Beginner's Guide to Choosing a Walk-In Cooler for Morgue Use

Why Walk-In Cooler Morgues Are Essential for Modern Funeral Operations

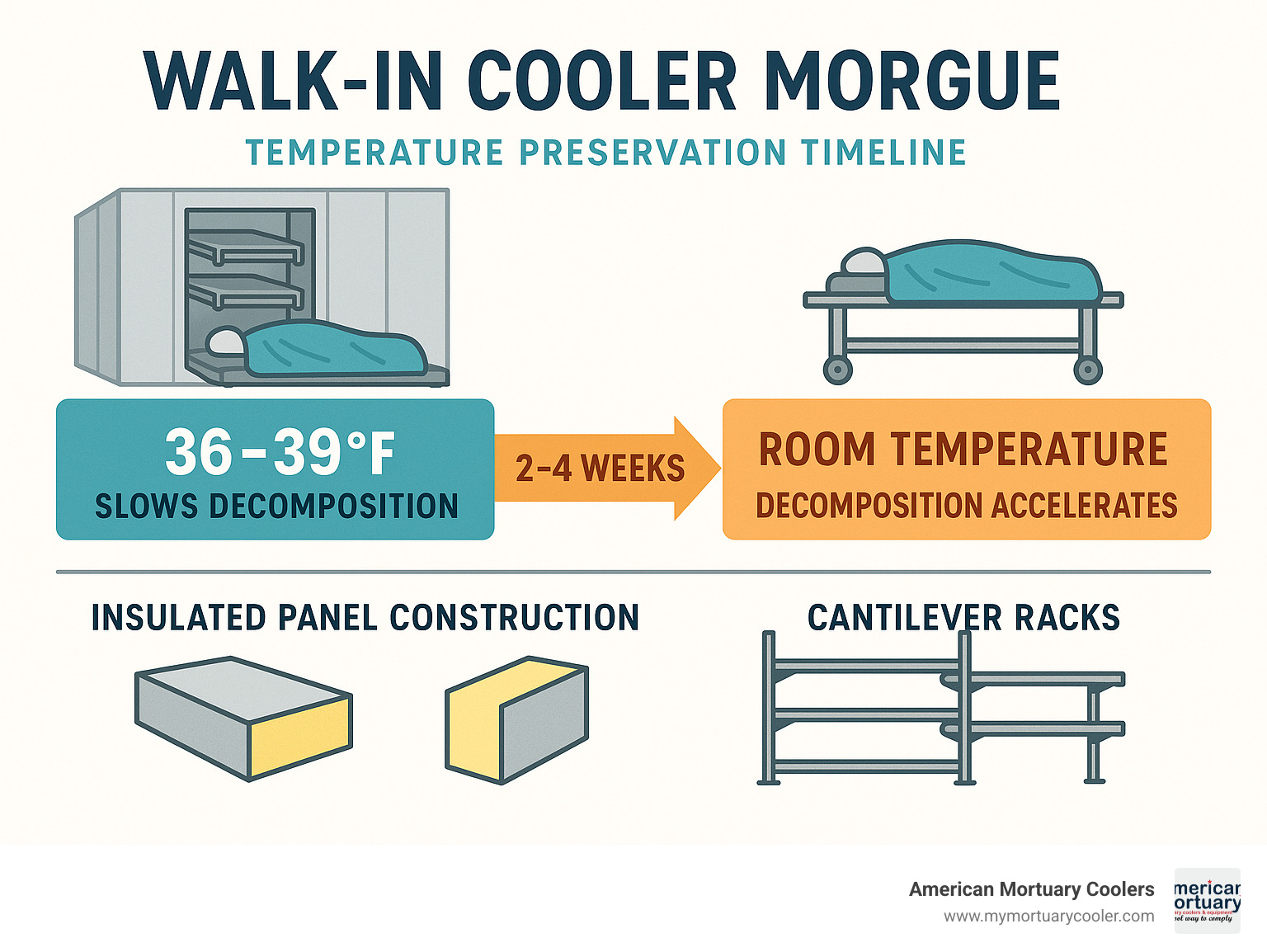

A walk in cooler morgue is a temperature-controlled room designed to preserve deceased bodies by maintaining temperatures between 36-39°F, slowing decomposition for weeks while families plan funeral services. These walk-in units differ from traditional body box refrigeration by offering larger storage capacity (4-50 bodies vs 2-23), easier access for staff, and flexible configurations that can expand with your facility's needs.

