Beginner's Guide to Choosing a Commercial Freezer Refrigerator

Why Every Business Needs the Right Commercial Freezer Refrigerator

A commercial freezer refrigerator is essential equipment for any business that needs to preserve perishable goods safely and efficiently. Unlike residential units, these heavy-duty systems are built to handle constant use, maintain precise temperatures, and meet strict health codes.

Key differences from home units:

- Heavy-duty compressors designed for 24/7 operation

- NSF certification for food safety compliance

- Higher capacity ranging from 2 to 56+ cubic feet

- Dual-temperature zones for flexible storage needs

- Commercial-grade construction with stainless steel interiors

Main types available:

- Reach-in units - Most common, 1-3 door configurations

- Walk-in coolers/freezers - Large capacity, custom sizing

- Undercounter models - Space-saving kitchen integration

- Prep tables - Combine work surface with refrigerated storage

- Merchandisers - Glass doors for product display

As American Mortuary Coolers, a national-level mortuary cooler supplier, we've helped countless businesses select the right commercial freezer refrigerator systems for their specific needs.

Commercial freezer refrigerator helpful reading:

Commercial Freezer Refrigerator 101: Types, Uses & Sizing

When you're shopping for a commercial freezer refrigerator, it helps to understand what makes these units tick. Think of them as the workhorses of the cooling world - built to run 24/7 while maintaining precise temperatures between -20°F to 41°F. The real magic happens in their ability to handle the constant door openings, temperature swings, and heavy-duty cycles that would make a home refrigerator wave the white flag.

The capacity world of commercial refrigeration is straightforward once you break it down. Compact units under 2 cubic feet work great for coffee shops. Standard reach-in models ranging from 12-49 cubic feet are the bread and butter for most restaurants. When you need serious storage power, large capacity units over 50 cubic feet step up to the plate.

You'll find reach-in refrigerators with their classic 1-3 door setups in most commercial kitchens. Walk-in coolers handle the bulk storage needs, while undercounter units tuck neatly beneath prep surfaces. Merchandiser units with their glass doors put products on display beautifully, and prep tables cleverly combine work surfaces with refrigerated storage underneath.

How a Commercial Freezer Refrigerator Differs From Residential Units

The engineering gap between commercial and home refrigeration is dramatic. At the heart of every commercial freezer refrigerator sits a heavy-duty compressor that's designed for continuous operation. Your home fridge compressor expects to take breaks throughout the day. This duty cycle difference means commercial units can handle the punishment of constant door openings without breaking a sweat.

NSF certification is where things get serious about food safety. The National Sanitation Foundation sets strict standards for commercial food equipment that go way beyond what your home appliances need to meet. We're talking stainless steel interiors, rounded corners for easy cleaning, and specific temperature recovery requirements.

Many modern commercial units have switched to hydrocarbon refrigerants like R-290, which are much friendlier to the environment than older refrigerant types. True Manufacturing offers a pioneering 7-year warranty covering labor, parts, and compressor on all their hydrocarbon units.

Industries That Rely on Commercial Freezer Refrigerators

Restaurants are the biggest users of commercial refrigeration. They use reach-in units for daily prep work and walk-in systems for bulk storage. Fast-casual restaurants especially love undercounter units and prep tables because they maximize efficiency in cramped kitchen spaces.

Supermarkets and convenience stores depend heavily on merchandiser-style units with glass doors. These units need to keep beverages, frozen foods, and grab-and-go items at perfect temperatures while giving customers easy access and clear product visibility.

Laboratories and medical facilities need precision temperature control for storing samples, medications, and research materials. These applications often require specialized features like temperature monitoring systems and backup power capabilities.

At American Mortuary Coolers, we've spent years understanding how funeral homes require specialized refrigeration for their unique preservation needs. Our custom solutions ensure proper temperature control while meeting the specific requirements of the funeral industry.

