Beginner's Guide to Accuid: What It Is and How It Works

Understanding AccuID: The SMT Barcode Revolution

AccuID is a specialized component reel barcode scanning system designed to streamline electronics manufacturing through automated identification and verification of SMT (Surface Mount Technology) components.

Quick Answer for AccuID:

- What it is: Benchtop barcode scanner for SMT component reels

- Who makes it: Accu-Assembly

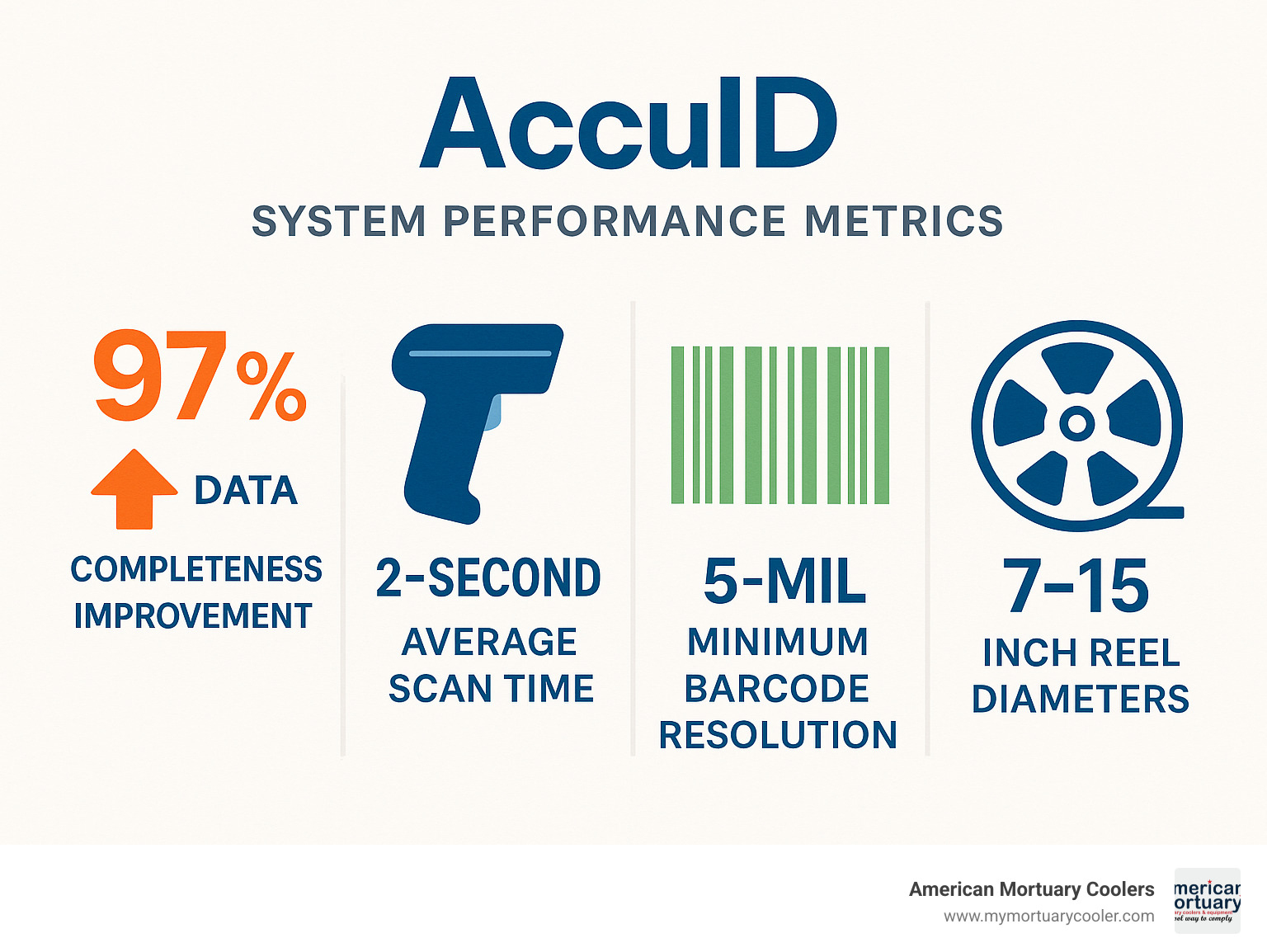

- Key benefit: Decodes all barcodes on a reel in 2 seconds

- Reel compatibility: 7" to 15" diameter reels

- Barcode types: 1D (down to 5 mils) and 2D (down to 10 mils)

