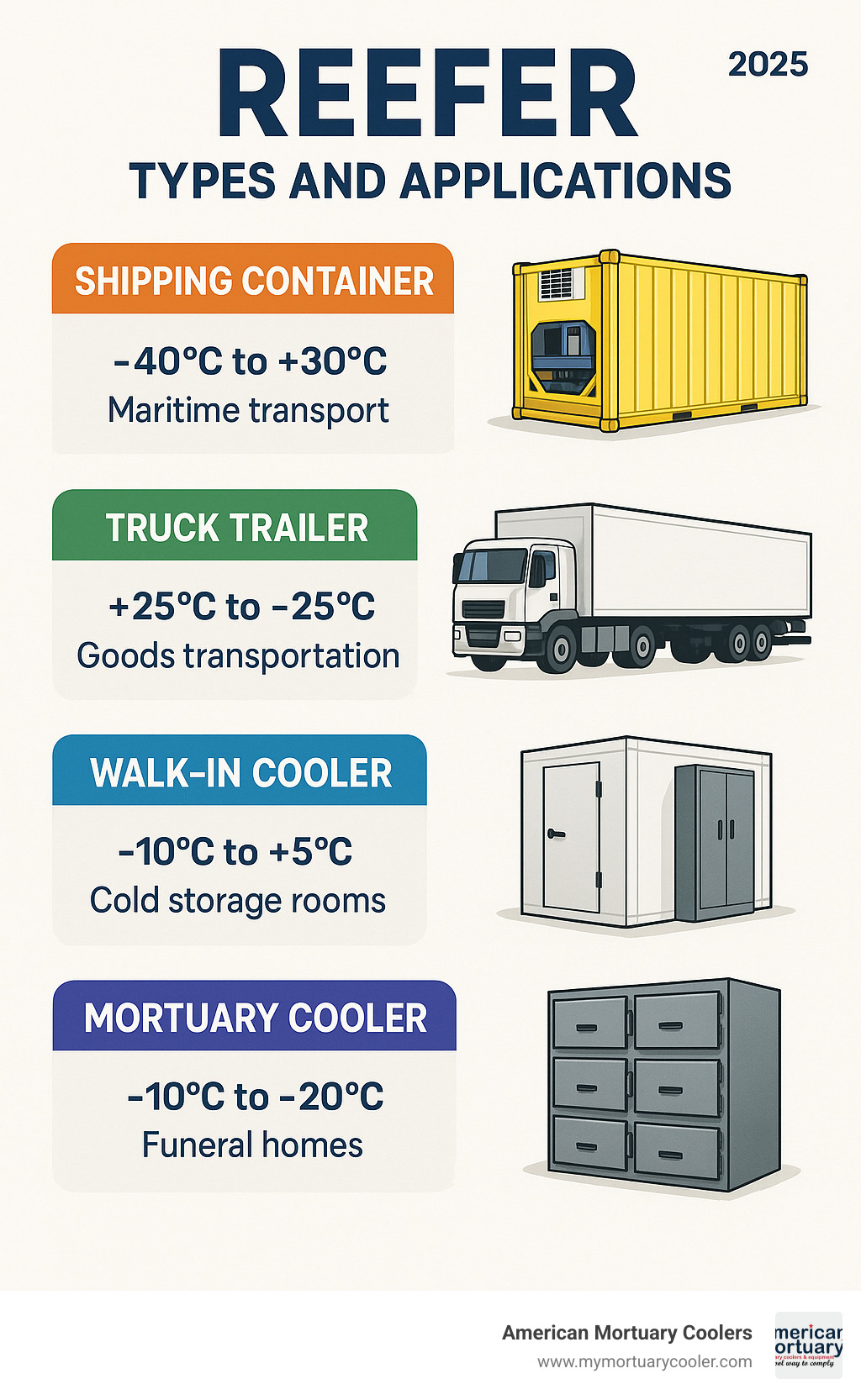

Main Types of Reefers:

- Shipping Containers - 20' and 40' units for maritime transport (-40°C to +30°C)

- Truck Trailers - 53-foot refrigerated semi-trailers with diesel generators

- Cargo Ships - Specialized vessels for perishable goods transport

- Walk-in Coolers - Stationary cold storage rooms for facilities

- Mortuary Coolers - Specialized units for funeral homes and disaster response

Temperature Ranges:

