All About Shelf Poles: Types, Materials, and Buying Tips

Why Shelf Poles Are Essential for Professional Storage

A shelf pole is a vertical support post that connects wire shelving units, creating sturdy storage systems for commercial and industrial use. These steel or chrome posts form the backbone of modular shelving, allowing you to stack multiple shelves while maintaining structural integrity.

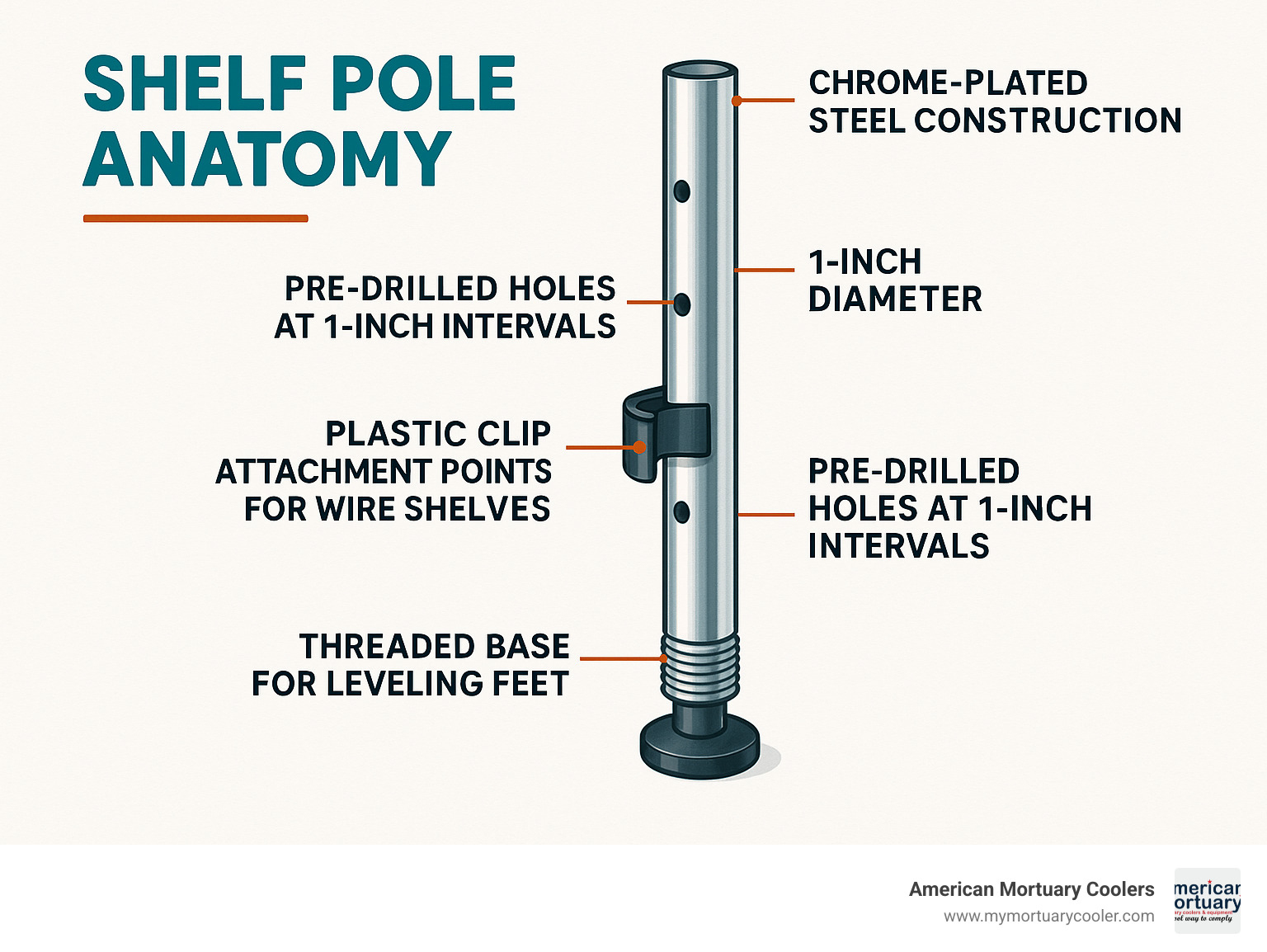

Key shelf pole specifications:

- Standard diameters: 1" and 3/4"

- Common heights: 8" to 96"

- Materials: Chrome steel, stainless steel, epoxy-coated steel

- Weight capacity: Up to 1,200+ lbs per shelf (varies by pole thickness)

- Connection method: Plastic clips or metal brackets at 1" intervals

When choosing shelf poles, you need to match the diameter and thickness to your existing shelving system. The research shows that pole thickness varies between 1.0mm, 1.2mm, and 1.4mm - getting the wrong size means your clips won't fit properly.