- Main uses: Inventory tracking, incoming inspection, production verification

If you've ever worked in electronics manufacturing, you know the pain of manually scanning individual barcode labels on component reels. One wrong scan can derail an entire production run. AccuID eliminates this headache by automatically reading multiple barcodes in any orientation during a single pass.

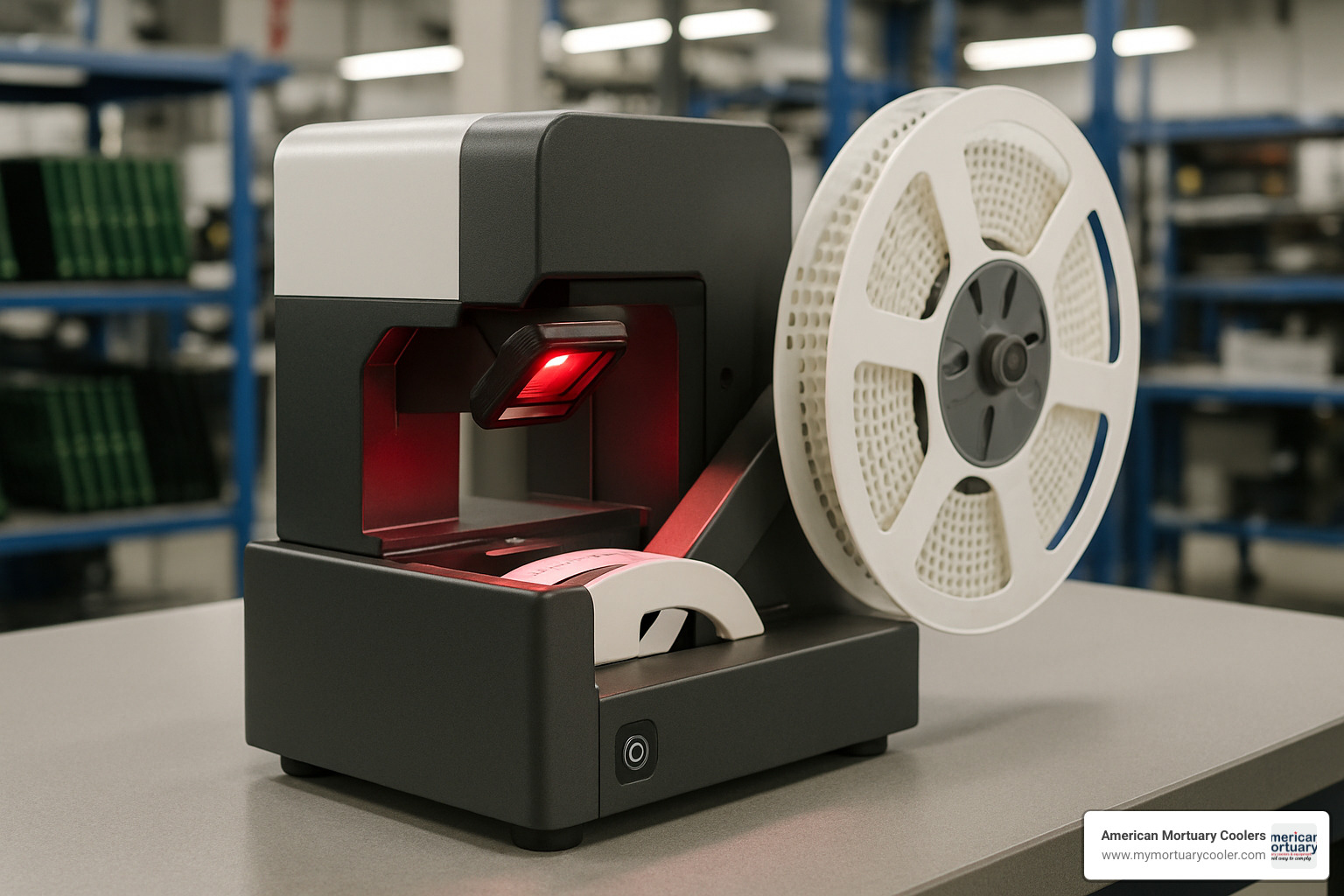

The system was developed by Accu-Assembly specifically for the electronics industry, where accurate component identification is critical for quality control and traceability. Instead of hunting for the right barcode label with a handheld scanner, operators simply place the reel into the benchtop unit and let the system do the work.

