Beginner's Guide to Choosing the Best Walk-In Cooler

Why Choosing the Right Walk-In Cooler Matters for Your Business

A cooler walk in keeps products between 35 °F and 41 °F so you stay compliant, protect inventory and avoid sky-high energy bills. Choose wisely and the unit pays you back for 15-20 years; choose poorly and you burn cash every day.

Key Features:

- Temperature range: 35–41 °F (38 °F is ideal)

- Sizes: 8 × 8 ft to 40 × 40 ft+

- Insulation: 4-in foamed urethane, R-29 rating

- Typical life: 15–20 years with maintenance

- Power: 15–30 amps, 208–230 V, 3-phase

Main Components:

- Compressor & condenser

- Evaporator coils

- Insulated panels and doors

- Digital temperature controls

Restaurants, labs, breweries and funeral homes all rely on the same basics: stable temps and low operating costs. Entry-level 8 × 8 ft units start near $6,500; custom builds can reach $24,000+. Getting the size and options right up front is the cheapest insurance you can buy.

I'm Mortuary Cooler, a national supplier focused on durable, right-sized solutions for the funeral industry and beyond. We match space, budget and compliance so you can focus on your business.

Cooler walk in word roundup:

Cooler Walk In Basics: How It Works & Key Components

Think of a cooler walk in as your home refrigerator's bigger, stronger cousin. The basic principles are the same, but everything is scaled up to handle commercial demands and keep your products at that perfect sweet spot between 35°F and 41°F.

38°F is the magic number most professionals aim for. It's cold enough to keep everything fresh and safe, but not so cold that you're wasting energy or risking freeze damage to delicate items. The FDA requires commercial refrigeration to stay at 41°F or below, so there's no wiggle room when it comes to food safety.

Your cooler walk in has several key players working together around the clock. The compressor and condenser are like the engine of your system - they're usually located outside the cooler and do the heavy lifting. Most units need 1½ to 3 horsepower systems that draw 15-30 amps on 208-230 volt, 3-phase power.

Inside your cooler, the evaporator coils circulate that precious cold air throughout your storage space. Keep your cooler between 75% and 90% full for optimal efficiency. Too empty and the air circulation goes haywire; too packed and nothing stays properly cold.

The thermostat and digital controls are your cooler's brain, constantly monitoring temperature and kicking the compressor on or off as needed. Modern systems can even connect to smart monitoring setups, so you can check temperatures from your phone.

Don't overlook the insulated panels that wrap around your entire cooler like a thermal blanket. The door seals and magnetic gaskets might seem like small details, but they're what keep your system from working overtime every time someone opens the door.

Typical Applications for a Cooler Walk In

Walk-in coolers show up in more places than you might expect, each with their own specific needs and challenges.

Restaurants and food service operations need reliable bulk storage for ingredients and prepared foods. Breweries often get creative with custom keg coolers and rail systems. Funeral homes and mortuaries have very specific requirements for their cooling systems - precision and reliability are essential.

Medical facilities and pharmaceutical companies deal with vaccines, specimens, and temperature-sensitive medications that can be worth thousands of dollars. Scientific laboratories face similar challenges with research samples and reagents.

The floral industry uses walk-in coolers to extend the life of cut flowers and arrangements. Convenience stores create those popular beer caves that customers love browsing through. Even hunters and meat processors rely on specialized units with hanging rails for proper game processing.

How a Refrigeration Cycle Keeps Products Cold

The refrigeration cycle is beautifully simple once you understand what's happening. Your cooler walk in is constantly moving heat from inside the cooler to outside - it's not actually "making cold" but rather "removing heat."

The process starts when refrigerant in the evaporator coils absorbs heat from your cooler's interior. This causes the refrigerant to change from liquid to gas. Next, the compressor pressurizes this gas, which makes it much hotter. The hot, pressurized gas then travels to the condenser outside, where it releases all that absorbed heat to the outdoor air and condenses back into liquid.

Finally, the liquid refrigerant passes through an expansion valve that drops both pressure and temperature before sending it back to the evaporator to start the whole cycle again.

For a deeper dive into refrigeration principles, check out How Does a Walk-in Cooler Work? - it's got some great technical details that can help you troubleshoot issues down the road.