- Standard reefers: +25°C to -25°C

- Super freezers: Down to -70°C

- Mortuary units: Typically -10°C to +5°C

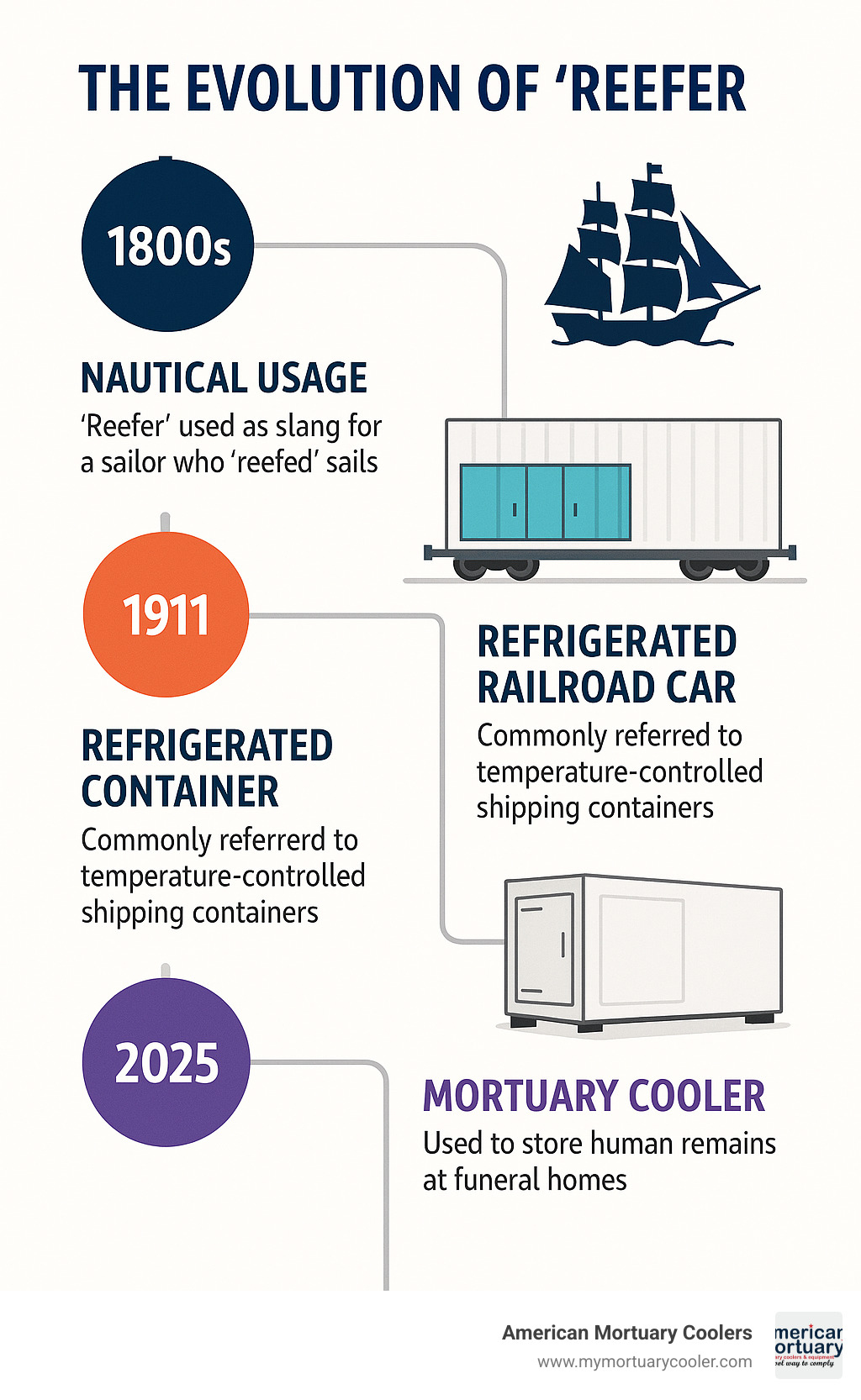

The term "reefer" has fascinating origins - it started as nautical slang in 1800 for sailors who "reefed" (adjusted) ship sails. By 1911, the term evolved to describe the first refrigerated railroad cars that revolutionized food transport. Today, reefers form the backbone of the global cold chain, moving everything from fresh produce to life-saving vaccines.

