All About Walk-In Freezer Floor Options

Why Walk-In Freezer Floor Selection is Critical for Your Operation

A walk in freezer floor is one of the most critical components of any commercial refrigeration system, yet it's often overlooked until problems arise. Walk-in freezer floors must handle extreme temperature changes, heavy loads, and constant moisture while maintaining proper insulation to prevent energy loss and structural damage.

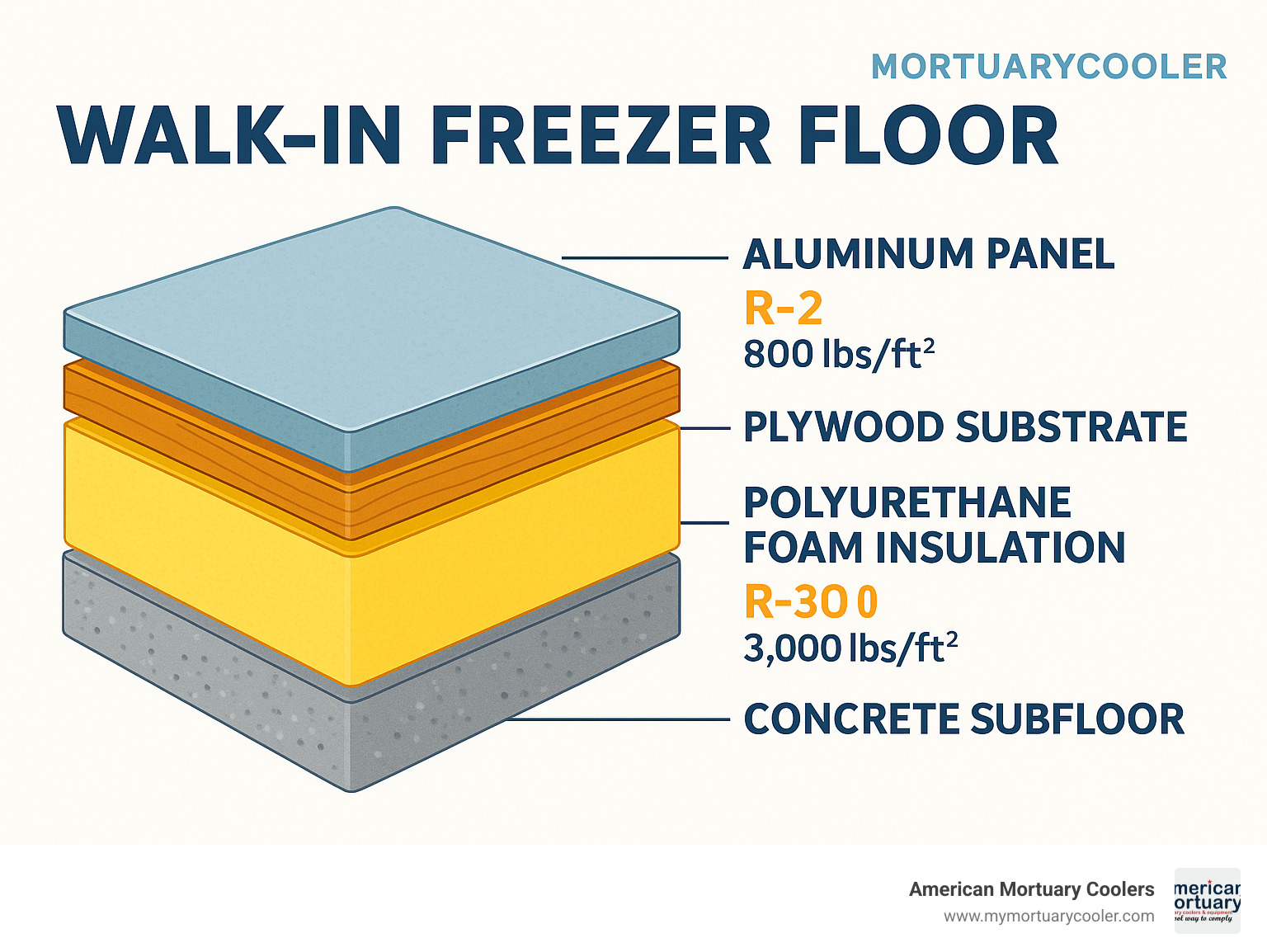

Key Walk-In Freezer Floor Requirements:

