An Essential Guide to Comparing Commercial Refrigeration Equipment

Why Commercial Refrigeration Equipment is Critical for Your Business Success

Commercial refrigeration equipment forms the backbone of any food service operation, keeping products fresh, safe, and compliant with health regulations. Whether you're running a restaurant, supermarket, or specialized facility, the right refrigeration system can make or break your business.

Key Types of Commercial Refrigeration Equipment:

- Reach-in refrigerators and freezers - Standard upright units for daily access

- Walk-in coolers and freezers - Large-capacity storage rooms

- Display merchandisers - Glass-door units for product visibility

- Prep tables - Refrigerated work surfaces for food preparation

- Undercounter units - Space-saving solutions for tight kitchens

- Ice machines - Modular or standalone ice production

- Specialty units - Blast chillers, wine coolers, and custom solutions

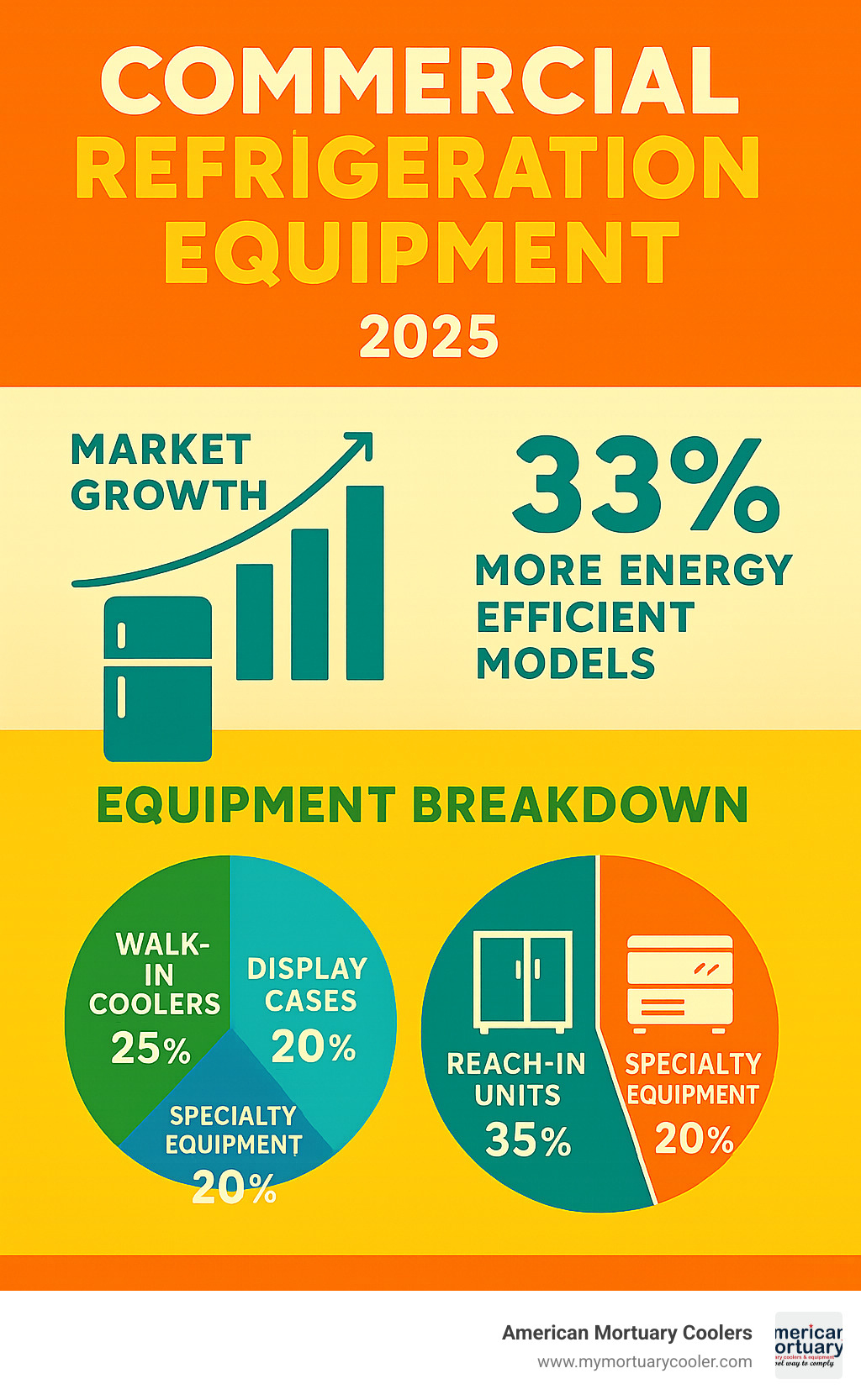

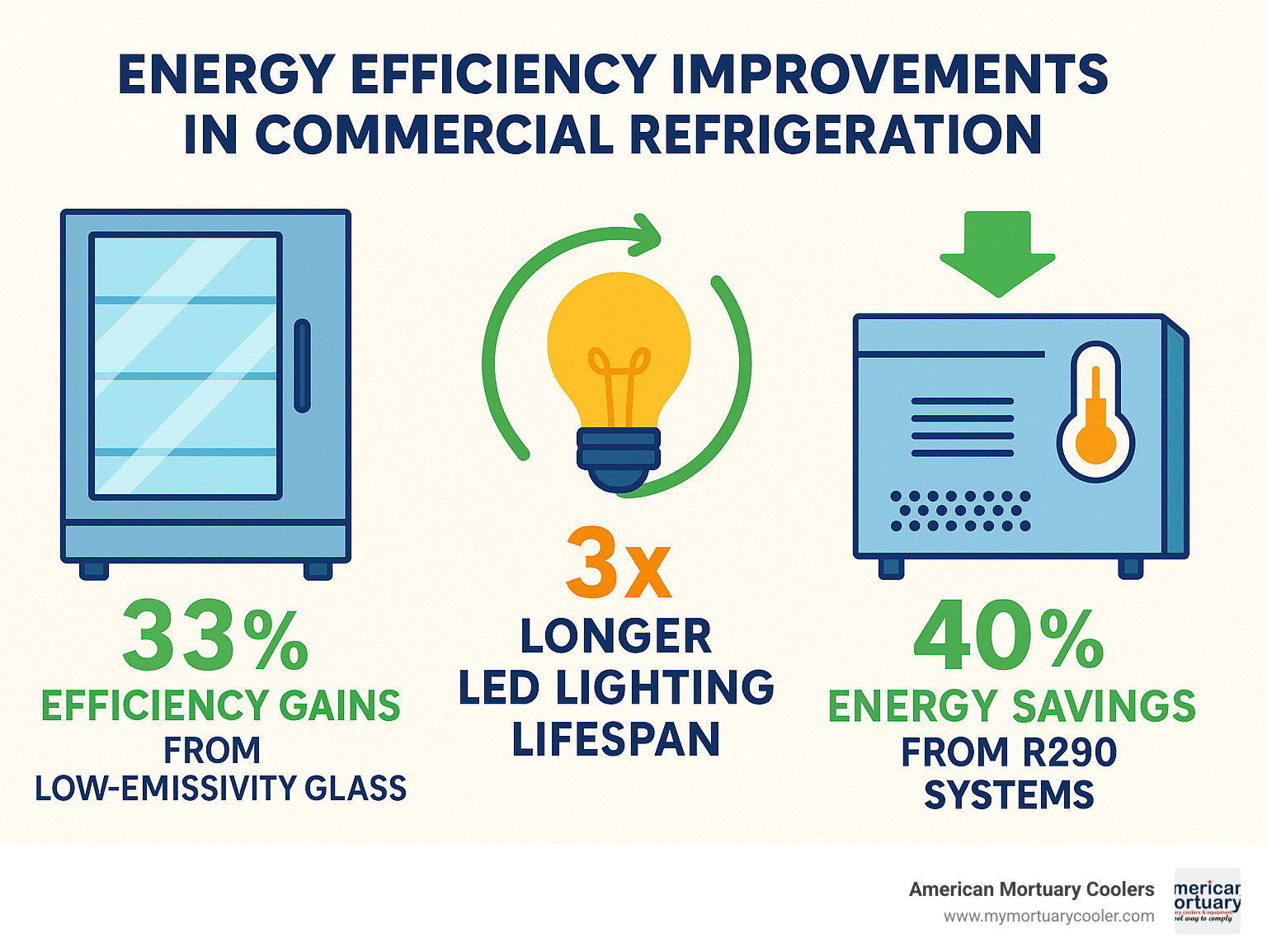

The commercial refrigeration market continues growing as businesses prioritize energy efficiency and food safety. Modern units feature LED lighting that lasts three times longer than fluorescent lamps, while low-emissivity glass makes refrigerators 33% more energy efficient than triple-pane alternatives.