For mortuary and medical facilities, shelf poles serve a critical role in body storage racks and equipment organization. The 84-inch vertical support poles mentioned in industry data are particularly popular for walk-in cooler installations where maximizing vertical space is essential.

Chrome-plated poles offer the best corrosion resistance, while epoxy-coated options provide chemical resistance in harsh environments. NSF-certified poles ensure food safety compliance in facilities that store both medical supplies and consumables.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes optimize their storage systems using the right shelf pole configurations. My background includes sourcing and installing thousands of wire shelving units across the country, giving me deep insight into what works best for different facility needs.

Shelf Pole Fundamentals

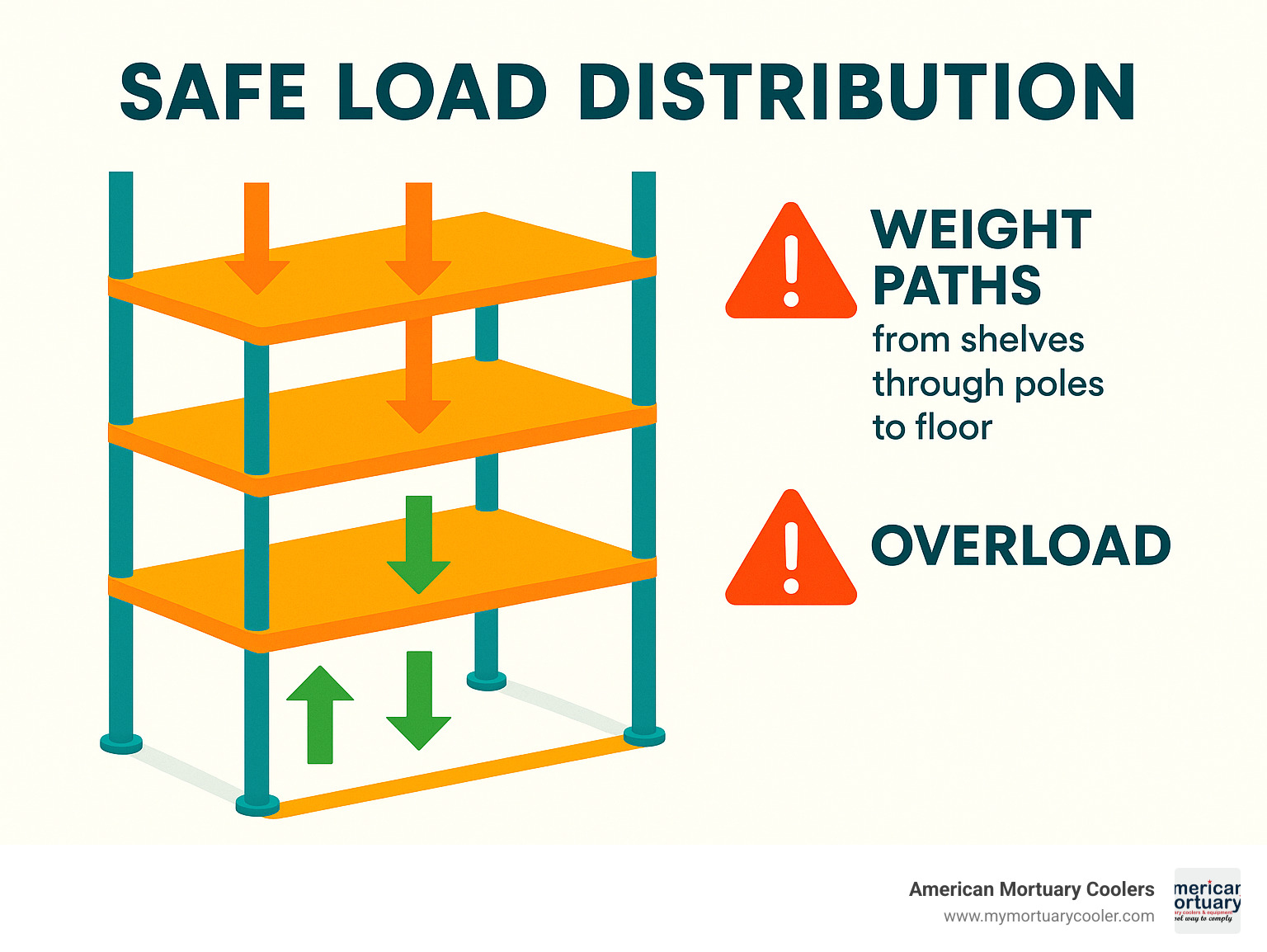

Think of shelf poles as the backbone of your storage system. Without them, even the strongest wire shelves would collapse under the weight of your equipment and supplies. These vertical supports distribute weight evenly across your entire shelving unit.

Wire shelving systems depend on shelf poles for their incredible flexibility. Unlike fixed wooden shelves, these poles feature notches or holes at 1-inch intervals. This means you can adjust your shelf heights whenever your storage needs change.

The beauty of this system is its adaptability. Need more space for taller equipment? Simply move the clips and reposition your shelves. It's like having custom shelving that grows with your business.

More info on wire shelving poles

What is a Shelf Pole?

A shelf pole is essentially a vertical steel or chrome post that holds up your wire shelving system. These posts come with regularly spaced notches or holes where you attach plastic clips or metal brackets to hold your shelves in place.

While the concept sounds straightforward, there's serious engineering behind these poles. They're built to handle not just weight pressing down from above, but also sideways pressure when loads shift or aren't perfectly balanced.

The tricky part is compatibility. Your pole's diameter, thickness, and clip system must match your existing shelving perfectly. Most commercial systems use either 1-inch or 3/4-inch diameter poles, but thickness can vary significantly between manufacturers. Get the wrong size, and your clips simply won't fit.