- R-value of 28 or higher (federal requirement for freezers)

- Load capacity ranging from 800 to 5,000 pounds per square foot

- Seamless construction to prevent bacteria growth and moisture infiltration

- Proper insulation to prevent frost heave and concrete cracking

- Slip-resistant surfaces for worker safety

The consequences of poor flooring choices are severe. Bad flooring in walk-in boxes is the number one reason for health inspection violations in foodservice establishments. Without proper insulation, water can freeze under your floor panels, causing expansion that buckles surfaces and creates breeding grounds for mold and bacteria.

Energy efficiency is another major concern. Uninsulated floors allow significant heat transfer, forcing your refrigeration system to work harder and driving up operating costs. Federal guidelines require walk-in freezer floors to have an R-value of at least 28 to prevent concrete cracking and ice formation underneath.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes select the right walk in freezer floor solutions for their specific needs.

Key terms for walk in freezer floor:

Walk-In Freezer Floor Basics: Why Insulation Isn't Optional

Walk in freezer floor insulation isn't just recommended—it's required by federal guidelines. Every freezer floor must have an R-value of at least 28 to prevent serious structural problems that can cost thousands to repair.

Without proper insulation, ground moisture freezes and expands beneath your concrete slab. This frost heave literally pushes up from below, cracking concrete foundations and buckling floor panels until your once-smooth floor looks like a miniature mountain range.

Polyurethane foam insulation solves this problem beautifully. This closed-cell foam material provides excellent thermal resistance while still supporting heavy loads—exactly what you need for a mortuary cooler that might hold multiple caskets. Scientific research on polyurethane insulated floors shows these installations can dramatically reduce energy costs compared to less efficient materials.

Thermal Physics 101

Heat moves in three ways: conduction, convection, and radiation. For walk in freezer floors, conduction is your main concern. This is direct heat transfer through solid materials—like warmth from the ground traveling through concrete and into your freezer.

The K-factor measures how well materials conduct heat. Lower numbers are better for insulation. R-value works opposite to K-factor—higher numbers mean better insulation. The R-value definition describes thermal resistance, and freezer floors need a minimum R-28 rating.

