An Essential Guide to 404A Refrigerant: Properties & Uses

Why 404A Remains Critical for Commercial Refrigeration

404a is a near-azeotropic blend refrigerant that has powered commercial cooling systems for over two decades. This hydrofluorocarbon (HFC) refrigerant combines three components - R-125, R-143a, and R-134a - to deliver reliable performance in medium and low-temperature applications.

Key 404A Facts:

- Chemical name: Near-azeotropic HFC blend

- Boiling point: -46.5°C (-51.2°F)

- Safety rating: ASHRAE A1 (non-flammable, low toxicity)

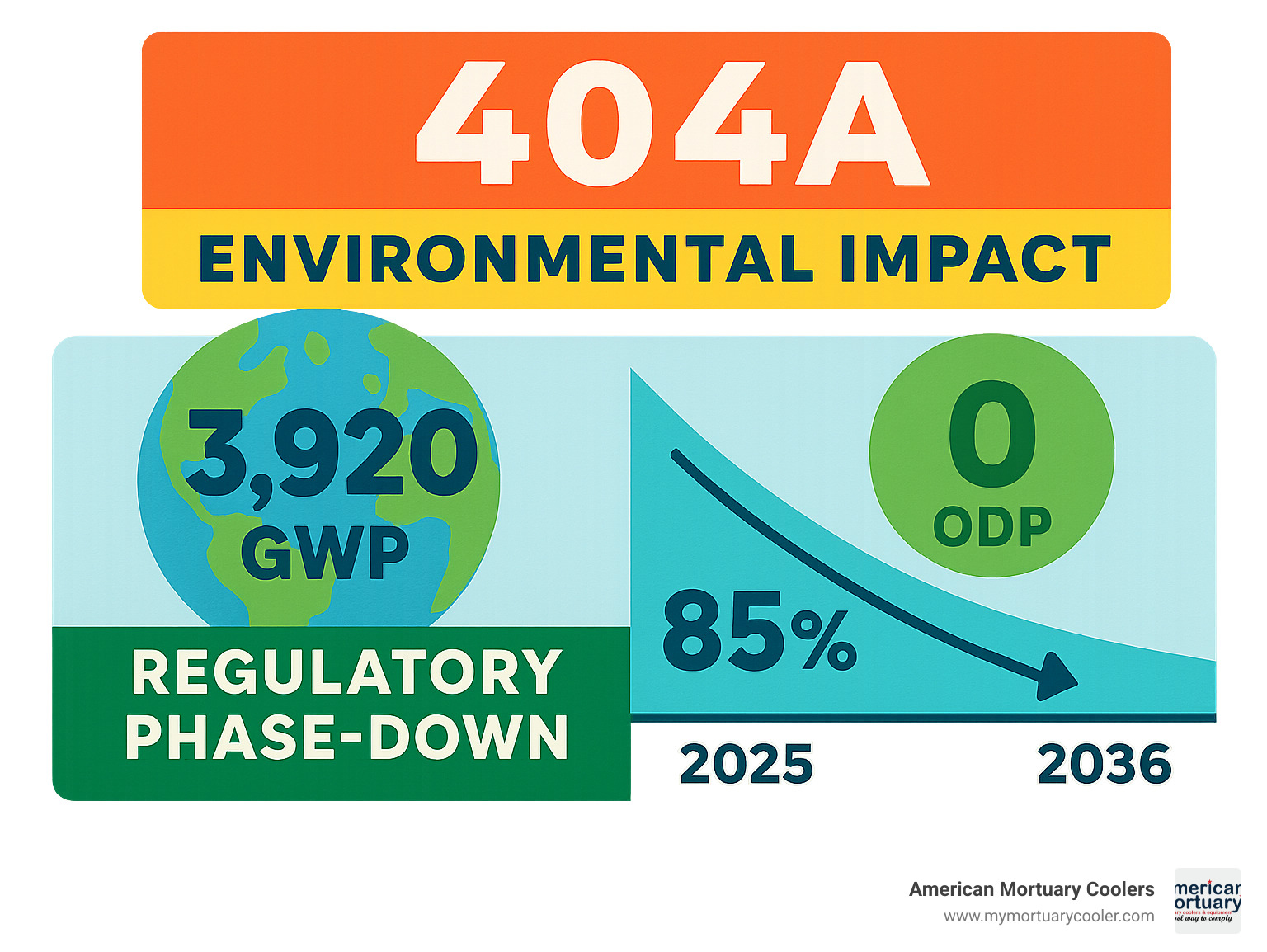

- GWP: ~3,920 (high global warming potential)