For funeral home directors, understanding reefer technology is crucial when selecting mortuary cooling solutions. The same principles that keep seafood fresh during ocean crossings also preserve human remains with dignity and reliability.

I'm Mortuary Cooler, a national-level mortuary cooler supplier specializing in REEFER technology for funeral service professionals. With years of experience providing custom cooling solutions across the mortuary industry, I've seen how the right refrigeration equipment can transform funeral home operations and ensure families receive the respectful care they deserve.

Learn more about REEFER:

REEFER 101: What Does the Term Mean?

Ever wondered why we call refrigerated containers "reefers"? The story behind this word is more interesting than you might think—and it has absolutely nothing to do with what your teenager might be thinking about.

The journey from sailing ships to mortuary coolers is a fascinating tale of how language evolves with technology.

Nautical Roots of "REEFER"

Picture this: it's the 1800s, and you're aboard a tall ship battling fierce ocean winds. When storms hit, sailors had to quickly "reef" the sails—which meant pulling in and tying up sections of canvas to prevent the ship from capsizing.

These brave sailors who scrambled up the rigging to reef sails became known as "reefers." It was dangerous, skilled work that required steady hands and nerves of steel. The term had nothing to do with keeping things cold—just keeping ships afloat.

This nautical slang stuck around maritime communities for decades, long before anyone dreamed of refrigerated transport.

Evolution to Refrigerated Transport: REEFER Today

Fast-forward to 1911, when the cold storage revolution began changing how we moved perishable goods. The first refrigerated railroad cars hit the tracks, and workers started calling them "reefers" too.

Why the name stuck is anyone's guess—maybe it was the maritime connection to cargo transport, or perhaps railroad workers just liked the sound of it. Either way, these early reefer units changed everything.

Suddenly, fresh beef from Chicago could reach New York without spoiling. California oranges made it to Maine in perfect condition. The intermodal standardization that followed meant reefers evolved from just train cars to include trucks, ships, and specialized containers.

Today's REEFER technology extends far beyond food transport. In the funeral industry, mortuary reefers use the same principles that keep seafood fresh to preserve human remains with dignity and respect. Whether it's a 40-foot shipping container crossing the Pacific or a mortuary cooler serving a small-town funeral home, the core mission remains the same: reliable refrigeration when it matters most.

Main Types of Reefers

When it comes to REEFER units, there's no one-size-fits-all solution. Different industries need different cooling approaches, and understanding your options helps you make the right choice for your specific needs.

Standard Reefer Containers (20' & 40' HC)

These are the workhorses of global shipping—the big metal boxes you see stacked on cargo ships and trains. Standard reefer containers follow strict ISO standards, which means they play nicely with all kinds of transport equipment worldwide.

The 20-foot reefer gives you about 27 cubic meters of internal space and can handle up to 27,500 kg of cargo. It's perfect for smaller shipments of seafood, produce, or meat, maintaining temperatures from +25°C down to -25°C.

The 40-foot high cube reefer is the heavy hitter, offering 67 cubic meters of space while handling up to 29,500 kg of cargo. These bigger units cover the same standard temperature range, but super-freezer versions can plunge all the way down to -70°C—ideal for pharmaceuticals or specialized preservation needs.

Here's what really matters: these containers aren't just boxes with cooling units stuck on. They're engineered systems with proper insulation, airflow management, and precise temperature control that keeps your cargo safe whether it's crossing an ocean or sitting in a port.

Reefer Trailers & Trucks

Road transport is where reefer trailers shine. Picture those long 53-foot semi-trailers you see on highways—the ones with the refrigeration unit humming away at the front.

These trailers run on their own diesel-powered refrigeration systems, typically carrying about 50 gallons of fuel separate from the truck's main tank. That means your cooling stays consistent even when the truck stops for breaks or fuel.

Modern reefer trailers come loaded with features like air ride suspension to protect delicate cargo, temperature data logging to prove your cold chain stayed intact, and multi-temperature partitions when you need different zones for different products.