Key Features of Walk-In Cooler Morgues:

- Temperature Range: 36-39°F for optimal preservation

- Storage Capacity: 4 to 50+ bodies depending on rack configuration

- Construction: 4-inch insulated panels with high R-value

- Safety Features: OSHA-compliant handles, emergency releases, vapor-proof lighting

- Power Requirements: Standard 110V or 208/230V three-phase options

- Customization: Modular design allows future expansion and relocation

Walk-in morgue coolers serve hospitals, funeral homes, forensic labs, and medical examiner offices. Unlike individual body lockers, walk-in units create a sterile environment where staff can easily maneuver gurneys, accommodate bariatric cases, and perform necessary procedures while maintaining dignified care.

The modular panel construction means these units can be assembled, disassembled, and relocated as your facility grows. Most facilities choose walk-in coolers over body boxes when they need to store more than 6-8 bodies regularly or want the flexibility to handle varying caseloads.

As one HVAC technician noted in an industry forum: "A funeral director and state inspector both didn't know what temperature a mortuary cooler should run at" - highlighting why proper guidance is crucial for first-time buyers.

We're American Mortuary Coolers, a Tennessee-based manufacturer specializing in custom mortuary refrigeration solutions with direct delivery across the contiguous 48 states. Our background includes working directly with funeral directors nationwide to design walk in cooler morgue systems that balance capacity, energy efficiency, and budget constraints.

Walk-In Cooler Morgue 101: Purpose, Temperature, Benefits

When you're caring for families during their most difficult moments, reliable preservation becomes absolutely critical. A walk in cooler morgue does exactly what its name suggests - it creates a controlled environment that dramatically slows decomposition while maintaining the dignity every person deserves.

The science is actually pretty straightforward. At room temperature, bacterial activity accelerates decomposition within 24-48 hours. But drop that temperature below 40°F, and you can preserve bodies for weeks instead of days. This gives families the time they need to plan services, complete paperwork, and say their goodbyes without rushing through such an important process.

What makes walk-in systems special is their flexibility. Unlike cramped individual compartments, these refrigerated rooms let your staff move freely with gurneys and equipment. You can handle bariatric cases that simply won't fit in standard body boxes. And when your caseload unexpectedly increases - which always seems to happen at the worst times - you have the space to manage it professionally.

The modular panel construction means you're not locked into today's needs forever. As your funeral home grows, you can literally add more panels to expand the room. Try doing that with a traditional body box system.

Standard Temperature Ranges for Your Walk-In Cooler Morgue

Here's where things get interesting - ask three funeral directors about the "right" temperature, and you might get three different answers. The industry standard sits between 36-39°F, though some facilities operate in the broader 34-42°F range.

Based on our experience working with funeral homes across the country, we recommend targeting 36-38°F for the sweet spot between effective preservation and reasonable energy costs. Scientific research on cooler setpoints from HVAC professionals confirms that standard refrigeration temperatures work perfectly for mortuary applications.

One experienced technician put it simply: "Normal food-service refrigeration setpoints work just fine for mortuary use." The key difference is consistency - you need that temperature rock-solid reliable, not fluctuating like a grocery store cooler.

Digital controllers have become the standard because they're precise and dependable. The old mechanical systems had a nasty habit of "sticking" at the wrong temperature, especially during humid weather. Modern digital systems maintain your setpoint within a degree or two, day and night.

Temperature alarms aren't optional - they're essential. We've seen too many facilities find problems Monday morning after a weekend failure. One funeral home's system failed Friday night, and by Monday morning, temperatures had climbed to 88°F. That's a conversation with families no director ever wants to have.

Energy costs matter too. Each degree lower increases your electric bill by about 3-5%. Setting your walk in cooler morgue at 35°F instead of 38°F might sound more conservative, but it could cost hundreds extra per year with minimal preservation benefit.