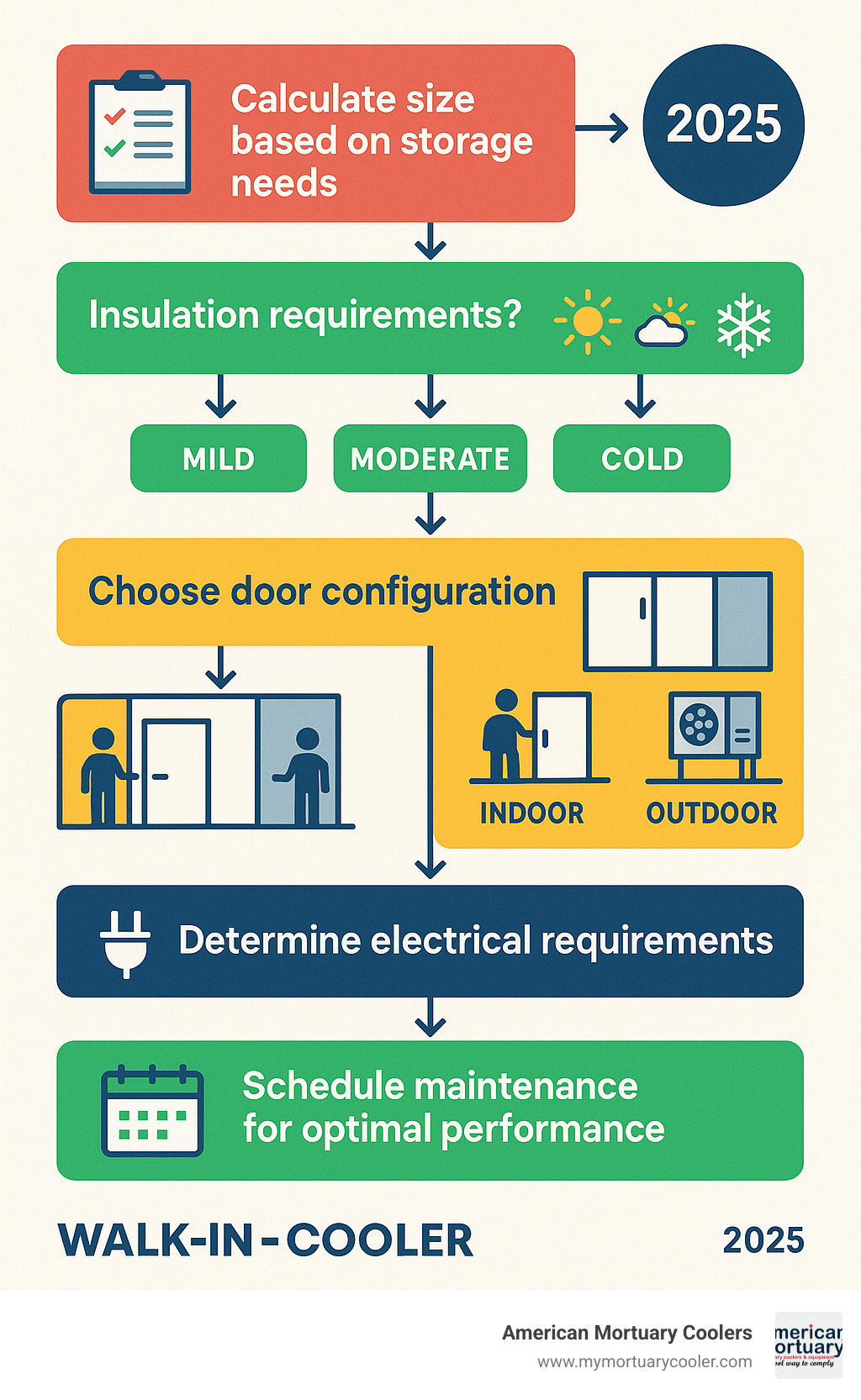

Sizing & Configurations: Finding the Perfect Fit

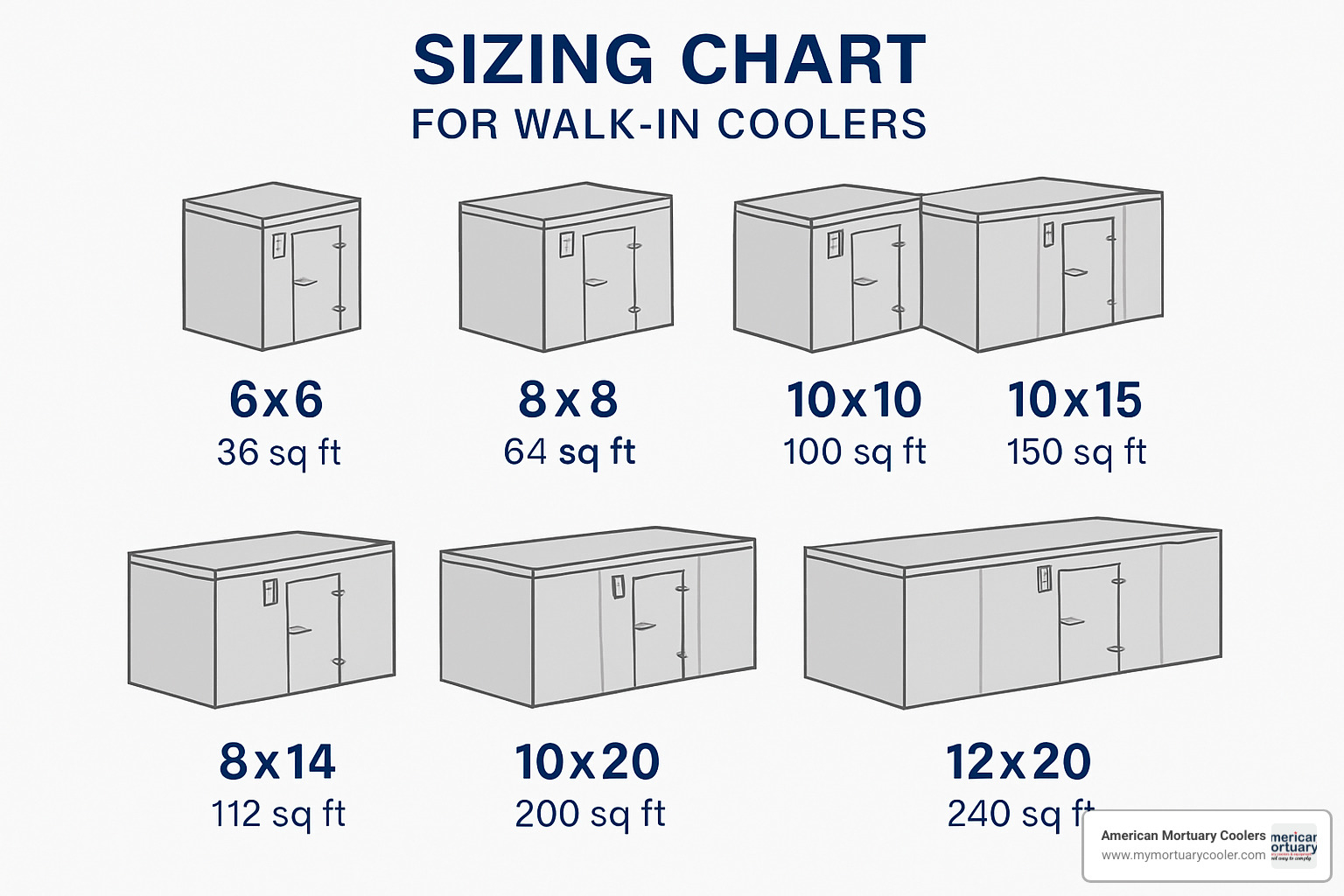

Picking a size is like buying shoes—just enough room to grow, never more than you need.

Approximate pricing:

- 8 × 8 ft (64 sq ft): $6,500–$8,700

- 8 × 12 ft (96 sq ft): $7,450–$9,500

- 10 × 10 ft or 12 × 12 ft (100–144 sq ft): from $7,950

Key decisions:

- Indoor vs. outdoor placement

- With floor vs. floorless on a level slab

- Single- or dual-temperature (-30 °F to +86 °F)

Capacity & Growth

Figure your current cubic-foot need, add roughly 25 % for growth, and plan to keep the box 75–90 % full for best airflow.

Doors & Options

- Door widths: 36 in walk-through, 42 in most popular, 48 in for high volume

- Ramps, strip curtains and safety releases improve efficiency and safety

- LED lighting, diamond tread kick plates and custom shelving boost workflow

For detailed sizing math, see More info about size selection.