Model Selection & Configuration Strategies

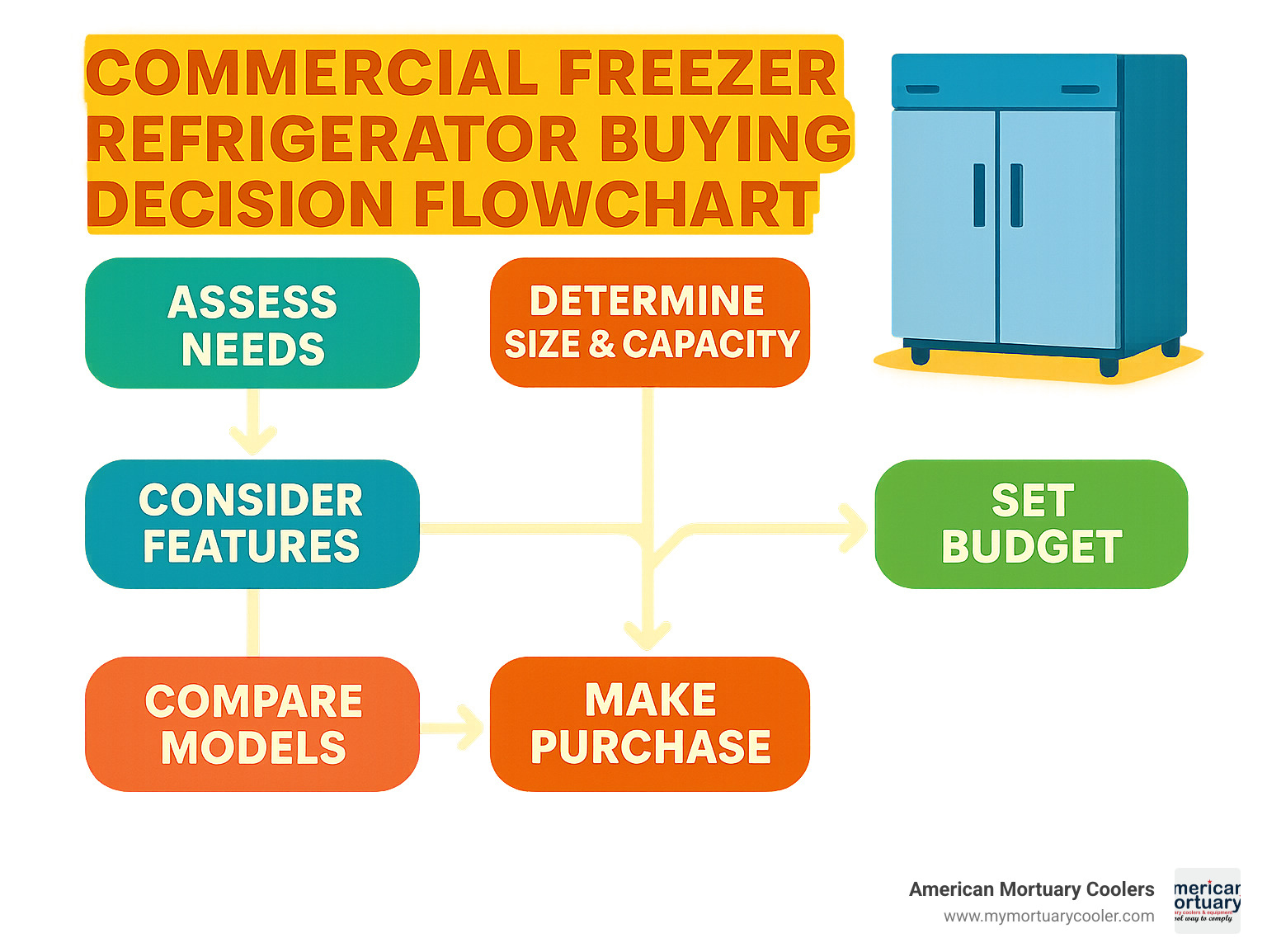

Choosing the right commercial freezer refrigerator is like solving a puzzle - every piece needs to fit perfectly. The first step is measuring your space, but don't just grab a tape measure and call it done. You need to think about door swing clearance, ventilation space, and whether your service technician can actually reach the back of the unit when something needs fixing.

Cubic foot calculations require honest thinking about your peak needs, not your average day. If you're running a restaurant, take your daily food volume and multiply by 1.5. This accounts for those crazy busy weekends and the times when your delivery arrives early and you're already stocked up. The advertised capacity isn't what you actually get - shelving and interior components eat up about 10-20% of that space.