This technology addresses a real manufacturing bottleneck. As one industry expert noted: "AccuID produces a unique reel ID barcode label for each SMT component reel" - creating a reliable chain of custody from incoming inspection through final assembly.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in precision equipment for specialized industries. While AccuID serves electronics manufacturing, I understand the importance of reliable identification systems in maintaining quality standards across all technical fields.

What Is AccuID and Who Developed It?

AccuID was born from a simple observation: electronics manufacturers were wasting precious time and making costly mistakes with traditional barcode scanning methods. The team at Accu-Assembly saw operators struggling with handheld scanners, hunting for the right barcode label on component reels, and decided there had to be a better way.

What they created was in its simplicity. AccuID functions as a specialized barcode scanning system that reads all the barcodes on an SMT component reel in one quick operation. No more guessing which label to scan or worrying about missing critical information.

The system tackles three major headaches that plague electronics manufacturing. Reel ID creation becomes automatic - the system generates unique identification labels for seamless inventory tracking. Barcode verification happens instantly during incoming inspection, catching errors before they reach the production floor. And incoming material verification ensures component data flows smoothly into your SMT placement equipment without hiccups.

Here's what makes AccuID special: it doesn't just scan barcodes, it understands them. The system automatically decodes all readable information and creates a comprehensive reel ID that follows your components through their entire journey in your facility.

Accu-Assembly built the system with a plugin software architecture that puts you in the driver's seat. You get complete control over custom interface development, which means AccuID adapts to your existing workflows instead of forcing you to change everything. For more details about the innovative company behind this technology, check out Accu-Assembly.

Key Industries and Applications

AccuID has found its home across industries where precision isn't just nice to have - it's absolutely critical.

In electronics manufacturing, AccuID serves as the backbone of component tracking. Contract manufacturers especially love how it prevents the dreaded component mix-ups that can shut down entire production lines. When you're dealing with hundreds of different component types, having reliable identification isn't optional.

Automotive electronics presents unique challenges with its strict traceability requirements. Modern cars are essentially computers on wheels, packed with electronic components that must be tracked from cradle to grave. AccuID helps automotive suppliers maintain the bulletproof documentation that regulators demand.

The aerospace industry takes component traceability to another level entirely. When component failure could mean the difference between a safe flight and disaster, AccuID's ability to decode even tiny 5-mil barcodes ensures nothing gets missed. Every component gets properly identified and tracked through the entire manufacturing process.

Contract EMS providers face a particularly tough challenge - they handle components from dozens of different suppliers, each with their own labeling quirks. AccuID's omni-directional scanning capability means it reads barcodes no matter how they're oriented, making it perfect for high-mix operations where variety is the name of the game.

How the Accuid SMT Barcode System Works

Here's where AccuID really shines. The system uses something called omni-directional scanning, which is a fancy way of saying it can read barcodes no matter how the reel is positioned. You know that frustrating dance you do with handheld scanners, trying to get the angle just right? AccuID eliminates that entirely.

The whole process takes about two seconds per reel. That's not a typo - two seconds to decode all the barcodes on a component reel. Compare that to the minutes you might spend wrestling with a handheld scanner when labels are damaged or hard to reach.

The system handles component reels from 7 inches to 15 inches in diameter, which covers pretty much every SMT component you'll encounter in electronics manufacturing. Whether you're dealing with tiny resistors or larger connectors, AccuID has you covered.

The benchtop unit itself is surprisingly compact at 17 inches by 15 inches by 27 inches. It won't take over your workspace, but it packs serious scanning power. The system can decode down to 5 mils on 1D barcodes and 10 mils on 2D barcodes - that's incredibly fine resolution for industrial scanning.