The beauty of these units is their flexibility—whether you're moving fresh flowers, frozen foods, or need specialized transport for funeral services, there's likely a trailer configuration that fits your needs.

Want to dig deeper into reefer trailers? Check out our in-depth guide to reefer trailers.

Specialized Solutions: Mortuary Reefers & Super Freezers

The funeral industry has unique requirements that standard shipping containers just can't meet. That's where specialized mortuary reefers step in to provide dignified, reliable solutions.

Mortuary coolers typically maintain temperatures between -10°C and +5°C—the sweet spot for proper preservation of human remains. These units come in portable configurations for disaster response or permanent walk-in installations for funeral homes and hospitals.

Super freezers take things to the extreme, reaching temperatures as low as -70°C. While most funeral applications don't require such extreme cold, these units prove invaluable for long-term preservation or forensic applications.

At American Mortuary Coolers, we understand that every funeral home has different needs. That's why we craft custom mortuary reefers designed specifically for your space, capacity requirements, and operational workflow. Our durable solutions come with direct delivery across all 48 contiguous states.

Non-Operating Reefers (NOR)

Here's a clever shipping trick that saves money: Non-Operating Reefers (NOR) are regular reefer containers with their refrigeration units turned off, used as high-quality dry containers.

Why would anyone do this? Simple economics. Shipping lines need to move empty containers back to where they're needed, and shippers get access to well-insulated, durable containers at a discount. It's a win-win that helps keep global logistics costs reasonable.

These NOR units work perfectly for back-haul cargo that doesn't need temperature control but benefits from the extra protection that comes with a container built to higher standards than basic dry boxes.

How a Reefer Unit Works

Ever wonder what keeps your food fresh during a cross-country trip or maintains the dignity of remains in a mortuary cooler? It's actually pretty fascinating science, and once you understand the basics, REEFER technology becomes a lot less mysterious.

At its heart, every reefer unit—whether it's hauling ice cream across the continent or serving a funeral home—works on the same fundamental principle of thermodynamics. Think of it like your home air conditioner, but built tough enough to handle the road, the sea, and everything in between.

The magic happens through a continuous cycle that moves heat from where you don't want it (inside your cargo space) to where it doesn't matter (outside). The compressor acts like the heart of the system, pressurizing refrigerant and pushing it through the circuit. The condenser outside the box dumps all that unwanted heat into the surrounding air or water. Meanwhile, the evaporator inside your cargo space does the heavy lifting—absorbing heat and cooling the air that circulates around your goods.

Here's something that surprises a lot of people: most reefers are designed to maintain temperature, not dramatically cool things down. If you load warm cargo into a reefer, you're asking for trouble. Pre-cooling is absolutely essential for proper operation.

Core Components Inside a REEFER

The beauty of reefer technology lies in how these key components work together seamlessly. The compressor serves as the powerhouse, continuously circulating refrigerant through the system with remarkable reliability. The evaporator quietly does its job inside the cargo space, pulling heat out of the air while fans distribute that cooled air evenly throughout the unit.

The condenser handles the tough job of rejecting all that heat to the outside environment—no small task when you're dealing with extreme weather conditions. High-quality insulation in the walls, floor, and ceiling creates a thermal barrier that keeps outside heat where it belongs.