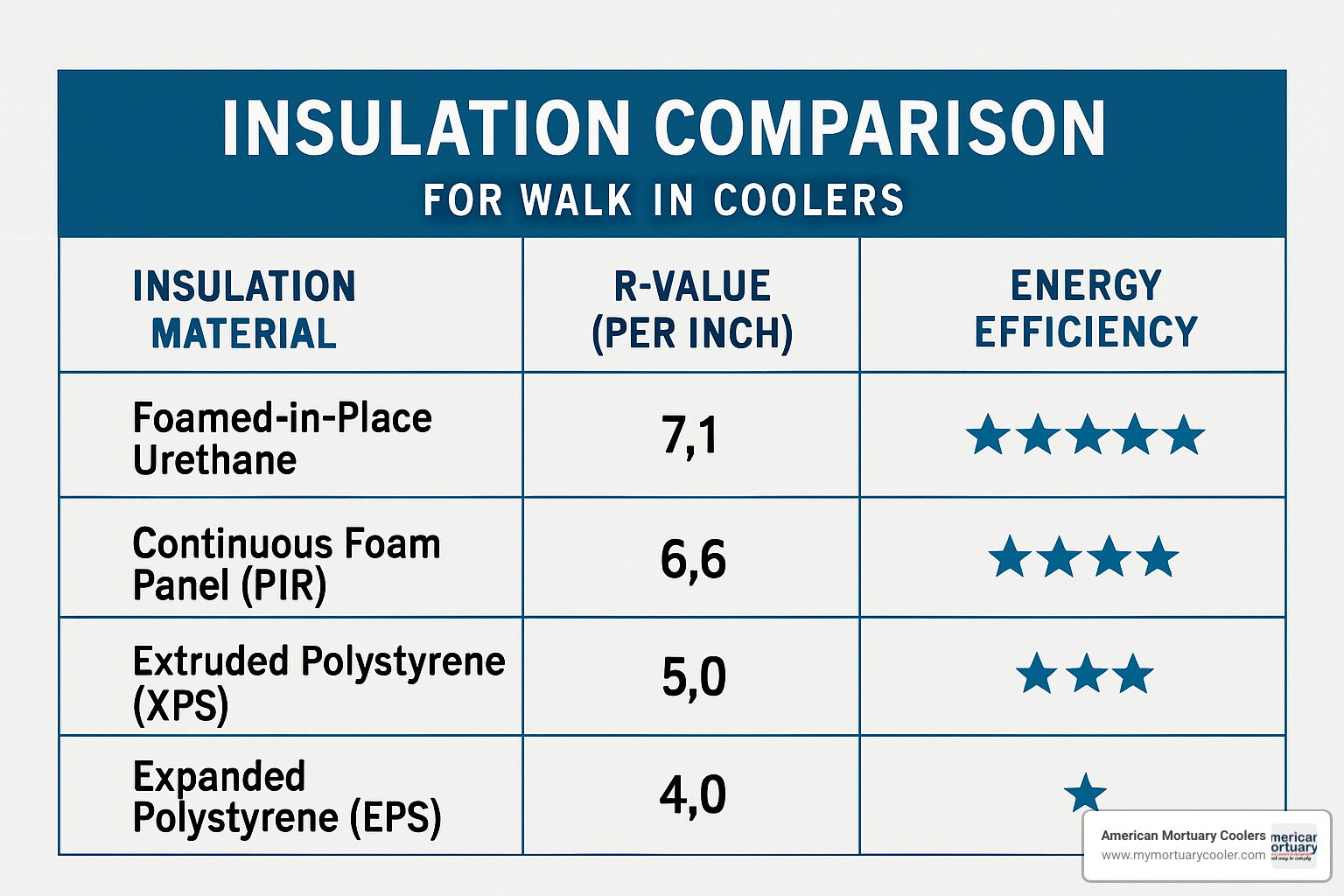

Building Blocks: Insulation, Doors & Energy-Smart Features

Four-inch foamed-in-place urethane panels (R-29 for coolers, R-32 for freezers) are the backbone of an efficient box. Some builders upgrade to polyiso cores for extra strength and moisture resistance.