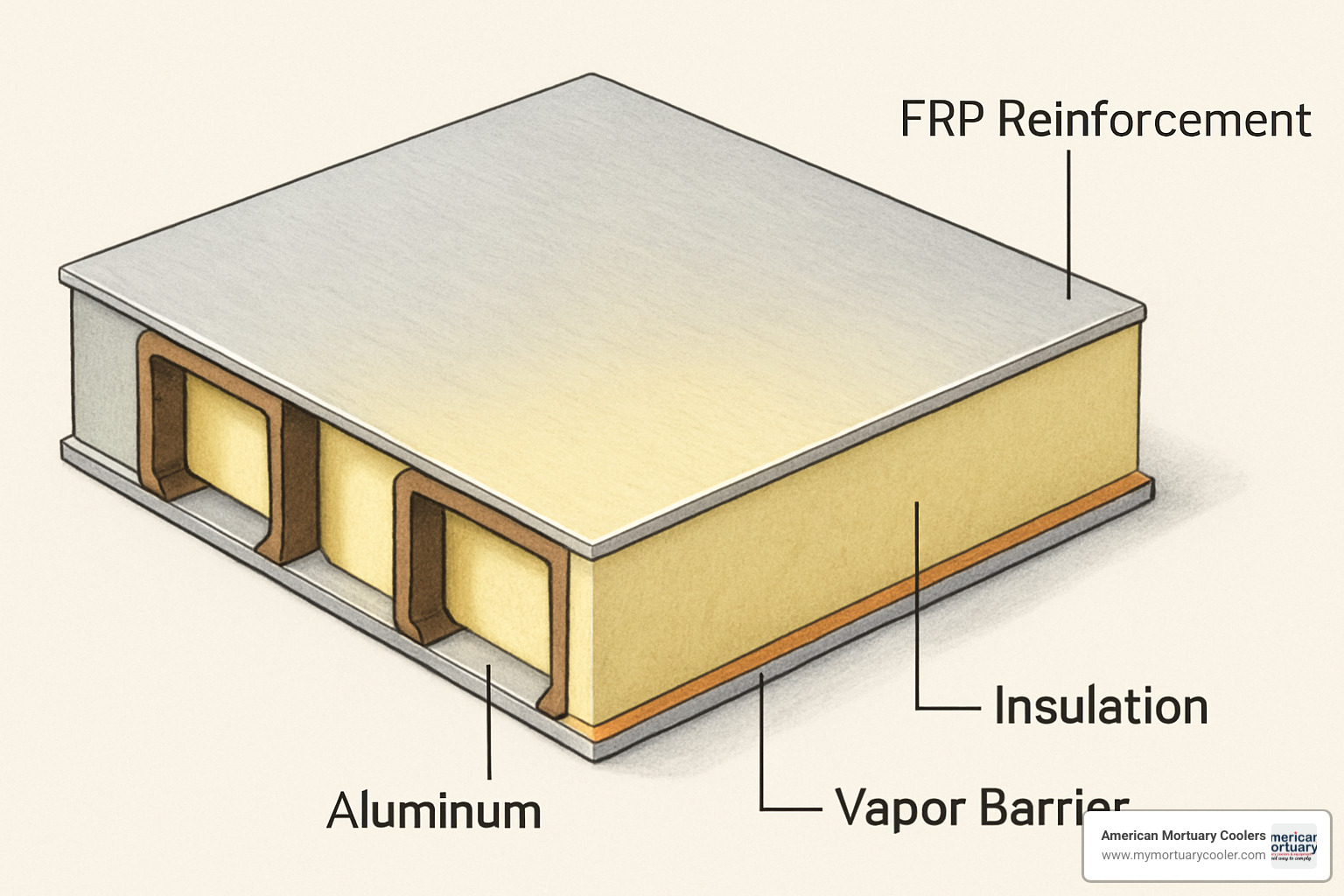

Vapor barriers prevent moisture from sneaking into your insulation layer, where it could freeze and cause damage. Proper vapor barrier installation requires careful sealing at seams and any penetrations through the floor.

Choosing a Walk-In Freezer Floor for Heavy Loads

Standard floors handle 800 pounds per square foot of evenly distributed load—perfect for foot traffic and lightweight storage. But mortuary applications often demand much more.

Heavy-duty floors support up to 5,000 pounds per square foot, making them suitable for multiple caskets, heavy preparation equipment, or full storage racks. The key difference is between stationary loads (things that sit still) and rolling loads (things being moved on wheels).

Pallet jacks create unique challenges because their small wheels concentrate weight into tiny contact points. For regular pallet jack use, structural floors with FRP channels (fiberglass-reinforced plastic) provide the necessary reinforcement.

Fork truck operations require the most robust solutions. Forklifts typically need insulated concrete slabs with thermal breaker strips—2-inch polyurethane foam barriers that prevent heat transfer while supporting heavy equipment.

Flooring Types & Load Capacities

Choosing the right walk in freezer floor can feel overwhelming with so many options available. Let me walk you through each type so you can make an informed decision that fits your specific needs and budget.

| Floor Type | Load Capacity (PSF) | R-Value | Traffic Type | Typical Lifespan | Cost Level |

|---|---|---|---|---|---|

| Standard Aluminum Panels | 500-800 | 28+ | Foot traffic only | 10-15 years | $ |

| Plywood Underlay | 1,000-1,500 | 28+ | Light carts | 8-12 years | $$ |

| FRP Reinforced | 2,600-5,000 | 28+ | Heavy pallets | 15-20 years | $$$ |

| Insulated Concrete | 5,000+ | 28+ | Forklift traffic | 20+ years | $$$$ |

| Seamless Epoxy | 800-1,200 | Varies | All traffic types | 10-15 years | $$$ |

Standard Insulated Panel Floors

Standard aluminum panels are your budget-friendly choice for most funeral homes. These panels feature smooth aluminum surfaces over polyurethane foam insulation and can handle 500-800 pounds per square foot—perfect for foot traffic and lightweight storage.