Wire shelves and shelf poles make a perfect team, especially in refrigerated environments. The open wire design allows air to circulate freely while the vertical posts provide rock-solid support.

Standard Sizes & Diameters of Shelf Poles

The 1-inch diameter has become the gold standard for commercial and heavy-duty applications. This size offers excellent load capacity while working with most standard clip systems you'll find in the market.

For lighter applications or tight spaces, 3/4-inch diameter poles offer a more compact solution. They're easier to handle during installation and work well when maximum load capacity isn't your primary concern.

Height options run from 8-inch short posts for specialized applications up to 96-inch floor-to-ceiling installations. Poles taller than 64 inches often come in two pieces that twist together, saving on shipping costs and making them easier to maneuver during installation.

When working in regulated environments, NSF standards become crucial. These standards ensure that poles used in food service and medical facilities meet strict requirements for materials, finishes, and construction methods.

| Diameter | Thickness | Typical Weight Capacity | Best Use |

|---|---|---|---|

| 1" | 1.4mm | 1,200+ lbs per shelf | Heavy commercial |

| 1" | 1.2mm | 800-1,000 lbs per shelf | Standard commercial |

| 3/4" | 1.2mm | 400-600 lbs per shelf | Light commercial |

| 3/4" | 1.0mm | 200-400 lbs per shelf | Residential |

Types & Materials of Shelf Poles

When it comes to shelf pole materials, chrome steel reigns supreme for most storage applications. That bright, mirror-like finish isn't just for looks - the chrome plating creates a protective barrier that resists rust and corrosion beautifully.

But chrome has its limits. In facilities with harsh chemicals or extreme conditions, you'll want to step up to stainless steel poles. Yes, they cost more upfront, but they're practically indestructible.

For budget-conscious buyers who still need chemical resistance, green and black epoxy coatings offer a smart middle ground. The green epoxy carries NSF certification for food service applications, while black epoxy gives retail spaces that sleek, modern look.