Walk-In Cooler Morgue vs Body Box Refrigeration

Choosing between walk-in coolers and body box systems often comes down to capacity, workflow, and future growth plans. Both have their place, but the differences are significant.

Walk-in morgue coolers create actual refrigerated rooms - think of them as cold storage warehouses scaled for funeral home use. Most start around 8' x 8' x 8', but the modular panels let you build virtually any size. Inside, you'll use cantilever racks, rolling racks, or floor-mounted systems to organize storage efficiently.

Body box refrigeration works more like a high-tech filing cabinet. Individual compartments stack vertically, each holding one body. They're compact and organized, but they're also fixed in capacity and configuration.

The capacity difference becomes dramatic as you scale up. A standard 8' x 8' walk-in with three-tier racks holds 12-15 bodies in just 64 square feet. Add five-tier racks, and you're looking at 20-25 bodies in the same footprint. Meanwhile, body box systems typically max out around 23 compartments total, and that requires significant wall space.

Workflow efficiency heavily favors walk-in systems. Your staff can maneuver gurneys easily, work with multiple bodies simultaneously, and handle oversized cases without wrestling with compartment doors. Body boxes require lifting and positioning bodies into individual spaces - not ideal when you're dealing with bariatric cases or managing multiple services.

The expansion factor seals the deal for many facilities. Need more capacity next year? With a walk-in system, you add more panels. With body boxes, you're buying entirely new units and finding wall space for them.

We've helped funeral homes transition from body boxes to walk-in systems when their caseloads outgrew their original capacity. The difference in daily operations is remarkable - staff work more efficiently, families feel more comfortable with the professional appearance, and directors have the flexibility to handle whatever comes through their doors.

Anatomy of a Walk-In Cooler Morgue: Components, Safety, Innovations

When you peek inside a quality walk in cooler morgue, you're looking at engineering designed for one of life's most important moments. Every component works together to create a dignified, safe environment that serves families during their most difficult times.

The heart of any walk-in morgue system starts with 4-inch thick insulated panels featuring high R-value construction. These aren't your typical storage room panels - they're precision-formed with metal cladding and vapor barriers that meet strict Federal Energy Independence & Security Act requirements. Think of them as the thermal fortress that keeps temperatures steady while keeping energy costs reasonable.

Insulated doors deserve special attention because they're the weak link in many systems. Quality doors feature heated frames that prevent annoying condensation buildup and overlapping magnetic gasket seals that actually stay sealed. You'll find options ranging from sliding doors for tight spaces to manual or electric bi-parting doors for high-traffic facilities.

Safety features aren't afterthoughts in morgue design - they're literally life-savers. OSHA-compliant safety release handles let anyone exit from inside the cooler, even if the door mechanism fails. These handles work without electricity or special knowledge, which matters when someone's panicking in a cold, enclosed space.

Cantilever racks and rolling rack systems transform empty cooler space into organized storage that actually makes sense. A standard three-tier setup fits 12-15 bodies in an 8x8 footprint, while five-tier configurations handle 20-25 bodies. The adjustable shelving means you're not stuck with one-size-fits-all storage.

LED vapor-proof lighting provides bright, energy-efficient illumination that won't fail in humid conditions. These systems include exterior switches and pilot lights, so staff know what's happening inside without opening doors unnecessarily.

Modern digital PLC controls have replaced the mechanical systems that used to stick and fail at the worst possible times. These controllers maintain precise temperatures while providing alarm capabilities that alert staff when something goes wrong - like that facility that finded their weekend temperature spike to 88°F before major damage occurred.

Refrigeration redundancy options include backup compressors and remote monitoring that prevents those middle-of-the-night emergency calls. Self-contained units need only standard electrical connections, though larger systems benefit from three-phase power for efficiency.

Environmental controls like dehumidifier systems prevent moisture buildup that can create maintenance nightmares down the road. Some facilities choose dual-temperature zones within larger walk-in spaces for specialized storage needs.

More info about cooler features covers additional technical specifications and pricing considerations for different component combinations.