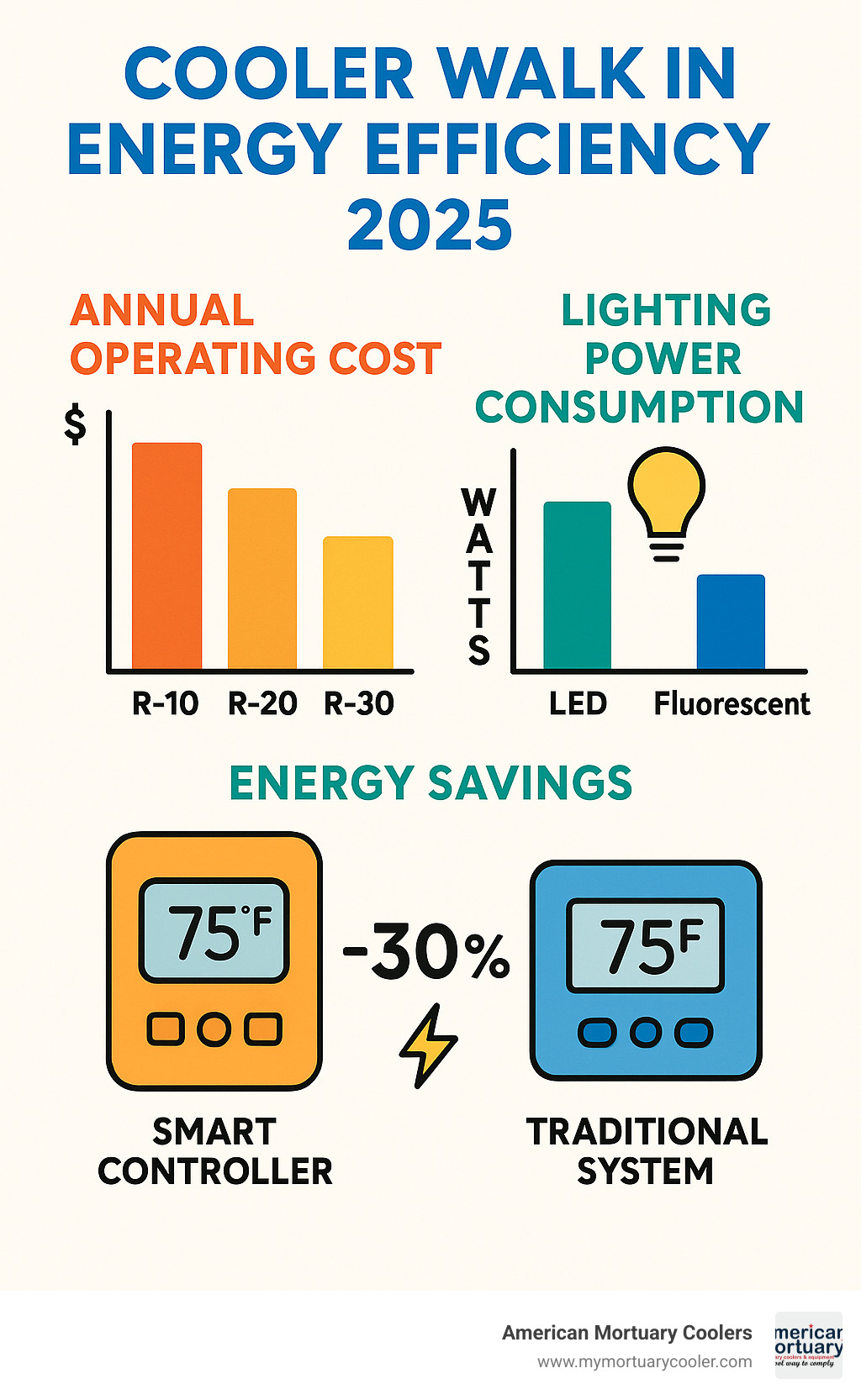

Energy-smart upgrades:

- LED lighting

- EC motors that slow when loads are light

- Smart controllers with phone alerts

- Optional humidity control (50–60 %)

Why R-Value Counts

Higher R-values cut compressor run time, curb temperature swings and kill condensation—savings that compound for decades.

Doors, Floors & Accessories

Spend money where cold air escapes: cam-lift hinges, magnetic gaskets and self-closing hardware. Choose the floor for your traffic—standard NSF aluminum (to 1,200 lb), heavy-duty cartable or floorless on a level slab. Add PVC strip curtains, epoxy-coated shelving, data loggers and digital status lights to streamline daily use.

