An Essential Guide to Choosing Refrigerator Wall Panels

Why Refrigerator Wall Panels Are Essential for Temperature Control

Refrigerator wall panels are specialized insulated panels that form the walls of walk-in coolers, freezers, and cold storage rooms. These panels provide thermal insulation, structural support, and hygienic surfaces to maintain precise temperature control for perishable goods.

Key types and applications of refrigerator wall panels:

- Insulated metal panels - For walk-in coolers with R-values up to R-72

- Decorative appliance panels - Wood or metal covers for panel-ready refrigerators

- PVC wall panels - 100% moisture-resistant for high-humidity environments

- Foam core panels - Polyurethane or polyisocyanurate insulation between metal skins

- Structural panels - Load-bearing walls that support refrigeration equipment

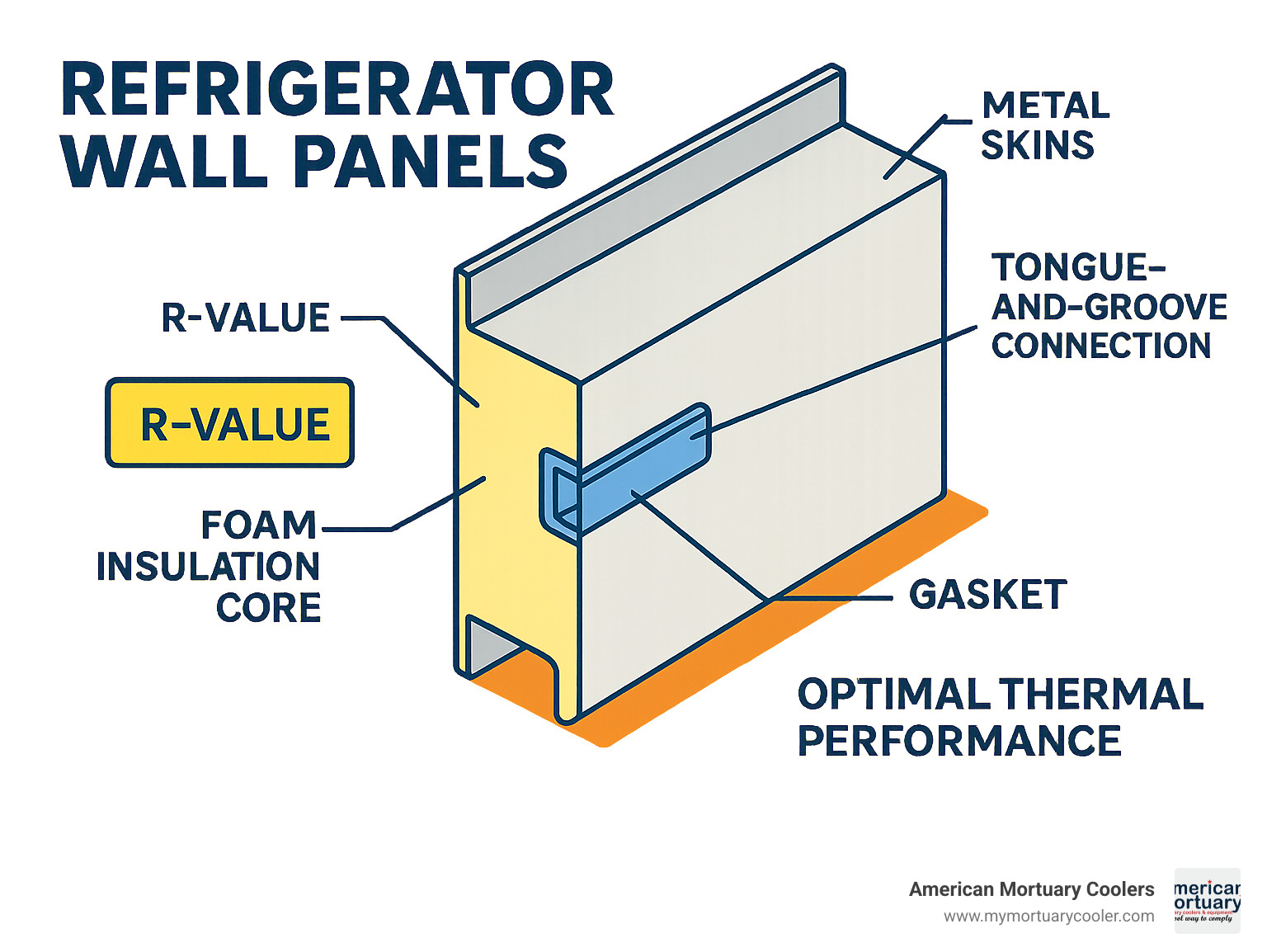

These panels typically range from 2-8 inches thick, with standard widths of 24-45 inches and heights up to 20 feet. They feature tongue-and-groove interlocking systems that create airtight seals and reduce installation time by up to 50% compared to traditional construction methods.