Cutting-Edge Upgrades & Trends

The funeral industry isn't exactly known for rapid technology adoption, but modern walk in cooler morgue systems are embracing innovations that make real differences in daily operations.

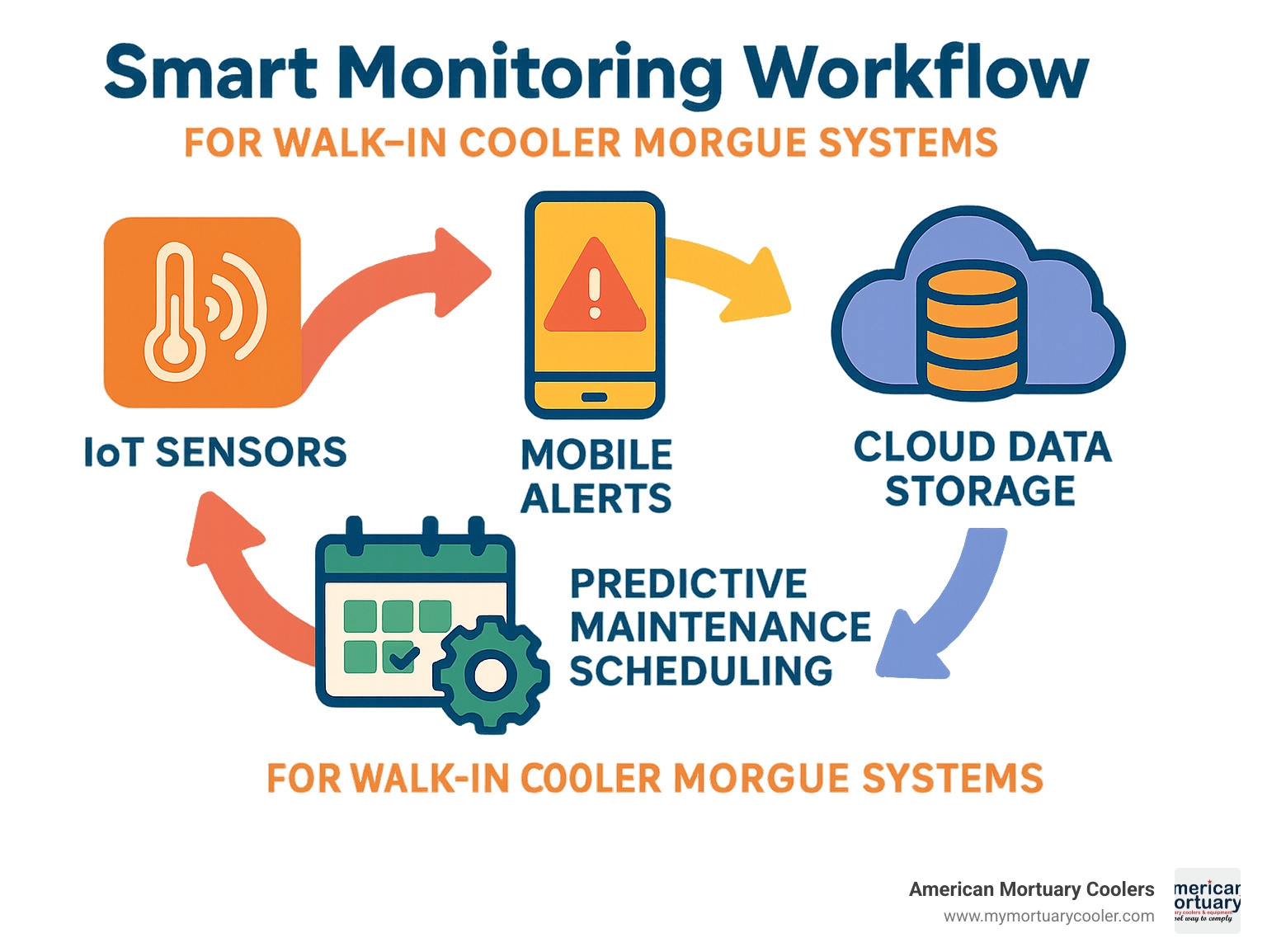

IoT sensors and remote monitoring represent the biggest game-changer we've seen. Smart sensors continuously track temperature, humidity, and system performance, sending alerts directly to facility managers' phones when conditions drift from normal ranges. No more weekend surprises or Monday morning disasters.