For rental options, check walk in refrigerator rental info

Ownership 101: Maintenance, Cleaning, Troubleshooting

A few minutes each month saves thousands in repairs.

Monthly checklist:

- Inspect and clean door gaskets

- Vacuum or brush condenser coils

- Verify thermostat accuracy with a backup thermometer

- Keep inventory 75–90 % full and clear evaporator fans

Seasonal professional service (spring & fall) should cover refrigerant levels, defrost testing and a full electrical inspection.

Common red flags:

- Temperature drift (dirty coils or worn gaskets)

- Ice on evaporator (defrost or humidity issues)

- Compressor short-cycling

- Unusual noises or unexplained energy spikes

Modern add-ons—variable-speed fans, IoT monitoring, quick-ship prefab units and solar-ready condensers—trim operating costs even further.

For more, see More info about walk-in service.

Purchase & Installation Guide + FAQs

Site prep:

- Level concrete slab (±¼ in per 10 ft) extending 6 in past the box

- 208–230 V, 3-phase, 15–30 amp electrical service

- Clear airflow around the outdoor condenser

Pricing drivers:

- Size and insulation level

- Self-contained vs. remote refrigeration

- Construction extras and installation complexity

Basic 8 × 8 ft units start near $6,500; a fully-loaded 12 × 12 ft can reach $24,000+. Many customers use 100 % financing backed by 20-year panel and 5-year compressor warranties.

Typical timeline:

- Standard quick-ship: 10–30 days

- Custom builds: 6–12 weeks

- Installation: 1–2 days

Always check local building, health and seismic codes before ordering.

FAQ 1 – What temperature should my cooler walk in be set to?

38 °F keeps you safely below the FDA maximum of 41 °F without freezing sensitive items.

FAQ 2 – How long does a cooler walk in last?

Quality units last 15–20 years; good maintenance can push life past 25 .

FAQ 3 – What factors affect the price of a cooler walk in?

Size, insulation quality, refrigeration type, construction extras, freight and installation complexity.

Conclusion

Finding the perfect cooler walk in doesn't have to feel overwhelming. After helping countless funeral homes and businesses steer this decision, I've learned that success comes down to three simple principles: buy for your actual needs, invest in quality components, and partner with someone who understands your industry.

The Smart Buyer's Approach

Start with your current storage needs, then add about 25% for growth. This prevents the costly mistake of outgrowing your system too quickly while avoiding the waste of paying for space you'll never use. That R-29 insulation rating isn't just a number - it's the difference between reasonable energy bills and watching your profits disappear into thin air.

Quality components matter more than flashy features. UL-NSF certification keeps you compliant with health codes. DOE standards ensure your system won't become an energy hog. These aren't optional extras - they're the foundation of a system that'll serve you well for the next 15-20 years.

Where the Real Savings Hide

A modern cooler walk in with premium insulation, LED lighting, and smart controls can slash your operating costs by 30% compared to older systems. Yes, you'll pay more upfront, but those energy savings add up to real money over two decades of operation.

We've seen funeral homes cut their refrigeration costs in half simply by upgrading from basic systems to properly engineered solutions. That's not marketing talk - that's math working in your favor.

Beyond the Purchase

The best equipment in the world won't help if it's installed poorly or maintained badly. Make sure your site preparation meets specifications - that level concrete slab and proper electrical service aren't suggestions. Budget for professional installation and stick to maintenance schedules.

Why Partnership Matters

At American Mortuary Coolers, we've built our reputation on understanding what funeral directors actually need. Not what some corporate catalog says you should want, but what works in the real world of funeral service. Our custom approach means you get exactly what fits your space, your budget, and your operational requirements.

With direct delivery across all 48 contiguous states and locations from Tennessee to California, we're positioned to support your business wherever you're located. But more importantly, we're here for the long haul - because a cooler walk in isn't just equipment, it's a 20-year relationship with the system that protects your most important assets.

Your Next Step

Whether you're replacing a failing system or planning your first installation, the right choice protects both your inventory and your peace of mind. If budget is your primary concern, our guide Walk-In Coolers That Won't Freeze Your Budget shows you exactly how to maximize value without sacrificing quality.

Choose wisely, maintain properly, and your cooler walk in will quietly do its job for decades while you focus on serving families in their time of need. That's what good equipment should do - work so well you forget it's there.