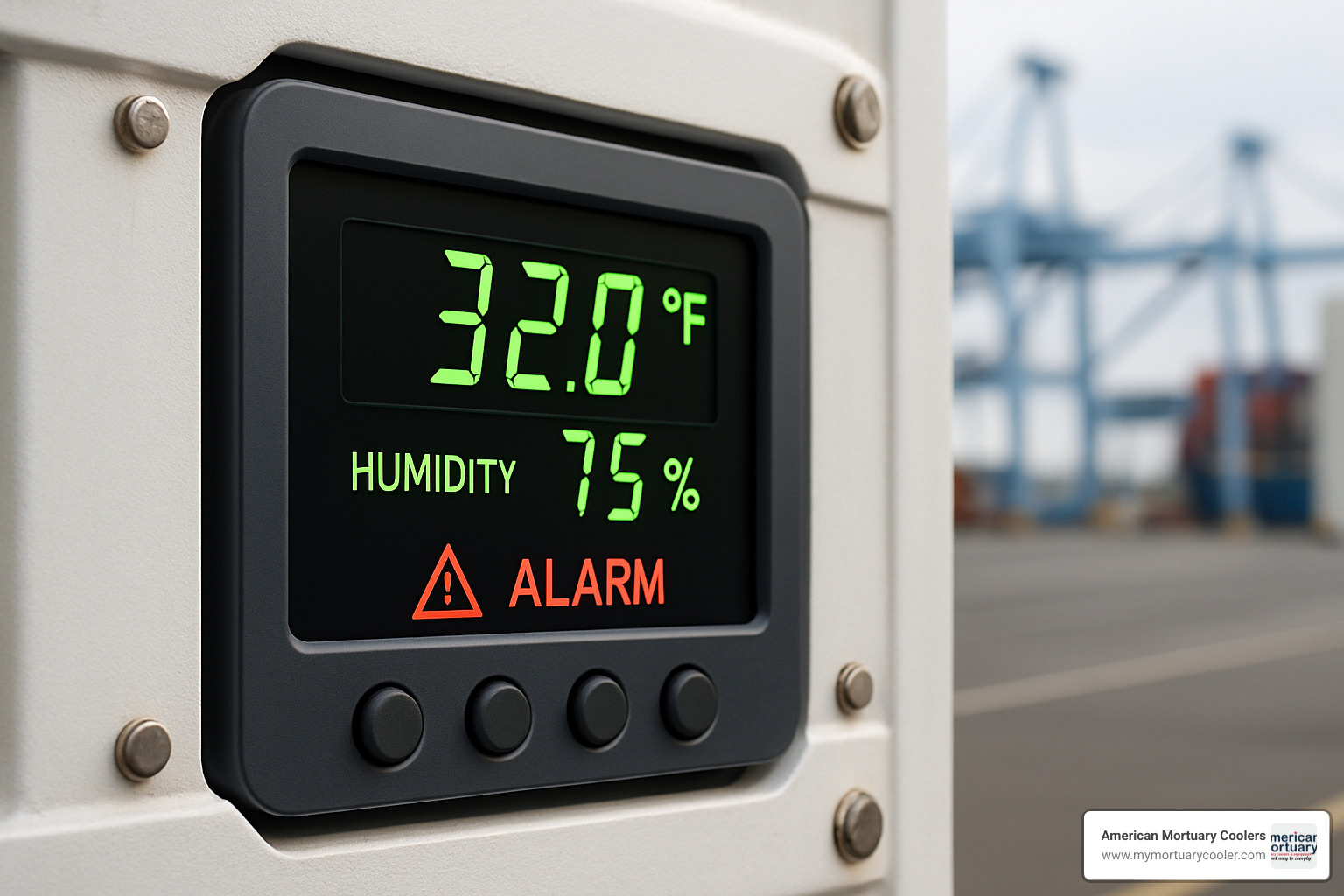

What really makes modern reefers smart is the micro-controller—essentially the brain of the operation. This sophisticated system manages temperature set-points, monitors performance, logs data for compliance, and sounds alarms when something needs attention. For funeral directors, this level of control and monitoring provides crucial peace of mind.

Temperature, Humidity & Ventilation Management

Modern reefers are incredibly sophisticated when it comes to environmental control. Temperature precision ranges from super-freezer capabilities at -70°C all the way up to +30°C for delicate items like tropical flowers. This flexibility makes them perfect for everything from pharmaceutical transport to mortuary applications.

Humidity management is equally important, with most units maintaining 60-85% relative humidity. This matters tremendously for fresh produce, but it's also crucial in mortuary settings where proper humidity levels help preserve remains with dignity.

Fresh-air exchange systems prevent dangerous gas buildup—essential for respiring cargo like fruits and vegetables, and occasionally important in specialized mortuary applications. Atmosphere control in advanced units can even regulate oxygen and carbon dioxide levels, dramatically slowing decomposition or ripening processes.

Data logging capabilities track every aspect of the journey—temperature fluctuations, humidity levels, door openings, and system performance. For funeral homes, this documentation provides valuable compliance records and helps ensure the highest standards of care. Scientific research on refrigerated vessels continues to drive improvements in these monitoring systems.