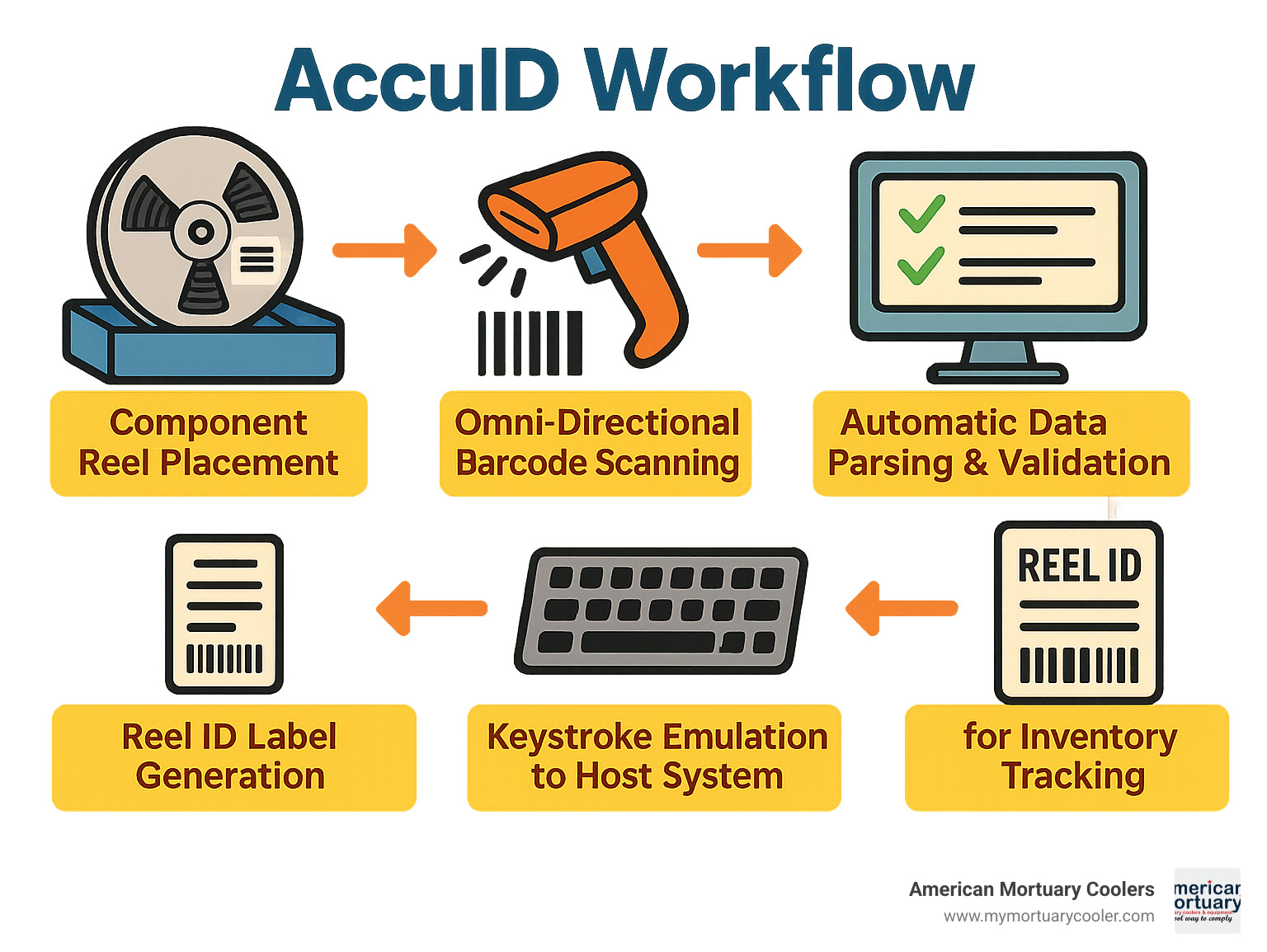

Accuid Scan Sequence

The beauty of AccuID lies in its simplicity. The scanning process follows five straightforward steps that practically run themselves:

Place the reel in the system - no need to worry about positioning or orientation. Just set it down and let the system do its thing.