The debate between adjustable and fixed poles comes down to your priorities. Adjustable poles with stackable extensions give you incredible flexibility - perfect when your storage needs change frequently. However, those connection points do create slight weak spots that reduce overall weight capacity.

Fixed-height poles are the workhorses of permanent installations. Without joints or connections, they can handle maximum loads safely.

Stackable extensions revolutionize storage flexibility. These systems use threaded connectors or twist-lock mechanisms to join pole sections seamlessly. You can start with standard heights and add extensions as your needs grow.

The difference between residential and commercial poles is like comparing a bicycle to a motorcycle - they might look similar, but the performance gap is huge. Commercial shelf poles use thicker steel, superior finishes, and connection methods built to withstand daily punishment.

Heavy-Duty & Commercial Shelf Poles

Heavy-duty shelf poles bump up from the standard 1.2mm wall thickness to a robust 1.4mm. That tiny difference translates to dramatically higher load capacity and virtually eliminates flex under heavy loads.

When you're storing embalming equipment or heavy mortuary supplies, that extra strength isn't luxury - it's necessity.

NSF certification separates the professionals from the pretenders. This rating guarantees that your shelf pole won't contaminate stored items and can survive repeated sanitization cycles. Every pole we recommend for mortuary coolers carries this certification.

Food-service applications demand poles that resist both corrosion and bacterial growth. The smooth, non-porous surfaces make thorough cleaning possible while preventing contamination.

Stackable & Adjustable Shelf Poles

Threaded connectors are the secret sauce of stackable systems. Quality connectors use fine threads and locking mechanisms that prevent loosening under load. The plastic versions work for light duty, but smart buyers choose metal-reinforced connectors for heavy-duty applications.

Extension kits give you building blocks for custom heights. Popular stackable post configurations include 4-pole sets that reach 72" total height, extension sections in 12", 18", and 24" lengths, universal connectors that fit multiple diameters, and reinforcement sleeves for high-load situations.

Caster-compatible feet transform your static shelving into mobile storage units. The threaded bottom of each shelf pole accepts standard caster stems or leveling feet.

Specialty Poles for Mortuary & Medical Use

84-inch vertical support poles hit the sweet spot for walk-in cooler installations. This height maximizes storage capacity while fitting comfortably within standard ceiling heights. These poles have become the go-to choice for mortuary facilities building body storage rack systems.

Body storage racks place unique demands on shelf poles. The cantilever design creates additional stress on vertical supports, requiring heavier-gauge materials and specialized mounting hardware.

Finish hygiene becomes paramount in medical environments. Smooth, non-porous surfaces prevent bacterial growth and withstand aggressive disinfectants. Stainless steel and high-grade epoxy finishes meet these demanding requirements while delivering long-term durability.

At American Mortuary Coolers, we've installed storage systems in funeral homes from Tennessee to California. The 84-inch stainless steel poles consistently outperform other options in these challenging environments.

More info about cooler rack options

Choosing, Installing & Accessorizing Your Shelf Pole

Selecting the right shelf pole starts with understanding your load requirements. Calculate the total weight of everything you plan to store, plus the weight of the shelves themselves. Then add a safety margin of at least 20% - it's better to overestimate than deal with a collapsed shelf full of expensive equipment.

The thickness of your pole matters more than you might think. Even a difference of 0.2mm in wall thickness can dramatically affect how much weight your system can handle safely. When you're torn between two options, go with the thicker pole.

Getting the right clips is crucial for a secure installation. Your shelf pole diameter and shelf wire gauge must match perfectly with your clip system. Plastic clips work great for most situations and won't scratch your chrome finish. Metal clips are your friend when dealing with heavy loads.

If you want to make your shelving mobile, casters are a game-changer. Just make sure they're rated for your total loaded weight, and check that the stem fits your pole's threading. Locking casters are worth the extra cost.

Don't underestimate the importance of leveling feet. They compensate for uneven floors and can be adjusted to eliminate wobble.

For tall installations over 72 inches, wall brackets aren't optional - they're essential safety equipment. Install them every 4 feet of height, and definitely use them in earthquake-prone areas.

If you need custom heights, cutting poles yourself is totally doable with the right approach. Use a hacksaw with fine teeth, and always file the cut end smooth to prevent injuries. Measure twice, cut once.