Energy-efficient compressors with variable-speed technology adjust cooling output based on actual demand rather than running full-blast constantly. These systems cut energy consumption by 20-30% while running quieter and lasting longer due to reduced cycling stress. Your electric bill and your neighbors will thank you.

Eco-friendly refrigerants aren't just feel-good technology - EPA regulations continue pushing toward refrigerants with lower global warming potential. These newer options maintain excellent cooling performance while meeting increasingly strict environmental standards.

Modular plug-and-play design has evolved to the point where facilities can expand cooler capacity in a single day without major construction. Advanced modular systems assemble with standard tools and minimal specialized knowledge.

Bariatric roll-in modules address the growing need for oversized storage capacity that traditional systems simply cannot accommodate. These specialized modules integrate seamlessly with standard walk-in systems while providing the extra space required for larger cases.

These technological advances aren't just flashy upgrades - they solve real problems that funeral directors face every day. Smart monitoring prevents equipment failures, efficient compressors reduce operating costs, and modular design provides flexibility as facilities grow and change.

Planning Capacity & Layout: Racks, Bariatric, Customization

Choosing the right size for your walk in cooler morgue feels overwhelming at first, but breaking it down by your typical caseload makes the decision much clearer. We've worked with facilities ranging from small-town funeral homes to major metropolitan medical examiner offices, and the patterns are pretty consistent.

Small funeral homes handling 2-3 cases per week typically choose 4-5 body modules in a compact 6x8 or 8x8 foot space. These units use simple two-tier rack systems and keep costs reasonable while providing room for busy periods.

Mid-size facilities usually need 8-10 body capacity to handle fluctuating caseloads without stress. A three-tier rack system in an 8x10 or 8x12 space gives you breathing room during difficult weeks while staying efficient during slower periods.

Hospital morgues and medical examiner offices often require 16-20 body modules with four or five-tier rack configurations. These larger systems handle the unpredictable nature of institutional work where you might receive multiple cases in a single day.

The largest standard configurations accommodate 24-30 bodies and serve major metropolitan areas or regional facilities covering multiple jurisdictions. Beyond 30 bodies, you're looking at custom installations with specialized rack systems that can reach 50+ body capacity - though these represent unique situations rather than typical needs.

The type of storage racks you choose makes a huge difference in daily operations. Cantilever racks provide easy access from one side and work great when you have wall space. Rolling racks let bodies slide in and out on tracks, which reduces lifting and makes transfers smoother. Many larger facilities combine both systems within their walk-in space for maximum flexibility.

Adjustable shelving proves invaluable because not every case fits standard dimensions. Being able to modify shelf heights accommodates everything from pediatric cases to unusually tall individuals without wasting space.

Bariatric cases present special challenges that walk-in coolers handle much better than body box systems. Standard morgue equipment works fine for bodies up to 350-400 pounds, but larger cases need specialized bariatric roll-in modules and lifting equipment. The open space in a walk-in cooler accommodates these specialized carts and gives staff room to maneuver safely.

One of the biggest advantages of modular panel construction is future expansion capability. We've had customers literally add panels to extend their refrigerated space as their communities grew or caseloads increased. This flexibility saves thousands compared to replacing entire systems.

Some facilities also incorporate specimen freezers within their walk-in space for forensic samples or long-term storage needs. The passthrough options between different temperature zones work particularly well for medical examiner offices handling complex cases.

Planning for relocation might seem odd, but funeral homes do move or expand. The modular design means your investment can move with you rather than becoming a stranded asset.

Custom Design Checklist

Getting the details right on your walk in cooler morgue prevents headaches later and ensures smooth daily operations. We've learned which decisions matter most through years of customer feedback and service calls.