Auto-trigger activation happens automatically when the system detects the reel. You don't need to press buttons or flip switches.

Decoding occurs for all barcodes simultaneously. The system reads everything at once, parsing out part numbers, date codes, lot codes, and quantities without you having to hunt for specific labels.

Keystroke emulation feeds the decoded data directly into your PC application. It's like having an incredibly fast, accurate typist entering all the information for you.

MES hand-off routes the data to your Manufacturing Execution Systems or ERP systems based on configurable settings. The system knows where different types of data need to go.

This automated sequence removes the human error factor while speeding up component identification dramatically. No more squinting at tiny labels or wondering if you scanned the right barcode.

Why Accuid Beats Handheld Scanners

Let's be honest - handheld scanners can be a real pain when you're dealing with SMT component reels. AccuID solves the problems that make traditional scanning so frustrating.

Speed is the obvious winner. While you might spend 30 to 60 seconds per reel with a handheld scanner (including time to find the right barcode), AccuID finishes the job in about 2 seconds.

Error reduction happens because the system reads all barcodes at once, then uses smart parsing to extract the right information. No more accidentally scanning the wrong label or missing important data.

Traceability improves dramatically since the system creates a complete digital record of every barcode on each reel. You get comprehensive documentation that goes far beyond what's possible with selective manual scanning.

The difference becomes clear when you look at the numbers. AccuID eliminates orientation sensitivity entirely - you can't place the reel "wrong." Traditional scanners require precise positioning and often multiple attempts to get a good read.

| Feature | AccuID | Traditional Handheld Scanner |

|---|---|---|

| Scan Time | ~2 seconds | 30-60 seconds |

| Orientation Sensitivity | None (omni-directional) | High (must be positioned correctly) |

| Multiple Barcode Reading | All codes simultaneously | One at a time |

| Error Rate | Minimal (automated) | Higher (human factor) |

| Traceability | Complete reel documentation | Limited to scanned codes |

| Integration | Automated keystroke/API | Manual entry required |

For manufacturers dealing with high-volume component processing, these improvements add up to significant time savings and fewer headaches. The system integrates seamlessly with existing workflows while providing better data accuracy than traditional methods.

Technical Features, Reel Range & Integration

When it comes to technical precision, AccuID doesn't mess around. The system can decode barcodes down to an impressive 5 mils for 1D symbologies and 10 mils for 2D codes. To put that in perspective, we're talking about reading barcodes so small you'd need a magnifying glass to see them clearly with the naked eye.

The beauty of this precision is that it covers virtually every barcode you'll encounter in electronics manufacturing. Whether you're dealing with tiny passive components or large integrated circuits, AccuID handles them all with the same reliable accuracy.

Reel compatibility spans from 7" to 15" diameter, which means you won't find yourself stuck with a system that only works for certain component types. From the smallest resistor reels to the largest connector packages, everything fits within this range.

The desktop footprint of 17" x 15" x 27" is surprisingly compact for such a capable system. Most workbenches can accommodate it without requiring a complete layout reorganization. It's like having a powerful scanning station that doesn't dominate your workspace.

Integration is where AccuID really shows its engineering smarts. The plugin-based software architecture means you're not locked into a rigid system that forces you to change your entire workflow. Instead, you can customize the interface to work exactly how your operation needs it to work.

For manufacturers who want to dive deeper into the technical validation behind barcode accuracy standards, scientific research on barcode accuracy provides comprehensive industry benchmarks that demonstrate how AccuID's capabilities stack up against established requirements.

Accuid Software Flexibility

The software side of AccuID is where the system truly adapts to your world rather than forcing you to adapt to it. The plugin architecture gives you complete control over how data flows through your manufacturing process.

Keystroke mapping lets the system talk to virtually any PC application by emulating specific key sequences. Got an older inventory system that doesn't have fancy API connections? No problem. AccuID can feed data into it just like a human operator typing at lightning speed.

Database routing uses configurable prefix codes to automatically send different types of information where it needs to go. Part numbers might head straight to your inventory management system, while quality control data gets routed to your inspection database. It's like having a smart postal system for your manufacturing data.