They use tongue-and-groove joints with cam-lock fasteners and NSF-approved gaskets to create tight seals. This modular design means quick installation and easy modifications if needed.

Heavy-Duty & Structural Panel Floors

Heavy-duty options incorporate metal grid systems or FRP channels embedded into the insulation core, boosting capacity to nearly 2,600 pounds per square foot. FRP-reinforced walk in freezer floors distribute weight across the entire panel structure, preventing stress concentrations that can crack weaker floors.

The investment is higher upfront, but these floors typically last 15-20 years with proper care.

Seamless Resin & Epoxy Floors

Seamless epoxy systems like JetRock and Everlast eliminate every seam where bacteria and debris love to hide. JetRock epoxy flooring offers a 10-15 year lifespan and is three times stronger than concrete.

The installation speed is remarkable—most epoxy floors go in overnight and you're back in business within 8 hours. Unlike metal panels with seams everywhere, epoxy creates one continuous barrier.

Concrete & Tile Solutions

Sealed concrete floors offer incredible durability and load capacity, but they need proper preparation to prevent moisture problems. You need to warm your freezer floor to at least 50°F before applying the sealer for proper curing.

Quarry tile floors are tough but those grout lines can harbor bacteria and let moisture seep through.

Overlay & Retrofit Systems

Eco-Tek overlay systems provide cost-effective solutions for upgrading damaged floors without complete replacement. These systems install right over existing aluminum panels with minimal prep work, finishing in a single day.

However, these systems typically can't achieve NSF listing for open food storage because of screw-hole openings in the substrate.