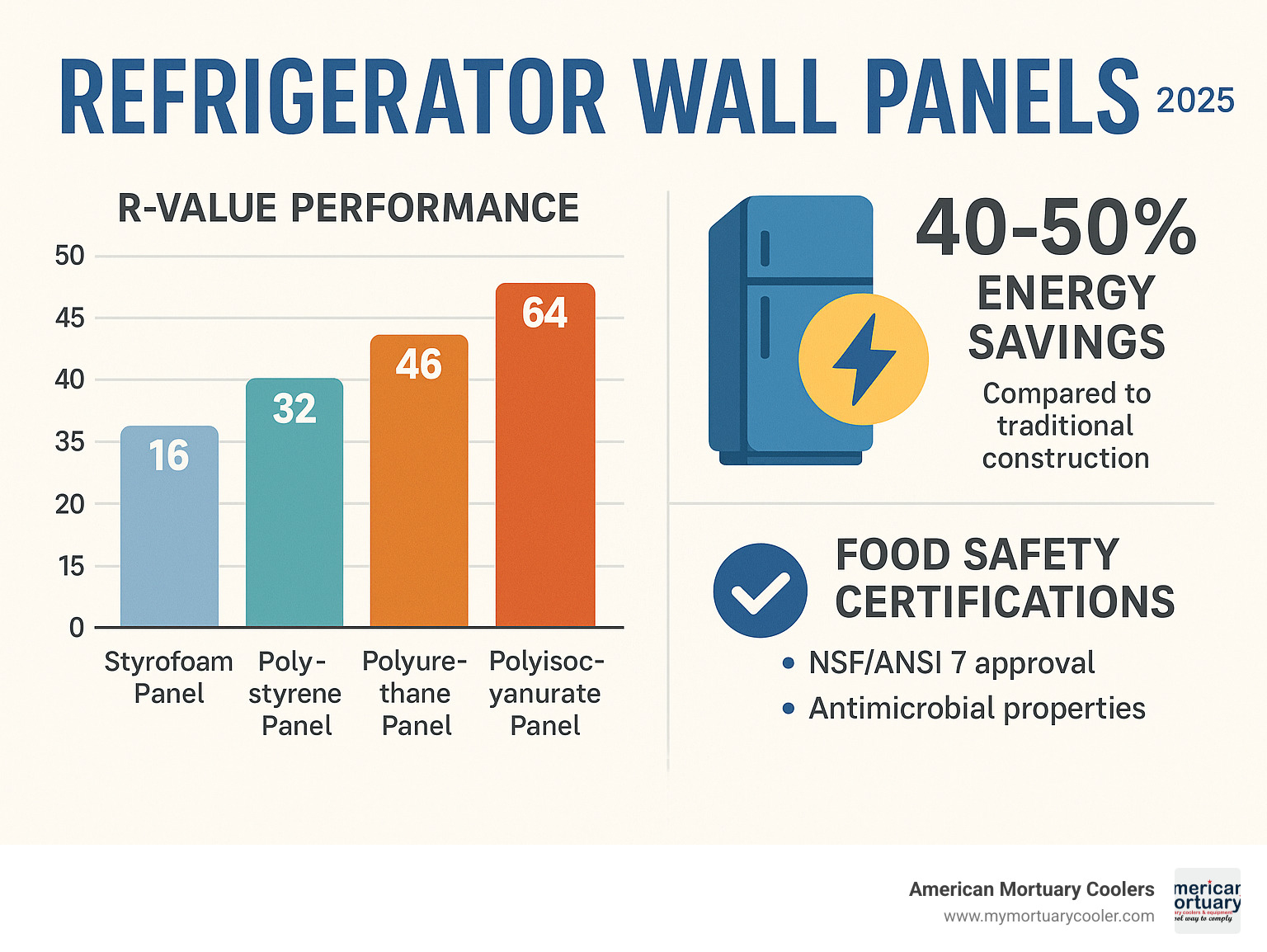

The panels must meet strict food safety certifications including NSF, USDA, and FDA standards for commercial applications. High-performance panels can achieve R-values as high as R-64 to R-72, leading to significant long-term energy savings through improved thermal efficiency.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes select the right refrigerator wall panels for their specific needs. My expertise in custom cold storage solutions ensures you get panels that deliver reliable temperature control and seamless integration with your facility's requirements.