Energy-efficient refrigeration equipment can significantly reduce utility costs and support sustainability goals for businesses. Advanced features like polyurethane insulation, R290 refrigerant systems, and digital temperature controls help operators maintain product quality while minimizing operating expenses.

I'm Mortuary Cooler, a national-level supplier specializing in commercial refrigeration equipment with extensive experience helping businesses select the right cooling solutions for their specific needs. My background includes working with funeral homes, medical facilities, and food service operations to implement reliable, energy-efficient refrigeration systems.

Learn more about commercial refrigeration equipment:

Understanding Commercial Refrigeration Equipment Basics

Think of commercial refrigeration equipment as the hardworking hero of your business - quietly doing its job 24/7 to keep everything fresh and safe. The magic happens through a cooling cycle that's surprisingly straightforward: a compressor pushes refrigerant through a closed system, where it expands from liquid to gas in the evaporator coil, creating that essential chill.

Here's where physics becomes your friend. Heat naturally flows toward cold, so when air gets blown over those cold coils, it transfers its heat away and keeps your storage space at just the right temperature. It's the same principle whether you're talking about a compact undercounter unit or a massive walk-in freezer.

Modern systems maintain precise temperature ranges - typically between 33°F to 41°F for refrigeration and 0°F or below for freezing. The compressors and evaporators work together like a well-choreographed dance, ensuring consistent cooling that meets strict HACCP standards and regulatory codes.

| Equipment Type | Temperature Range | Typical Capacity | Energy Usage |

|---|---|---|---|

| Refrigerator | 33°F - 41°F | 20-50 cubic feet | 2-4 kWh/day |

| Freezer | -10°F to 0°F | 15-40 cubic feet | 3-6 kWh/day |

What is Commercial Refrigeration Equipment?

Commercial refrigeration equipment covers any cooling system built for business use - and there's a world of difference between your home fridge and these workhorses. We're talking about everything from sleek reach-in units that restaurants depend on daily to enormous walk-in coolers that could fit a small car.

The real star of the show is something called the cold chain - think of it as an unbroken relay race where perishable goods stay properly chilled from the moment they're produced until they reach the customer. Restaurants need reliable reach-in refrigerators for quick ingredient access during busy dinner rushes. Supermarkets rely on attractive display merchandisers that keep products visible while maintaining perfect temperatures.

Every piece of equipment must meet strict compliance standards, including HACCP requirements and local health department regulations. It's not just about keeping things cold - it's about proving you're keeping them cold safely and consistently.

Why Commercial Refrigeration Equipment is Essential?

Here's where reliable refrigeration becomes your business's best friend - or worst enemy if it fails. Proper temperature control can extend shelf life dramatically, which translates to real money saved. I've seen restaurants cut their food waste by 30% just by upgrading to more reliable refrigeration systems.

Customer safety sits at the heart of everything. When temperatures drift outside safe ranges, you're not just risking spoiled inventory - you're putting people's health on the line. Health inspectors know this, which is why they scrutinize refrigeration systems so closely during inspections.

The financial impact of equipment failure can be devastating. Picture walking into your restaurant on a Monday morning to find that your main cooler died over the weekend. Thousands of dollars in inventory gone, plus the cost of emergency repairs, potential health department issues, and disappointed customers who can't get their favorite dishes.

That's why smart business owners invest in quality commercial refrigeration equipment with proper maintenance plans. The peace of mind alone is worth it, knowing your cold chain stays strong no matter what.

Comparing Major Types of Commercial Refrigeration Equipment

When you're shopping for commercial refrigeration equipment, the sheer variety of options can feel overwhelming. But here's the good news - each type serves a specific purpose, and understanding what you actually need makes the choice much clearer.

Think of it like choosing the right tool for the job. You wouldn't use a hammer to tighten a screw, and you wouldn't use a small reach-in unit when you need the storage capacity of a walk-in cooler.

More info about equipment choices

Reach-In vs Walk-In vs Undercounter

Reach-in units are like the reliable pickup trucks of commercial kitchens. They're sturdy, practical, and get the job done every single day. These upright units typically hold between 12 and 47 cubic feet of food, making them perfect for restaurants that need quick access to daily ingredients. The best part? Installation is as simple as plugging them into a wall outlet.