- ODP: 0 (zero ozone depletion)

- Main uses: Supermarket freezers, transport refrigeration, mortuary coolers

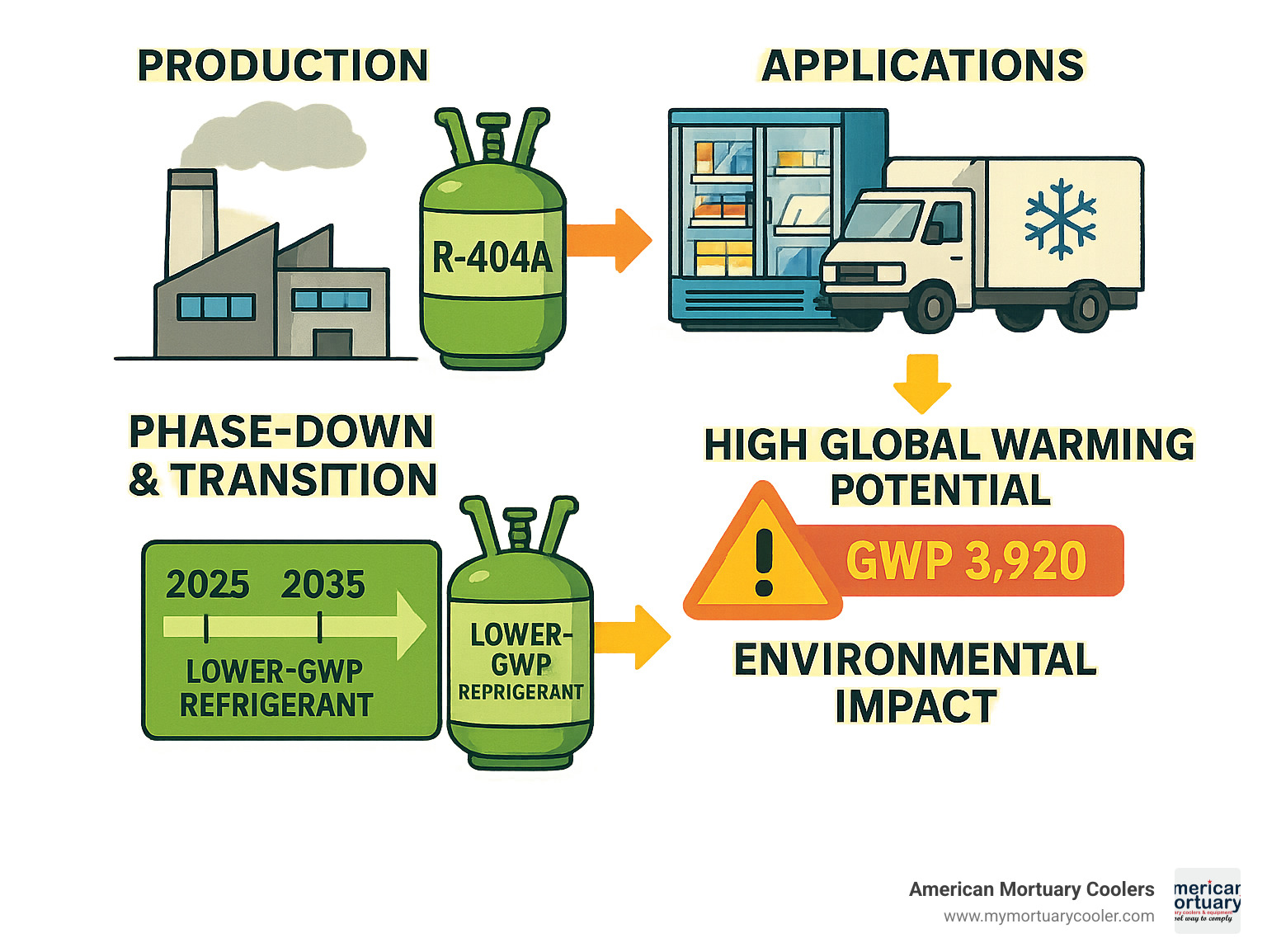

Despite facing regulatory phase-downs due to its high global warming potential, 404A continues serving existing equipment while the industry transitions to lower-GWP alternatives like R-449A and R-448A.

The refrigerant operates at higher pressures than older options like R-22, requiring polyolester (POE) lubricants and specific system components. Many businesses still rely on 404A for critical applications where temperature stability matters most.