Floor versus no-floor installations represents your first major decision. Insulated floors provide better thermal performance and create a completely sealed environment, but they cost more and require careful drainage planning. No-floor installations work beautifully when built on concrete slabs with proper vapor barriers underneath. Most customers choose no-floor options to save money without sacrificing performance.

Ramp systems make everyone's life easier by facilitating smooth gurney movement. Exterior ramps help staff steer from vehicles to the cooler entrance, while interior ramps handle the transition from floor level to no-floor installations. We recommend removable ramps for easier cleaning and maintenance access.

View windows divide our customers - some love being able to check inside without opening doors, while others see them as unnecessary complexity. Windows do create potential thermal bridging and cost more, but they can reduce door openings in busy facilities.

Dual-temperature zones work well for larger facilities needing different storage conditions. You might want standard cooling temperatures for most cases but freezer temperatures for long-term storage or forensic specimens. This requires more complex refrigeration systems but provides tremendous flexibility.

Outdoor versus indoor condensers affects both performance and convenience. Outdoor condensing units reduce interior noise and heat but need weather protection and proper drainage. Indoor units require adequate ventilation and service access but stay protected from weather extremes. Climate plays a big role in this decision.

Interior finish options balance cost against durability and hygiene. Stainless steel provides the most hygienic and durable surface but costs significantly more than galvanized steel. Many facilities compromise by choosing stainless steel for high-use areas and galvanized for less critical surfaces.

Power requirements need early planning to avoid installation delays. Smaller units under 10 bodies often operate on standard 110V outlets you can plug into existing electrical systems. Larger systems require 208/230V three-phase power that needs professional electrical work. Getting this sorted early prevents costly delays.

Humidity control becomes critical in humid climates or facilities with frequent door openings. Dedicated dehumidification systems prevent condensation and ice buildup that can damage equipment and create safety hazards. The upfront cost pays for itself in reduced maintenance and better performance.

More info about cooler dimensions covers the technical specifications in detail if you want to dive deeper into sizing calculations and space planning.

From Installation to Operating Costs: Energy Efficiency, Compliance, Maintenance

Getting your walk in cooler morgue properly installed sets the foundation for years of reliable service. The process isn't overly complicated, but attention to detail during installation prevents headaches down the road.

Site preparation starts with a level concrete slab that can handle the weight - we're talking about 150-200 pounds per square foot when your cooler is fully loaded with bodies and rack systems. Proper drainage and vapor barriers are crucial here. One facility we worked with skipped the vapor barrier and ended up with moisture problems that took months to resolve.

The modular panel assembly is where the magic happens. Our trained installation teams can put together a standard 8x8 cooler in about 4-6 hours. The precision-formed panels fit together like puzzle pieces, creating an airtight seal without specialized construction skills. It's honestly pretty satisfying to watch the whole thing come together.

You have two installation options with us. Factory installation means our Tennessee-based technicians handle everything, ensuring proper assembly and validating your warranty coverage. Approved contractor installation works well for remote locations where scheduling our team might take longer. Both approaches work, but factory installation gives you that extra peace of mind.

Compliance requirements might seem overwhelming, but they're designed to keep everyone safe and ensure your cooler operates efficiently. Your system needs to meet EISA/DOE insulation standards for energy efficiency, NSF approval for sanitation (yes, food service standards apply to morgue equipment), UL certification for electrical safety, OSHA requirements for workplace safety features, and EPA refrigerant rules for proper handling and disposal.

Energy efficiency pays dividends over time. High R-value insulation panels cost more upfront but dramatically reduce operating costs over your cooler's 15-20 year lifespan. LED lighting is a no-brainer upgrade - it uses 60-70% less energy than fluorescent systems while providing better illumination and lasting much longer.

Preventive maintenance keeps everything running smoothly. Monthly tasks include cleaning condenser coils, checking door seals, and verifying temperature readings. Annual professional service covers refrigerant levels, electrical connections, and safety system testing. It's like getting a physical - not exciting, but essential for long-term health.

Cleaning protocols vary by facility, but regular sanitization with approved disinfectants is non-negotiable. Stainless steel surfaces make this easier, and proper drainage systems facilitate thorough cleaning. Some facilities deep clean weekly, others after each use - it depends on your volume and internal protocols.