Walk-in coolers and freezers are the big leagues - we're talking about storage spaces you can literally walk into. These units range from cozy 68-square-foot spaces to massive 1,600-square-foot warehouses. Yes, they require professional installation and custom setup, but when you're running a high-volume operation, nothing else comes close.

Here's something most people don't realize: a well-maintained walk-in cooler compressor will keep running for about 15 years, while freezer compressors typically last around 10 years. That's a solid return on your investment.

Undercounter refrigeration solves one of the biggest problems in commercial kitchens - space. These clever units slide right under your prep counters, giving you 2 to 6 cubic feet of storage exactly where you need it most. No more running across the kitchen every time you need an ingredient.

Specialized Units: Display Merchandisers & Prep Tables

Display merchandisers are the show-offs of the refrigeration world - and that's exactly what they're supposed to be. These glass-front units keep your products cold while putting them on full display for customers. Modern units come with LED lighting that makes everything look appetizing and low-emissivity glass that's 33% more energy efficient than old-school triple-pane glass.

Prep tables are genius inventions that combine cold storage with workspace. Whether you're making sandwiches, prepping pizza toppings, or doing general food prep, these units keep your ingredients at safe temperatures right where you're working. No more walking back and forth to the cooler every five minutes.

Ice Machines & Combo Solutions

Let's be honest - ice machines might not be glamorous, but try running a restaurant without one. Modular cubed ice machines give you flexibility in both where you put them and how much ice you make. Some operations go with combo units that provide both refrigeration and freezing in one footprint, which is perfect when space is tight.

Here's a money-saving tip: scientific research on energy-efficient ice machines shows that proper maintenance can extend your ice machine's life from 10 to 15 years. That's five extra years of service just from taking care of your equipment.

Key Features, Energy Efficiency & Sustainability Focus

Over the past decade, commercial refrigeration equipment has transformed from simple chill boxes into smart, energy-saving workhorses. Energy Star units typically cut operating costs by 10-20%.

Key innovations driving those savings:

- Variable-speed compressors match cooling output to real demand.

- Remote monitoring warns you the moment temperatures drift.

- LED lighting lasts three times longer than fluorescents while drawing far less power.

Combine polyurethane insulation with low-emissivity glass (33 % more efficient than triple-pane) and you create an impressive barrier against heat gain—delivering long-term savings that dwarf the upfront cost.

Many utility companies recognise these benefits and offer rebates that can cover 10-30 % of an efficient unit’s purchase price.

More info about walk-in freezer cost

Must-Have Features in Commercial Refrigeration Equipment

Maintenance, Service, and Total Cost of Ownership

Here's the reality about commercial refrigeration equipment: proper maintenance can make the difference between a unit lasting 20+ years versus failing after just 5-7 years. I've watched businesses save tens of thousands of dollars simply by staying on top of routine care, while others face costly emergency replacements because they skipped basic upkeep.

The numbers tell the story clearly. Well-maintained equipment runs more efficiently, breaks down less often, and protects your investment far longer than neglected units. When you're looking at the total cost of ownership, maintenance isn't an expense - it's insurance.

Preventive Maintenance Checklist

Condenser coil cleaning sits at the top of every maintenance schedule for good reason. These coils need attention quarterly or twice yearly, depending on your environment. When coils get dirty, your compressor works overtime trying to maintain temperature, which drives up energy bills and shortens equipment life.

Use non-acid-based cleaners and rinse thoroughly to prevent corrosion damage. I can't stress this enough - harsh chemicals might seem like they clean better, but they'll eat away at your coils over time.

Temperature logs act like an early warning system for problems. Digital monitoring takes this a step further by sending alerts the moment temperatures drift outside safe ranges. This immediate notification can save entire inventories from spoilage.

Leak detection should happen annually using electronic detectors rather than just looking around for obvious signs. Small leaks often stay hidden until they become major problems, so professional detection pays for itself quickly.

Don't overlook fan inspection during routine checks. Blades should spin freely and quietly. Tighten any loose set screws and lubricate motors when needed. A damaged fan blade might seem minor, but it creates vibration that can destroy the motor over time.

Financing & Cost Considerations

The sticker price on commercial refrigeration equipment only tells part of the financial story. Smart buyers look at the complete picture: energy consumption, maintenance costs, and potential downtime expenses all factor into your real investment.

Rent-try-buy programs have become popular because they spread costs over time while letting you test equipment performance. Many suppliers offer these flexible financing options, making high-quality units accessible without major upfront capital.