Current market reality: New 404A installations face restrictions, but servicing existing systems remains legal. California and New York now require reclaimed 404A for repairs as of January 2025, signaling the regulatory shift ahead.

We're American Mortuary Coolers, a national mortuary cooler supplier with experience in 404a refrigeration systems for funeral homes and morgues. Our team has installed hundreds of custom mortuary cooling solutions using 404a refrigerant, understanding both its reliable performance characteristics and the evolving regulatory landscape affecting funeral service operations.

404a terms made easy:

What Is R-404A? Chemistry, Pressure-Temperature Data & Performance

404a is essentially a carefully crafted cocktail of three different refrigerants mixed together to create something better than any single ingredient alone. This near-azeotropic blend combines 44% R-125 (pentafluoroethane), 52% R-143a (1,1,1-trifluoroethane), and 4% R-134a (1,1,1,2-tetrafluoroethane) to replace older, ozone-damaging refrigerants like R-502 and R-22.

Think of it like a recipe that's been perfected over decades. The molecular weight averages 97.6 g/mol, with a normal boiling point of -46.5°C (-51.2°F) and a critical temperature of 72.0°C (161.7°F). These numbers aren't just technical jargon - they tell us exactly why 404a works so well in commercial freezers and mortuary coolers where consistent, reliable cooling is non-negotiable.

404A Chemical Composition & Physical Constants

The magic of 404a lies in its near-azeotropic behavior. This fancy term simply means the three components stick together like a team - they boil and condense at nearly the same temperature and composition. Unlike some refrigerant blends that can separate over time (like oil and water), 404a stays mixed and performs consistently.

The key physical properties include a liquid density of 1.04 g/cm³ at 25°C, liquid heat capacity of 1.84 kJ/kg·K, and vapor heat capacity of 1.22 kJ/kg·K. Most importantly, the temperature glide is minimal - less than 1°C - which means it behaves almost exactly like a single-component refrigerant.

This near-azeotropic nature makes life easier for technicians. Charging, recovery, and system operation work just like they would with older single-component refrigerants. No complicated procedures or special considerations for blend separation.

404A Pressure-Temperature Essentials

Understanding how 404a behaves at different temperatures is crucial for anyone working with these systems. Based on NIST REFPROP data, this refrigerant operates at significantly higher pressures than older options like R-22 - something that caught many technicians off guard during the early transition years.

More info about 404A PT charts

Here are the critical pressure points you need to know: at -49°C, pressure is 0.09 MPa (0.3 bar, -45 psig), at 0°C it jumps to 1.04 MPa (10.6 bar, 15 psig), and at 25°C it reaches 2.58 MPa (25.8 bar, 124 psig). These higher pressures require robust components and proper safety protocols.

| Temperature | R-404A Pressure | R-507A Pressure | Difference |

|---|---|---|---|

| -40°F | 9.6 psig | 9.8 psig | -0.2 psig |

| -20°F | 21.4 psig | 21.7 psig | -0.3 psig |

| 0°F | 37.0 psig | 37.4 psig | -0.4 psig |

| 20°F | 56.8 psig | 57.4 psig | -0.6 psig |

The comparison with R-507A shows how similar these two refrigerants perform, which explains why both became popular replacements for R-502. The pressure differences are minimal, but every technician should understand these operating characteristics for proper system design and troubleshooting.

Where 404A Shines: Core Applications in Cold Chain & Funeral Services

Walk into any supermarket and you're surrounded by 404a at work. Those humming frozen food cases keeping your ice cream solid? That's R-404A doing its job. This refrigerant became the backbone of commercial cooling because it simply works - day after day, year after year.

The cold chain industry acceptd 404a when R-502 got phased out for ozone depletion. What they found was a refrigerant that could handle the demanding world of commercial refrigeration better than its predecessor. From supermarket display cases that get opened hundreds of times daily to refrigerated trucks crossing the country in summer heat, R-404A delivers consistent performance.

The Definitive Guide to R404A Refrigerant

Industrial cold storage facilities rely on R-404A for good reason. These massive warehouses need to maintain precise temperatures while constantly loading and unloading products. The refrigerant's excellent capacity means systems can quickly recover when those big dock doors open, preventing temperature spikes that could spoil entire shipments.

Marine refrigeration presents unique challenges - salt air, constant vibration, and limited maintenance opportunities. 404a proves its worth on fishing vessels and cargo ships where reliable cooling means the difference between profit and loss. Ice makers in restaurants and hotels depend on this refrigerant to produce crystal-clear ice consistently, even during peak demand periods.