Safety & Performance Features

Safety features in modern reefers go way beyond basic refrigeration. Panic alarms and interior LED lighting are absolutely critical in walk-in units and mortuary coolers—no one should ever be trapped in a cold space without a way to call for help.

Shore power connections let units plug into facility power (typically 460V, 15KVA) instead of running on diesel generators. This saves fuel, reduces noise, and provides more reliable power during extended stationary periods.

Roll-stability systems on trailer units prevent dangerous accidents during transport, while automatic drainage systems remove condensation that could otherwise create "container rain" and damage cargo.

Anti-dock walk devices keep trailers stable during loading and unloading—particularly important when handling sensitive cargo or working in mortuary applications where stability and precision matter most.

At American Mortuary Coolers, we incorporate all these advanced features into our custom mortuary solutions, ensuring funeral professionals have the most reliable and safe equipment available.

Operating, Maintaining & Troubleshooting Reefers

Getting the most out of your REEFER isn't just about flipping a switch and hoping for the best. Whether you're running a mortuary cooler or managing a fleet of refrigerated containers, proper operation and maintenance make all the difference between reliable performance and costly headaches.

Think of it this way: a reefer is like a high-tech athlete that needs proper care to perform at its peak. Skip the basics, and you'll pay for it later—sometimes at the worst possible moment.