Our warranty coverage reflects the robust construction these systems require. We offer 15-year warranties on panels and doors, with 5-year coverage on mechanical components. These extended warranties aren't just marketing - they reflect our confidence in the durability required for mortuary applications.

More info about walk-in specs covers the technical details if you want to dive deeper into specifications and compliance requirements.

Frequently Asked Questions about Walk-In Cooler Morgues

What temperature should I set?

Set your walk in cooler morgue between 36-38°F for the sweet spot of preservation effectiveness and energy efficiency. This range slows decomposition beautifully while keeping your electric bill reasonable.

Avoid the temptation to go colder thinking it's better - temperatures below 34°F increase energy costs by 3-5% for each degree without meaningful preservation benefits. We've seen facilities waste thousands annually by running unnecessarily cold.

Digital controllers are worth every penny over mechanical systems. They maintain precise temperatures and won't "stick" like older mechanical units. Install temperature alarms too - one facility experienced a weekend failure where temperatures hit 88°F, creating a situation nobody wants to deal with.

How many bodies can I store in 100 sq ft?

A 100 square foot walk in cooler morgue (10x10) accommodates 15-20 bodies with three-tier rack systems, or 25-30 bodies with five-tier configurations. The actual number depends on your rack design, how much aisle space you need, and whether you require room for gurneys and equipment inside.

Plan for approximately 4-5 square feet per body for efficient operations with adequate access. Cramming too many bodies into the space creates workflow problems that offset the capacity benefits.

Cantilever racks provide easy access from one side, while rolling racks let bodies slide in and out on tracks. Many facilities combine both systems in larger spaces for maximum flexibility.

Do I need a floor in my walk-in cooler?

Insulated floors improve energy efficiency by 10-15% and provide better temperature uniformity throughout the space. However, they're not always necessary and add significant cost to your installation.

If you're building on a concrete slab with proper vapor barriers, a no-floor design works well and saves money. The concrete provides adequate thermal mass, and you avoid the complexity of drainage systems within the insulated floor.

Consider insulated floors for larger coolers, outdoor installations, or facilities in extreme climates where ground temperature variations affect performance. Also factor in drainage requirements - insulated floors need proper slope and drains for effective cleaning, which adds complexity to the installation.

Conclusion & Next Steps

Choosing the right walk in cooler morgue comes down to understanding your facility's unique needs - from daily capacity requirements to future growth plans. The good news? Modern modular systems give you flexibility to start where you are today and expand as your community grows.

We've walked through everything from temperature settings to rack configurations, safety features to energy efficiency. The key takeaway is that quality matters when you're entrusting such an important aspect of your operations to any piece of equipment.

At American Mortuary Coolers, we've built our reputation on understanding exactly what funeral professionals need. Based right here in Tennessee, we manufacture every unit in our own facility and deliver directly across all 48 contiguous states. No middlemen, no markup, no confusion about who to call when you need support.

What sets us apart is our single-contact approach. From initial design consultation through installation and ongoing maintenance, you work with the same team who built your system. We know your facility, understand your challenges, and can provide solutions that actually work in the real world.

Our process starts with understanding your specific situation. Maybe you're a small funeral home handling 3-4 cases monthly, or perhaps you're a regional medical examiner's office managing much higher volumes. We design each system to match your workflow, space constraints, and budget reality.

The modular construction we use isn't just about easy installation - though our crews can typically have you up and running in a single day. It's about giving you options down the road. Need more capacity in five years? We can add panels and expand your existing system without starting over.

Quality construction pays for itself over time. Our 15-year panel warranties and energy-efficient designs mean lower operating costs and fewer headaches. When you're dealing with families during difficult times, the last thing you need is equipment problems.

Ready to explore what's possible for your facility? Our experienced team can walk you through options that fit your specific needs and budget. We'll help you steer everything from power requirements to rack configurations, making sure you get exactly what works best for your operation.

More info about choosing a walk-in mortuary cooler - or contact us directly for a personalized consultation and quote.

Because when it comes to providing dignified care, you shouldn't have to compromise on quality.