Refrigerator wall panels vocab to learn:

What Are Refrigerator Wall Panels & Why They Matter

Refrigerator wall panels are specialized insulated components that combine two metal skins (usually aluminum, stainless steel, or galvanized steel) with a high-density foam core. Unlike traditional stud walls with fiberglass insulation, these panels create one continuous thermal barrier with no gaps or weak spots.

Quality refrigerator wall panels deliver temperature stability within ±2°F consistently and boost energy efficiency by cutting cooling costs up to 30%. They meet critical certifications like NSF, USDA, and FDA standards while providing structural durability to support heavy refrigeration equipment and loaded shelving systems.

| Feature | Refrigerator Wall Panels | Traditional Stud Walls |

|---|---|---|

| Thermal Performance | R-31 to R-72 continuous | R-13 to R-19 with gaps |

| Installation Time | 50% faster | Standard construction |

| Moisture Resistance | 100% sealed system | Vulnerable joints |

| Food Safety Compliance | NSF/USDA certified | Requires additional finishes |

Key Purposes of Refrigerator Wall Panels

Modern refrigerator wall panels create rock-solid thermal barriers with polyisocyanurate foam cores achieving R-values of 31 at just 4 inches thick. Advanced QuadCore technology delivers R-values up to 9.0 per inch in cold storage applications.

Hygiene performance is exceptional. PVC wall panels are 100% moisture resistant, meeting CFIA, FDA, USDA, and cGMP requirements. Their non-porous surfaces prevent bacteria, mold, or virus growth, with ISO 846:2019 testing confirming full antimicrobial protection.

For design integration, decorative panels work seamlessly with panel-ready appliances, allowing custom wood panels to match existing cabinetry while maintaining full functionality.

Types and Materials of Refrigerator Wall Panels

Refrigerator wall panels come in several types, each designed for specific applications. Insulated metal panels are commercial workhorses, sandwiching high-performance foam between metal skins. Foam core options include polyurethane (PUR), polyisocyanurate (PIR), and newer QuadCore technology delivering 11% better thermal performance than PIR.

PVC board panels excel in high-moisture environments. Companies like Trusscore engineer these with internal truss structures eliminating adhesives or backing boards, preventing moisture traps that create mold and bacteria breeding grounds.

Wood cabinetry panels transform appliances into design statements, attaching to panel-ready refrigerators using magnet strips or mechanical fasteners to match existing cabinetry.

Metal skin options include stainless steel for premium applications, galvanized steel for cost-effective solutions, and aluminum for lightweight installations.

Decorative vs. Structural Refrigerator Wall Panels

Decorative panels focus on aesthetics for panel-ready fridges. Cabinetry integration happens through appliance panels covering exposed refrigerator sides with matching finishes, while end panels create seamless transitions between appliances and cabinetry.

Structural panels are heavy-duty, supporting refrigeration equipment weighing hundreds of pounds, loaded shelving systems, and frequent door usage. They feature thicker cores (4-8 inches), reinforced connections, and heavy-duty gaskets creating airtight seals.

Insulated Refrigerator Wall Panels for Walk-In Coolers

Walk-in applications demand high-density foam cores. Polyisocyanurate delivers R-values of 7-7.2 per inch, while QuadCore technology reaches 8.0 per inch at 75°F and 9.0 per inch at 35°F.

The tongue-and-groove interlocking system ensures perfect alignment and tight sealing. Cam-locks provide mechanical strength against thermal expansion and contraction, cutting installation time in half versus traditional construction.

For specialized mortuary applications requiring precise temperature control, we offer Custom Walk-In Cooler Solutions incorporating the latest panel technologies.

Performance & Benefits: Insulation, Energy Efficiency, Food Safety

Quality refrigerator wall panels deliver impressive thermal performance with R-values ranging from R-5 for decorative panels up to R-72 for commercial cold storage. QuadCore technology achieves these high values while eliminating thermal bridges that reduce traditional wall R-values by 20-30%.

Moisture resistance is critical for our industry. PVC panels handle repeated pressure washing and chemical cleaning while their non-porous surfaces resist bacteria growth, unlike materials that become contamination risks over time.

For technical details on core materials and thickness effects, check these technical insights on insulated metal panels.

How Refrigerator Wall Panels Cut Energy Bills

High-performance panels achieving R-64 to R-72 slash cooling loads by 40-50% compared to traditional construction. Your compressor runs less, wears out slower, and uses less electricity during expensive peak demand periods.