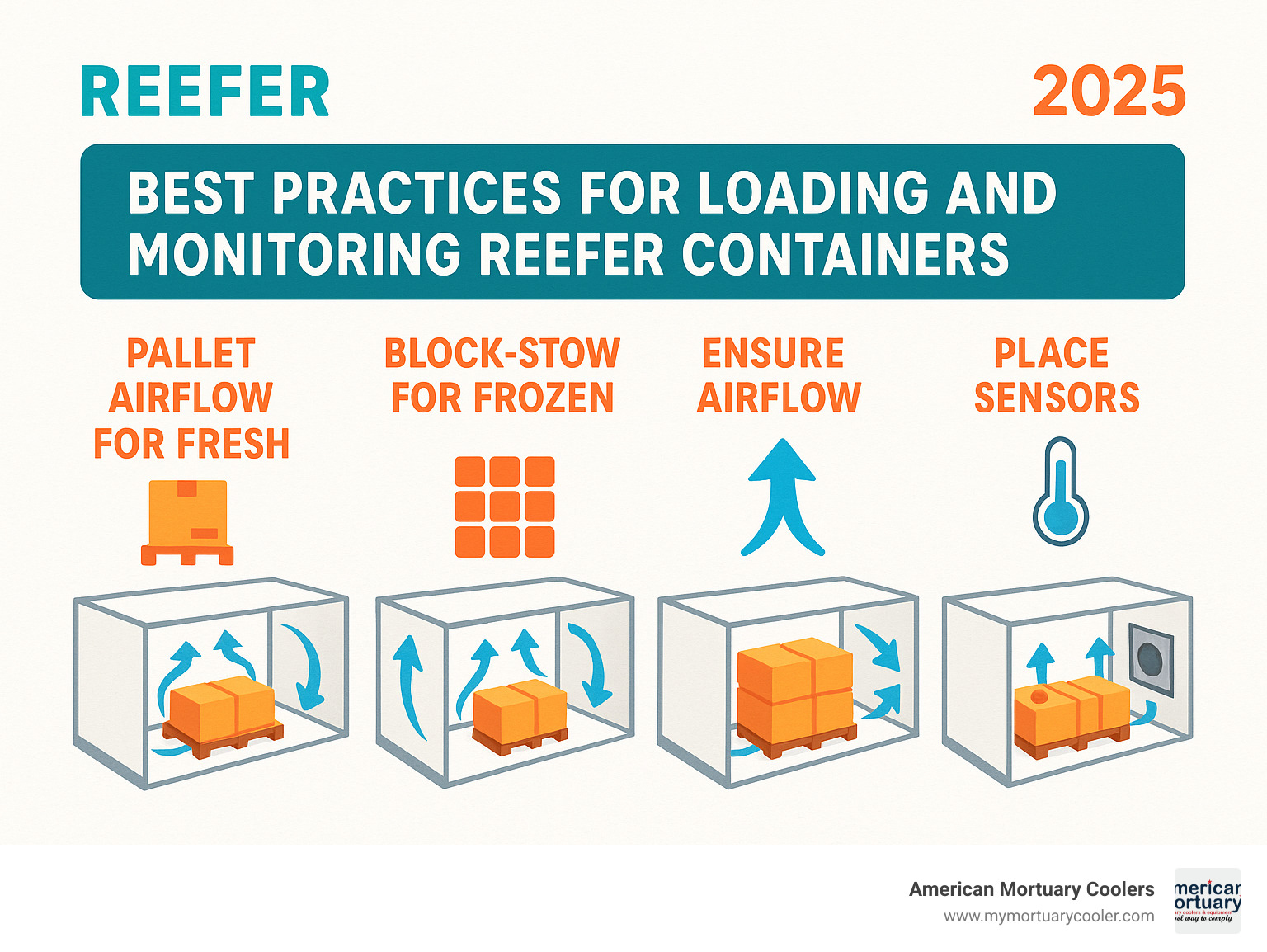

Best Practices for Safe Reefer Operations

The golden rule of REEFER operation? Pre-cool your cargo, not just the container. This is especially critical for mortuary and food applications. Your reefer unit is designed to maintain temperature, not bring warm goods down from room temperature. Loading a body at ambient temperature into a mortuary cooler and expecting it to quickly reach proper preservation temperature is asking for trouble.

Block-stow for frozen, pallet airflow for fresh is another key principle. Frozen cargo likes tight packing—it helps maintain consistent temperatures throughout the load. But fresh goods need breathing room. Air needs to circulate around pallets and packages to keep everything at the right temperature and prevent hot spots.

Don't forget your seal checks. Those door gaskets might look simple, but they're your first line of defense against warm air infiltration and condensation problems. A worn gasket can cost you hundreds in energy waste and potentially compromise your cargo.

Real-time monitoring has become a game-changer, especially for high-value loads or sensitive mortuary applications. Whether you're using remote sensors or doing manual temperature checks, staying on top of conditions helps you catch problems before they become disasters.

For mortuary and food-grade reefers, regular cleaning and sanitation isn't optional—it's essential. Those stainless steel interiors aren't just for looks; they're designed for easy, hygienic cleaning that meets health department standards.

Common Challenges & How to Fix Them

Even the best-maintained REEFER units face challenges. Power loss tops the list of nightmare scenarios, especially for funeral homes during natural disasters. Having a backup power plan isn't just smart—it's essential. Whether that's a portable generator or an alternate power supply, make sure you can keep your mortuary coolers running when the lights go out.

Mechanical failures happen to even the most reliable units. The key is being prepared with spare parts and a trusted service partner. Keep critical components like compressors, fans, and controllers in stock, and have your service technician's number on speed dial. When you're dealing with human remains, there's no such thing as "we'll fix it Monday."

Temperature excursions are every reefer operator's fear. This is where data loggers earn their keep—they catch problems early, often before you'd notice anything wrong. Modern units come with sophisticated alarm systems that can alert you via phone or email the moment temperatures drift outside acceptable ranges.

"Container rain" might sound harmless, but condensation buildup can damage cargo and create unsanitary conditions. Managing humidity levels, using moisture absorbers when needed, and keeping doors closed as much as possible helps prevent this common problem.

For more detailed maintenance information, check out our guide to refrigerated boxes.

Reefers in the Global Cold Chain

REEFER technology touches more lives than most people realize. Beyond moving fresh produce from farm to table, these units are the backbone of food security worldwide, dramatically reducing spoilage and extending the reach of nutritious foods to underserved areas.

The pharmaceutical and vaccine industry depends heavily on reefer technology, especially for temperature-sensitive medications. Those COVID-19 vaccines that required -70°C storage? They traveled in specialized super-freezer reefers from manufacturing facilities to distribution centers.

Even the floral industry relies on refrigerated transport to keep flowers fresh from field to florist. Those Valentine's Day roses probably spent time in a reefer container crossing an ocean.

But perhaps most importantly for our industry, mortuary reefers serve as emergency relief infrastructure during disasters. When communities face mass casualty events, portable mortuary coolers provide respectful, hygienic storage that helps families and first responders during their darkest hours.