Custom scripts take things even further for operations with complex requirements. Need data format conversions? Multi-system updates? Custom validation rules? The scripting capability handles these specialized needs without requiring expensive custom programming.

This flexibility has made AccuID particularly popular with contract manufacturers who deal with multiple customers, each with their own systems and requirements. Instead of juggling different scanning solutions, they configure one system to handle various integration scenarios.

Accuid Hardware Specs

The hardware engineering behind AccuID focuses on reliability in real manufacturing environments. The illumination system uses advanced LED lighting that ensures consistent barcode reading regardless of whether your facility has perfect lighting or those flickering fluorescents that seem to plague every factory floor.

The vision engine combines high-resolution cameras with sophisticated image processing algorithms. This means the system can decode barcodes that look pretty rough to the human eye - those labels that got dinged during shipping or printed with slightly off-spec equipment.

ESD-safe enclosure design meets the electrostatic discharge requirements that are critical in electronics manufacturing. The last thing you want is a scanning system that damages the sensitive components you're trying to track.

Every component in the benchtop unit is rated for continuous industrial operation. This isn't consumer-grade equipment that might struggle with the demands of a production environment. It's built to handle the reality of manufacturing - long shifts, demanding schedules, and the occasional bump or jostle that comes with busy production floors.

Benefits, Use Cases & Related Solutions

The implementation of AccuID delivers measurable benefits across multiple aspects of electronics manufacturing operations. The most immediate impact is typically seen in inventory accuracy, where the system's comprehensive barcode reading eliminates the data gaps that occur with selective manual scanning.

Inventory Accuracy - By reading all barcodes on each reel and creating complete digital records, AccuID ensures that inventory systems have comprehensive component data. This reduces discrepancies and improves material planning accuracy.

Incoming Inspection - The system excels at verifying barcode label accuracy during receiving operations. Rather than spot-checking individual labels, inspectors can verify all barcode data on each reel in seconds.

Placement Feeder Check - Before loading components into SMT placement equipment, AccuID can verify that the correct components are being used, preventing costly wrong-part errors.

Quality Control - The comprehensive traceability provided by AccuID supports quality investigations and regulatory compliance requirements.