Commercial Food & Transport Uses

The reach-in coolers at your local convenience store and the blast freezers at food processing plants both depend on R-404A's reliable performance. In food service, timing is everything. A restaurant's walk-in freezer using 404a can quickly recover from the dinner rush when staff repeatedly access frozen ingredients.

Reefer trucks represent one of R-404A's most demanding applications. These mobile refrigeration units must maintain precise temperatures while bouncing down highways in 100°F heat. The refrigerant's stability across varying conditions makes it possible to transport frozen foods from California farms to New York grocery stores without quality loss.

Display cases in supermarkets face a unique challenge - they must keep products frozen while being visually appealing and accessible to shoppers. R-404A systems handle the constant heat load from lighting, defrost cycles, and frequent door openings while maintaining the -18°C temperatures that keep frozen foods safe.

404A in Mortuary & Morgue Coolers

Our experience installing mortuary refrigeration systems across Tennessee, the Southeast, and beyond has shown us why 404a remains essential in funeral service. Body storage requires unwavering temperature control - there's no room for equipment failure when families are counting on you.

More info about mortuary coolers

Mortuary coolers need to maintain that critical 35-38°F range without fluctuation. We've seen R-404A systems in funeral homes operate flawlessly for over 15 years, providing the temperature stability that protects both dignity and public health. When a funeral director opens a cooler door, the system must quickly recover to maintain proper conditions.

The quiet operation of 404a systems matters in funeral homes where families gather to mourn. These aren't industrial facilities - they're places where respectful silence is important. Our custom mortuary refrigeration solutions using R-404A run whisper-quiet while delivering the reliable performance funeral professionals need.

From the busy coolers at large funeral homes handling multiple services daily to smaller operations in rural communities, R-404A has proven itself as the refrigerant that funeral directors can trust. Its A1 safety rating provides additional peace of mind in occupied buildings where safety is never negotiable.

Environmental Footprint & Global Regulations

The environmental story of 404a is complicated. On one hand, it completely solved the ozone layer problem that plagued older refrigerants like R-22. With zero ozone depletion potential (ODP = 0), R-404A helped heal the hole in our atmosphere.

But there's a catch. 404a has a global warming potential of approximately 3,920 times that of CO₂. That's a massive environmental footprint that regulators worldwide couldn't ignore.

The American Innovation and Manufacturing (AIM) Act gives the EPA sweeping authority to phase down HFC production and consumption by 85% below baseline levels by 2036. That's not a gentle transition – it's a dramatic reduction that's already affecting 404a availability and pricing across the country.

International pressure is mounting too. The Kigali Amendment to the Montreal Protocol commits nearly 200 countries to HFC phase-downs. The EU F-Gas Regulation has already restricted high-GWP refrigerants across Europe. Even individual states are taking action – California and New York now mandate reclaimed refrigerant use for many applications.

Phase-Down Timeline & Compliance Checklist

The regulatory timeline isn't just theory – it's creating real compliance headaches for businesses using 404a systems right now. We've seen funeral homes scramble to understand what these rules mean for their mortuary coolers.

The 2022-2024 period brought initial production cuts and import quota reductions. By 2025, new equipment restrictions began kicking in, along with reclaimed refrigerant requirements in some states. The 2026-2027 timeframe will bring additional equipment bans and stricter servicing rules. By 2036, we'll hit that 85% reduction target, making virgin 404a extremely scarce and expensive.

Here's what funeral homes and other 404a users need to tackle: Inventory your existing equipment and refrigerant quantities so you know what you're working with. Plan replacement timelines for aging systems before you're forced into emergency decisions. Source reclaimed 404A where state law requires it – and expect this requirement to spread. Maintain detailed records of refrigerant purchases and usage because regulators are watching. Train your technicians on alternative refrigerants so they're ready for the transition. Budget for higher costs because refrigerant prices and system upgrades aren't getting cheaper.

The funeral industry faces unique challenges here. Mortuary coolers can't just go offline for extended retrofits – they're protecting public health and maintaining dignity for families during their most difficult moments. That's why we recommend planning these transitions carefully, rather than waiting until regulations force your hand.

Retrofitting From or To 404A: Lubricants, Alternatives & Best Practices

Retrofitting 404a systems requires careful attention to lubricants, component compatibility, and system adjustments. Most R-404A systems use polyolester (POE) lubricants, which remain compatible with many alternative refrigerants, simplifying conversions.