Pole connectors let you join sections for custom heights or make emergency repairs. The metal ones cost more but they're worth it for the peace of mind.

Step-by-Step Installation of Shelf Poles

Start your installation by marking where each shelf pole will go on your floor. Position them to support shelf corners and any spots where you'll have heavy loads. The standard 36-inch spacing works for most applications.

Before installing shelves, attach all your plastic clips at the heights you want. They should snap into those pole notches with a satisfying click - not too loose, not requiring a hammer.

When you're ready to install the shelves, place them onto the clips and press down firmly until everything seats properly. The shelf wires should rest snugly in the clip grooves without any gaps.

Save the leveling feet adjustment for last, after all your shelves are in place. This prevents the poles from shifting while you're loading everything up.

Common Mistakes to Avoid with Shelf Poles

The biggest mistake people make is overloading their shelf poles. Exceeding weight ratings can cause permanent bending or complete failure - neither is fun to deal with in a professional setting.

Mismatched diameters between poles and clips cause more problems than you'd expect. Even small differences prevent proper clip engagement, leading to loose connections that fail when you least expect it.

Skipping wall brackets or back clips might save a few minutes during installation, but it's a recipe for trouble. These support points prevent lateral movement and keep your system rigid.

Floor level issues will make your life miserable if you ignore them. Minor variations can be handled with leveling feet, but major problems need to be addressed before installation.

Must-Have Accessories for Shelf Poles

Quality wire shelf clips are non-negotiable for connecting shelves to your shelf poles. The good ones use durable plastics that won't crack when you're loading heavy items.

Caster wheels transform static storage into flexible solutions that can adapt to your changing needs. Choose wheels that match your floor surfaces - soft wheels protect delicate floors but don't roll as smoothly, while hard wheels roll easily but might leave marks.

Post caps give your installation a professional finished look while preventing injuries from sharp pole ends. They also keep dust and debris from getting inside hollow poles.

Label holders might seem like a small detail, but they make a huge difference in keeping everything organized. They attach to shelf edges or poles and protect your labels from moisture and handling damage.

At American Mortuary Coolers, we've helped countless funeral homes across the country optimize their storage systems. Getting the shelf pole selection and installation right the first time saves money and headaches down the road.

Maintenance, Safety & Replacement Tips

Rust prevention starts with proper material selection and continues with regular maintenance. Chrome and stainless steel shelf poles resist corrosion naturally, while epoxy-coated poles need periodic inspection for coating damage.

Cleaning schedule should include regular inspection of all connection points. Look for loose clips, damaged finishes, or signs of overloading. Address problems immediately to prevent escalation.

Inspecting couplers is critical for multi-section poles. Check for cracks, flexing, or looseness during routine maintenance.

Reinforcing joints with metal inserts or wooden dowels significantly improves strength. One user reported inserting a 7/16-inch wood dowel into both pole halves and securing with screws to eliminate flex at the plastic coupler.

Cutting poles safely requires proper tools and technique. Use a fine-tooth hacksaw and cut slowly to prevent binding. File cut ends smooth and remove all metal burrs.

Replacing damaged posts is straightforward if you match the original specifications exactly. Keep records of pole dimensions, materials, and suppliers to ensure proper replacements.

OSHA considerations include proper load ratings, stable installation, and safe access for loading and unloading. Ensure aisles remain clear and that stored materials don't create falling hazards.

Shelf Pole Safety for Tall or Heavy-Load Racks

Anchor brackets become essential for installations over 72 inches tall. They connect shelf poles to walls or ceiling structures, preventing toppling from lateral forces. Install brackets at least every 4 feet of height for maximum stability.

Seismic lips prevent stored items from sliding off shelves during earthquakes or vibrations. These simple accessories can prevent serious injuries and equipment damage in areas prone to seismic activity.

Floor-to-ceiling compression poles eliminate the need for wall anchoring by using spring-loaded mechanisms to apply constant pressure between floor and ceiling.

Extending Service Life of Shelf Poles

Epoxy touch-up kits can repair minor coating damage before rust develops. Clean the damaged area thoroughly, apply the touch-up material according to instructions, and allow proper curing time.

Chrome polishing maintains appearance and provides additional corrosion protection. Use appropriate chrome cleaners and soft cloths to avoid scratching.