Utility rebates can offset 10-30% of your purchase price when you choose Energy Star certified equipment. The paperwork takes a little effort, but the savings add up quickly. Most energy-efficient units pay for themselves within 2-4 years through reduced utility bills alone.

Consider the cost of downtime when making your decision. A failed refrigeration system doesn't just mean repair bills - it means lost inventory, potential health code violations, and angry customers. Investing in quality equipment and service contracts protects against these expensive surprises.

Service contracts provide peace of mind and predictable costs. Regular professional maintenance catches problems early and keeps warranties valid. The monthly cost usually pays for itself by preventing one major breakdown.

Choosing the Right Commercial Refrigeration Equipment for Your Business

Finding the perfect commercial refrigeration equipment for your operation isn't just about picking the biggest unit or the cheapest option. It's about understanding exactly what your business needs and matching those needs with equipment that'll serve you well for years to come.

Think about your daily routine first. A busy restaurant that goes through cases of produce daily needs different storage solutions than a small café serving pastries and sandwiches. Your menu analysis tells the real story - do you need more freezer space for proteins, or refrigeration for fresh ingredients? Are you storing bulk items or individual portions?

Space planning becomes crucial next. We've seen too many businesses fall in love with a walk-in cooler only to find it won't fit through their back door. Measure twice, order once - and don't forget about clearance for ventilation and service access.

Your climate zone matters more than most people realize. Equipment working in hot, humid Florida faces different challenges than units in dry Colorado. Condenser performance varies significantly based on ambient temperature, and what works perfectly in one location might struggle in another.

More info about selecting equipment

Branding customization might seem like a luxury, but it's often worth the investment. Custom powder coating can match your restaurant's aesthetic while providing superior durability compared to standard finishes. At American Mortuary Coolers, we've seen how the right customization transforms utilitarian equipment into something that actually improves your space.

Working with Reputable Suppliers & Brands

The supplier you choose matters just as much as the equipment itself. We've been in this business long enough to see what happens when businesses go with the lowest bidder only to find parts aren't available when something breaks down.

Strong warranties should be your first red flag test. Reputable manufacturers typically offer 3-5 years on major components like compressors because they stand behind their work. If someone's only offering a one-year warranty, ask yourself why they're not confident in their product's longevity.

Parts availability becomes critical when you're facing a breakdown on the busiest night of the week. Established suppliers maintain inventory of common replacement parts and have relationships with manufacturers that ensure quick access to specialized components.

Don't underestimate the value of proper training either. Your staff needs to understand how to operate equipment correctly - simple things like not overloading shelves or keeping doors closed can dramatically extend equipment life. Many suppliers provide on-site training as part of their service package, and it's worth asking about.

Reputation in this industry travels fast. Ask other business owners about their experiences, check online reviews, and don't be afraid to ask suppliers for references. A company that's been around for years and has happy customers is usually a safer bet than someone who just started yesterday.

Installation & After-Sales Support Impact

Here's where many businesses make costly mistakes - skimping on professional installation to save a few dollars upfront. Professional installation isn't just recommended; it's essential for warranty coverage and optimal performance. All refrigeration systems require licensed technicians for refrigerant handling and final commissioning.

Poor installation creates problems that haunt you for years. We've seen units that never quite reach proper temperatures, doors that don't seal correctly, and compressors that work overtime because someone cut corners during setup. These issues void warranties and create ongoing headaches that cost far more than proper installation would have.

Response times for service calls can make or break your business continuity. When your walk-in cooler stops working on Friday night, you need someone who answers the phone and shows up quickly. Look for suppliers offering 24/7 emergency service, especially if your operation depends on continuous refrigeration.

Remote diagnostics capabilities are becoming increasingly valuable. Modern systems can alert technicians to problems before they become catastrophic failures, and many issues can be diagnosed remotely. This reduces downtime and often prevents emergency service calls altogether.

At American Mortuary Coolers, we understand that after-sales support isn't just about fixing problems - it's about preventing them. Our maintenance plans help businesses stay ahead of potential issues while maximizing equipment lifespan and efficiency.

Frequently Asked Questions about Commercial Refrigeration Equipment

How does commercial refrigeration equipment support food safety?

Commercial refrigeration equipment acts as your first line of defense against foodborne illness and costly health code violations. When your refrigeration system maintains that critical 33°F to 41°F temperature range, it dramatically slows bacterial growth that could make customers sick or spoil your inventory.