Proper airflow makes the difference between a unit that hums along efficiently and one that struggles to maintain temperature. Your commercial freezer refrigerator needs space around it to breathe, and the inside needs room for air to circulate evenly.

| Feature | Reach-In Units | Walk-In Systems |

|---|---|---|

| Capacity | 12-49 cu ft | 100+ cu ft |

| Installation | Plug-and-play | Professional required |

| Flexibility | Limited | Highly customizable |

| Cost | $1,000-$8,000 | $5,000-$25,000+ |

| Energy Use | Lower total | Higher efficiency per cu ft |

Reach-In, Undercounter & Prep Tables

Reach-in units are the reliable workhorses that keep most commercial kitchens running smoothly. They're simple, dependable, and fit into tight spaces where walk-in coolers would be overkill. Chef bases are particularly clever - they slide right under your cooking equipment, putting cold storage exactly where your cooks need it most.

Most quality reach-in units come with heavy-duty casters and locking brakes. The wheels make repositioning easy during deep cleaning, and the locks keep everything stable during busy service.

Sandwich prep tables are space-saving champions that combine refrigerated storage with a work surface and ingredient rails on top. If you're running a sub shop, pizzeria, or any fast-casual operation, these units earn their keep by speeding up order assembly.

Beverage coolers and merchandisers with glass doors serve double duty - they store your products and help sell them. Customers can see what's available without opening doors and letting cold air escape. Modern units use LED lighting that lasts three times longer than old fluorescent bulbs.

Walk-In and Combo Solutions

When you need serious storage capacity, walk-in systems deliver the goods. Modern walk-ins use modular panel systems that can be configured to fit almost any space or building layout. These panels typically feature 4-inch thick insulation that exceeds energy standards, keeping temperatures stable while keeping your electric bills reasonable.

Remote condensing units are a smart choice in many situations. By locating the condenser outside your building, you reduce heat and noise in your kitchen while improving temperature control.

Combination cooler-freezer units give you the best of both worlds in a single walk-in space. These systems use separate evaporators and controls for each zone, so you can maintain different temperatures for different products.

If you're considering a walk-in solution, check out our detailed Commercial Walk-In Freezer Cost guide for pricing and configuration information.

Features, Innovations & Sustainability

Today's commercial freezer refrigerator units deliver precision and efficiency that were luxury only a few years ago. Digital thermostats now hold temperatures within 1–2 °F and show live readings on an external display, so staff know conditions instantly.

LED lighting has replaced fluorescent tubes for good: it is brighter, lasts three times longer, and cuts lighting energy by roughly 75 %.

On glass-door models, a low-emissivity coating can trim energy use up to 33 % versus standard glass – real savings month after month.

The service side has improved, too. With the plug-and-play Cassette® refrigeration system, technicians swap a sealed module in minutes instead of performing major on-site repairs.

Environmentally, natural R-290 hydrocarbon refrigerant delivers higher efficiency with near-zero ozone or global-warming impact, and many R-290 models qualify for utility rebates. Pair that with an Energy Star label and you could see 10-30 % of the purchase price returned through local incentive programs. For deep-dive technical reading, visit Refrigeration Basics.

Critical Feature Checklist

Focus on what affects everyday use:

- Usable capacity after shelving and the evaporator, not just the headline cubic feet.

- Insulation – at least 2 in. in coolers and 3 in. in freezers; 4 in. saves even more energy.

- Door style – solid doors save energy; glass doors speed product identification.

- Easy service access so down-time stays minimal.

Game-Changing Options

- Smart IoT monitoring sends temperature or service alerts straight to your phone.

- Convertible or blast-chill modes quickly drop food from cook temp to safe storage.

Going Green & Saving Energy

Upgrade paths are straightforward: swap fluorescent bulbs for LEDs, spec low-E glass on display units, choose hydrocarbon refrigerants, and claim available utility rebates. Efficiency upgrades usually pay for themselves through lower operating costs inside two or three years.

Budget, Warranty & Smart Purchasing Tips

A commercial freezer refrigerator is a major line-item, but smart planning keeps costs manageable.

Entry-level reach-ins start near $1,000, while a fully featured walk-in can exceed $25,000. Larger boxes often cost less per cubic foot, yet oversizing wastes energy, so match capacity to your busiest day – not your average one.

Compressor choice also matters. Standard fixed-speed models cost less upfront; variable-speed units run 20-30 % more efficient and often repay the premium within a few utility cycles.