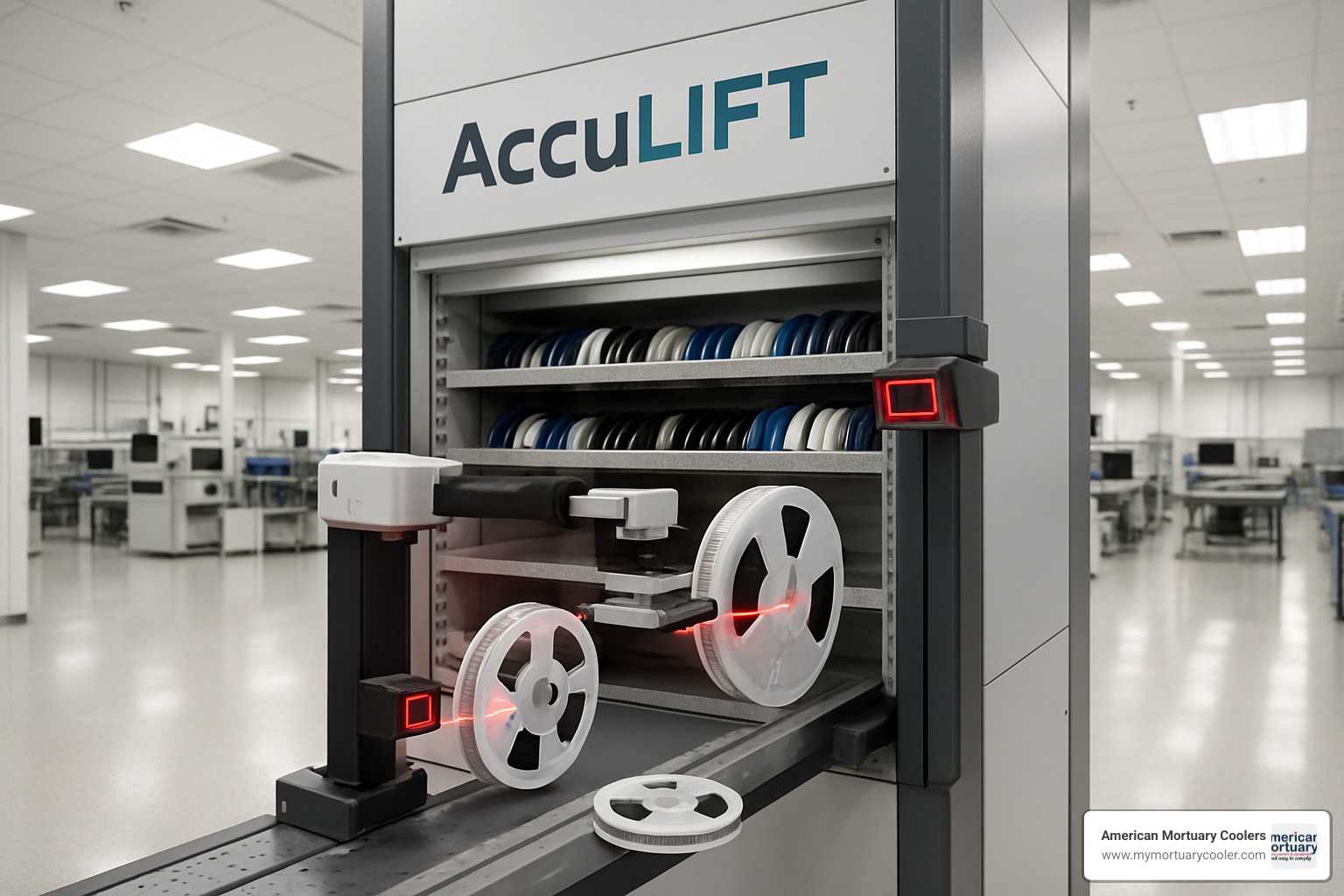

AccuID is part of a broader ecosystem of intelligent manufacturing solutions. Related products include AccuLiFT (automated storage), BarTector (component verification), and Dr. Storage (controlled environment storage). These systems work together to create comprehensive component management solutions.

The AccuLiFT system, for example, provides maximum storage capacity of 8,300 SMT component reels with integrated barcode tracking. When combined with AccuID, manufacturers can achieve complete automation from receiving through storage and kitting operations.

For facilities managing multiple types of specialized equipment, understanding proper safety protocols is crucial. Our guide on essential safety protocols for morgue freezers provides insights into maintaining safe operations with precision equipment.

Real-World Testimonials

Manufacturing professionals who have implemented AccuID report significant operational improvements:

Speed Improvement - "The 2-second decode time has transformed our incoming inspection process. What used to take our team hours now takes minutes," reports a quality manager at a major contract manufacturer.

Storage Integration - Facilities using the complete ecosystem report managing up to 8,300 reels with zero mis-feeds, thanks to the integrated barcode tracking throughout the storage and retrieval process.

Error Elimination - "We haven't had a wrong-part error since implementing AccuID," notes a production supervisor at an automotive electronics supplier. "The system catches discrepancies that would have slipped through manual scanning."

These testimonials highlight the real-world impact of transitioning from manual to automated component identification systems.

Other Smart Tools in the Ecosystem

The AccuID system integrates with several complementary solutions that create a comprehensive smart manufacturing environment:

Dr. Storage Dry Cabinets - These controlled-environment storage systems maintain optimal humidity levels for moisture-sensitive components. Available with 1% RH, <1% RH, and 60°C baking modes, they protect component integrity while providing network connectivity for monitoring and alarms.

Vertical Lift Modules - The AccuLiFT system uses proven VLM technology to maximize storage density while minimizing floor space requirements. The double pallet buffer system enables continuous loading and unloading without production interruption.

Reel Kitting Robots - Automated systems that can stack 30-100 reels on modular stackers, with robotic arms handling the placement and retrieval operations. This eliminates the manual labor traditionally required for reel management.

These integrated solutions demonstrate how AccuID fits into the broader trend toward Industry 4.0 manufacturing, where intelligent systems communicate and coordinate to optimize operations.

Frequently Asked Questions About Accuid

What reel sizes and barcode types can AccuID handle?