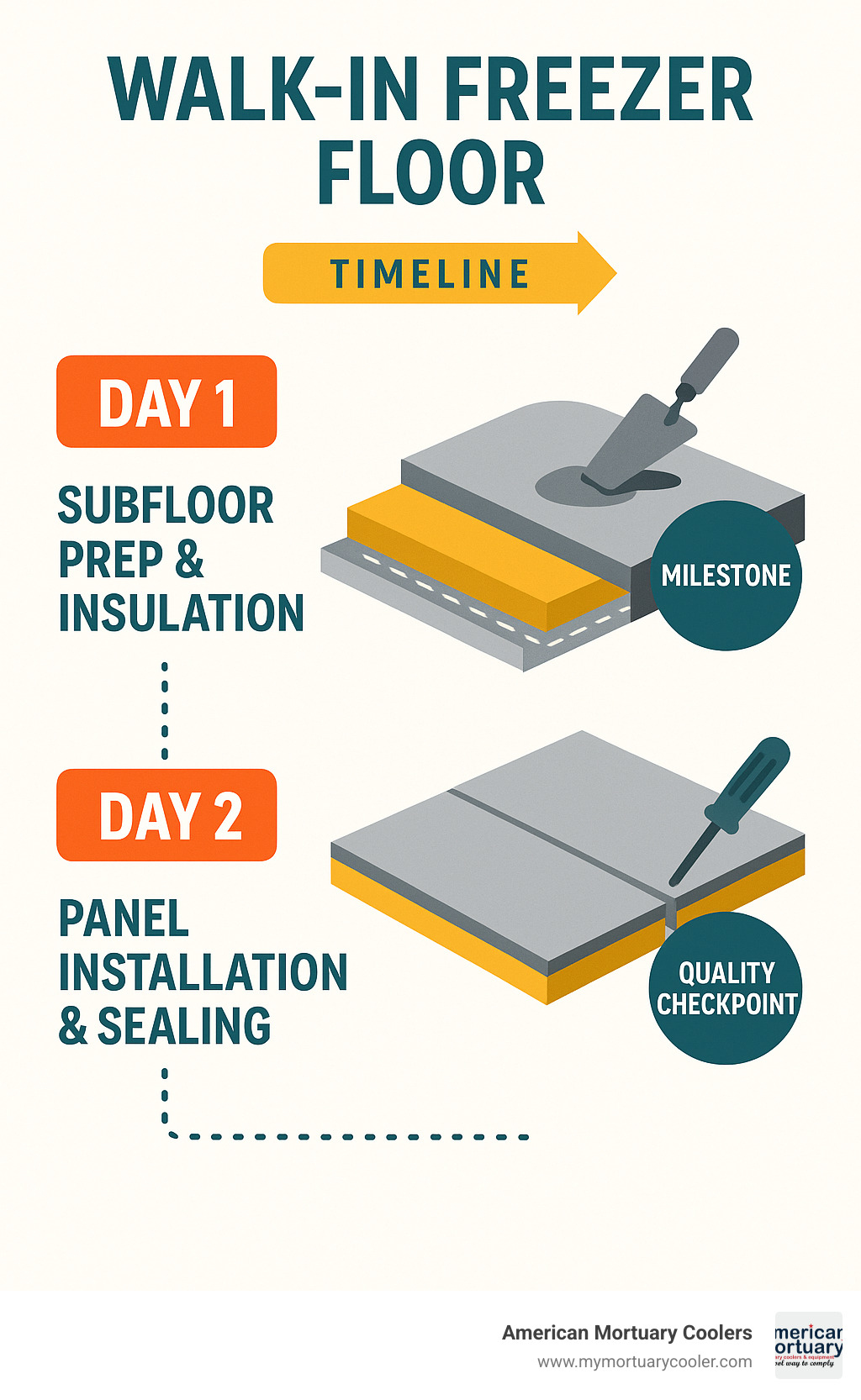

Installation & Best Practices to Prevent Failure

Getting your walk in freezer floor installed correctly is absolutely critical—and frankly, it's where many projects go wrong. Following proper installation practices prevents most common problems and saves you money in the long run.

Sub-floor preparation is your foundation for success. Your concrete slab needs to be level, completely dry, and properly cured before any floor installation begins. Even small imperfections in the slab can create stress points that lead to panel failure years later.

Thermal breaks are absolutely essential around the perimeter where your walls meet the floor. These 2-inch polyurethane foam strips create a continuous insulation barrier that prevents heat transfer from the ground.

Tongue-and-groove panel installation demands precision and patience. Each panel must align perfectly with its neighbors, and those cam-lock fasteners need proper tightening to ensure airtight seals.

Cove bases create smooth transitions between floors and walls while eliminating corners where debris loves to hide. U-shaped vinyl screeds seal the joint between floorless coolers and existing concrete slabs.

Don't forget about proper slope to drains—even small amounts of standing water become major problems in freezer environments.

Floorless vs. Floored Configurations

Not every walk-in installation needs a dedicated floor system. On-grade coolers sitting directly on concrete slabs might work fine if you're only dealing with foot traffic.

Lifted freezers are a completely different story. If your unit sits above basements or other spaces, you absolutely must have insulated floors. That air gap underneath creates additional heat transfer that causes condensation problems and energy loss.

Best Practices Checklist

Load verification ensures your chosen floor can actually handle your real-world operating conditions. Don't just calculate the weight of stored products—include the dynamic loads from carts, pallets, and equipment too.

Seal integrity testing should happen during and after installation. Temperature monitoring helps you catch performance issues before they become expensive problems.

Door threshold design affects both energy efficiency and floor durability. More info about thresholds can help you select the right option for your specific application.

Maintenance, Cleaning & Repair

Taking care of your walk in freezer floor isn't just about keeping it looking good—it's about protecting your investment and keeping your staff safe. Proper maintenance doesn't have to be complicated or time-consuming.