Air-tight seals between panels prevent energy waste. Even 1/8-inch gaps can increase energy consumption by 15-20%. Proper sealing maintains consistent internal conditions without constant warm air infiltration.

Temperature stability within ±2°F means reduced compressor runtime, less equipment wear, and predictable operating costs month after month.

Food-Safety Advantages of Refrigerator Wall Panels

Commercial refrigerator wall panels must meet strict NSF/ANSI 7 standards, ensuring no contamination of stored products. Modern panels with antimicrobial surfaces actively prevent bacterial growth through smart materials and surface treatments.

PVC panels meeting ISO 846:2019 standards resist mold, bacteria, and viruses even after countless cleaning cycles. They handle high-pressure washing up to 3000 PSI, chemical disinfectants, and steam cleaning at 180°F.

Pressure-wash durability ensures panels maintain protective properties indefinitely, unlike FRP panels whose adhesives break down under moisture cycling.

Installation, Sizing & Customization Tips

Modern refrigerator wall panels use interlocking tongue-and-groove systems that click perfectly into place, creating continuous thermal barriers. Most panels arrive factory pre-cut to exact specifications with tolerances within 1/8 inch.

DIY versus professional installation depends on your application. Decorative residential panels are often weekend DIY projects, but walk-in coolers require professional installation for code compliance, warranty coverage, and proper integration with refrigeration systems.

The cam-lock system provides mechanical strength and disassembly capability when needed. Heavy-duty gaskets create crucial airtight seals that keep energy bills reasonable.

For installation guidance, check this How to Create Refrigerator Panels – Video demonstrating key techniques.

Measuring for Refrigerator Wall Panels

Accurate measurements are critical when ordering refrigerator wall panels. Start with internal dimensions, then add panel thickness for external measurements.

Depth clearance varies significantly: residential panels need 24-25 inches, while walk-in coolers require 4-8 feet depending on shelving and equipment. Always verify door, shelving, and maintenance access clearances.

Height options include 84, 90, and 96 inches for standard applications, with custom heights up to 20 feet for commercial use. Panel widths range from 24 inches residential to 45⅝ inches commercial. Wider panels mean fewer joints and better thermal performance.

Common Mistakes to Avoid with Refrigerator Wall Panels

Improper blocking is the most common structural error. Panels need adequate support, especially at building connections. Use at least three angle brackets along floors and four up walls without proper blocking.

Insufficient sealant at joints allows air infiltration that increases operating costs. Use refrigeration-specific sealants that stay flexible at low temperatures.

Ignoring R-value requirements leads to undersized insulation. Know your requirements before ordering - cold storage warehouses might need R-64 while residential applications work with R-20.

For comprehensive guidance, our Complete Guide to Choosing a Walk-In Freezer covers installation best practices and system selection.

Maintenance, Cost & Long-Term Value

Quality refrigerator wall panels serve faithfully for 20-30 years with proper care. Modern panels withstand daily commercial operations while maintaining thermal performance year after year.

Chemical resistance is impressive - panels handle quaternary ammonium compounds, chlorine-based sanitizers up to 200 ppm, acid cleaners, and alkaline degreasers. Impact resistance means they handle cart bumps and equipment contact without compromising thermal barriers.

Lifecycle ROI shows panels typically pay for themselves within 3-5 years through energy savings alone. For detailed economics, see Decoding Walk-In Cooler Pricing Factors.

Budgeting for Refrigerator Wall Panels

Initial costs range from hundreds for residential decorative panels to $50-100 per square foot installed for commercial systems. Customization fees add 15-25% but ensure optimal performance. Installation labor runs $10-30 per square foot.

Energy savings offset initial investment quickly - high-performance panels reduce cooling costs $2-5 per square foot annually, generating positive cash flow within years.

Extending the Life of Your Refrigerator Wall Panels

Routine inspection should check for loose gaskets, damage compromising insulation, moisture infiltration, and proper cam-lock operation. Gasket replacement every 5-7 years maintains airtight seals.

Low-abrasive cleaners for maintenance:

- Mild dish soap and warm water for daily cleaning

- Isopropyl alcohol for sanitizing

- Specialized stainless steel cleaners for metal surfaces

- Non-abrasive all-purpose cleaners for PVC panels

At American Mortuary Coolers, we understand your cold storage system needs reliable daily operation - and we're here to ensure exactly that.

Frequently Asked Questions about Refrigerator Wall Panels

When you're investing in refrigerator wall panels, it's natural to have questions about certifications, installation, and design benefits. Let me walk you through the most common concerns I hear from clients looking to upgrade their cold storage systems.