When retrofitting from R-22 to R-404A, complete oil changes are necessary since mineral oil isn't compatible with HFC refrigerants. The retrofit typically requires:

- Oil conversion: Change to POE lubricant

- TXV adjustment: Modify or replace thermostatic expansion valves

- Charge weight: Use approximately 95% of original R-22 charge

- System cleanup: Remove residual mineral oil and contaminants

useful guide for R-404-to-R-449A retrofits

404A vs Lower-GWP Alternatives

The industry is transitioning to lower-GWP alternatives that offer similar performance with reduced environmental impact. Leading options include R-449A and R-448A, both designed as retrofit solutions for existing 404a systems.

| Refrigerant | GWP | Safety Class | Retrofit Ease | Performance vs 404A |

|---|---|---|---|---|

| R-404A | 3,920 | A1 | Baseline | 100% |

| R-449A | ~1,400 | A1 | Excellent | 95-105% |

| R-448A | ~1,300 | A1 | Good | 90-100% |

| CO₂ | 1 | A1 | Complex | Variable |

R-449A (Opteon XP40) offers the closest performance match to 404a, with capacity and efficiency within 5% of the original refrigerant. The retrofit typically requires only TXV adjustments and system rebalancing, making it the preferred choice for many applications.

R-448A provides slightly lower capacity but excellent energy efficiency, particularly in medium-temperature applications. Both alternatives use the same POE lubricants as R-404A, simplifying conversions.

Natural refrigerants like CO₂ offer the lowest GWP but require complete system redesigns due to different operating pressures and characteristics. These solutions work best in new installations rather than retrofits.

Retrofit Checklist for 404A Systems

Successful retrofits require systematic approaches to ensure performance and reliability:

Pre-retrofit assessment:

- [ ] Document baseline performance data

- [ ] Check system for leaks and needed repairs

- [ ] Verify component compatibility with new refrigerant

- [ ] Plan for proper refrigerant recovery and disposal

During retrofit:

- [ ] Recover existing 404a refrigerant completely

- [ ] Replace filter driers and clean system if needed

- [ ] Adjust or replace TXV components as required

- [ ] Charge new refrigerant as liquid to prevent fractionation

- [ ] Adjust pressure controls and safety settings

Post-retrofit verification:

- [ ] Verify proper superheat and subcooling

- [ ] Check system capacity and efficiency

- [ ] Update system labeling and documentation

- [ ] Train operators on new refrigerant characteristics

Safety, Handling & Current Market Pricing

Working with 404a refrigerant is relatively straightforward thanks to its ASHRAE A1 safety classification. This rating means the refrigerant is both non-flammable and has low toxicity - making it one of the safer options for technicians to handle during installations and repairs.

That said, "safer" doesn't mean you can skip proper procedures. We've seen too many close calls over the years when technicians get complacent with routine refrigerant work. The basics still matter: proper ventilation prevents oxygen displacement in tight spaces, and personal protective equipment protects against accidental exposure.

The market for R-404A has become quite interesting lately, and by "interesting" we mean expensive. Regulatory pressures have pushed pricing up significantly, with reclaimed 404a now commanding premium prices that would have shocked technicians just a few years ago.

wp support reclaimed 24 lb cylinder

Current pricing reflects the new reality of HFC regulations. 5-pound cylinders start around $199 for reclaimed refrigerant, while 24-pound containers can cost $545 or more. Virgin refrigerant costs even more, assuming you can find it and are legally allowed to use it for your application.

The two-tier market has created some complexity for our customers. California and New York customers must use reclaimed 404a for servicing existing mortuary coolers, while other states still allow virgin refrigerant for repairs. This patchwork of regulations means we help customers steer what's legal in their specific location.

Full pallet quantities (40 cylinders) run around $19,800, with half pallets at $10,200. These bulk prices help larger funeral homes and service companies manage costs, though the upfront investment is substantial.

404A Handling Precautions & SDS Access

Even though R-404A has low toxicity, smart handling practices protect both technicians and the environment. The refrigerant can displace oxygen in confined spaces - something that's particularly relevant when working in basement morgue areas or small equipment rooms.

Essential safety practices include wearing safety glasses and gloves, ensuring adequate airflow during service work, and using electronic leak detectors rather than relying on your nose. Never vent refrigerant to atmosphere - besides being illegal, it's wasteful given current pricing.

Cylinder storage requires keeping containers upright, properly secured, and away from heat sources. We've seen cylinders damaged by careless storage that could have been easily prevented with basic precautions.