Price Bands at a Glance

- $250–$1,000: Basic entry units with limited features.

- $1,000–$4,000: Sweet spot for most operations; expect digital controls and better insulation.

- $4,000–$8,000+: Premium materials, latest tech, multi-year warranties.

- Walk-ins: Begin around $5k; custom builds vary widely with size and installation complexity.

Warranty & After-Sales Support

Look beyond the sticker price at coverage terms. Many manufacturers offer one-year parts, 90-day labor. Leaders such as True Manufacturing include up to 7-year full coverage on hydrocarbon systems, saving thousands over a unit’s life.

Ensure parts remain available for 10-15 years, or an inexpensive component failure could sideline an otherwise sound unit.

Stretching the Budget

- Scratch-and-dent: Cosmetic blemishes, full warranty, 20-40 % savings.

- Refurbished walk-ins: Professionally rebuilt, 50-70 % of new cost; demand written warranties.

- Model-year clearances: 30 %+ discounts when factories swap to new lines.

For gasket care that keeps energy bills low, see our Ultimate Guide to Walk-In Freezer Door Gaskets Replacement.

Warranty, Maintenance & Best Practices

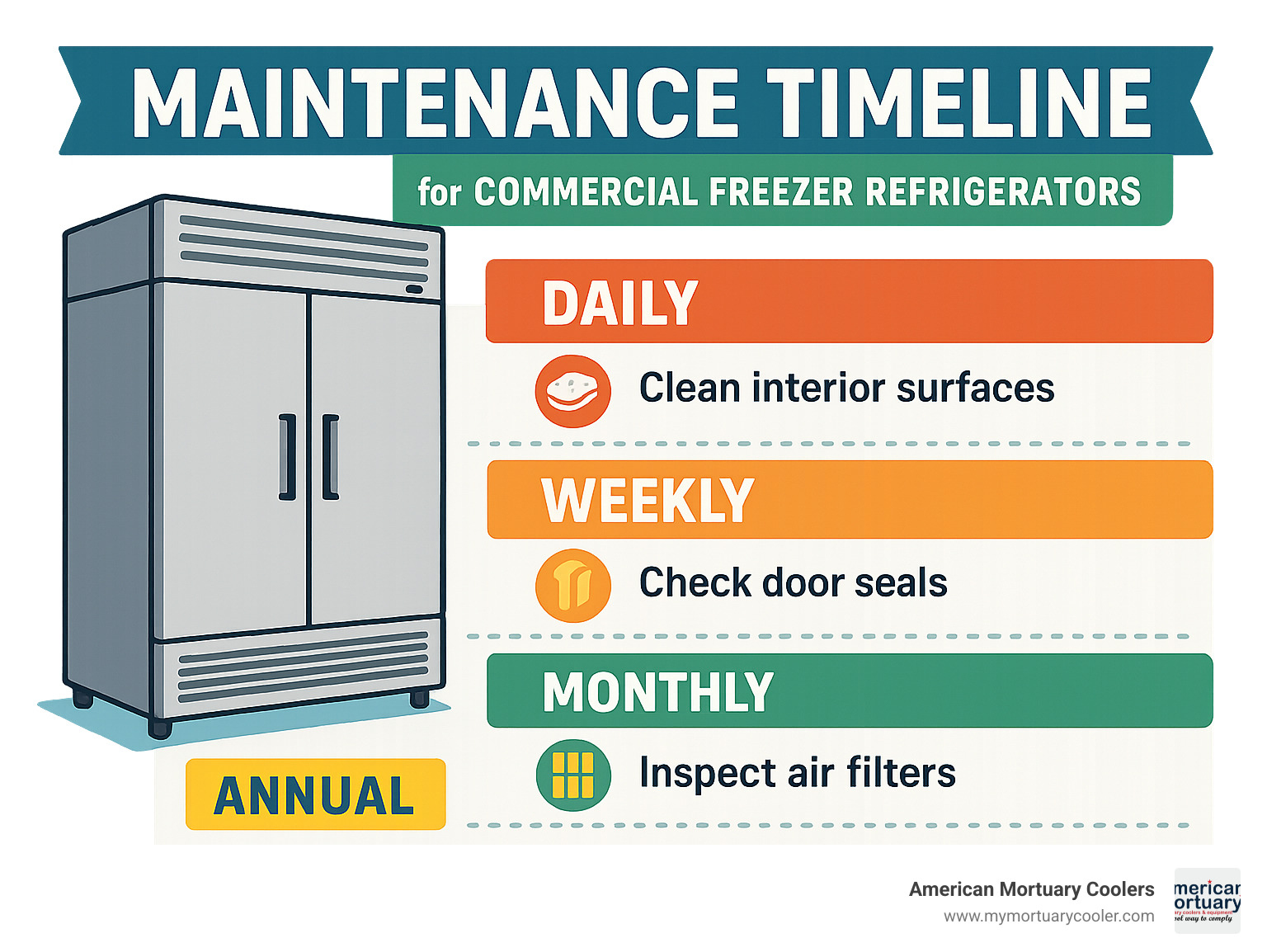

Taking care of your commercial freezer refrigerator isn't just about keeping it running - it's about protecting your investment and your business. Think of it this way: a well-maintained unit can serve you faithfully for 15-20 years, while a neglected one might give up the ghost in just 5-7 years.

Here's the thing about maintenance costs - they're always cheaper than emergency repairs. Plus, there's nothing worse than losing a freezer full of inventory because you skipped cleaning the coils.

The beauty of preventive maintenance is that most tasks are quick and simple. Your daily checks take just a few minutes, while weekly and monthly tasks require a bit more attention but catch problems before they become disasters.

Preventive Maintenance Routine for Commercial Freezer Refrigerators

Your daily routine should become as automatic as your morning coffee. Check the temperatures first thing - they should be exactly where you set them. Listen for unusual sounds - your equipment talks to you, and strange noises are its way of asking for help. Make sure doors close properly and gaskets seal tight. These simple steps take maybe five minutes but can save you thousands.

Monthly maintenance is where you get a bit more hands-on. Cleaning those condenser coils is absolutely critical - dirty coils make your compressor work overtime, which means higher energy bills and shorter equipment life. Use a soft brush or vacuum, and be gentle with those delicate fins.