At American Mortuary Coolers, we've seen how reliable reefer technology makes a difference in funeral service. Our custom mortuary coolers aren't just refrigerated boxes—they're tools that help funeral professionals serve families with dignity and respect, no matter what challenges they face.

Frequently Asked Questions about Reefers

Let's tackle the most common questions we hear about REEFER units. Whether you're shipping seafood across the Pacific or storing remains at a funeral home, these answers will help you understand what reefers can do.

What goods require a REEFER?

The world of temperature-sensitive cargo is bigger than you might think. Fresh produce like fruits and vegetables are obvious candidates—nobody wants mushy bananas or wilted lettuce. Meat, poultry, and seafood absolutely need refrigeration to stay safe and fresh during transport.

Dairy products and eggs are another major category, along with pharmaceuticals and vaccines that can lose their effectiveness if they get too warm (or too cold). The COVID-19 pandemic really highlighted how critical REEFER units are for vaccine distribution, especially those ultra-cold mRNA vaccines.

Flowers and plants might surprise you—they're actually huge users of refrigerated transport. That Valentine's Day bouquet probably traveled thousands of miles in a REEFER to reach your local florist looking fresh.

For our industry, human remains require specialized mortuary REEFER units that maintain dignity while providing reliable temperature control. We've also seen growing demand for transporting sensitive chemicals and electronics that can't handle temperature swings.

What temperature range can a reefer maintain?

Most standard reefers handle temperatures from +25°C down to -25°C—that covers everything from tropical fruits (which hate the cold) to frozen fish sticks. But the real workhorses can go much further.

Super freezers can plunge down to -70°C, which is colder than Antarctica in winter. These units are essential for certain vaccines, medical samples, and long-term forensic storage.

Mortuary units typically operate in the -10°C to +5°C range—cold enough for preservation but not so cold that it creates handling difficulties. Walk-in coolers usually stay between 0°C to +7°C, perfect for short-term storage at funeral homes or hospitals.

Here's something cool (pun intended): many advanced REEFER units can actually heat as well as cool. So if you're shipping wine through a Minnesota winter, your REEFER can keep it from freezing solid.

How do non-operating reefers cut costs?

This is where the shipping industry gets clever. Non-operating reefers (NORs) are basically REEFER containers with their refrigeration systems turned off, used as regular dry cargo boxes.

Here's why this matters: shipping lines need to move empty containers back to where they're needed. Instead of sending back completely empty REEFER units, they can fill them with dry cargo—things like textiles, electronics, or furniture that don't need temperature control.

Shippers love this because they get a high-quality, insulated container at a discount compared to booking a standard dry container. The insulation means better protection from temperature swings, and REEFER containers are often newer and better maintained than regular boxes.

It's honestly a win-win situation. Shipping lines avoid the cost of moving empty containers, shippers get premium boxes at lower rates, and the whole system runs more efficiently. The only downside? Those bananas we mentioned earlier would definitely prefer the refrigeration to stay on.

Conclusion

When it comes to REEFER technology, understanding the basics can make all the difference—whether you're shipping fresh salmon across the Pacific or ensuring dignified care for families during their most difficult moments.

At American Mortuary Coolers, we've built our reputation on one simple promise: custom mortuary reefers that work when you need them most. Based right here in Tennessee, we craft durable, reliable cooling solutions specifically for funeral professionals, with direct delivery across all 48 contiguous states.

What sets us apart isn't just our expertise in REEFER technology—it's our deep understanding of the funeral industry's unique needs. We know that when a family calls, your equipment can't fail. That's why every custom mortuary cooler we build is designed for decades of reliable service, backed by our commitment to dignity and care.

The cold chain connects us all, from the produce aisle to the funeral home. The same refrigeration principles that keep vaccines potent and flowers fresh also help funeral directors provide the respectful care every family deserves. Whether you need a walk-in mortuary cooler for your facility or a mobile reefer unit for transport, we're here to help you choose the right solution.

Thinking about adding refrigerated transport to your services? Our team has you covered with expert guidance on choosing the right truck with refrigeration for your specific needs.

From Johnson City to Los Angeles and everywhere in between, our expert team is ready to answer your questions and help you find the perfect REEFER solution. Because in this business, staying cool under pressure isn't just good advice—it's essential.

Stay cool, stay prepared, and remember: the right reefer makes all the difference.