If you're wondering whether AccuID will work with your component reels, the answer is probably yes. The system handles reels from 7 inches to 15 inches in diameter - which covers pretty much everything you'll find in electronics manufacturing, from tiny resistors to large connectors.

The barcode reading capabilities are where AccuID really shines. It can decode 1D barcodes down to 5 mils and 2D codes down to 10 mils. To put that in perspective, that's incredibly small - we're talking about barcodes that might be hard to read with the naked eye.

What makes this even better is the omni-directional scanning. You don't need to worry about which way the barcode is facing or spend time rotating the reel to find the "sweet spot." Just place it in the system and let it do its magic.

How does AccuID integrate with my existing SMT line?

This is where AccuID gets really practical. The folks at Accu-Assembly understood that nobody wants to overhaul their entire system just to add better barcode scanning.

The simplest integration method is keystroke emulation - basically, AccuID pretends to be a keyboard and types the data directly into whatever software you're already using. This works with older systems that don't have fancy modern interfaces.

For more sophisticated setups, the plugin-based software architecture lets you create custom connections through APIs. This means AccuID can talk directly to your MES or ERP systems without any manual data entry.

The really smart part is the prefix parsing capability. You can set up rules so different types of data automatically go to the right places. Part numbers might go to your inventory system while quality data heads to your inspection database.

Many manufacturers also integrate AccuID with their SMT placement feeders to double-check that the right components are loaded before production starts. It's like having a safety net that catches mistakes before they become expensive problems.

Does AccuID meet industry standards and certifications?

Electronics manufacturing has strict requirements, and AccuID is built to meet them. The system follows ISO/IEC 17025 standards for barcode reading accuracy, which means you can trust the data it provides.

For safety and electromagnetic compatibility, AccuID carries CE compliance, meeting European standards that are recognized worldwide. The ESD-safe enclosure is crucial for electronics work - you don't want static electricity damaging sensitive components.

All the internal components are UL certified, which speaks to the system's reliability and safety in industrial environments. This isn't some hobbyist gadget - it's built for the demanding world of electronics manufacturing.

The specific certifications you need might vary depending on your industry. Automotive and aerospace have their own additional requirements, so it's worth checking with Accu-Assembly about your particular situation. But the foundation is solid - AccuID is designed from the ground up to meet the standards that matter in professional manufacturing.

Conclusion

AccuID has fundamentally changed how electronics manufacturers handle SMT component identification. What used to be a tedious, error-prone process of hunting for the right barcode with a handheld scanner has become a simple 2-second operation that reads everything automatically.

The numbers speak for themselves - 5-mil resolution for 1D barcodes, 10-mil precision for 2D codes, and comprehensive scanning of 7" to 15" reels in a single pass. But the real value isn't just in the technical specs. It's in the peace of mind that comes from knowing your component data is accurate and your production line won't stop because of a scanning error.

What impresses me most about AccuID is how it fits into existing workflows without forcing major changes. Whether your facility needs simple keystroke emulation for older systems or sophisticated API integration with modern MES platforms, the system adapts to your needs rather than the other way around.

At American Mortuary Coolers, we've built our reputation on delivering precision equipment that performs reliably when it matters most. While we specialize in custom mortuary coolers and refrigeration solutions for funeral homes across the contiguous 48 states, we recognize excellence in specialized equipment wherever we see it. AccuID brings that same commitment to reliability and precision to electronics manufacturing.

The manufacturers we've heard from tell a consistent story - zero wrong-part errors, dramatic time savings in incoming inspection, and complete traceability that supports both quality control and regulatory compliance. These aren't just nice-to-have features; they're the foundation of modern manufacturing excellence.

For funeral industry professionals looking to understand precision equipment standards across different technical fields, our The Ultimate Guide to Mortuary Equipment provides valuable insights into maintaining quality standards in specialized applications.

The future belongs to manufacturers who accept intelligent automation that improves human capabilities rather than replacing them. AccuID represents exactly this philosophy - providing the accuracy and speed that modern production demands while remaining simple enough that operators actually want to use it.

If you're still relying on handheld scanners for component identification, you're working harder than you need to. AccuID offers a proven path to better accuracy, faster throughput, and the kind of operational confidence that lets you focus on what really matters - building quality products.