Ice buildup is your enemy, especially in freezers. If you're seeing ice stalactites hanging down like a frozen cave, your drainage system needs attention immediately. Proper defrost cycles and clear drain lines prevent this problem before it starts.

Don't skip the annual professional service. A qualified technician can spot problems you'd never notice and handle tasks like refrigerant level checks and electrical connections that require specialized knowledge.

Food Safety & Regulatory Compliance

Let's talk about the rules - because in the food business, the rules aren't suggestions. NSF Standard 7 sets the bar for commercial refrigeration equipment, ensuring your unit can handle the demands of food service while meeting health department requirements.

Temperature control isn't negotiable. Dairy products need 41°F or below, while frozen foods require 0°F or lower. These aren't rough guidelines - they're legal requirements. Keep those temperature logs religiously, because health inspectors will ask to see them.

Calibrating your thermometers annually ensures your readings are accurate. There's no point in maintaining perfect temperatures if your thermometer is lying to you.

HACCP protocols require documented temperature monitoring and corrective actions. This paperwork might seem tedious, but it protects your business and demonstrates your commitment to food safety.

Troubleshooting Common Issues

Ice buildup on evaporator coils is like a red flag waving at you. It usually means your defrost system isn't working properly or airflow is restricted. Don't ignore it - that ice acts like insulation, making your compressor work much harder than it should.

High energy bills often have simple solutions. Dirty condensers are the usual suspects, followed by worn door gaskets and incorrect temperature settings. Sometimes a quick cleaning or adjustment can cut your energy costs dramatically.

Warm spots in your refrigerated space typically mean you're overloading the unit or blocking airflow. Cold air needs to circulate freely. Don't pack products so tightly that air can't move around them.

Strange noises deserve immediate attention. Your commercial freezer refrigerator should run quietly and smoothly. Grinding, squealing, or rattling sounds often indicate worn components or loose hardware.

At American Mortuary Coolers, we've seen how proper maintenance extends equipment life and prevents costly failures. Our customers across the country have learned that a little attention goes a long way in keeping their refrigeration systems running reliably for years to come.

Frequently Asked Questions about Commercial Freezer Refrigerators

Why is energy efficiency so critical in a commercial freezer refrigerator?