What certifications should refrigerator wall panels meet?

The certification requirements for refrigerator wall panels depend on your specific application, but there are several key standards you'll want to look for. NSF/ANSI 7 approval is the gold standard for commercial refrigerated storage equipment—this certification ensures your panels meet strict safety and sanitation requirements.

If you're storing food products, USDA and FDA compliance isn't optional—it's required by law. For pharmaceutical or medical storage applications, you'll also need panels that meet cGMP standards (current Good Manufacturing Practices).

Fire safety certifications matter too, especially in commercial settings. Look for panels that meet ASTM E84 (UL 723) requirements for flame spread and smoke development. UL 471 certification covers how panels perform structurally when exposed to fire conditions, ensuring they won't contribute to dangerous situations.

For indoor air quality, GREENGUARD certification verifies that panels have low chemical emissions. Some manufacturers even provide Environmental Product Declarations (EPDs) that document the environmental impact throughout the entire product lifecycle—helpful if sustainability is important to your organization.

Do I need professional installation for insulated refrigerator wall panels?

Here's my honest take: if you're dealing with insulated refrigerator wall panels for commercial applications, professional installation isn't just recommended—it's essential. These panels need proper structural support calculations, and the installation must comply with building codes and fire safety requirements.

Professional installers also handle the tricky coordination between your refrigeration systems, electrical work, and the panels themselves. Plus, most manufacturers require certified installation to maintain warranty protection, so going the DIY route could cost you significantly if something goes wrong.

Now, if we're talking about simple decorative panels for your home refrigerator, that's a different story. Skilled DIYers can often handle these installations successfully. But when you're dealing with structural panels that support heavy equipment or create pressure-rated enclosures, leave it to the pros.

The tongue-and-groove interlocking system might look straightforward, but proper alignment and sealing require experience and specialized tools. Professional installers know how to avoid the common pitfalls that can compromise your panels' performance and longevity.

How do appliance refrigerator wall panels improve kitchen design?

This is where refrigerator wall panels really shine from a design perspective. Panel-ready refrigerators can accept custom wood panels that perfectly match your surrounding cabinetry, creating that seamless built-in look that makes kitchens feel more expensive and cohesive.

The visual continuity is remarkable—instead of having a big stainless steel appliance interrupting your design flow, the refrigerator disappears into your cabinetry. You get unlimited customization options with different wood species, finishes, and hardware choices that match your exact style.

Some homeowners use panels as accent opportunities instead, choosing contrasting materials that make their appliances into design focal points. You might use a darker wood tone or even incorporate architectural elements like shiplap or raised panels that echo other design features in your kitchen.

Counter-depth refrigerators with panels create the most dramatic change. They sit flush with your surrounding cabinets, making your kitchen appear larger and more thoughtfully designed while maintaining all the functionality you need from your refrigerator.

At American Mortuary Coolers, while we specialize in commercial cold storage solutions, we understand how important seamless design integration is across all applications. The same principles that make our mortuary coolers blend seamlessly into funeral home environments apply to residential and commercial kitchen designs as well.

Conclusion

Choosing the right refrigerator wall panels becomes straightforward when you understand what matters for your specific situation. Whether you need decorative panels for seamless kitchen integration or heavy-duty insulated panels for commercial walk-in coolers, match the panel's capabilities to your actual needs.

High-quality refrigerator wall panels with R-values reaching R-64 to R-72 can slash energy bills by 30-40% while maintaining precise temperature control essential for food safety and equipment efficiency.

At American Mortuary Coolers, we've perfected custom cold storage solutions that exceed basic refrigeration needs. Based in Tennessee, we deliver custom refrigerator wall panels and complete cooling systems across all 48 contiguous states. Our expertise lies in understanding that funeral homes, restaurants, medical facilities, and specialized operations can't afford cooling failures.

We take time to understand your specific requirements for thermal performance, sanitation standards, and space integration. Our custom approach delivers exactly what you need, not one-size-fits-all solutions that create problems later.

Quality panels pay dividends for decades. With proper installation and minimal maintenance, premium refrigerator wall panels deliver reliable service for 20-30 years while reducing operating costs annually. Energy savings, reduced maintenance, and extended equipment life typically provide payback within just a few years.

For detailed pricing considerations, check out The Complete Guide to Walk-In Refrigerator Prices. This resource breaks down everything from initial costs to long-term value.

Ready to explore how custom refrigerator wall panels can solve your specific challenges? Contact us today to discuss your project and find how our custom approach delivers the durability, performance, and peace of mind you need.