Think of it this way - bacteria multiply rapidly at room temperature, but proper refrigeration puts them in slow motion. Freezing at 0°F or below essentially hits the pause button on bacterial activity altogether. This temperature control isn't just good practice - it's required by HACCP compliance standards that health inspectors check during every visit.

Modern commercial refrigeration equipment goes beyond basic cooling with smart features like door alarms that sound when temperatures spike from extended openings. Some advanced systems even send alerts directly to your phone when something goes wrong, giving you a chance to fix problems before they become disasters.

The digital temperature monitoring built into today's units provides the documentation trail that health inspectors love to see. No more guessing whether your walk-in cooler stayed cold overnight - you'll have the data to prove it.

What innovations should I look for in 2024 models?

The refrigeration industry has made some exciting leaps forward, especially in energy efficiency and smart technology. Variable-speed compressors are probably the biggest game-changer - they adjust their cooling power based on actual demand rather than running full-blast all the time. This simple innovation can cut your energy bills by 20-30%.

IoT connectivity might sound fancy, but it's incredibly practical. Your refrigeration system can now text you when something's wrong, schedule its own maintenance reminders, and even diagnose problems before they cause breakdowns. It's like having a technician watching your equipment 24/7.

Natural refrigerants like R290 and CO₂ are becoming the new standard, and for good reason. They're better for the environment and often more energy-efficient than older refrigerants. Plus, they help you stay ahead of changing regulations without worrying about phase-outs.

Don't overlook the smaller improvements either - advanced insulation materials and improved door seals might not sound exciting, but they quietly reduce your operating costs month after month.

How often should condenser coils be cleaned?

Here's a maintenance task that many businesses overlook until it's too late. Condenser coils should be cleaned quarterly in most commercial kitchens, though you might need monthly cleaning if you're dealing with heavy grease production from fryers or grills.

Dirty coils are energy vampires - they can increase your electricity consumption by 20-30% while shortening your equipment's lifespan. We've seen businesses unknowingly waste thousands of dollars annually because nobody was cleaning their coils regularly.

Watch for warning signs that your coils need attention: higher operating temperatures, equipment that runs constantly, or visible dirt and grease buildup around the condenser area. Your refrigeration system will literally tell you when it's struggling if you know what to look for.

Professional cleaning is worth the investment because condenser fins are delicate and easy to damage with improper tools or techniques. A bent fin might seem minor, but it reduces airflow and forces your compressor to work harder. Taking care of this simple maintenance task can add years to your commercial refrigeration equipment lifespan.

Conclusion

Choosing the right commercial refrigeration equipment is one of those decisions that can make or break your business - literally. I've seen operations thrive with the right cooling systems and watched others struggle with equipment that just couldn't keep up with their needs.

The numbers tell a compelling story. Modern LED lighting lasts three times longer than those old fluorescent bulbs, while advanced R290 refrigerant systems can slash your energy bills by 40%. These aren't just nice-to-have features anymore - they're smart business investments that pay for themselves.

At American Mortuary Coolers, we've learned that no two businesses are exactly alike. That's why our Tennessee facility focuses on crafting custom solutions that fit your specific needs perfectly. Whether you're looking for a straightforward reach-in unit or need a complex walk-in system, we deliver directly across all 48 contiguous states.

Here's what really matters when you're comparing equipment options: Energy-efficient features like low-emissivity glass and variable-speed compressors will save you money month after month. Regular maintenance - especially those quarterly coil cleanings - can extend your equipment's life from the typical 10-15 years to well over 20 years. Natural refrigerants aren't just better for the environment; they often perform better too. And professional installation with solid ongoing support? That's non-negotiable.

I always tell my clients to look beyond the sticker price. That bargain unit might seem tempting, but when you factor in energy costs, maintenance headaches, and potential downtime, quality equipment from reputable suppliers is always the smarter choice. Good equipment, properly installed and maintained, becomes a reliable partner in your business for decades.

More info about walk-in options

The commercial refrigeration equipment world keeps evolving, and that's exciting news for business owners. New technologies and efficiency improvements pop up regularly, giving you more options to keep products fresh, customers safe, and operations profitable.

Whether you're upgrading tired old equipment or planning something completely new, the right refrigeration choices are investments in your business's future. They'll keep working hard for you long after you've forgotten what you paid for them - and that's exactly how it should be.