Periodic torque checks ensure all connections remain tight. Shelf poles experience constant loading cycles that can loosen threaded connections over time.

Frequently Asked Questions about Shelf Poles

How do I determine the weight capacity of a shelf pole set?

The weight capacity of your shelf pole system depends on several key factors working together. Your pole diameter, thickness, height, and how everything connects all play important roles in determining what your shelving can safely handle.

Most standard 1-inch poles with 1.2mm thickness can support 800-1,000 pounds per shelf level. If you upgrade to the heavier 1.4mm thickness, you're looking at 1,200+ pounds per shelf. But here's the catch - taller poles can't handle as much weight because they're more likely to buckle under pressure.

The real trick is finding your system's weakest link. Your shelf poles might be rated for 1,000 pounds, but if your wire shelves can only handle 600 pounds, that's your actual limit. Always use the lower rating to stay safe.

I always recommend adding at least a 25% safety margin to whatever capacity you calculate. In mortuary facilities, equipment failure isn't just inconvenient - it can be dangerous and costly. Better to overestimate your needs than deal with a collapsed shelf full of expensive equipment.

Can shelf poles be cut or custom-ordered to fit tight spaces?

Absolutely! Shelf poles are surprisingly easy to customize for your specific space. If you're handy with tools, you can cut them yourself using a hacksaw with a fine-tooth blade. The key is cutting slowly and steadily to prevent the blade from binding up.

After cutting, always file the end smooth to prevent injuries and make sure your clips fit properly. Those sharp metal edges can be nasty if left unfinished. Take your time with this step - it makes a real difference in the final result.

If DIY isn't your thing, most commercial suppliers offer custom cutting services. Just specify your exact dimensions, materials, and finishes when ordering. The downside is longer lead times compared to standard sizes, so plan ahead if you're working on a project deadline.

Custom ordering works great for those odd spaces that standard lengths just won't fit. We've helped funeral homes squeeze shelf poles into spaces that seemed impossible at first glance.

What accessories are required to add wheels to shelf poles?

Adding mobility to your shelving system is easier than you might think. You'll need casters with stems that thread into the bottom of your shelf poles. The standard threading is 1/2 inch with 12 threads per inch, though some manufacturers use different specifications.

The most important consideration is weight rating. Your casters need to handle your total loaded weight divided by the number of wheels. Don't forget to include the weight of the shelving itself in your calculations.

You'll also need to decide between swivel and fixed casters based on how you plan to move your unit. Swivel casters on all four corners give you maximum maneuverability - you can spin the unit around tight corners easily. However, they're less stable when loaded compared to a mix of swivel and fixed casters.

Locking mechanisms are essential for safety. Once you roll your mobile shelving into position, you want it to stay put. Quality locking casters prevent unwanted movement during loading and unloading, which is especially important in busy mortuary facilities where people are focused on their work rather than watching for rolling equipment.

Conclusion

Getting the right shelf pole setup transforms chaotic storage into organized, efficient systems that actually work for your facility. After reading this guide, you now have the knowledge to choose poles that won't let you down when you need them most.

The difference between a storage system that serves you for decades and one that fails after a few years often comes down to the quality of the shelf poles holding everything together. Chrome-plated steel with proper thickness ratings costs only slightly more than cheaper alternatives, but the performance gap is enormous.

We've seen too many funeral homes struggle with wobbly shelving that can't handle the weight of essential equipment. That's why at American Mortuary Coolers, we only recommend heavy-duty poles with proven track records in demanding environments. Our installations across the country - from the humidity of Tennessee to the dry heat of California - have taught us what really works.

Your facility deserves storage that keeps up with your needs. Whether you're setting up a new mortuary cooler or upgrading existing shelving, investing in quality poles pays off through years of reliable service. The peace of mind alone is worth the modest price difference.

We make the entire process simple with custom solutions delivered directly to your door across all 48 contiguous states. Our team understands the unique challenges of mortuary storage and can help you specify the exact shelf pole configuration your facility needs.

More info about cantilever shelf racks

Good storage isn't just about organization - it's about creating systems that support your important work without adding stress to your day. Quality shelf poles are the foundation that makes everything else possible.