Safety Data Sheets provide the detailed information technicians need for safe handling and emergency procedures. Major manufacturers maintain online SDS databases with current information, though honestly, most experienced techs know the basics by heart.

Proper disposal requires certified refrigerant recovery and recycling - no exceptions. EPA regulations mandate Section 608 certification for handling refrigerants, with specific requirements depending on system types and refrigerant quantities. Our installation teams maintain current certifications and follow all recovery procedures when servicing mortuary cooling equipment across our service territories.

Frequently Asked Questions about 404A

Is 404A being banned soon?

Here's the straight story about 404a regulations: it's not getting completely banned, but the rules are definitely tightening up. Starting in 2025-2026, you won't be able to install new equipment that uses 404a in many applications. But if you already have systems running on it, you can keep them going.

The EPA's phase-down plan cuts production by 85% by 2036, which means virgin 404a will become harder to find and more expensive. The good news? You can still service existing systems using reclaimed refrigerant. Think of it like classic car parts - they're still available, but you might pay more and need to plan ahead.

For our funeral home customers, this means your current mortuary coolers can keep running. We're helping our clients plan for the future by discussing retrofit options during routine maintenance visits, so there are no surprises down the road.

Can I mix 404A with other refrigerants?

Absolutely not - and we can't stress this enough. Mixing 404a with other refrigerants is like mixing medications without a doctor's approval. You create an unknown blend with unpredictable properties that could damage your equipment or create safety issues.

Even refrigerants that seem similar, like R-507A, shouldn't be mixed with 404a. They might have comparable performance, but their molecular structures are different enough to cause problems. We've seen expensive compressor failures from well-meaning technicians who thought "close enough" was good enough.

The right way to switch refrigerants is simple: recover all the existing refrigerant first, then charge with the new type. It takes a bit more time, but it protects your investment and keeps everyone safe.

What oil should I use with 404A?

Polyolester (POE) lubricants are the only way to go with 404a systems. This isn't a preference - it's a requirement for proper operation and equipment protection.

POE oil works with HFC refrigerants like 404a because they're chemically compatible. The oil circulates through your system, lubricating the compressor while maintaining the right viscosity at operating temperatures. Using the wrong oil is like putting diesel fuel in a gasoline engine - it might run briefly, but you'll pay for it later.

Never use mineral oil or alkylbenzene oils with 404a. These older lubricants don't mix with HFC refrigerants and can cause compressor damage that's expensive to repair. Always check your compressor manufacturer's specifications for the correct viscosity grade, as different applications might need different oil weights.

In our mortuary cooler installations, we use only manufacturer-approved POE lubricants to ensure reliable operation. It's one of those details that might seem small but makes a huge difference in system longevity.

Conclusion

The story of 404a refrigerant is far from over, even as the industry steers toward a more sustainable future. This reliable workhorse has kept our food fresh, our businesses running, and our loved ones properly cared for in funeral homes across the country for over two decades.

Here at American Mortuary Coolers, we've seen how 404a has served funeral service providers from the mountains of Tennessee to the coast of California. The refrigerant's steady performance and safety record have made it the backbone of mortuary refrigeration systems that families depend on during their most difficult times.

The regulatory landscape is changing, but that doesn't mean panic or rushed decisions. The transition to lower-GWP alternatives like R-449A and R-448A will happen gradually over the next decade. Smart funeral home operators are planning ahead while continuing to maintain their existing 404a systems properly.

We understand the unique challenges facing funeral service providers today. Rising refrigerant costs, changing regulations, and the need for reliable temperature control create a complex puzzle. That's why our custom mortuary cooling solutions are designed to work with both current 404a systems and future alternative refrigerants.

Your existing equipment isn't obsolete overnight. With proper maintenance and access to reclaimed refrigerant, 404a systems can continue serving your facility for years to come. When the time comes for upgrades or retrofits, our team will be there to guide you through the options that make sense for your specific needs and budget.

More info about our mortuary refrigeration solutions

From our home base in Tennessee to installations across all 48 contiguous states, we've built our reputation on understanding both the technical and human sides of mortuary refrigeration. We know that behind every temperature chart and pressure reading is a family trusting you to care for their loved one with dignity.

The future of refrigeration is evolving, but our commitment to supporting funeral service providers remains constant. Whether you're dealing with a 404a system that needs service today or planning for tomorrow's lower-GWP alternatives, American Mortuary Coolers has the expertise and custom solutions to keep your operations running smoothly through every change ahead.