Mold prevention should be your top priority. Falls cause more workplace injuries than any other single factor, and wet floors account for 10 percent of those incidents according to National Floor Safety Institute (NFSI) data.

I recommend monthly inspections for high-traffic facilities and quarterly checks for lighter-use applications. You're looking for signs of damage, wear, or moisture where it shouldn't be. Rising energy bills often signal floor problems before you can see any visible damage.

Cleaning a Walk-In Freezer Floor for Longevity

The best cleaning approach is simple: mild soap and warm water. Harsh chemicals might seem more effective, but they can actually damage aluminum finishes, compromise sealants, or even damage insulation if they seep through cracks.

Daily handle cleaning with approved disinfectants prevents bacterial growth. Bimonthly floor mopping keeps surfaces clean and safe, but always dry thoroughly afterward. Never leave standing water on freezer floors.

Drain maintenance is often overlooked but incredibly important. Flush drains regularly to remove debris that could cause blockages.

Repair vs. Replacement Decision Tree

Delamination between floor layers usually means moisture has gotten where it shouldn't be. Small areas can sometimes be repaired, but extensive delamination typically means section replacement is your best option.

Buckling surfaces indicate serious structural problems that rarely respond to surface repairs. The underlying cause must be addressed, which often means floor replacement.

Overlay systems like JetRock epoxy can give you a fresh start when the underlying structure is still sound. These systems cure in just 8 hours and provide a completely new wearing surface. More info about floor replacement provides detailed timelines to help you plan around your operation's needs.

Walk-In Freezer Floor Failure Red Flags

Condensation puddles indicate insulation failure or air infiltration problems. Water should never accumulate on properly functioning freezer floors.

Rising energy bills often signal trouble before you can see any visible damage. Track your energy consumption monthly to spot trends that could indicate floor problems.

Ice beneath panels is perhaps the most serious warning sign. This indicates moisture infiltration and freeze-thaw cycles that can cause structural damage.

Regular maintenance and quick attention to problems will keep your walk in freezer floor performing well for years to come.

Health, Safety & Customization Features

When it comes to walk in freezer floor safety, slip resistance isn't just a nice-to-have feature—it's absolutely critical for protecting your team. Diamond tread aluminum surfaces provide excellent traction even when frost builds up or surfaces get wet from cleaning.

NFSI data shows that choosing the right flooring can slash slip-and-fall incidents by up to 85 percent. That's not just about keeping your employees safe—it also means lower workers' compensation costs and reduced liability exposure.

For facilities handling food or working in healthcare environments, antimicrobial additives in epoxy floors offer an extra layer of protection against bacterial growth. If you're in an earthquake-prone area, seismic anchoring isn't optional—it's required by building codes in many regions.

Ramps need to handle the same loads as your main floor—there's no point having a 5,000-pound floor if your ramp can only handle 800 pounds. Good ramp design includes edge protection to prevent damage from pallet jack wheels.

Cove bases eliminate those sharp 90-degree corners where debris loves to hide and bacteria can grow. Health inspectors love seeing proper cove bases because they show you're serious about maintaining clean conditions.

Selecting the Right Walk-In Freezer Floor for Your Application

Choosing the right walk in freezer floor starts with honestly assessing how you actually use your space. Traffic patterns tell the real story. A storage area that only gets visited twice a day has very different needs than a prep area where staff are constantly moving in and out.

Product weight calculations can be tricky because you need to think beyond individual items. A single case might only weigh 40 pounds, but stack those cases on a pallet and you could be looking at over 2,000 pounds concentrated on four small pallet points.

Hygiene codes from NSF and FDA aren't suggestions—they're mandatory requirements that can shut down your operation if you don't comply. Budget considerations should look at the total cost of ownership, not just the upfront price tag. More info about affordable coolers can help you balance cost against long-term performance.

Different industries have distinct flooring needs. Restaurant applications involve high foot traffic and moderate loads—making epoxy floors ideal. Warehouse applications deal with heavy loads and pallet jack traffic—so structural floors work better. Mortuary applications require moderate load capacity with strict hygiene standards—seamless epoxy floors excel in these conditions.