Your electricity bill tells the story. A commercial freezer refrigerator runs 24/7, which means even small efficiency improvements add up to serious savings. In busy supermarkets, refrigeration can gobble up nearly half of the total energy bill - that's thousands of dollars every month.

Efficient units don't just save on electricity. They run less often, which means less wear and tear on the compressor and other moving parts. Think of it like a car that gets better gas mileage - it's also likely to need fewer repairs over time.

The government gets this too. That's why utilities across the country offer cash rebates for Energy Star certified equipment. These rebates can cover 10-30% of your purchase cost, making efficient units surprisingly affordable upfront.

Environmental regulations are getting stricter every year. Units with natural refrigerants like R-290 help you stay ahead of the curve while often running more efficiently than older systems.

How do I calculate the right capacity for my business?

Most people make the same mistake - they calculate based on their average day instead of their busiest day. That's like buying a car based on your Sunday drive instead of your daily commute.

For restaurants, take your daily food volume and multiply by 1.5. This accounts for busy weekends, holidays, and that time when your supplier delivers everything at once. You can't make money if your food spoils because you ran out of space.

Don't forget the "hidden" space loss. Shelving, air circulation areas, and the evaporator unit eat up 10-20% of the advertised capacity. A 20 cubic foot unit might only give you 16-17 cubic feet of actual storage space.

Product type matters too. Storing whole turkeys needs different space than storing individual steaks. Bulk items need fewer shelves but more height, while smaller items need more shelving levels.

Consider where you'll be in three years. It's usually cheaper to buy slightly larger capacity now than to squeeze in another unit later. But don't go crazy - oversized units waste energy heating empty space.

Are scratch-and-dent or used commercial freezer refrigerators worth it?

Scratch-and-dent units are often the best-kept secret in commercial equipment. These are brand-new units that got dinged during shipping or have a small scratch on the side. They work exactly the same as perfect units but cost 20-40% less.

The key is buying from reputable dealers who stand behind their products. These units come with full manufacturer warranties, so you're not taking any risk on performance. A small dent on the side panel doesn't affect how well it keeps your food cold.

Used equipment requires more detective work. A well-maintained 5-year-old unit from a restaurant that went out of business can serve you well for another decade. But you need to see maintenance records, test the temperatures, and check the compressor operation.

Here's the math that matters: total cost of ownership. An older unit might seem cheaper, but if it uses twice the electricity and needs repairs every six months, you're not saving money. Sometimes the "expensive" new efficient unit costs less over five years than the "bargain" used one.

At American Mortuary Coolers, we've seen businesses save thousands by choosing refurbished walk-in units that were professionally restored. The key is working with suppliers who know what they're doing and back their work with solid warranties.

Conclusion

Finding the perfect commercial freezer refrigerator doesn't have to feel overwhelming. Throughout this guide, we've walked through everything from basic types and sizing to advanced features and maintenance tips. The bottom line? Quality equipment that's properly matched to your needs will serve your business reliably for years to come.

What makes the difference between a smart purchase and a costly mistake? It's understanding your specific requirements, planning for growth, and choosing equipment built to handle your daily demands. Whether you're running a busy restaurant kitchen or managing specialized storage needs, the right commercial freezer refrigerator becomes an investment in your business success.

At American Mortuary Coolers, we've seen how the right refrigeration solution transforms operations. From our Tennessee headquarters, we've delivered custom solutions across all 48 contiguous states, helping businesses solve their unique storage challenges. Our focus on durability and custom solutions means you get equipment that works exactly how you need it to work.

The refrigeration industry keeps getting better. Today's units with low-emissivity glass deliver 33% better efficiency than older models. LED lighting systems last three times longer while using less energy. Smart monitoring helps prevent problems before they become expensive headaches. These aren't just nice features - they're investments that pay for themselves through lower operating costs and fewer service calls.

Buying the equipment is just the beginning. Regular maintenance keeps your commercial freezer refrigerator running efficiently and extends its life significantly. A few minutes of daily attention and proper monthly care can prevent thousands in repair costs and product losses.

Ready to find your perfect refrigeration solution? We'd love to help you steer the options and find equipment that fits your space, budget, and operational needs. Explore our walk-in refrigeration solutions to see how our custom approach can work for your business. Our team understands that every operation is different, and we're here to help you get exactly what you need.