The key is matching your floor choice to your actual operating conditions, not what sounds good on paper.

Frequently Asked Questions About Walk-In Freezer Floors

Do walk-in freezers always require an insulated floor?

Yes, walk-in freezers always require insulated floors with an R-value of at least 28 per federal guidelines. This isn't just a recommendation—it's a critical requirement that separates freezers from their cooler cousins.

Unlike walk-in coolers, which might get away without floor insulation in certain ground-level installations, freezers create a thermal battlefield beneath your feet. The temperature difference between your freezer interior (typically 0°F or below) and the ground creates the perfect storm for disaster.

Without proper insulation: moisture in the ground freezes and expands beneath your floor. This freeze-thaw cycle becomes a slow-motion wrecking ball, cracking concrete, buckling panels, and creating structural damage that can cost thousands to repair.

Even indoor freezers sitting on ground-level concrete slabs need that walk in freezer floor insulation. Most properly insulated floors pay for themselves through energy savings within 2-3 years.

What are the most common causes of walk-in freezer floor failure?

Moisture infiltration takes the crown as the biggest floor killer. When water sneaks through seams, cracks, or damaged areas, it freezes and expands like a tiny ice bomb.

Poor installation runs a close second. We've seen floors fail within months because of inadequate sealing, crooked panel alignment, or rushed substrate preparation.

Overloading causes dramatic failures that nobody forgets. A floor designed for 800 pounds per square foot doesn't forgive when you roll a 3,000-pound pallet across it.

Temperature fluctuations from frequent door openings create a constant expansion-contraction cycle. Materials and seals eventually fatigue from this thermal stress.

Neglected maintenance turns minor problems into major headaches. A small crack that could be sealed with a tube of caulk becomes a complete floor replacement when ignored.

Can a seamless epoxy be installed over an existing damaged floor?

Yes, seamless epoxy can often save the day for damaged floors, but success depends entirely on what's happening underneath. Think of epoxy as a high-tech band-aid—it can cover surface wounds but can't heal broken bones.

The existing floor must be structurally sound for epoxy to work. If your walk in freezer floor is buckling, delaminating, or showing signs of insulation failure, epoxy won't solve those underlying problems.

Surface preparation determines whether your epoxy installation succeeds or fails. All loose material, dirt, grease, and damaged sections must be completely removed.

The installation requires warming your freezer to at least 50°F for proper curing. JetRock epoxy systems cure in just 8 hours and provide a watertight, antimicrobial surface that can extend floor life by 10-15 years.

Conclusion

Choosing the right walk in freezer floor isn't just about picking the cheapest option—it's about finding the solution that keeps your operation running smoothly for years to come. The right floor prevents headaches down the road.

A walk in freezer floor that fails after three years costs far more than investing in the right system from the start. Between energy waste, replacement costs, and potential downtime, cutting corners on flooring is rarely worth the savings.

The most important factors to remember are load capacity based on how you actually use the space, proper insulation with that crucial R-28 rating, surface safety for your team, and realistic maintenance you can actually keep up with.

At American Mortuary Coolers, we've seen how the wrong flooring choice can disrupt funeral home operations. That's why we focus on durable, custom solutions that handle the unique demands of mortuary applications. Our floors need to support heavy loads while maintaining the strict hygiene standards funeral directors require.

We're not just selling equipment—we're helping you avoid the frustration of floor failures, energy waste, and regulatory headaches. Our team understands that funeral homes can't afford downtime, which is why we emphasize getting the installation right the first time.

Direct delivery across the contiguous 48 states means we can support your project whether you're in Tennessee, Texas, or anywhere in between. We've built our reputation on reliable service and equipment that performs when you need it most.

Ready to discuss your specific flooring needs? Our mortuary cold-room collection showcases the custom solutions we've developed for funeral homes nationwide. Let's work together to find the perfect walk in freezer floor that fits your facility, your budget, and your peace of mind.